A rapidly detachable prefabricated house structure and its construction method

A prefabricated and housing technology, applied in the direction of infrastructure engineering, roofs, building components, etc., can solve the problems of difficult operation, heavy prefabricated houses, and low recycling rate, so as to increase airtightness and waterproof, and facilitate the construction Design and matching, excellent thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

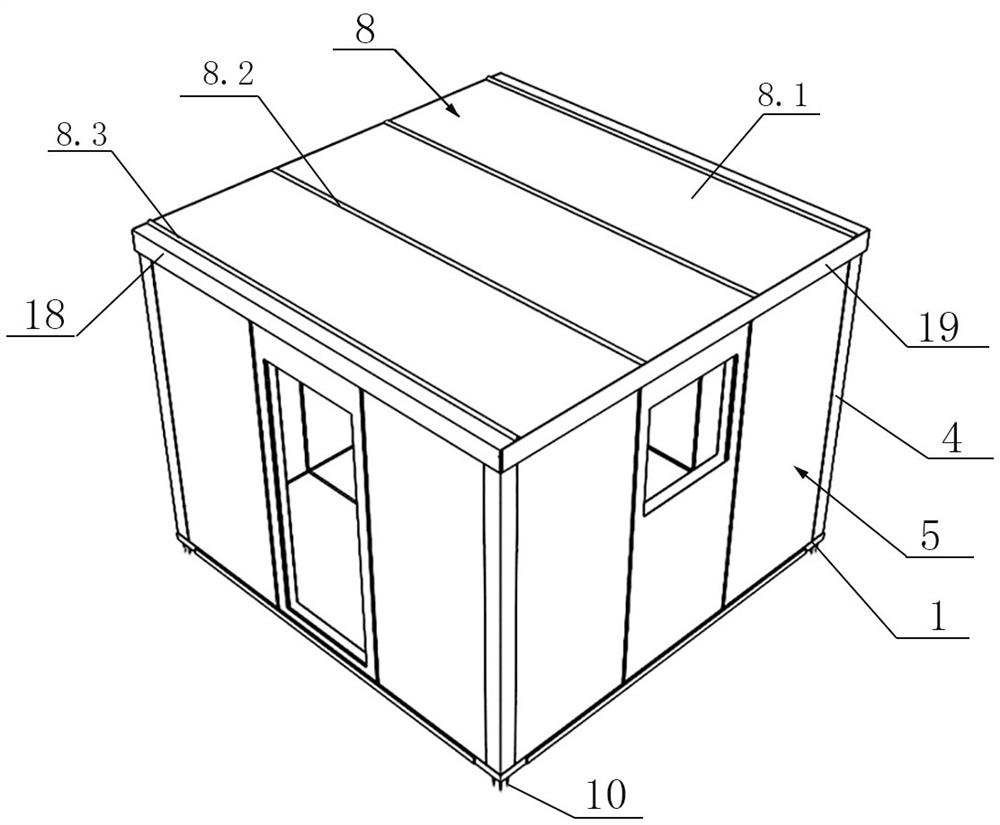

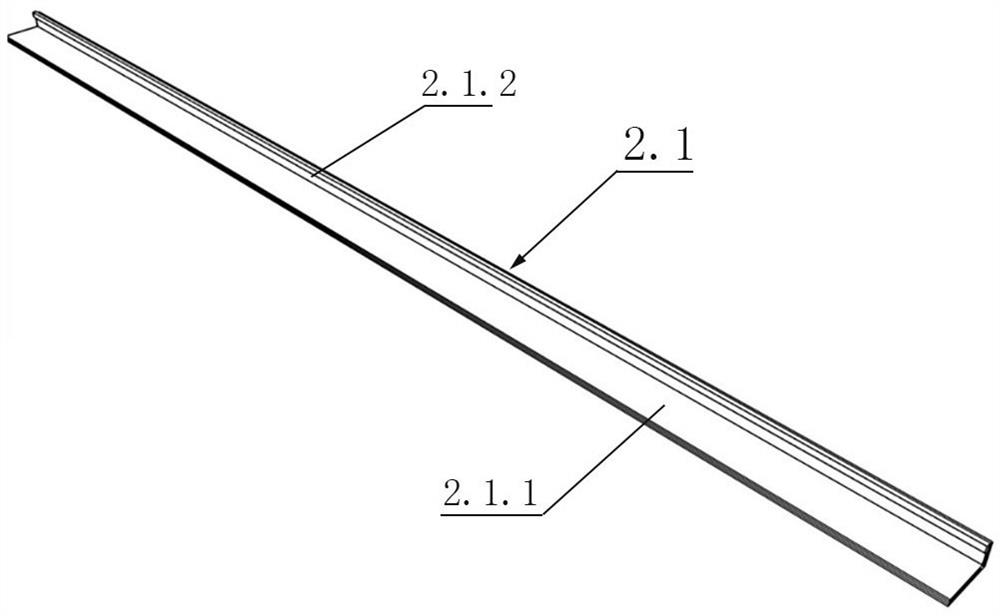

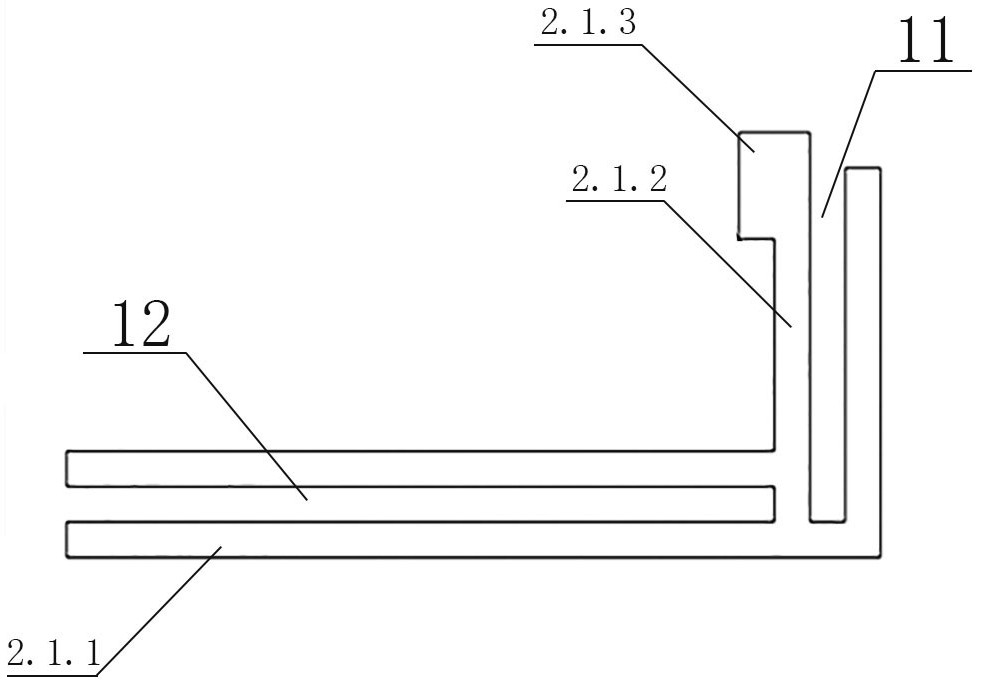

[0086] like Figure 1-44 As shown, the prefabricated house structure that can be quickly disassembled and assembled includes ground beam angle pieces 1, ground beams 2, bottom panels 3, corner posts 4, wall panels 5, top beam angle pieces 6, top beams 7 and top panels 8;

[0087] There are four ground beam corner pieces 1, which are arranged at four corner positions of the prefabricated house structure to be installed; the ground beam corner piece 1 includes a first vertical side plate 1.1, a column bottom connecting plate 1.2 and The ground beam connecting plate 1.3; the horizontal section of the first vertical side plate 1.1 is L-shaped, including a first transverse section 1.1.1 and a first longitudinal section 1.1.2; the column bottom connecting plate 1.2 is rectangular, It is horizontally connected at the corner position of the first vertical side plate 1.1, and the lateral side of the column bottom connecting plate 1.2 is smaller than the length of the first transverse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com