External wall insulation and decoration system

A technology of external wall thermal insulation and thermal insulation board, which is applied in the direction of covering/lining, building, building structure, etc. It can solve the problems of poor fire resistance, fire on the wall, and poor flatness of the decorative layer, so as to ensure thermal insulation performance and ensure the overall Flatness, improve the effect of installation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

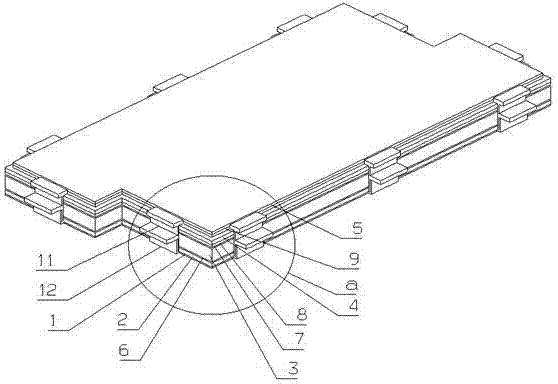

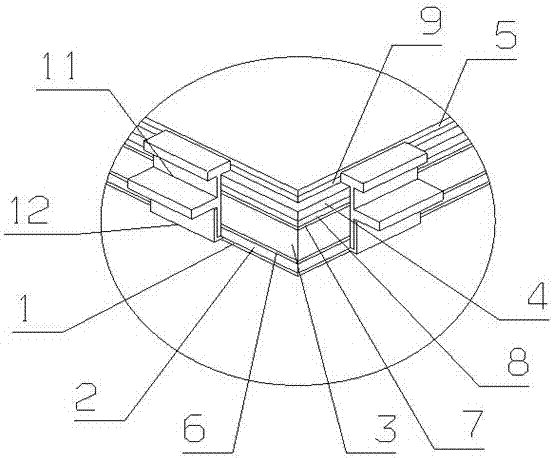

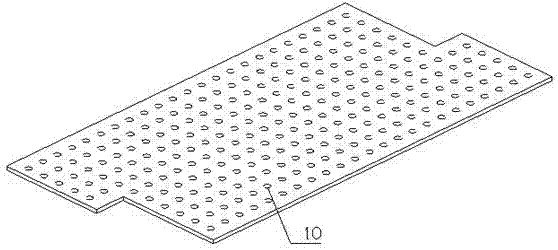

[0023] An external wall thermal insulation and decoration system includes a thermal insulation board body, a fastener and a thermal insulation strip 1 . The end face of the insulation board body is stepped. When two adjacent insulation board bodies are overlapped together, a weather-resistant and waterproof sealant is injected into the seam of the boards. Preferably, the weather-resistant and waterproof sealant is silicone sealant. The end face of the insulation board body is designed in a stepped shape, which can eliminate the cold and heat bridge phenomenon of the insulation board body and ensure the thermal insulation performance of the insulation board body. Described thermal insulation board body comprises backing board layer 2, insulation layer 3, substrate layer 4 and decoration layer 5, and the shape and size of backing board layer 2, insulation layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com