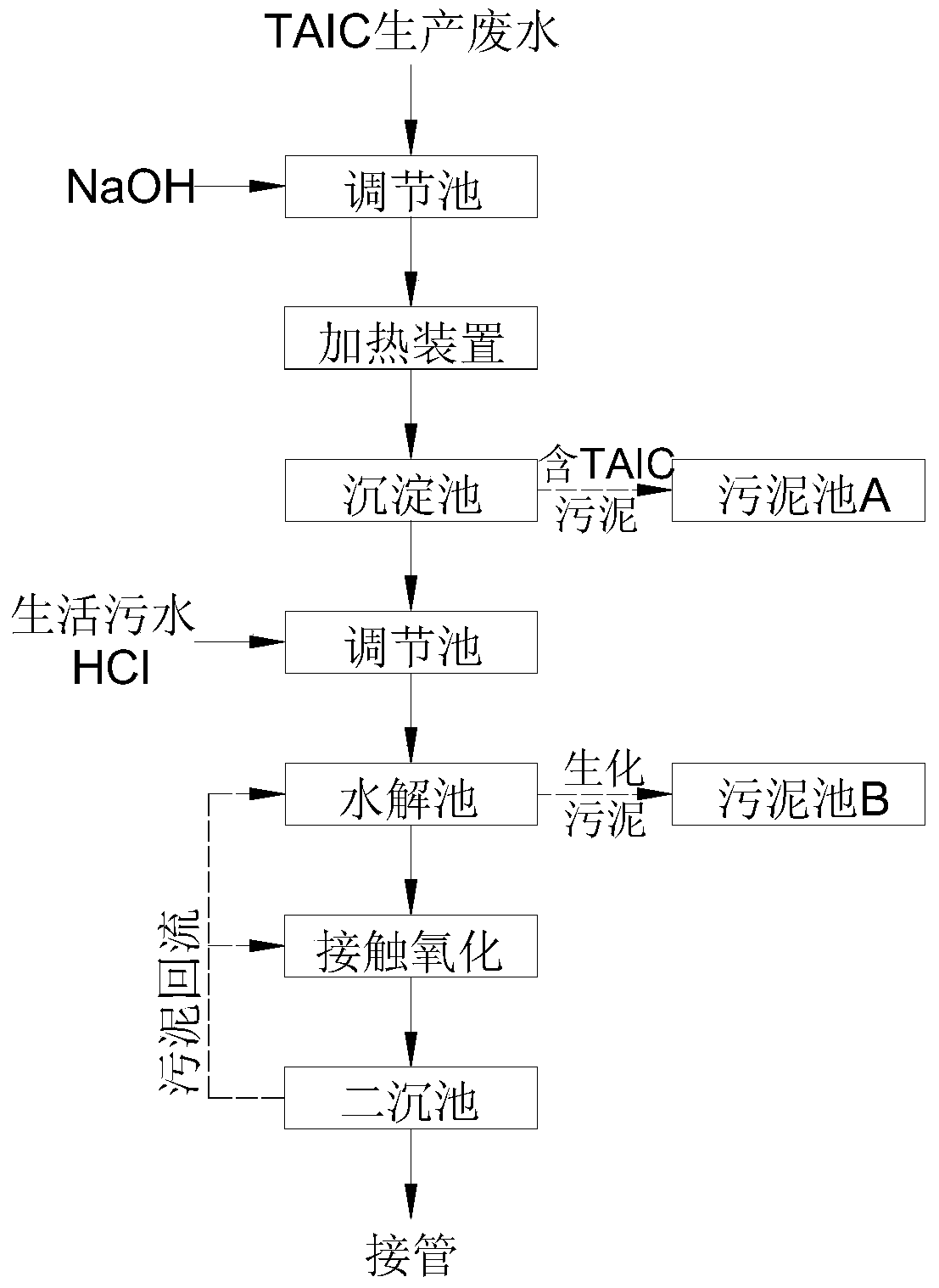

A kind of method of alkaline demulsification and hydrolysis-contact oxidation system joint treatment taic production wastewater

A technology for producing wastewater and contact oxidation, which is used in neutralized water/sewage treatment, multi-stage water treatment, aerobic process treatment, etc. problem, to achieve the effect of no secondary pollution, low treatment cost, stable and continuous treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The TAIC production wastewater used in this example is the wastewater produced by a TAIC manufacturer in Rudong using the cyanate process to produce TAIC. It mainly includes three pollutants: DMF, TAIC, and NaCl. The initial concentration of TAIC is 773mg / L. The concentration is 225mg / L, the COD is 20180mg / L, the salinity is 3%, and the pH is 4.5.

[0032] The present embodiment processes TAIC production wastewater according to the following steps:

[0033] (1) After the TAIC production wastewater is collected uniformly, it is introduced into the adjustment pool, and alkali is added to adjust the pH to 12;

[0034] (2) Subsequently, the TAIC production wastewater is introduced into the heating device, so that the TAIC production wastewater is heated to 60° C. to produce flocs;

[0035] (3) The heated TAIC production wastewater is introduced into the sedimentation tank, and the floc produced is precipitated into sludge;

[0036] (4) The supernatant in the sedimentation...

Embodiment 2

[0040] In this example, the same TAIC production wastewater was treated in the same manner as in Example 1, except that the heating temperature of the TAIC production wastewater in step (2) was 70°C.

[0041] After the TAIC production wastewater was treated according to the method of this example, the concentration of TAIC in the effluent of the sedimentation tank was 192 mg / L, the concentration of DMF was 19 mg / L, the COD was 5860 mg / L, and the salinity was 2.4%. The removal rate of TAIC reaches over 75%, the floc particles are relatively large, the sedimentation performance is very good, and the biochemical property is greatly improved. B / C can be improved to 0.34.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com