Exterior wall heat-preservation decorative plate structure

A thermal insulation decorative board and external wall thermal insulation technology, which is applied in the direction of building structure, floor, covering/lining, etc., can solve the problems of affecting the waterproof and decorative effect of the thermal insulation surface layer, and the decline of external wall thermal insulation performance, so as to eliminate Cold and heat bridge phenomenon, improvement of external wall thermal insulation and decoration structure, and improvement of the effect of external wall thermal insulation and decorative structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

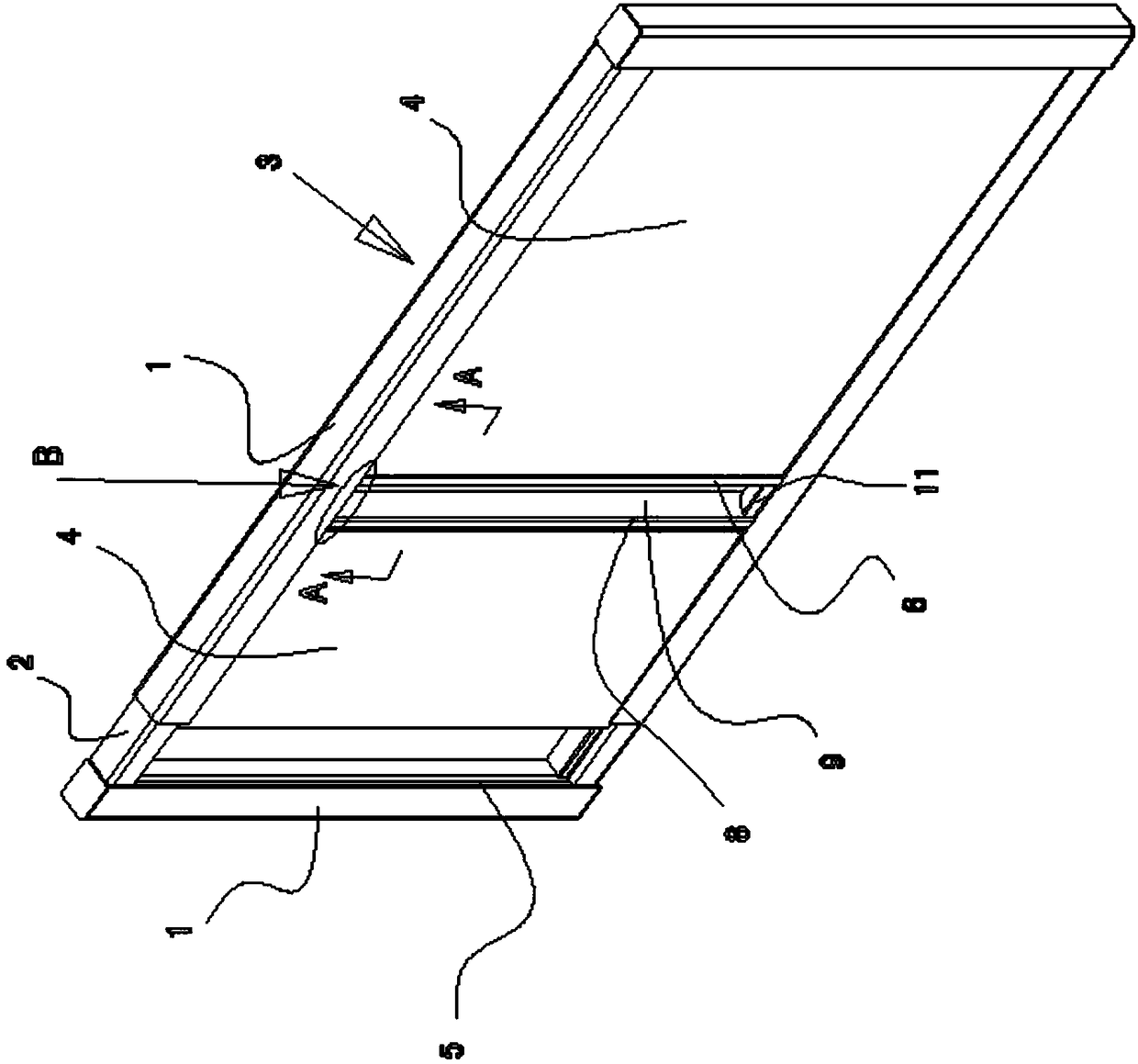

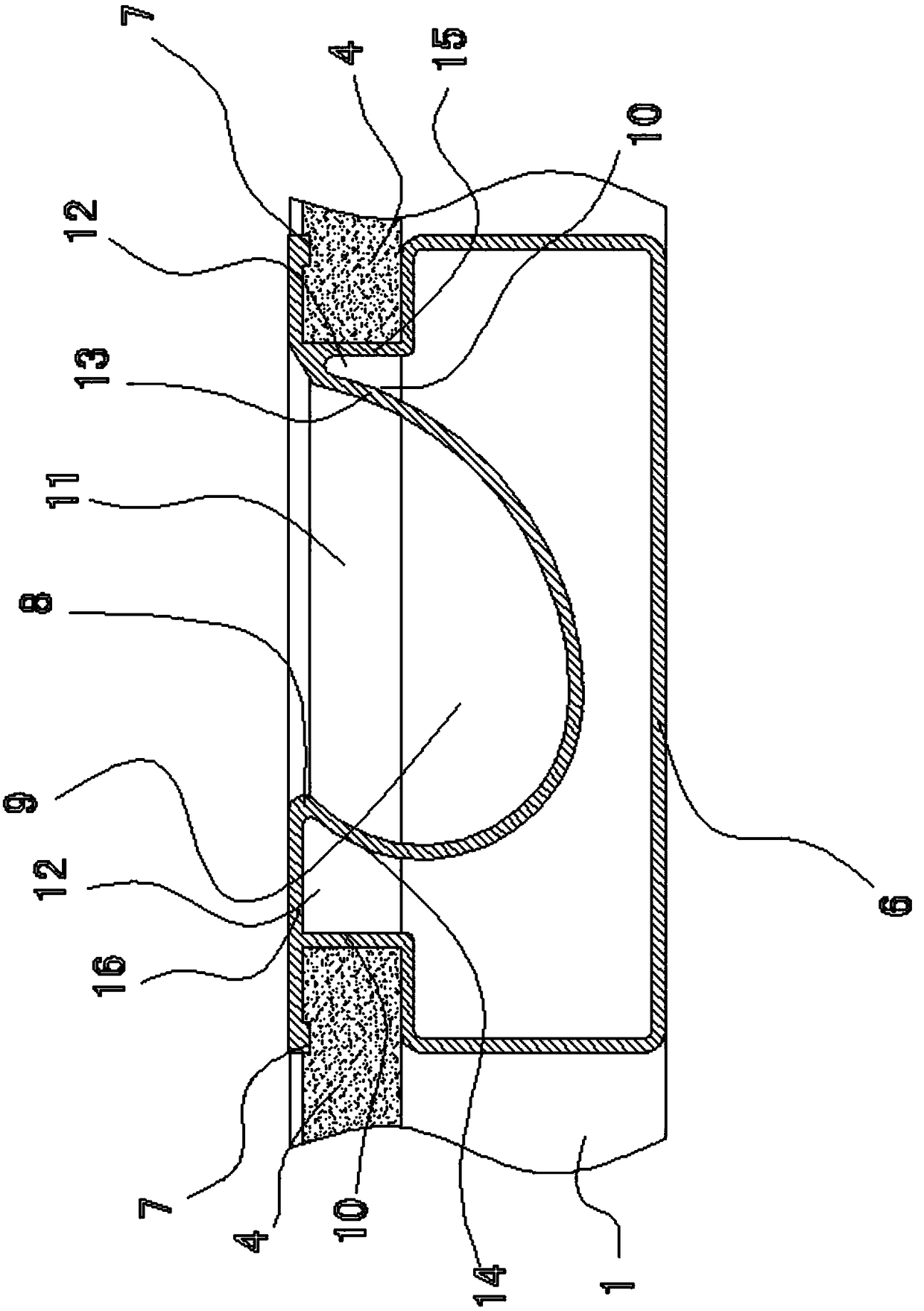

[0017] According to attached figure 1 , a kind of exterior wall thermal insulation decorative board structure of the present invention, comprises base wall body 1, mortar leveling layer 2, keel 3, fixing screw 5, thermal insulation decorative board 7, and mortar leveling layer 2 is attached on the base wall body 1, and keel 3 Fixedly connected to the mortar leveling layer 2, the thermal insulation decorative board 7 is installed on the keel 3, the inner surface of the external wall thermal insulation decorative board 7, except for the fixed connection surface with the keel 3, is covered with thermal insulation strips 4; the thermal insulation decorative board 7 The end face is a step-shaped groove. When installing, the grooves of two adjacent thermal insulation decorative panels are lapped together, and the sealant 6 is coated in the seam; the inner angle of the stepped groove of the end surface of the thermal insulation decorative plate 7 is 83°~ Between 88°, the step surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com