Patents

Literature

70results about How to "Eliminate peeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

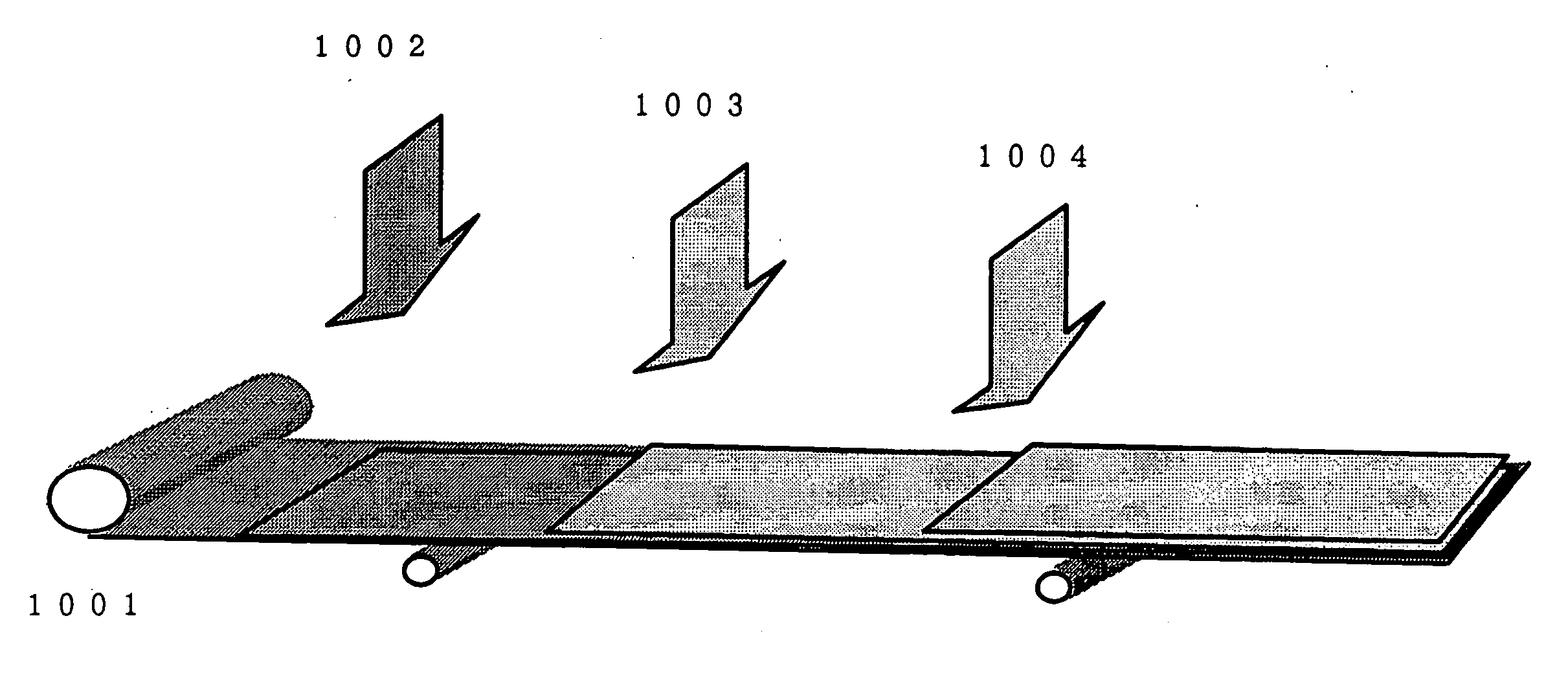

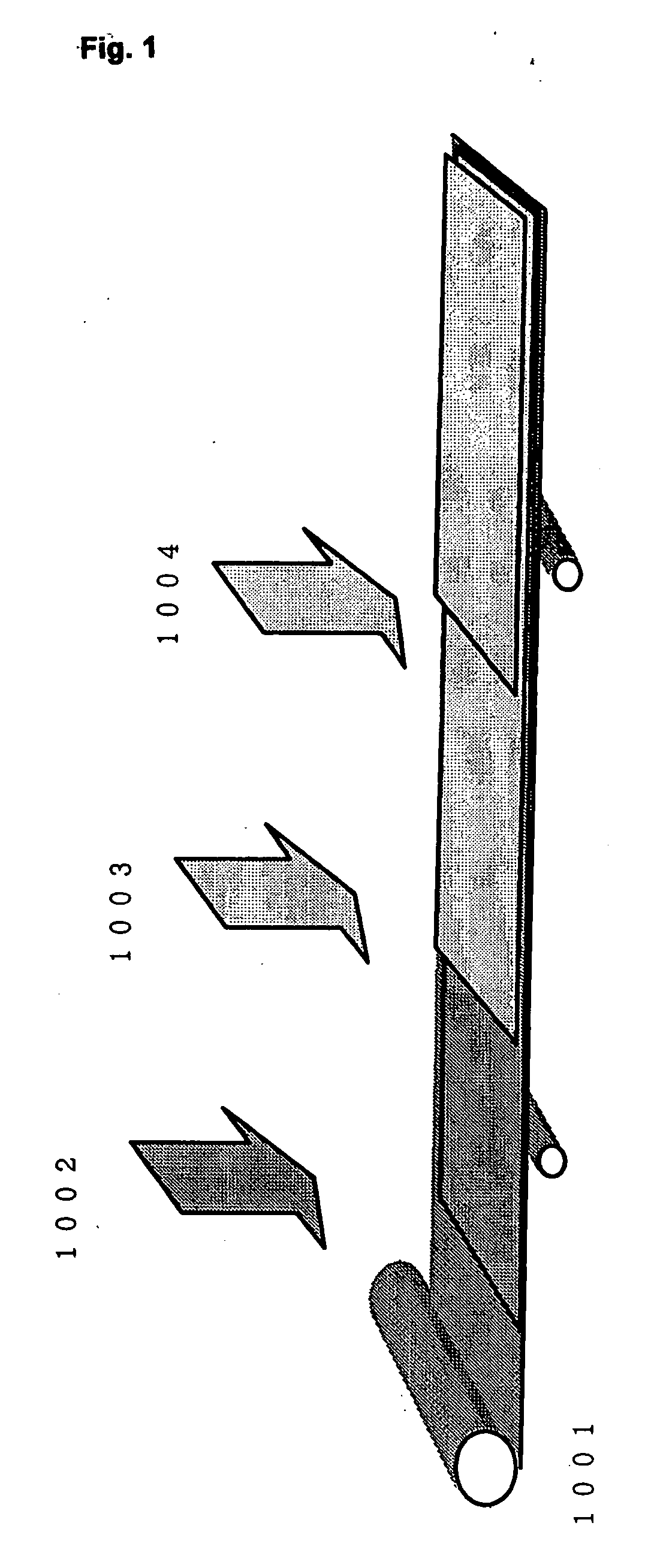

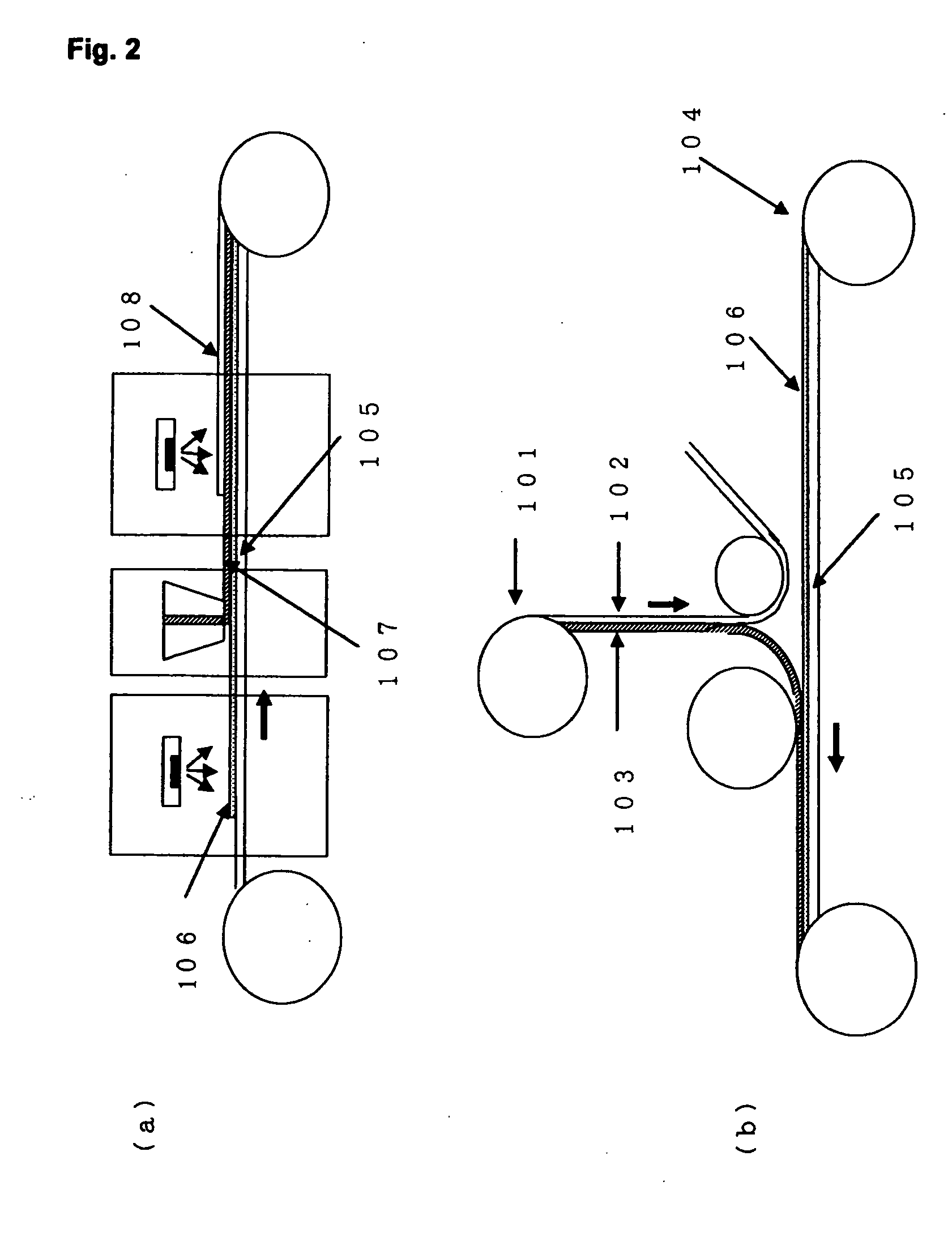

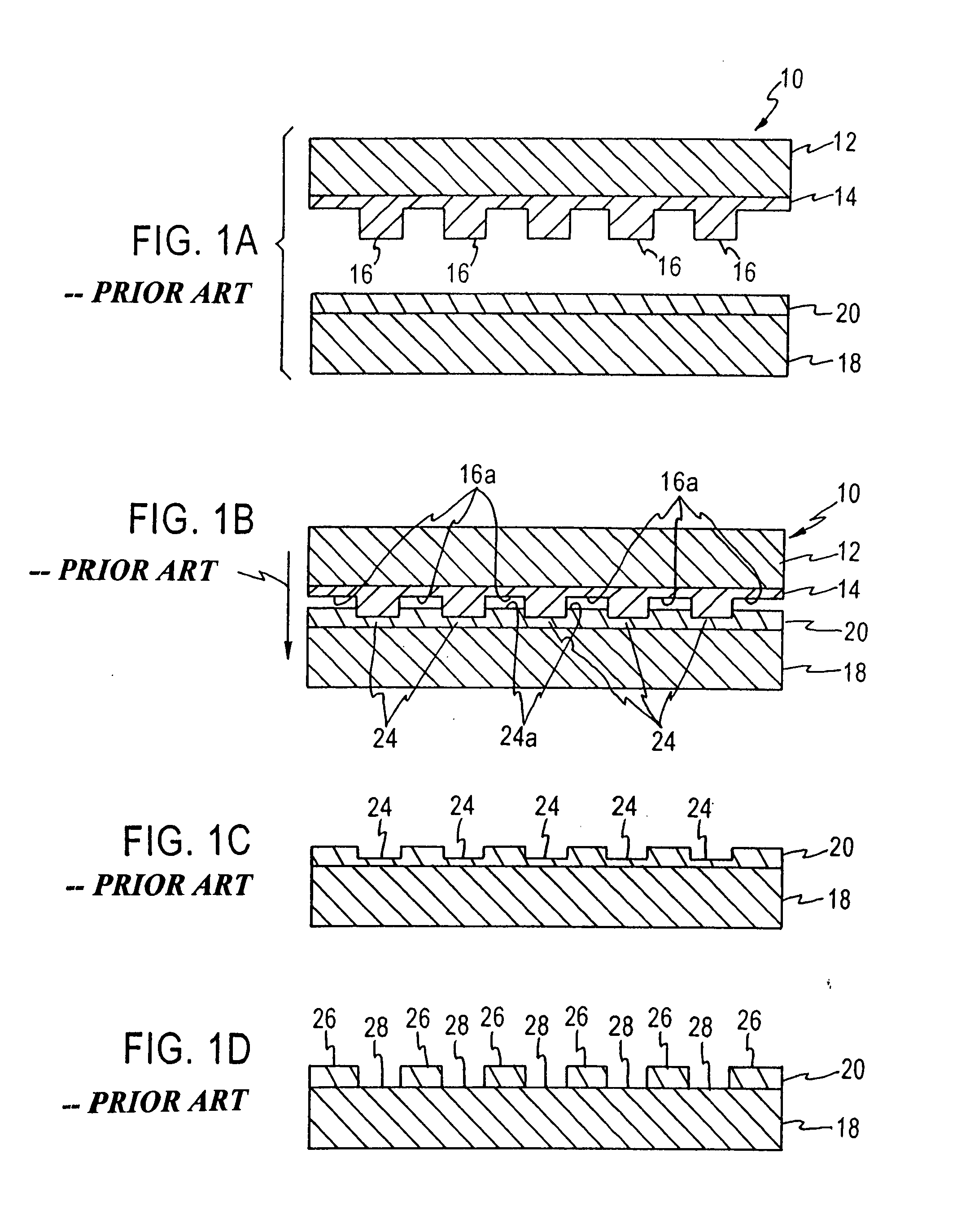

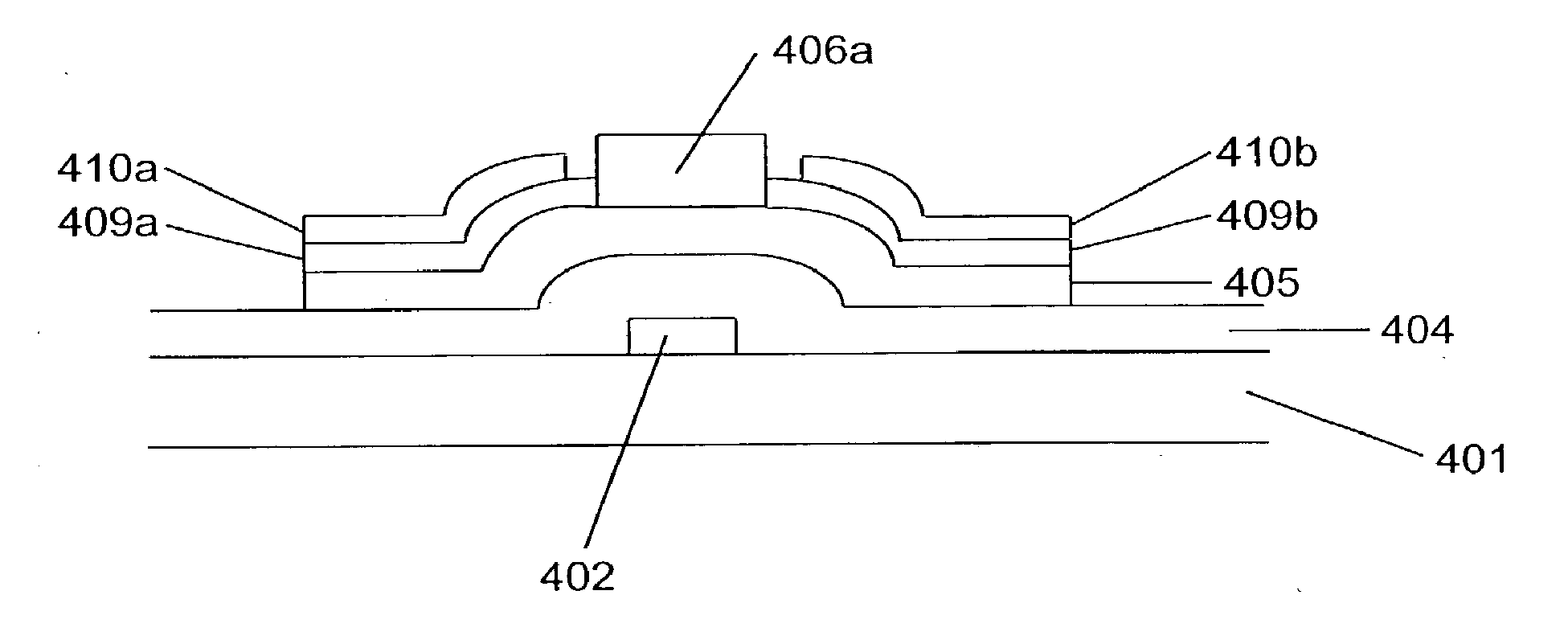

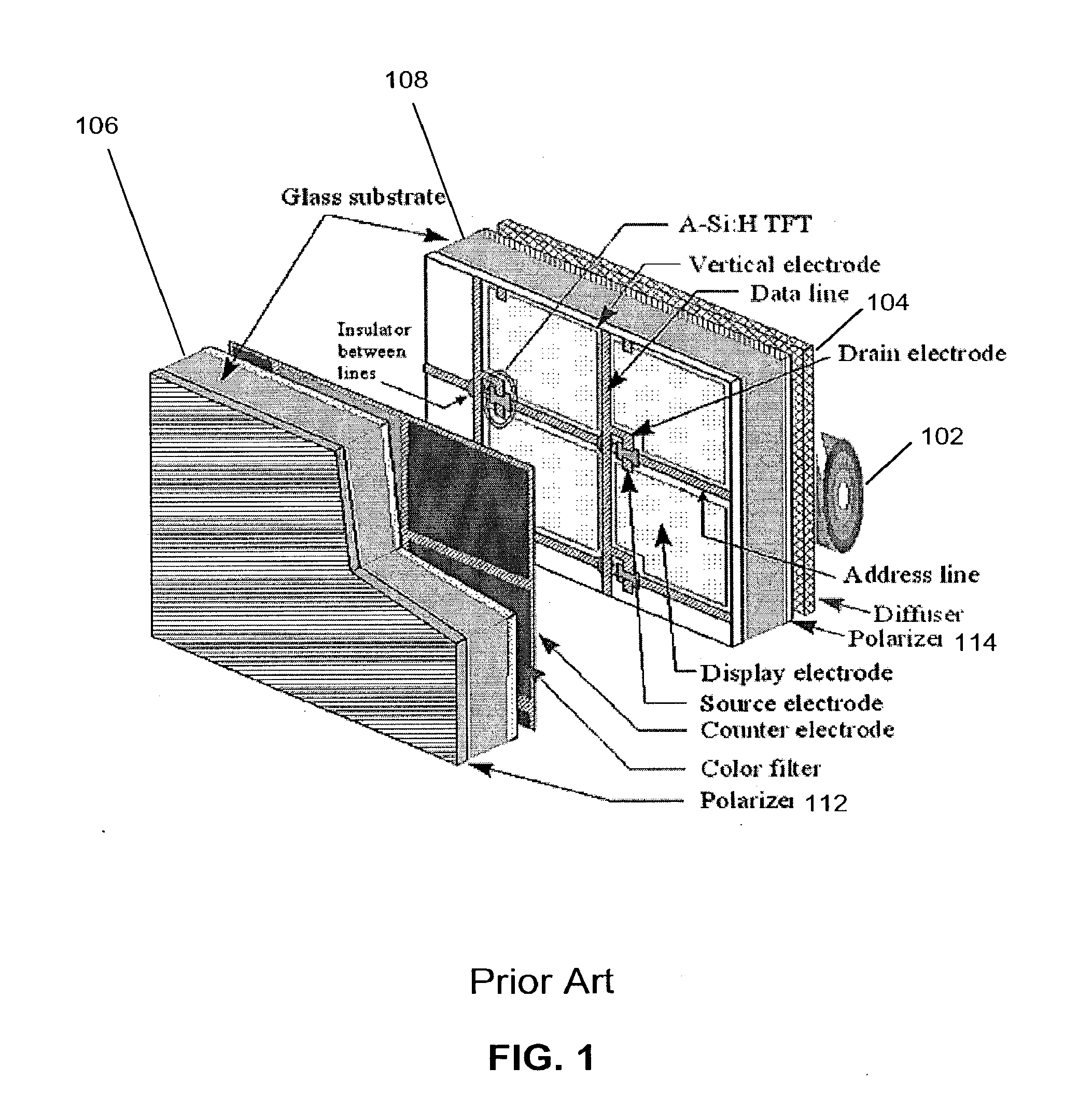

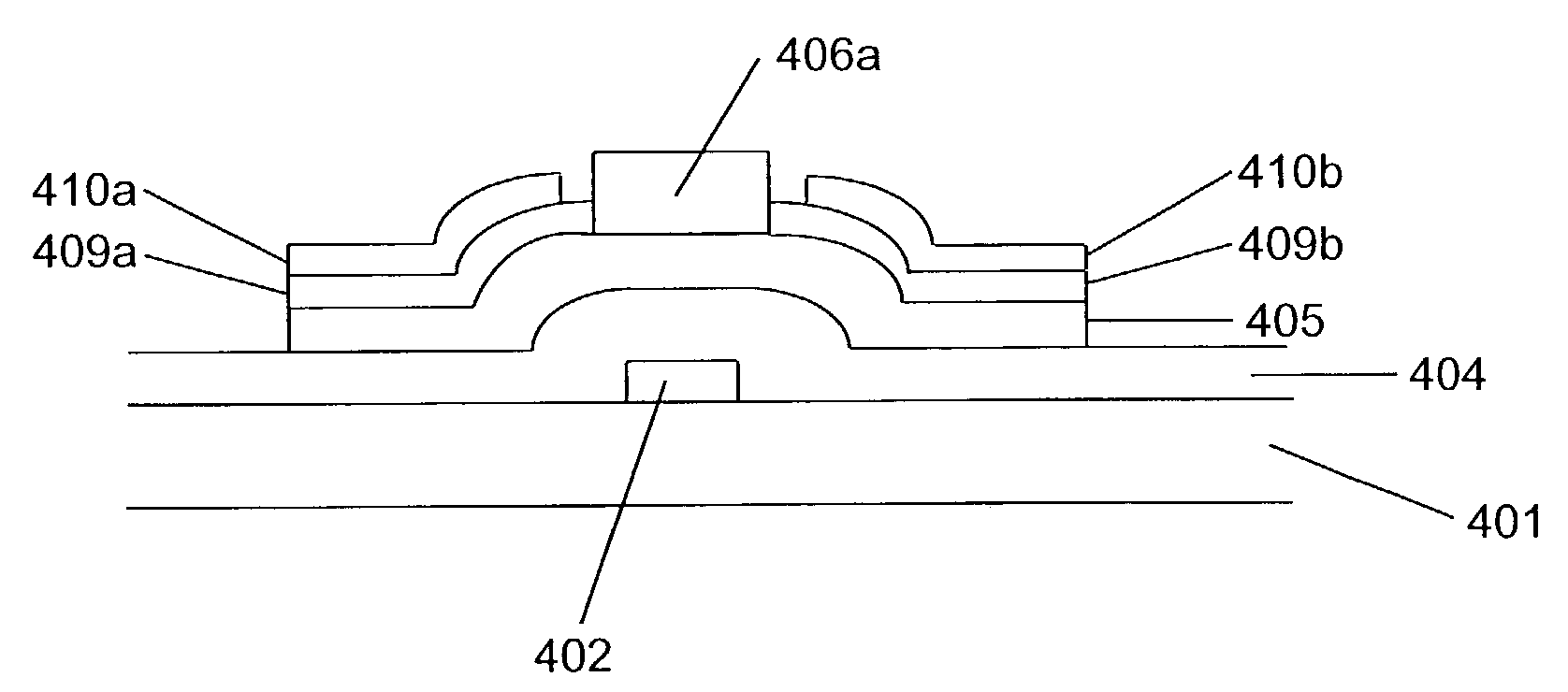

Base film for liquid-crystal panel, functional film for liquid-crystal panel, manufacturing process for functional film and manufacturing apparatus for functional film

InactiveUS20070126966A1Simplify configurationIntermittent operationLiquid crystal compositionsElectroluminescent light sourcesLiquid-crystal displayLiquid crystal

A conventional liquid crystal display comprises a number of components, so that a manufacturing cost cannot be reduced. Furthermore, a large-area substrate has problems in shipping. According to this invention, a liquid-crystal panel is prepared by forming individual optically functional films, a TFT device and a light-emitting device on a long thin film and then laminating the film by a transfer process. A base film to be a substrate in a liquid-crystal panel preferably has a thickness of 10 μm to 200 μm, a curvature radius of 40 mm or less as a measure of flexibility and a coefficient of thermal expansion of 50 ppm / ° C. or less. Furthermore, it more preferably gives a variation of ±5% or less in mechanical and optical properties to a thermal history at 200° C.

