Decorative heat preservation composite board with lugs and construction method thereof

A thermal insulation composite board and composite board technology, applied in the field of building materials, can solve the problems of complex manufacturing process of mechanical connection method and structural member connection method, affecting decorative effect of decorative panels, poor thermal insulation effect, etc., and achieves simple, convenient and good production. Thermal insulation effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

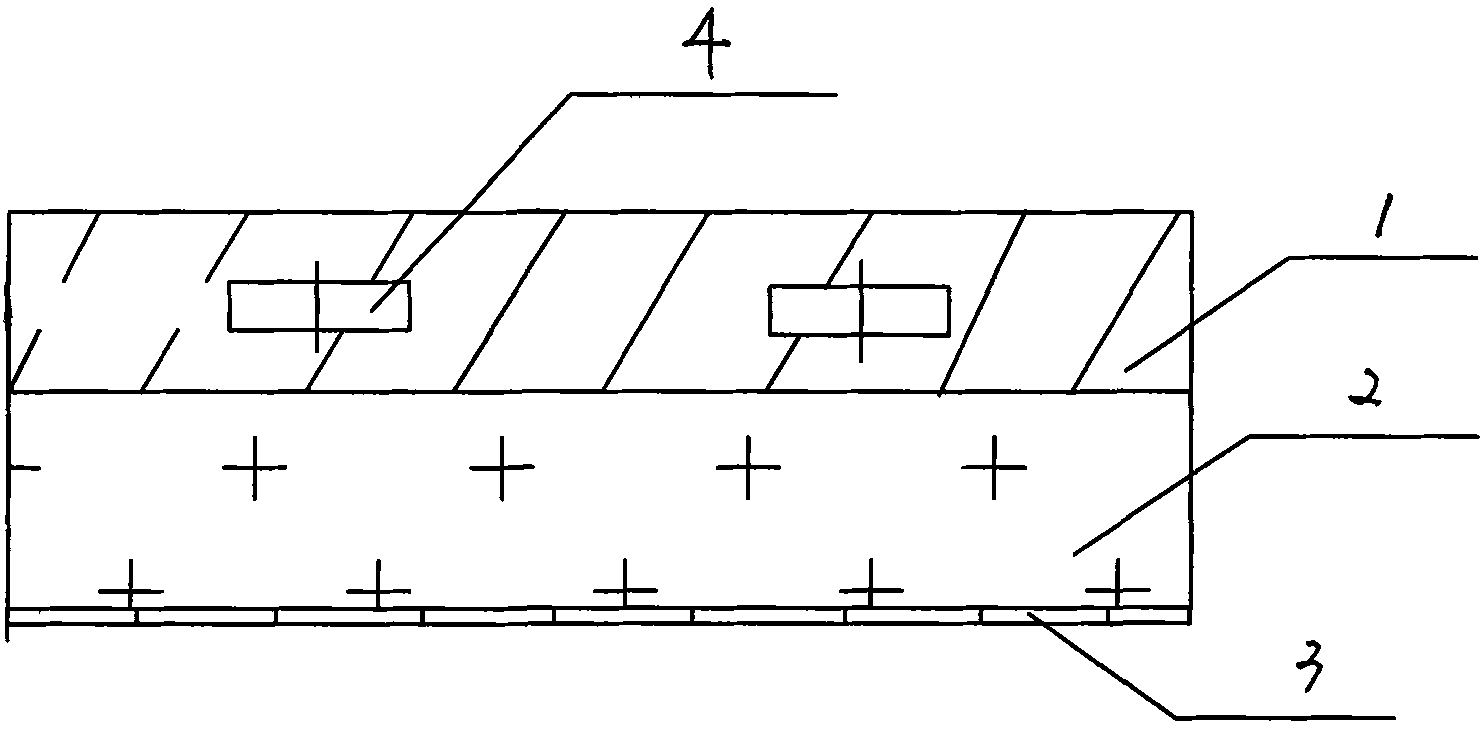

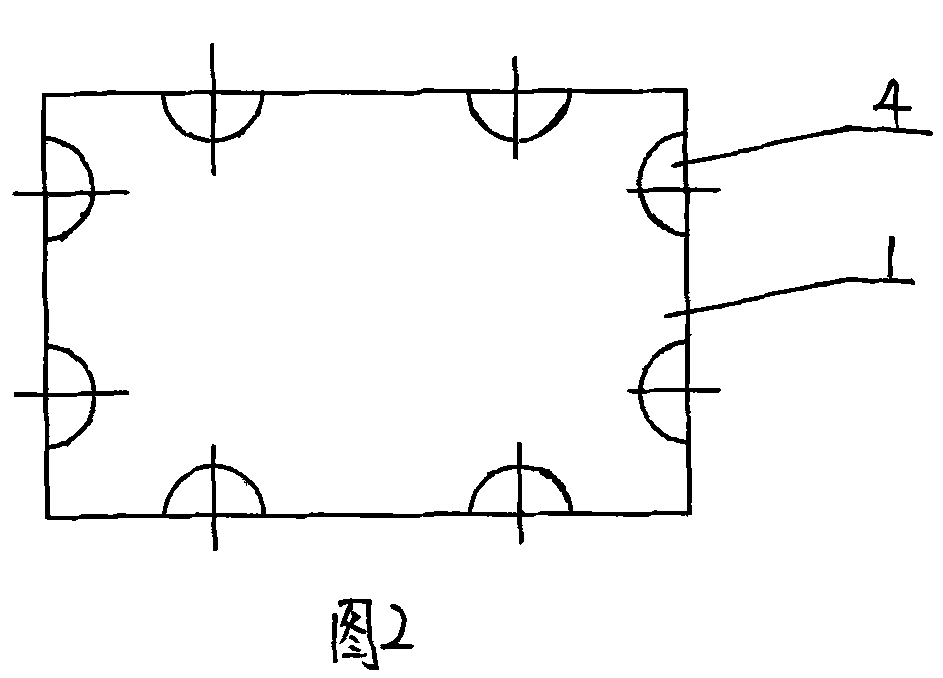

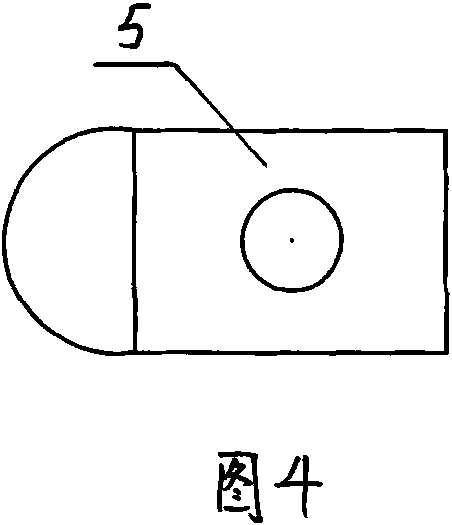

[0027] Example 1, referring to Figures 1, 2, 3, 4, 5, 6, the finishing layer 1, thermal insulation layer 2 and reinforced interface layer 3 are processed and compounded into a decorative and thermal insulation composite board according to the conventional process, and then on the surface layer 1 Hanging ear holes 4 are evenly opened on each side, and adhesive 7 is injected into the hanging ear holes 4, and the prepared hanging ears 5 are inserted into the hanging ear holes 4. The hanging ears 5 can be made of metal materials, so that the decorative layer 1 and the The hanging lug 5 is bonded and solidified to form a product.

[0028] Adhesive 7 of Example 1 is a two-component room temperature curing modified epoxy resin adhesive, which is made of epoxy resin E-51 105g, polyamide 651 75g, epoxy resin reactive diluent 50110g, coupling agent KH550 2g, Adhesives are made by conventional processes.

[0029] Adhesive 7 can also be made of epoxy resin E-51 100g, polyamide 65 150g, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com