Wheel for low-speed vehicles and preparation method thereof

A low-speed operation, wheel technology, applied in the field of auto parts, can solve the problems of non-wear resistance, easy air leakage, difficult replacement, etc., and achieve the effect of simple and easy preparation method, improved strength and wear resistance, and simple combination process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

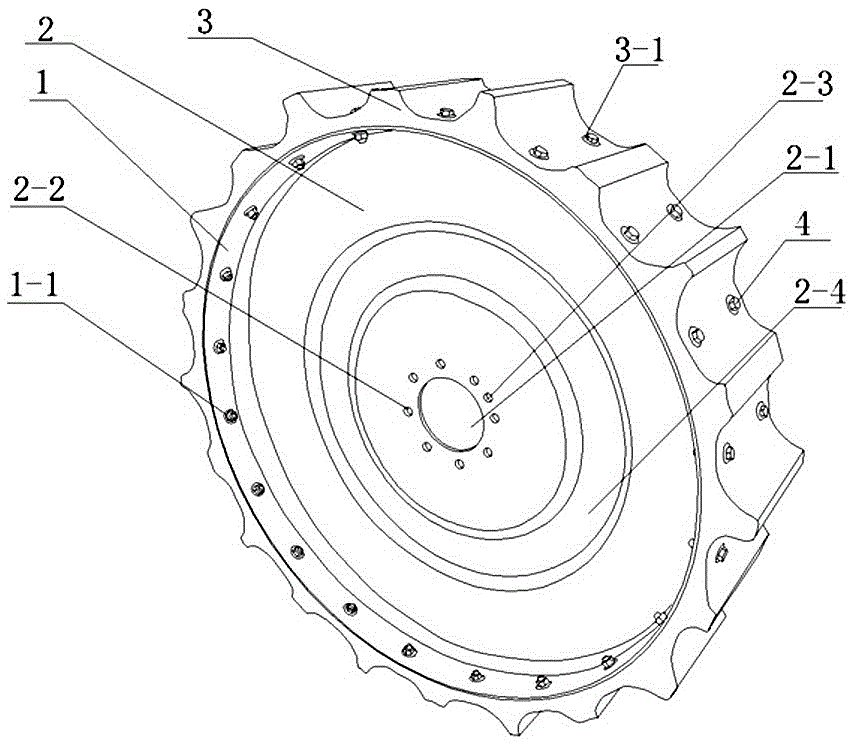

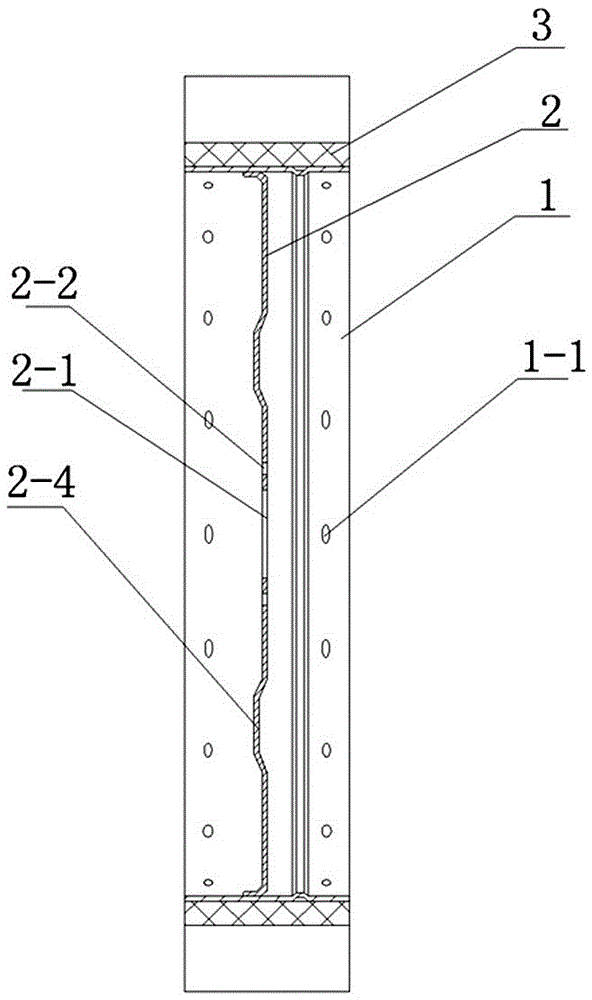

[0031] Attached below figure 1 and 2 The present invention is described in further detail, and the implementation details of the present invention are given.

[0032] as attached figure 1 and 2 As shown, a new type of wheel for a low-speed running vehicle includes a rim 1, a spoke 2 and a tire 3, the spoke 2 is in the shape of a whole disc, and the outer periphery of the spoke 2 is welded on the inner edge of the rim 1, and the rim 1 Two rows of connection holes 1-1 are evenly arranged on the radial circumference, and the wheel of the tire 3 is a gear-shaped rubber tire, and two rows of connection screw holes 3 matching the connection holes 1-1 are arranged on the tire 3 -1, the tire 3 and the rim 1 are fixedly connected by bolts 4, the middle part of the spoke 2 is provided with a shaft hole 2-1, and the edge of the shaft hole 2-1 is provided with a circle of threaded holes 2 evenly distributed -2 and a counterweight hole 2-3, and the spoke 2 is radially provided with a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com