Owner:NEC CORP +9

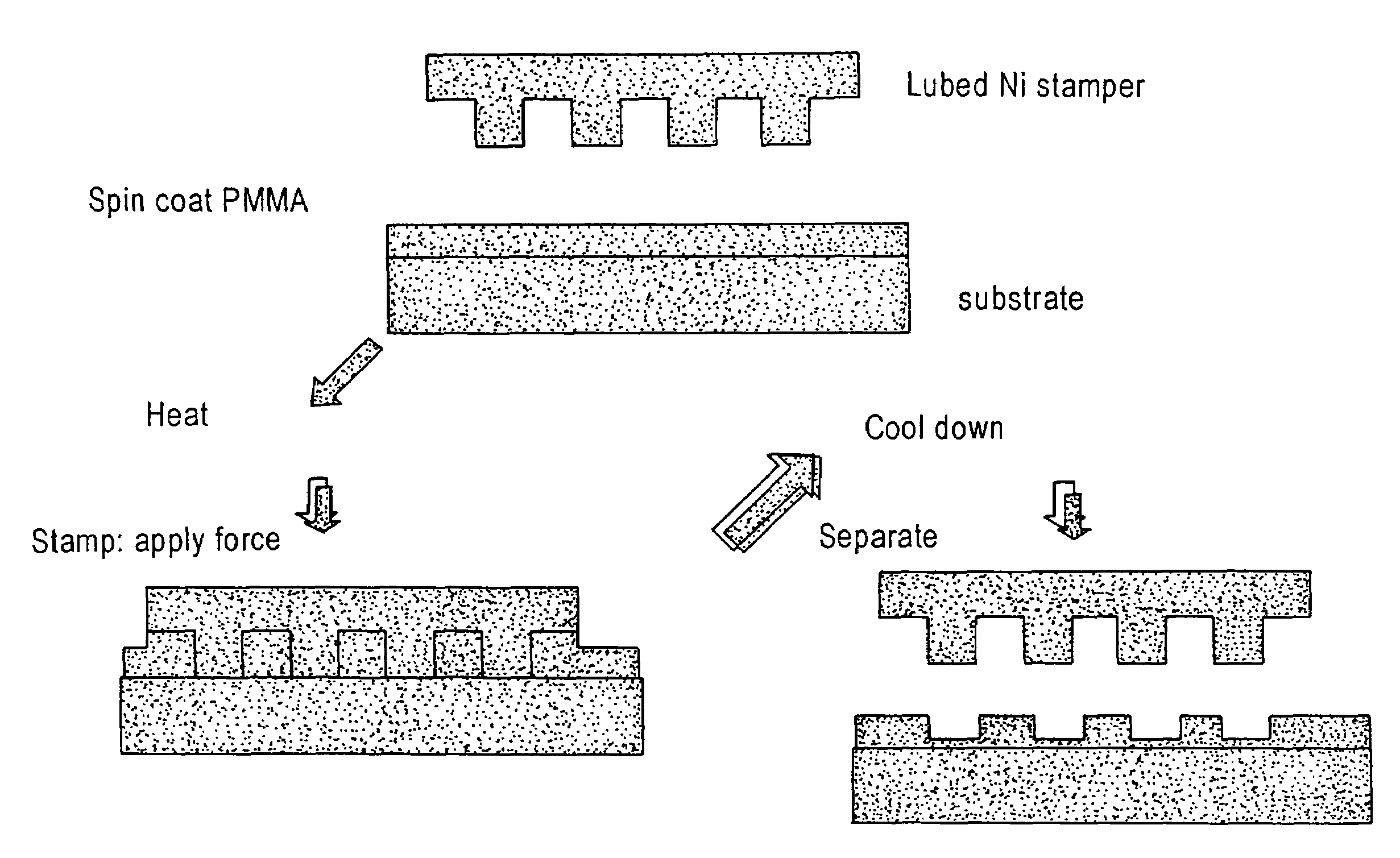

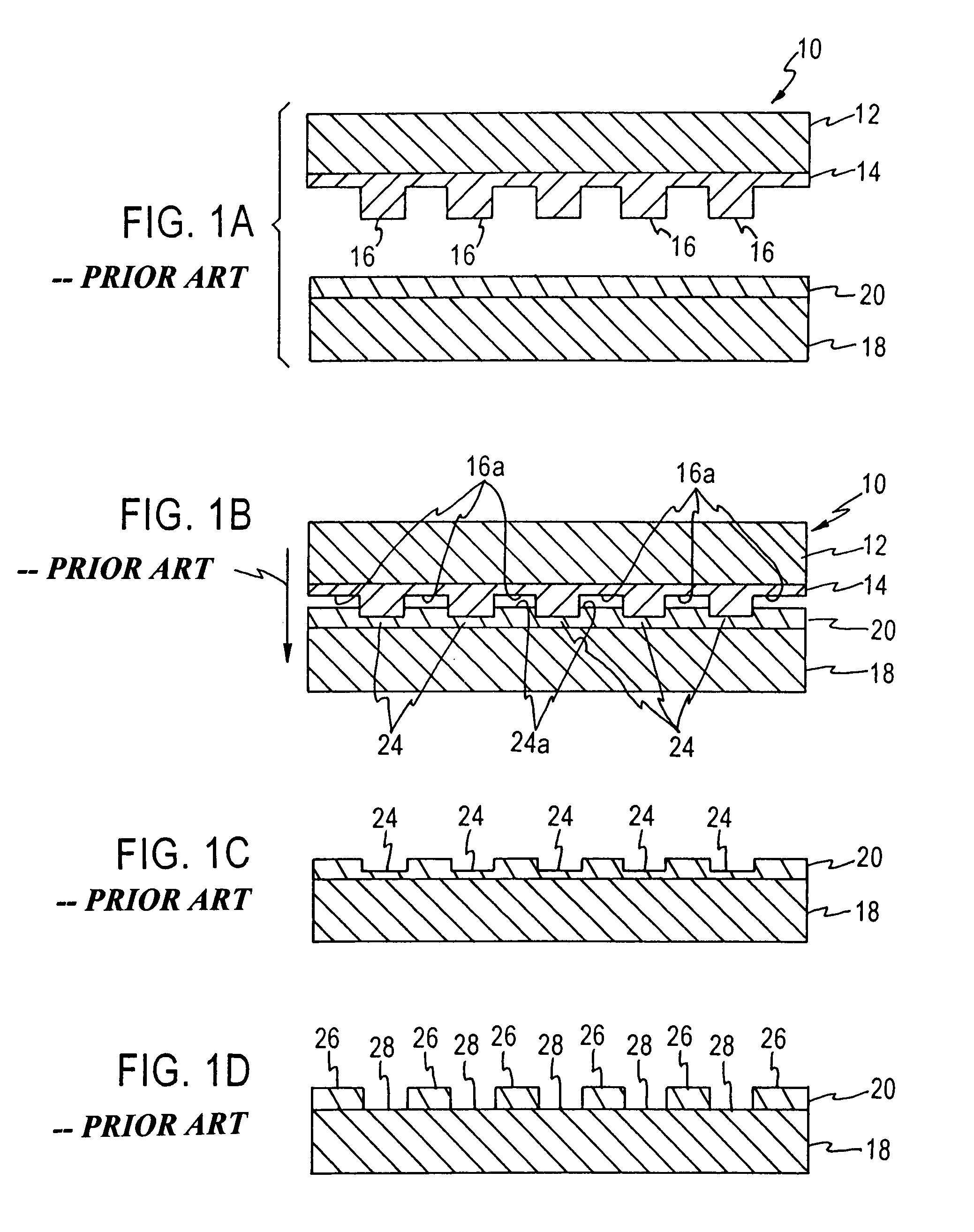

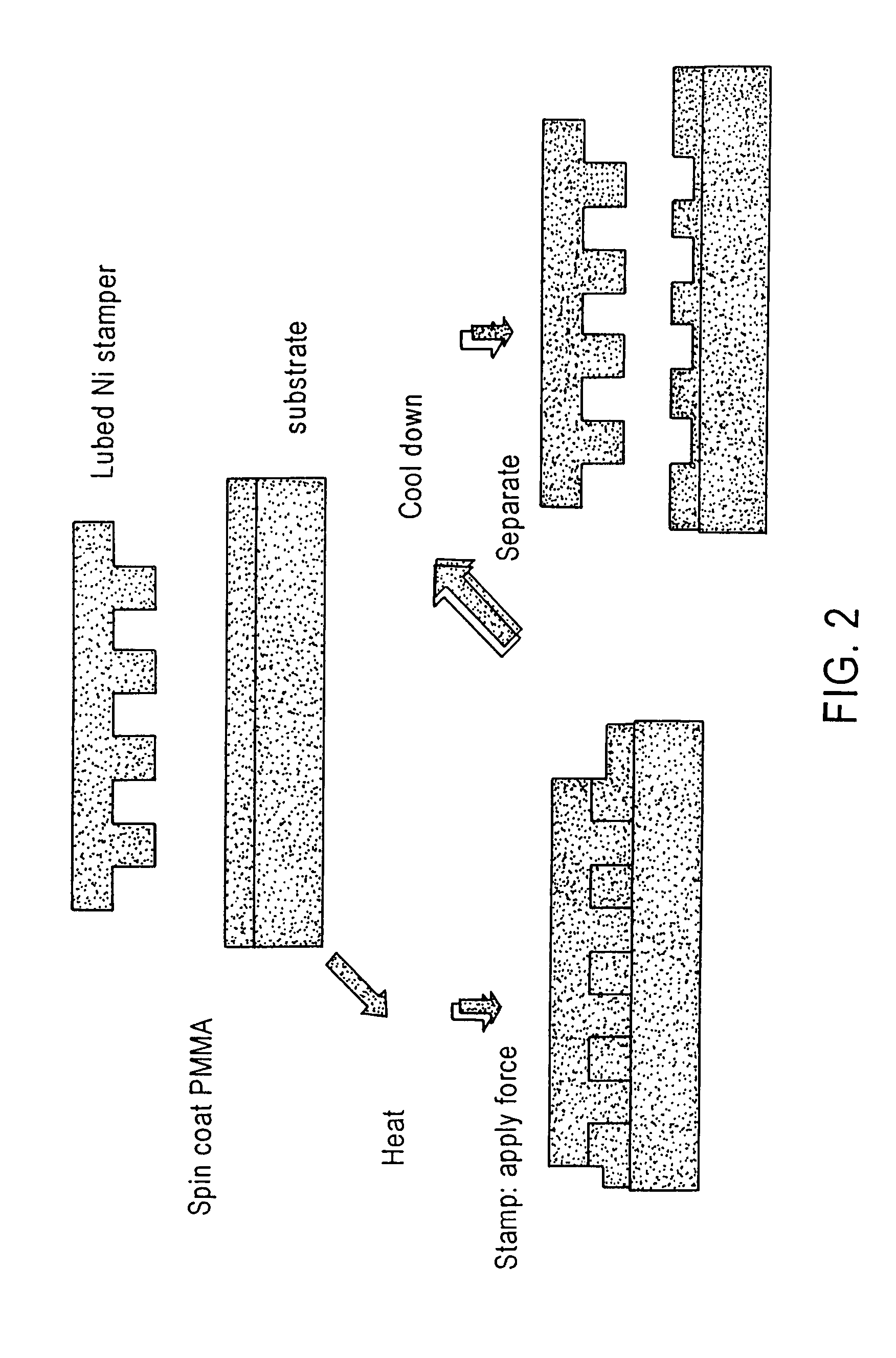

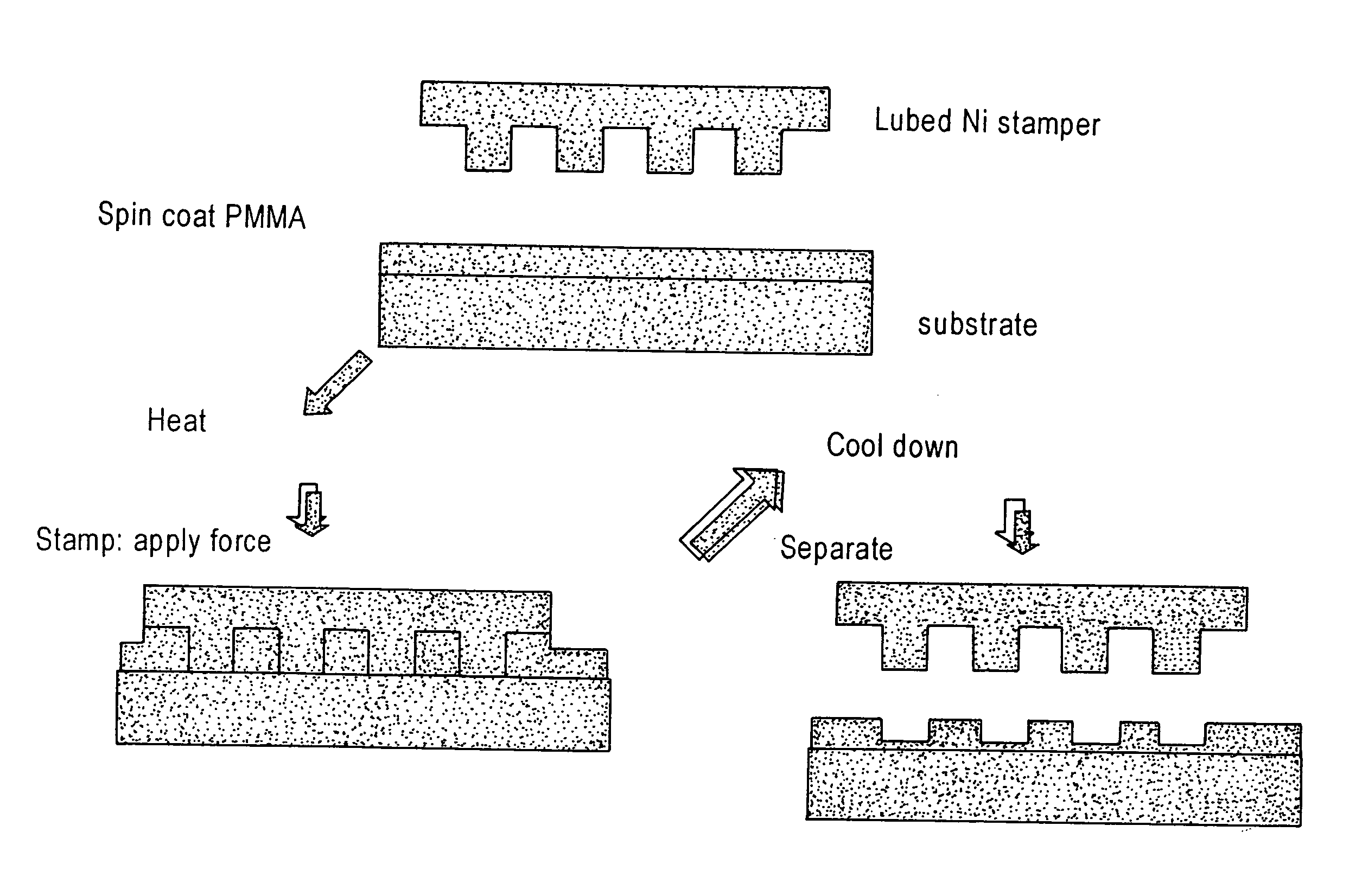

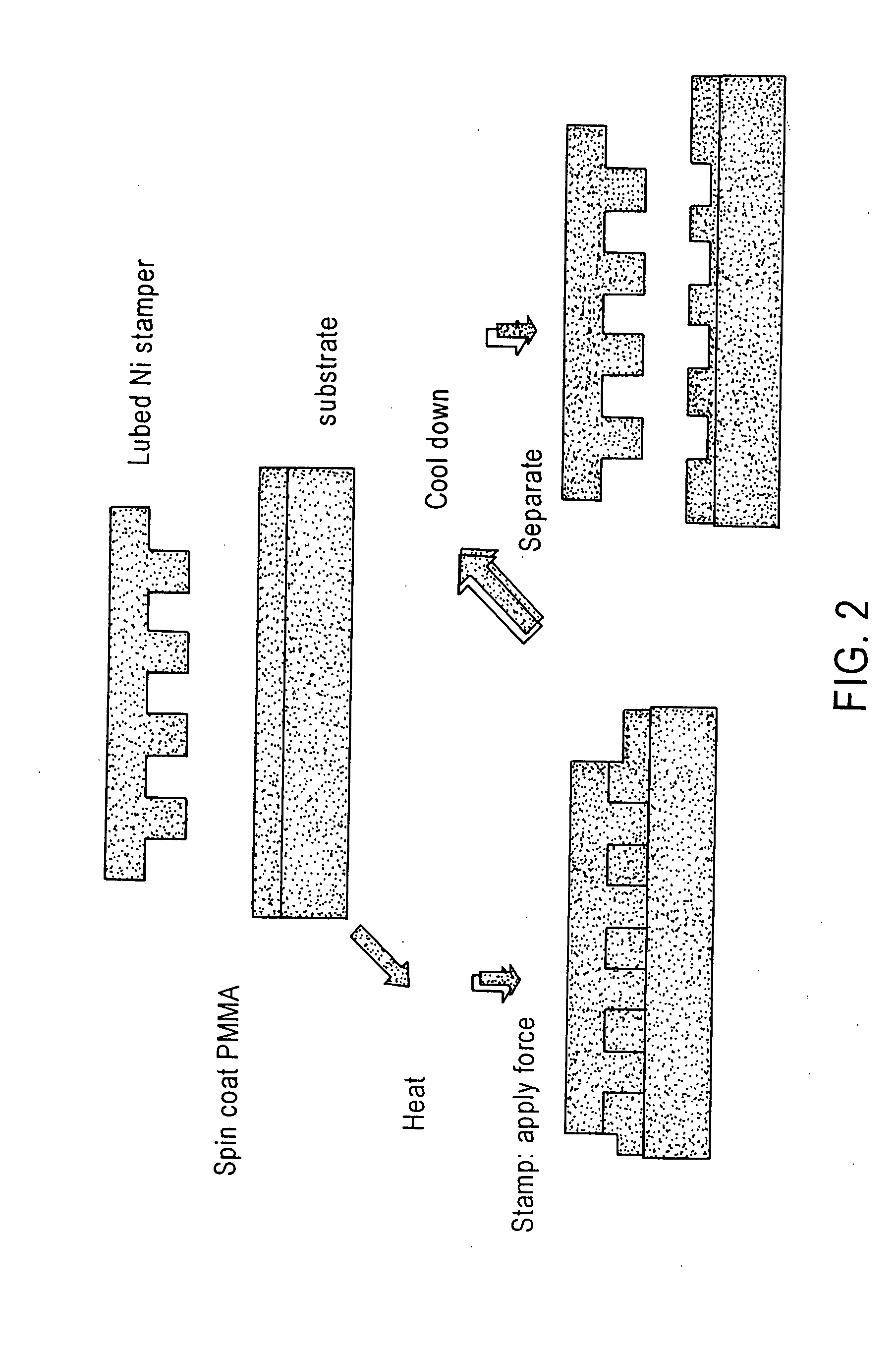

Surface modified stamper for imprint lithography

InactiveUS7294294B1Good release effectMinimize peelingRecord carriersNanoinformaticsLithographic artistEngineering

A method of performing imprint lithography of a surface substrate includes a stamper having a thin lubricant coating thereon to facilitate release of the stamper from the imprinted surface to reduce degradation of image replication. Embodiments of the invention include stampers suitable for use in patterning servo information on magnetic recording media having a lubricant coating of from about 1 nm to about 20 nm.

