Prefabricated light steel composite structure house and construction method

A combined structure and prefabricated technology, applied in building components, building structures, walls, etc., can solve the problems of high technical requirements, complex processes, and high costs for construction personnel, and achieve simplified installation processes, reduced technical requirements, and simple construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

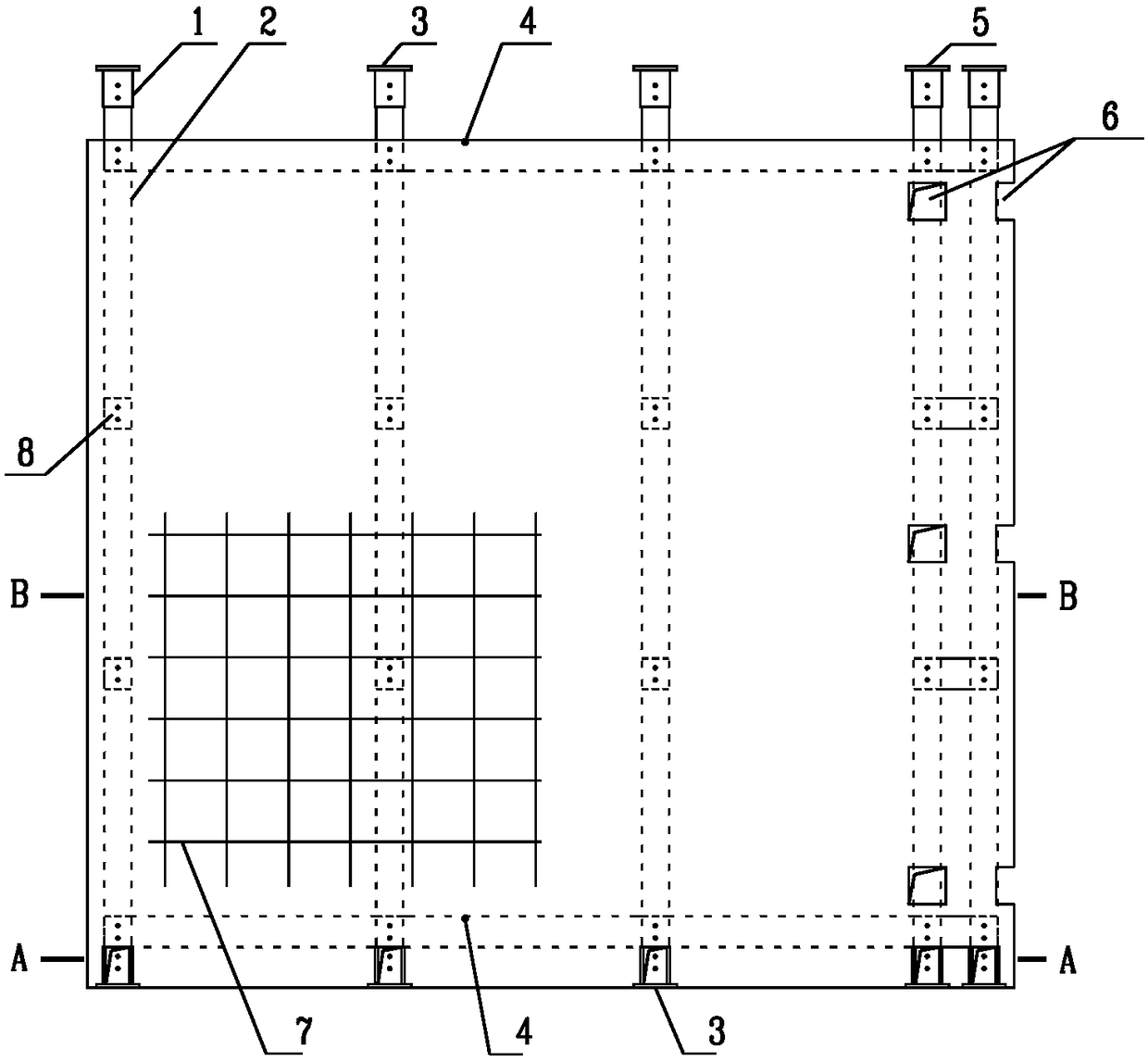

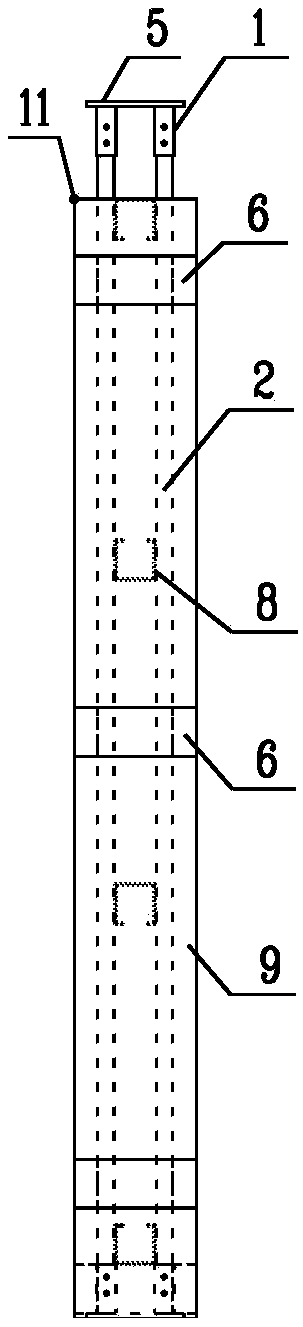

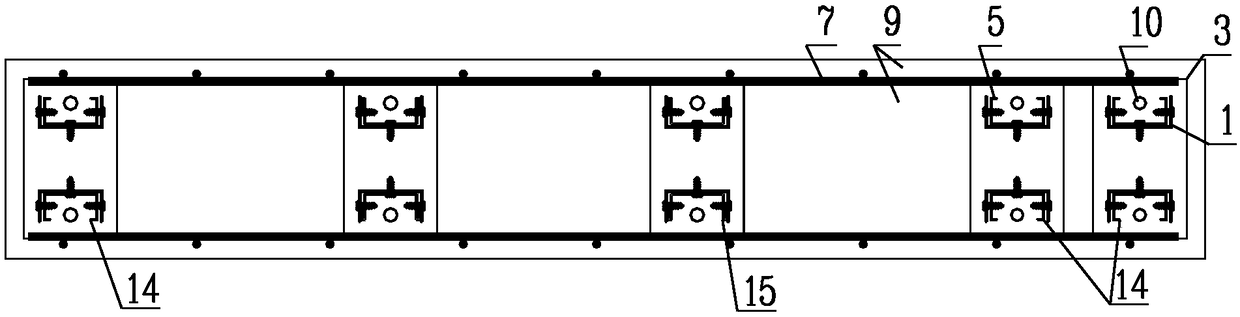

[0043] The present invention is a prefabricated light-steel composite structure house and construction method. The wall section has the following characteristics: each wall section uses a plurality of vertically spaced steel sections as keels, and each keel is provided with a wall A pair of section steel columns connected by a lattice structure arranged symmetrically in the middle of the section, the top and bottom of the wall section are crossed and fixed with connecting beams; the keel is embedded in the concrete filler; on the surface of the wall section connected with other wall sections An adapter groove is provided, and the groove bottom of the adapter groove is the outer surface of the profile steel column, and the adapter groove set at the same height as the adjacent wall section is used to fasten the adjacent wall section through the wall section connector.

[0044] The present invention will be further described below in conjunction with embodiments and drawings, but it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com