Owner:SEAGATE TECH LLC

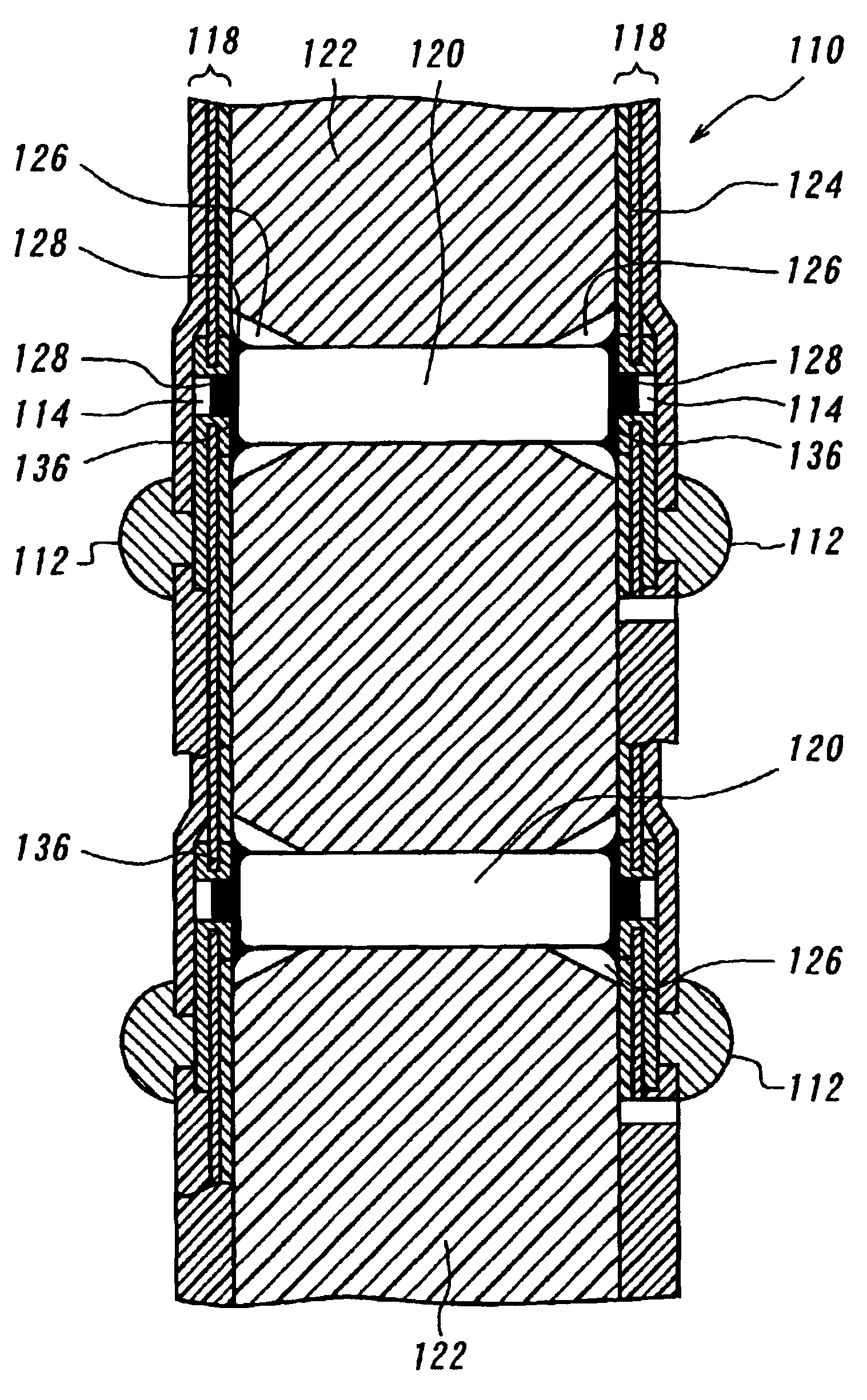

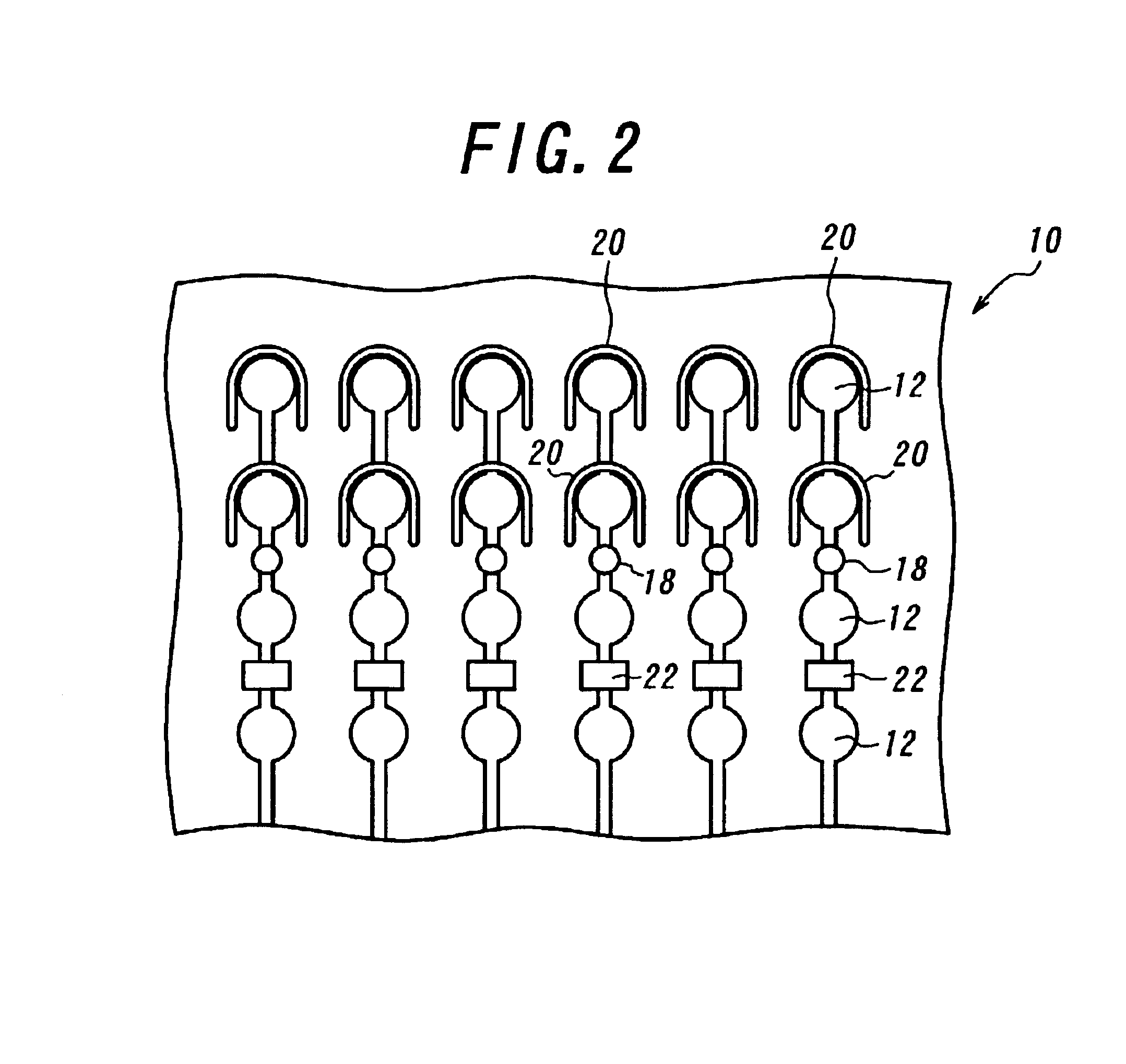

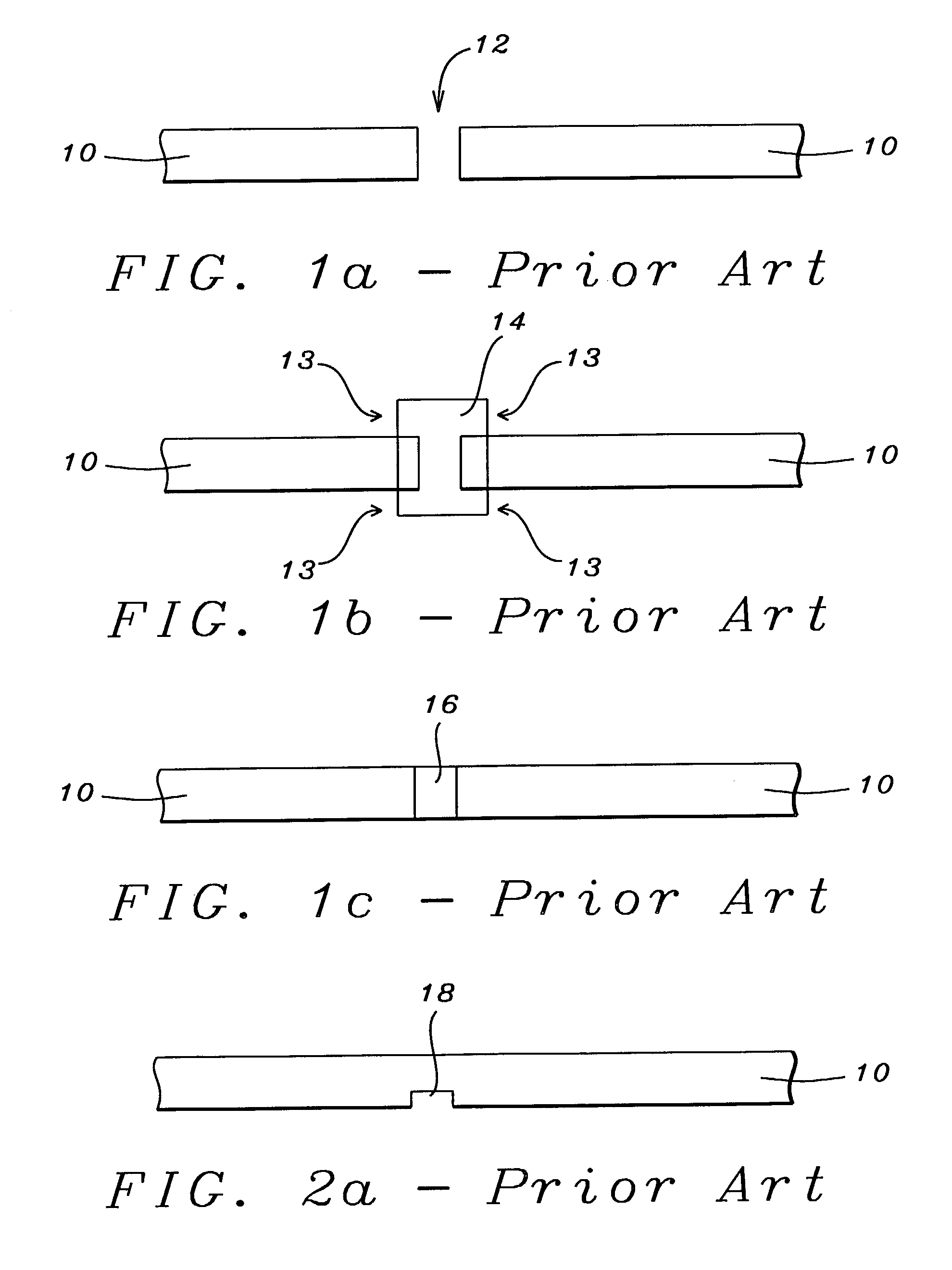

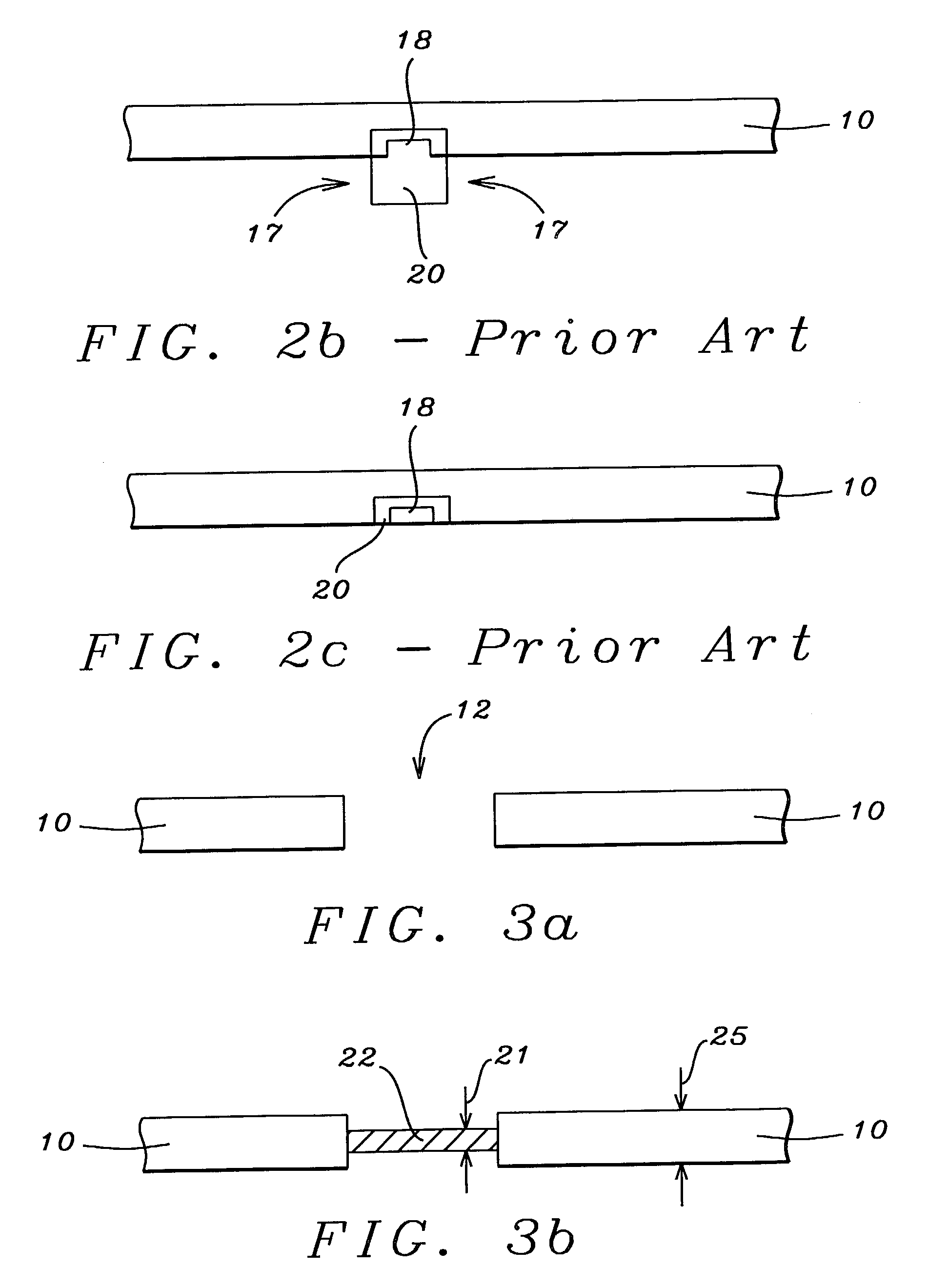

Electrical connector

InactiveUS6857880B2Easy to manufactureEliminate disadvantagesPrinted circuit assemblingElectrically conductive connectionsElastomerElectrical conductor

An electrical connector includes an elastomer layer or board and a plurality of fine lead wires embedded in the elastomer layer and extending rectilinearly therein at right angles to both the surfaces of the elastomer layer. Recesses are formed in the elastomer layer around peripheries of openings of through-holes in which the fine lead wires are embedded. The electrical connector further includes two flexible printed circuit boards on both the sides, each including electric contacts to be connected to mating contacts, connection portions each formed with a through-hole passing therethrough, and conductors each electrically connecting the connection portion to the electric contact. When the flexible printed circuit boards and the fine lead wires are electrically connected by vapor reflow soldering, the flexible printed circuit boards and the elastomer layer having the fine lead wires embedded therein are clamped by restraining jigs to prevent from the flexible printed circuit boards from moving away from the elastomer layer. With this arrangement, reliable connection between the fine lead wires and the flexible printed circuit boards can be achieved without need to control the length of the fine lead wires without any risk of the flexible boards being deflected or warped during soldering even if circumferences of portions to be electrically connected are covered by the insulator.

Owner:THE FUJIKURA CABLE WORKS LTD

Surface modified stamper for imprint lithography

InactiveUS20080038398A1Good release effectMinimize peelingRecord carriersConfectioneryEngineeringLubricant

A method of performing imprint lithography of a surface substrate includes a stamper having a thin lubricant coating thereon to facilitate release of the stamper from the imprinted surface to reduce degradation of image replication. Embodiments of the invention include stampers suitable for use in patterning servo information on magnetic recording media having a lubricant coating of from about 1 nm to about 20 nm.

Owner:SEAGATE TECH HDD HLDG +3

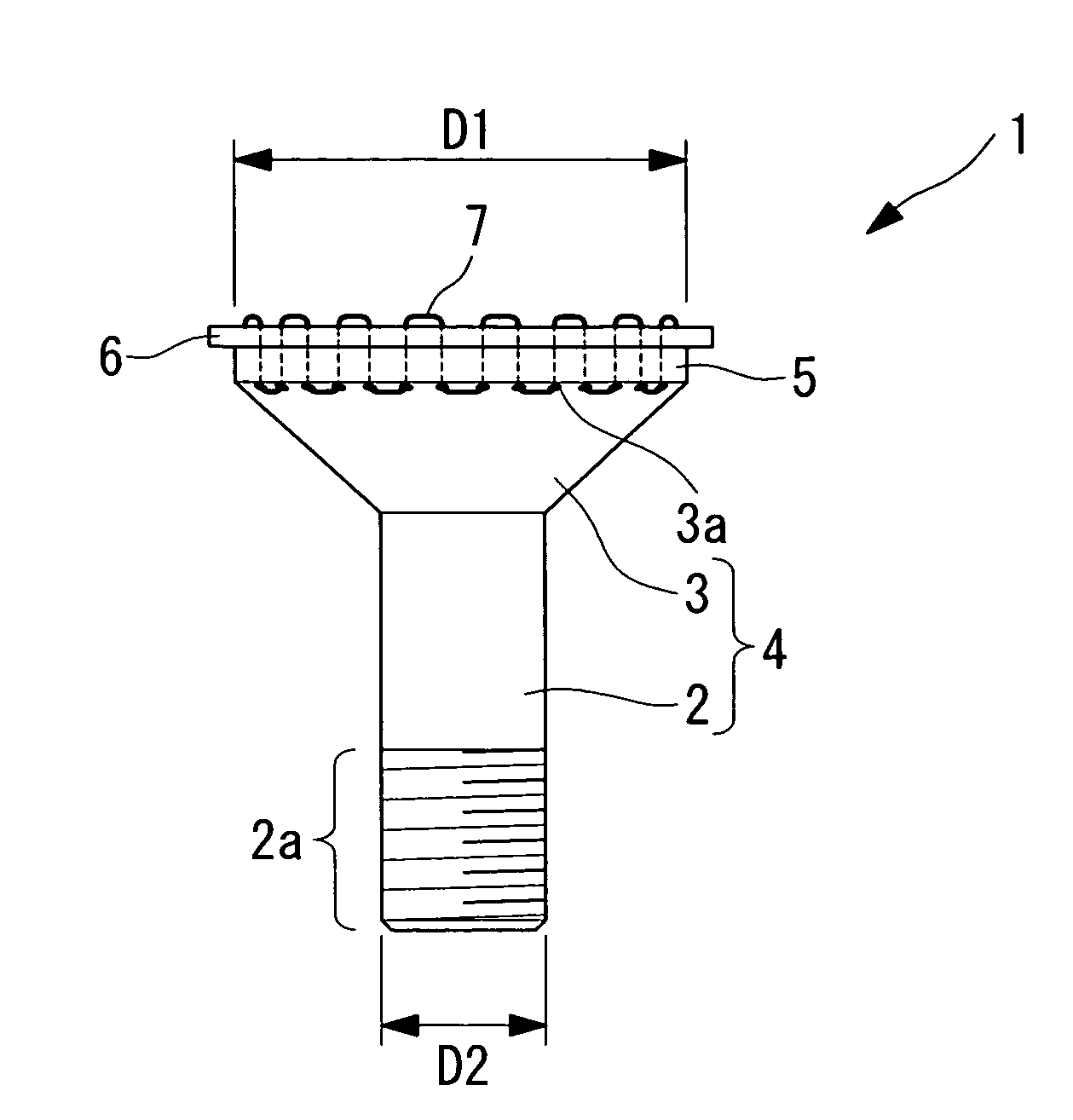

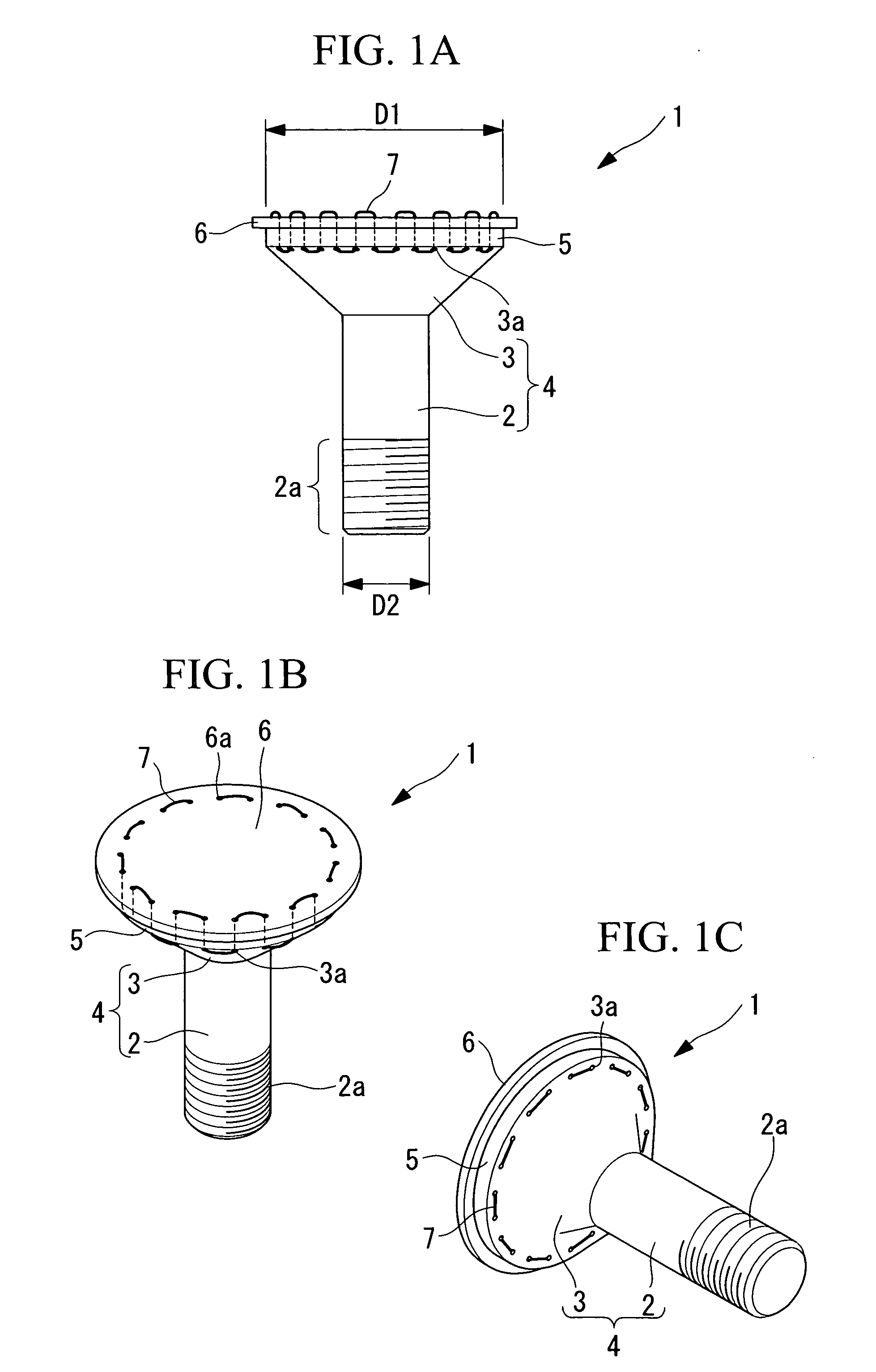

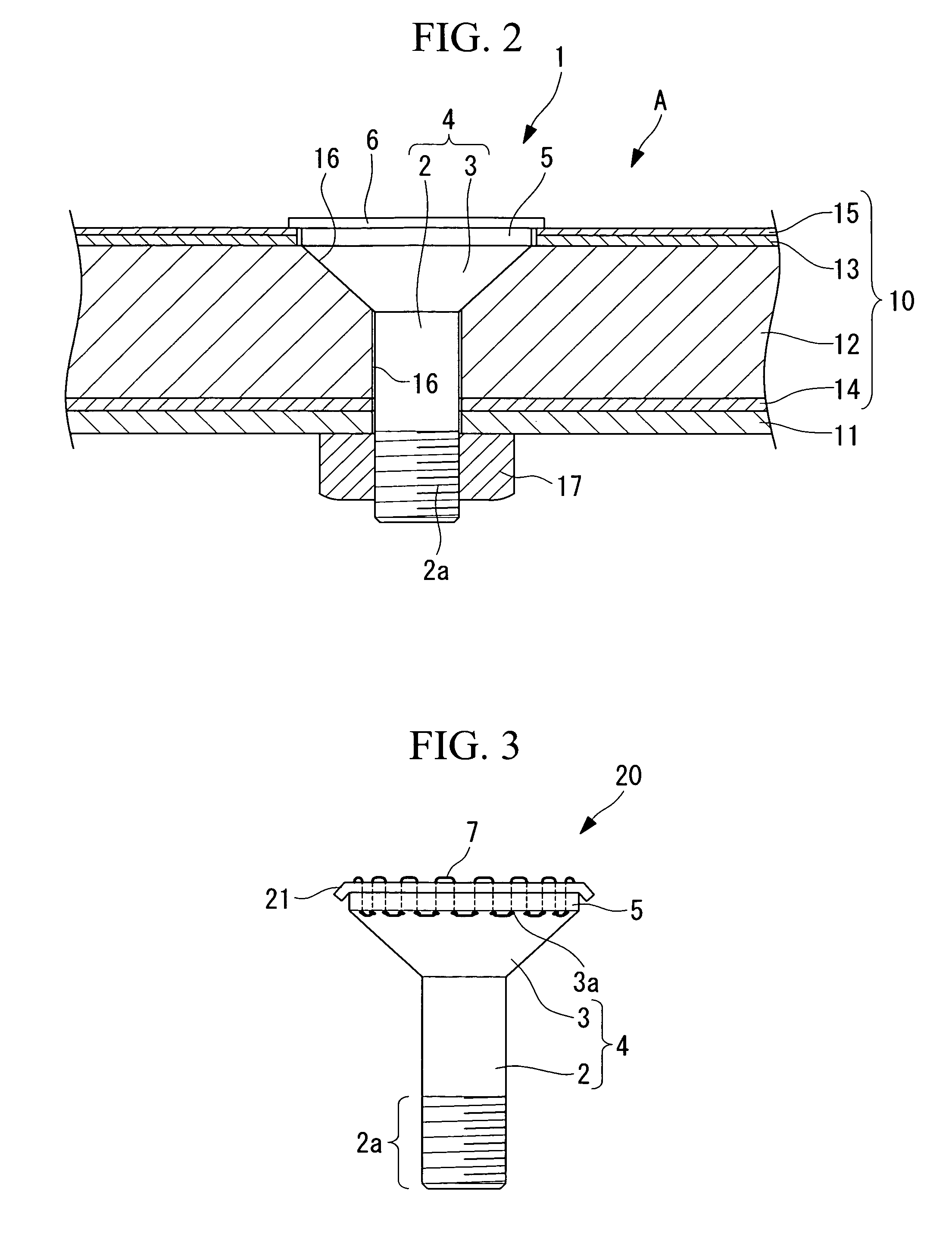

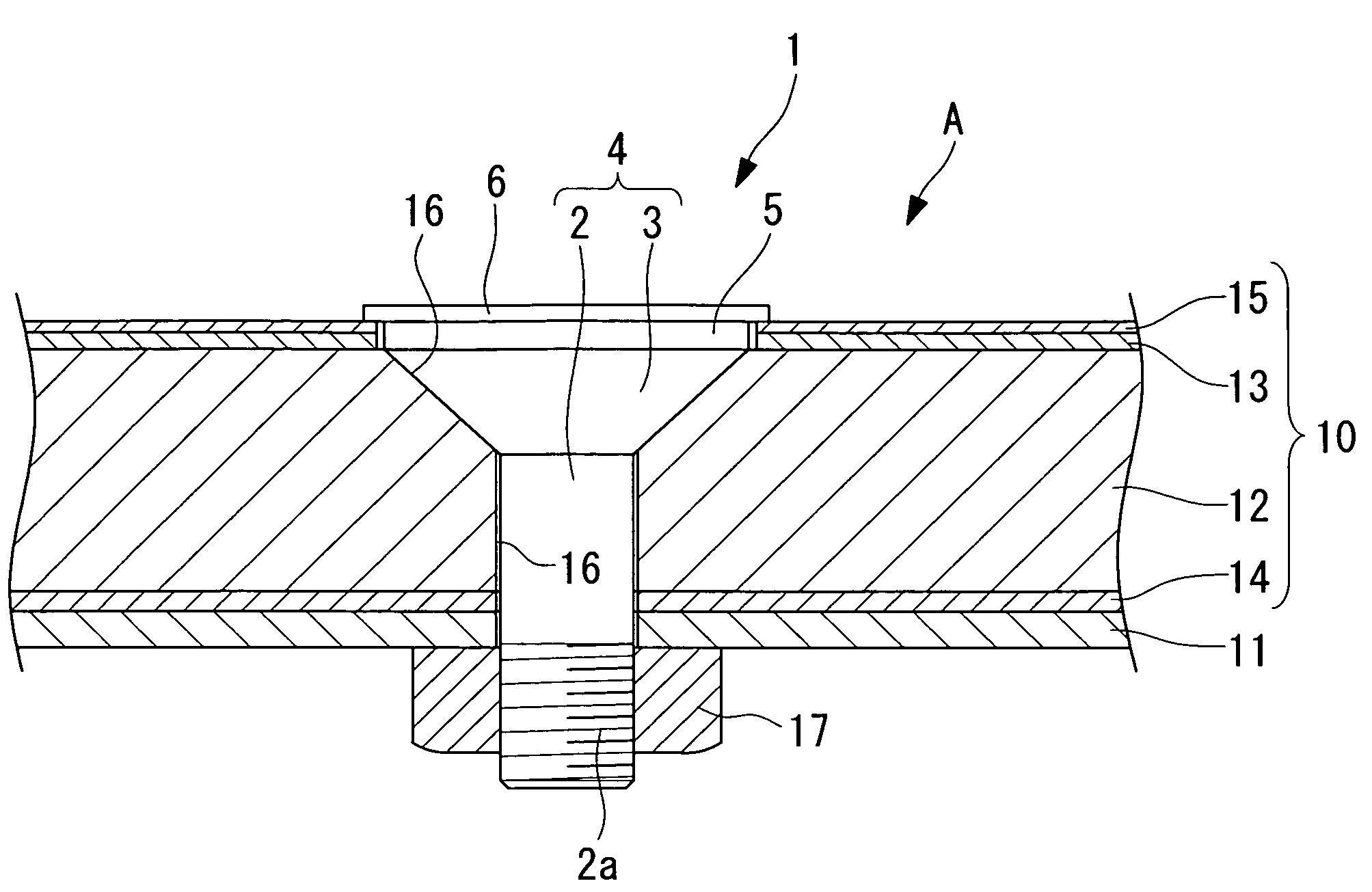

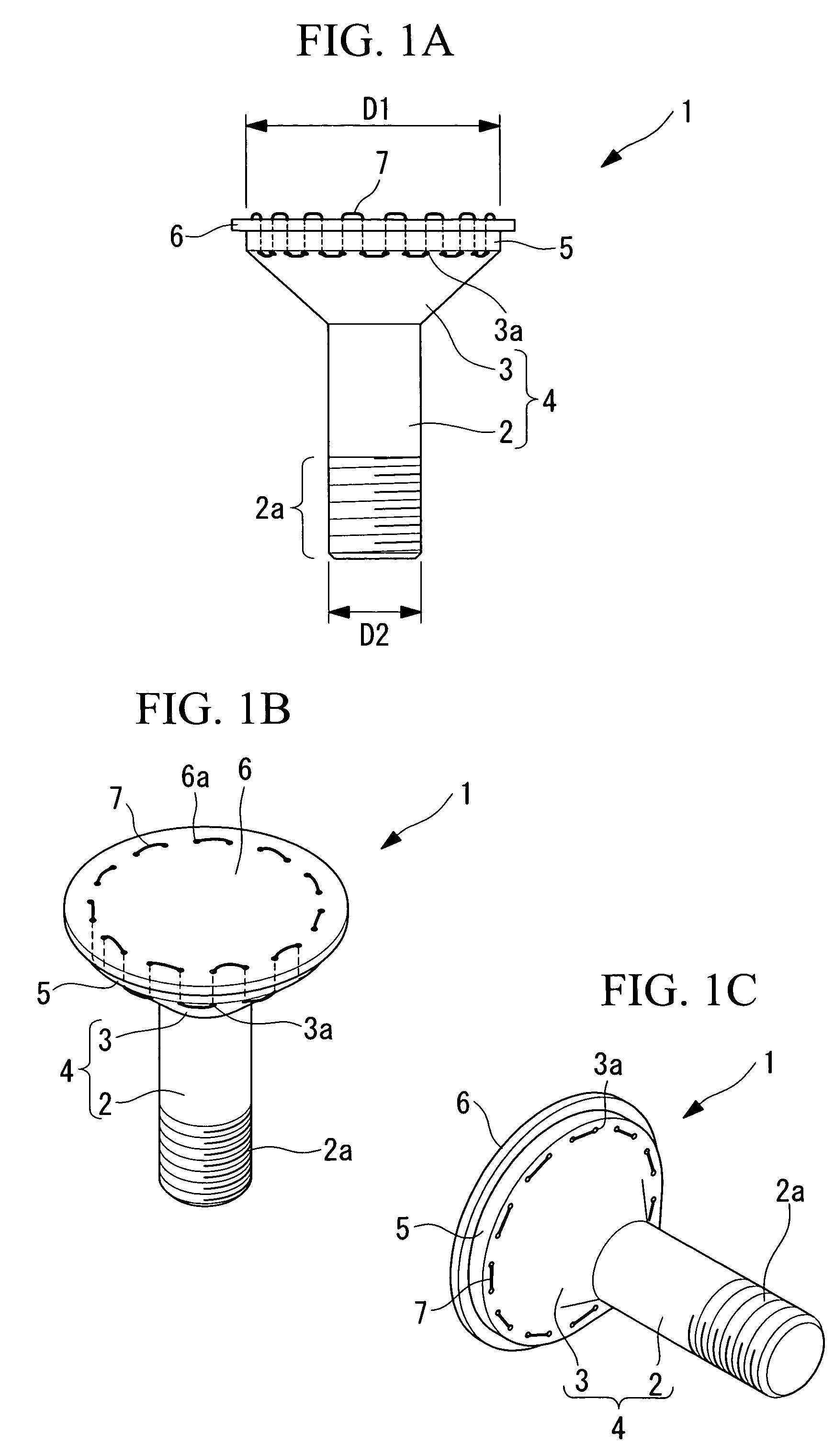

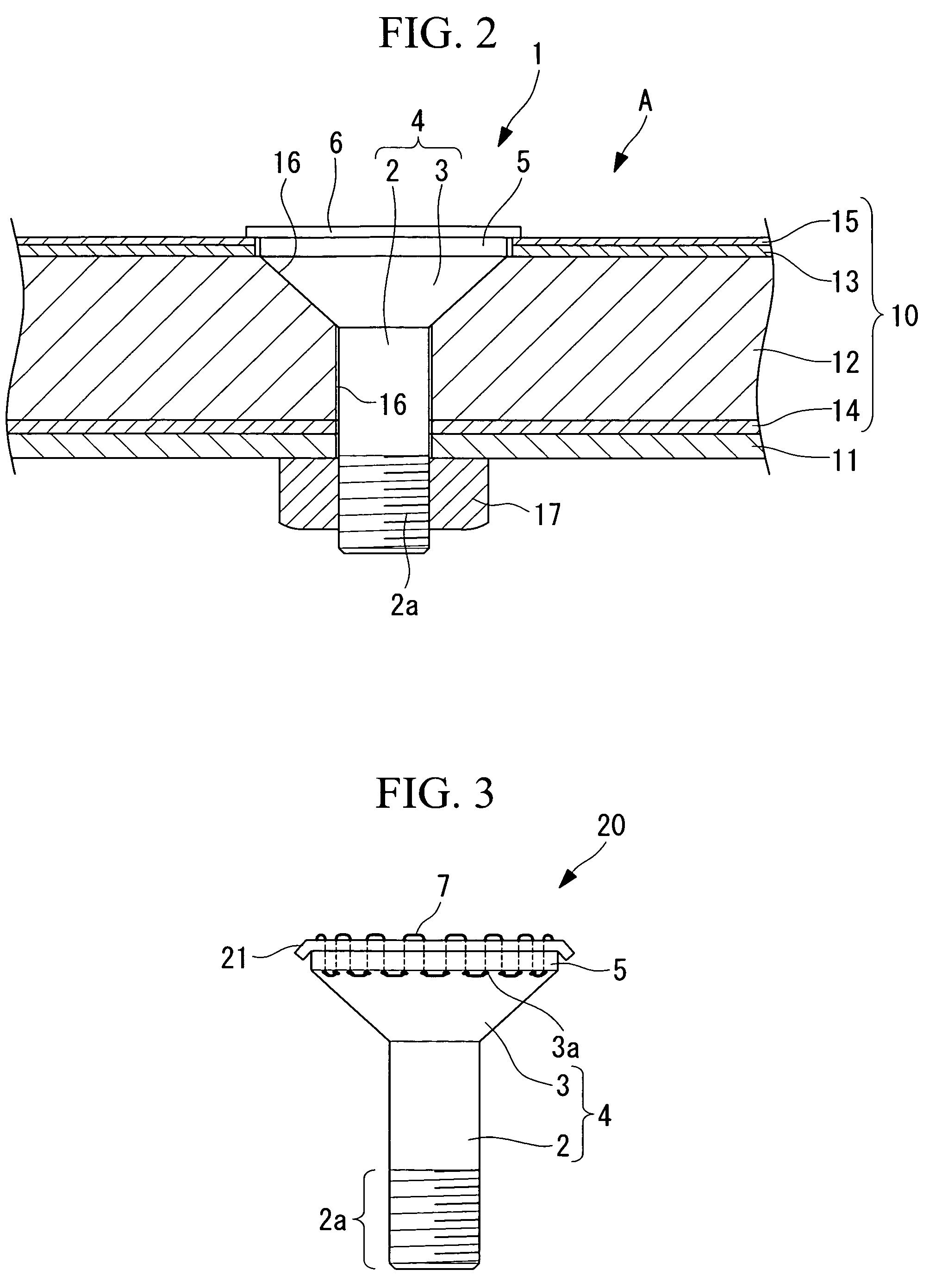

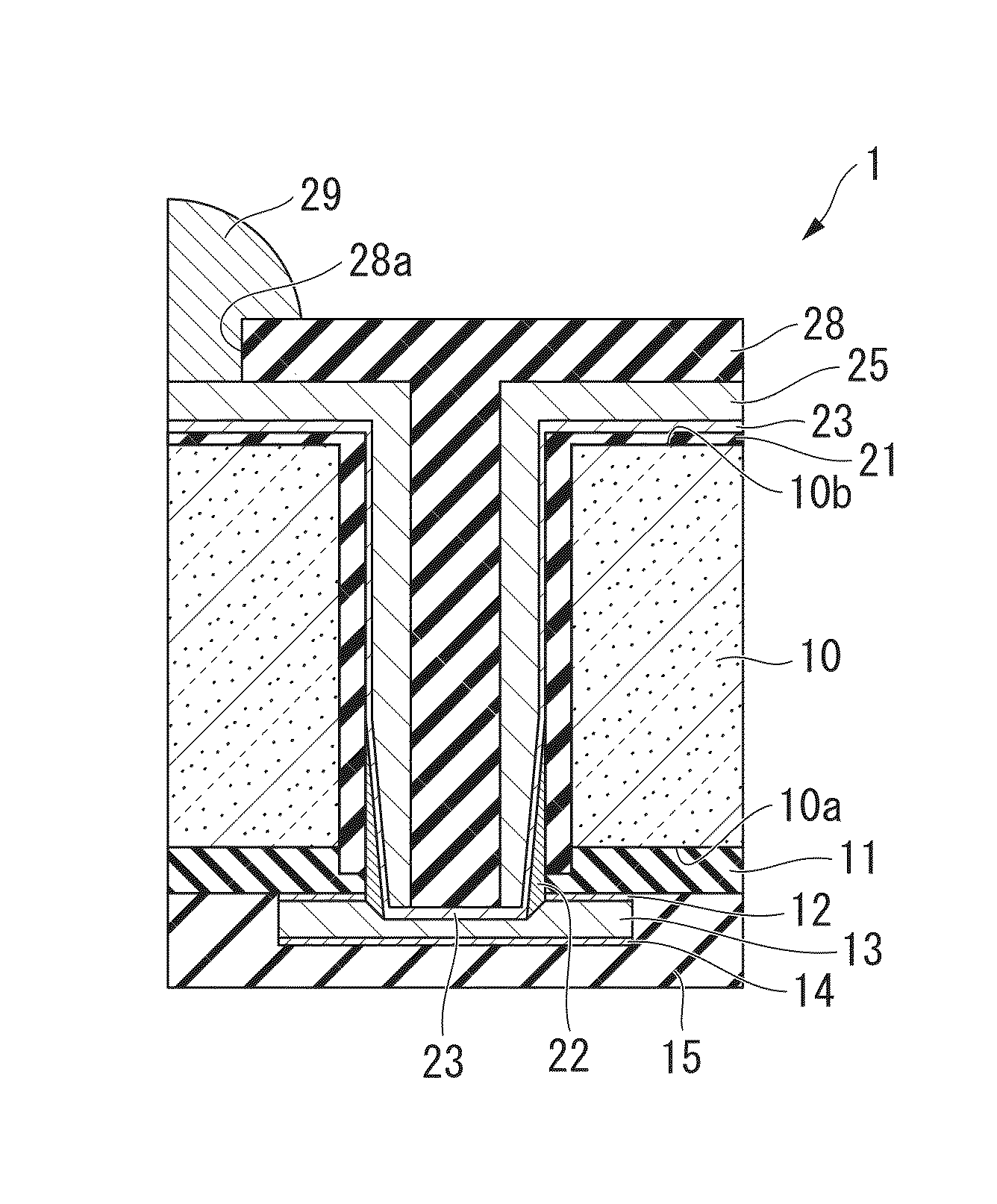

Fastener

InactiveUS20070081874A1Avoid damageEliminate peelingAircraft lighting protectorsNutsUltravioletEngineering

There is provided a fastener able to prevent damage due to environmental factors such as ultraviolet rays, and impact from sanddust, lumps of ice, and raindrops without obstructing a flow of electric shock current that flows along a top surface of an outer skin. The fastener connects an outer skin of an aircraft to a structural member positioned inside this outer skin, and is provided with a dielectric layer arranged to cover one end surface of a head section, and a conductive layer arranged to cover one end surface of this dielectric layer.

Owner:MITSUBISHI HEAVY IND LTD

Fastener

InactiveUS7740434B2Avoid damageEliminate peelingAircraft lighting protectorsNutsUltravioletElectric shock

There is provided a fastener able to prevent damage due to environmental factors such as ultraviolet rays, and impact from sanddust, lumps of ice, and raindrops without obstructing a flow of electric shock current that flows along a top surface of an outer skin. The fastener connects an outer skin of an aircraft to a structural member positioned inside this outer skin, and is provided with a dielectric layer arranged to cover one end surface of a head section, and a conductive layer arranged to cover one end surface of this dielectric layer.

Owner:MITSUBISHI HEAVY IND LTD

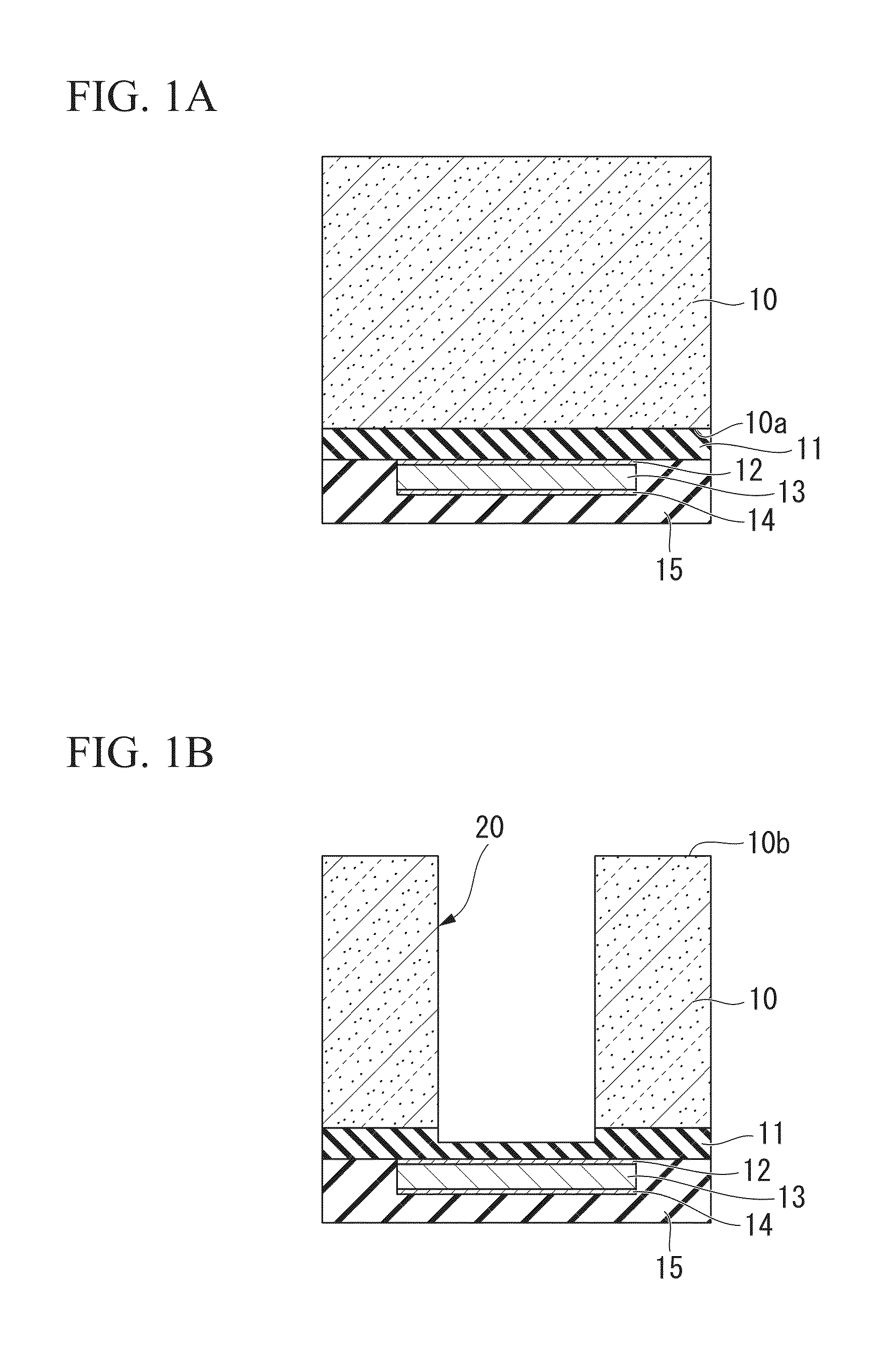

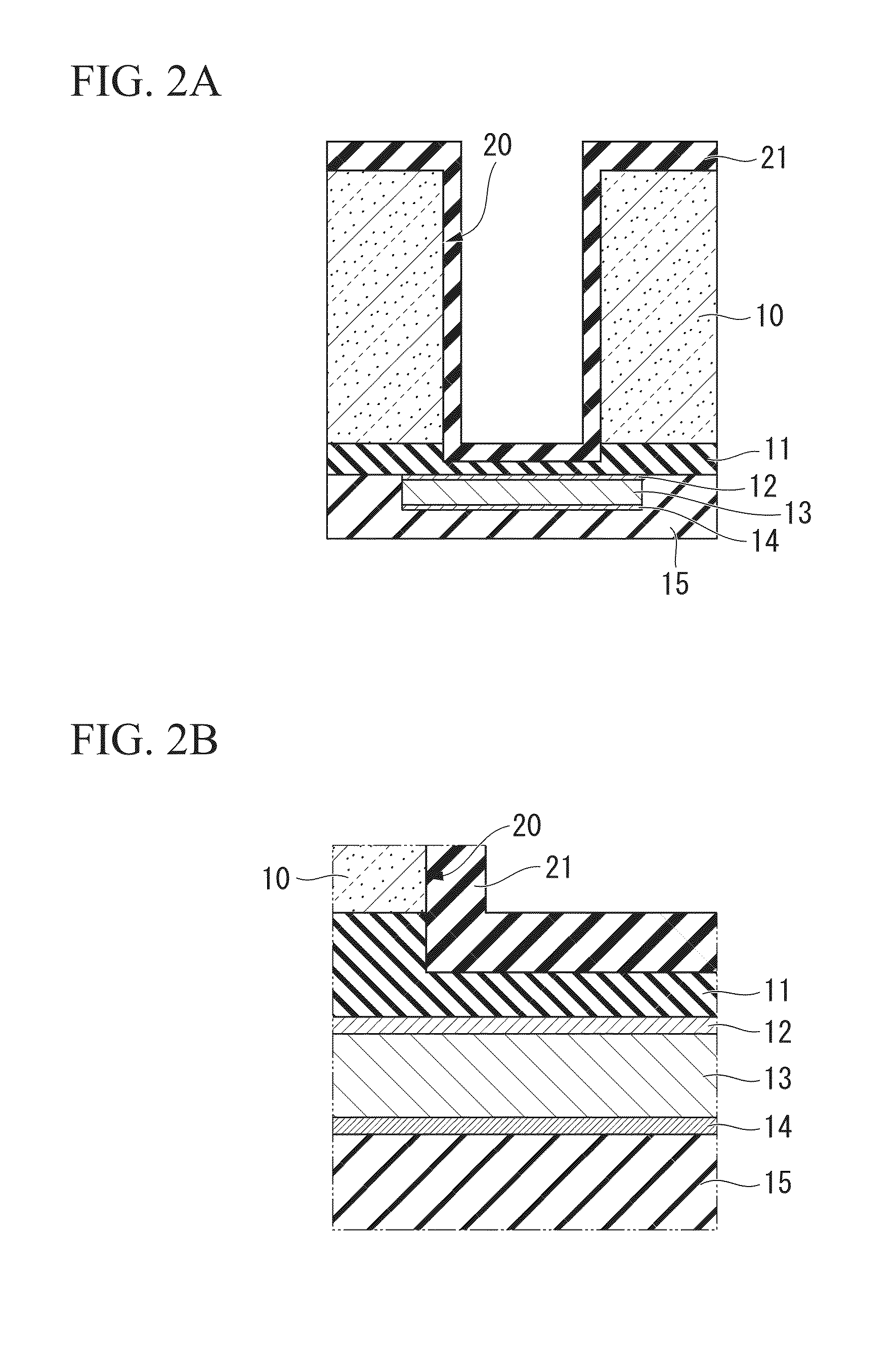

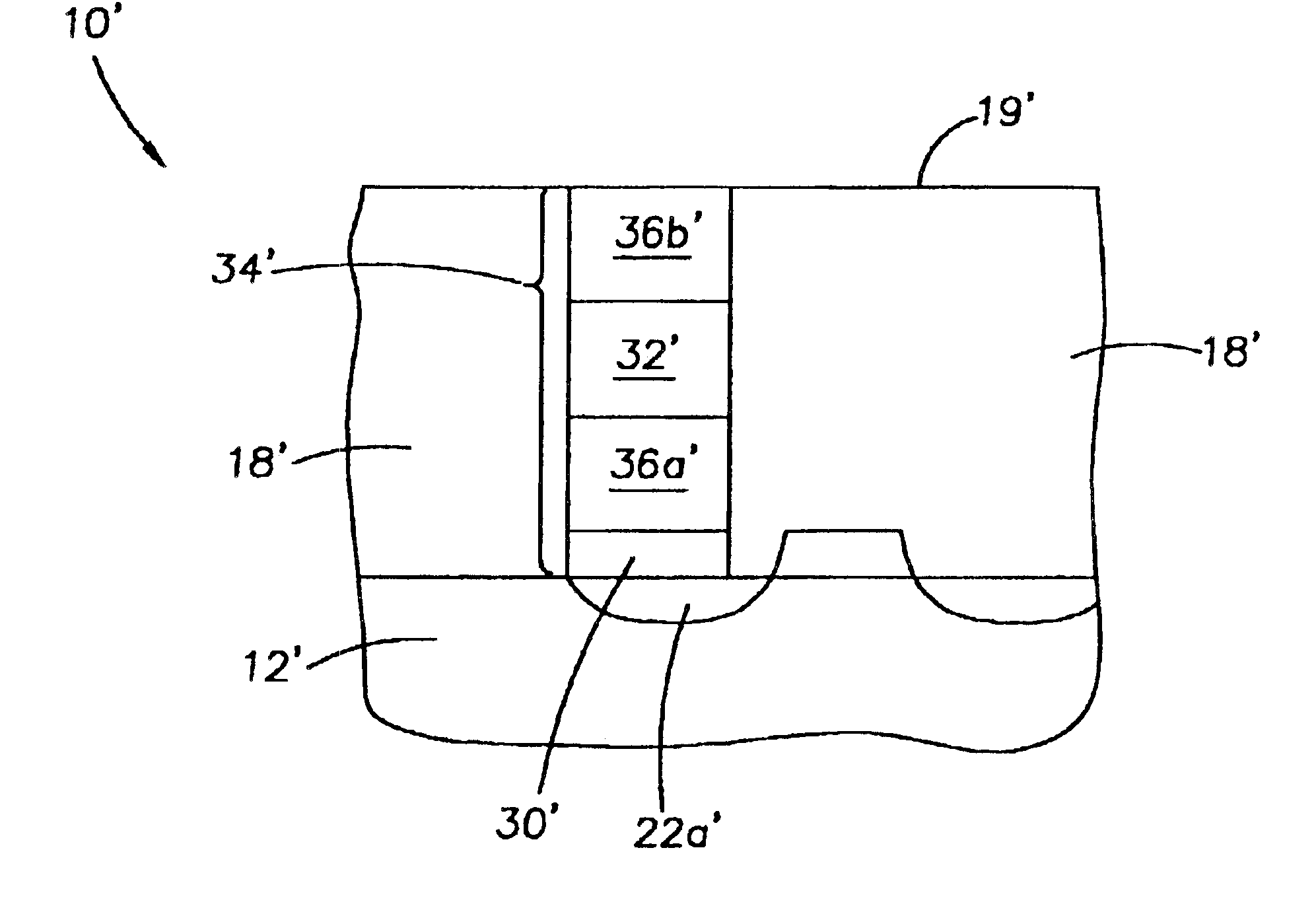

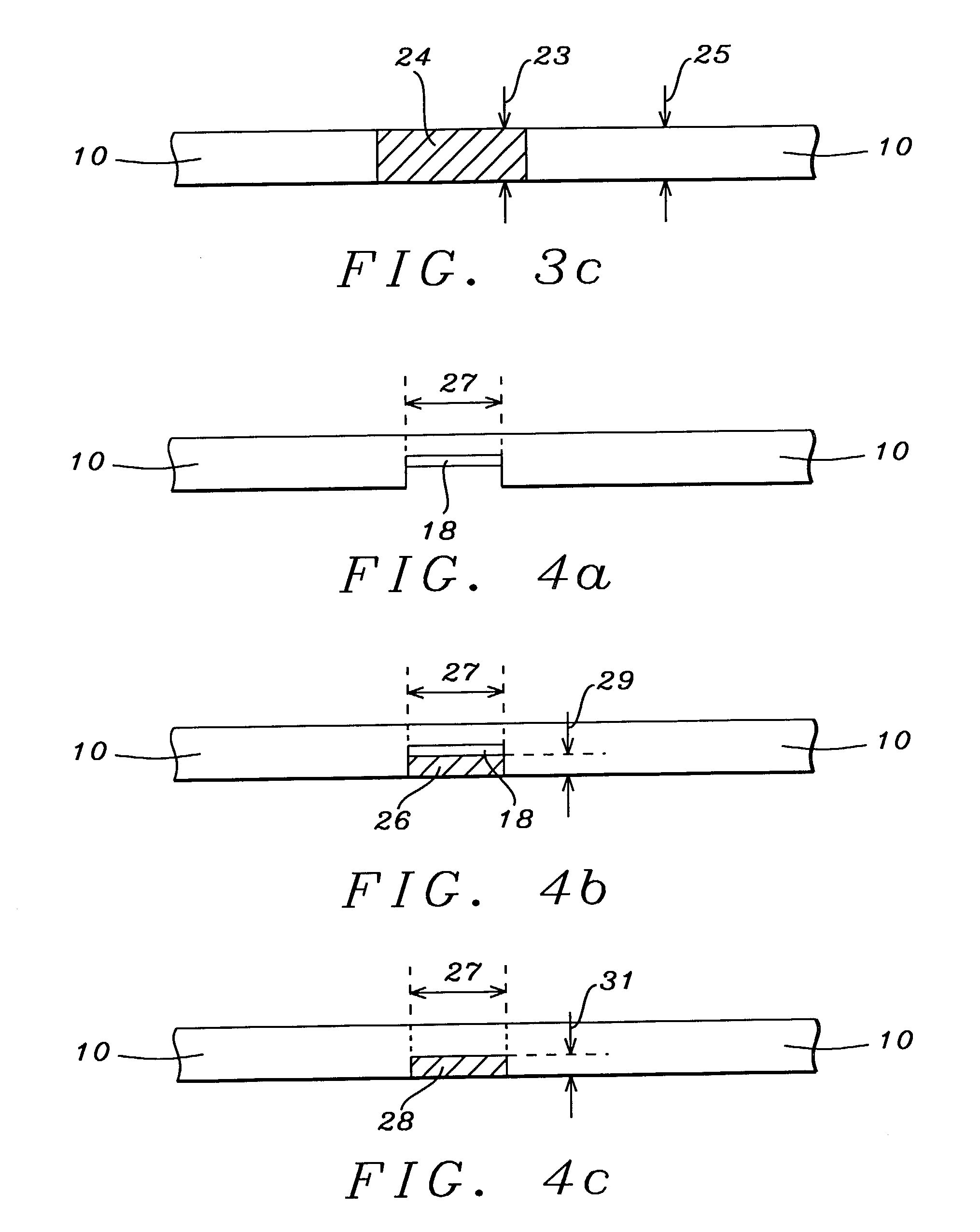

Interposer substrate manufacturing method and interposer substrate

InactiveUS20130234341A1Improve electrical stabilityStable formationSemiconductor/solid-state device detailsSolid-state devicesElectrically conductiveEngineering

A method for manufacturing an interposer substrate includes: forming a conductive portion on a first surface of a semiconductor substrate via a first insulating layer, the conductive portion being formed of a first metal; forming a through hole at a second surface side of the semiconductor substrate located on an opposite side to the first surface so as to expose the first insulating layer; forming a second insulating layer on at least an inner wall surface and a bottom surface of the through hole; exposing the conductive portion by removing portions of the first and second insulating layers using a dry etching method that uses an etching gas containing a fluorine gas, the portions of the first and second insulating layers being located on the bottom surface of the through hole; and forming a conductive layer on the second insulating layer and electrically connecting the conductive layer to the conductive portion, wherein when exposing the conductive portion, forming a tapered portion is performed.

Owner:THE FUJIKURA CABLE WORKS LTD

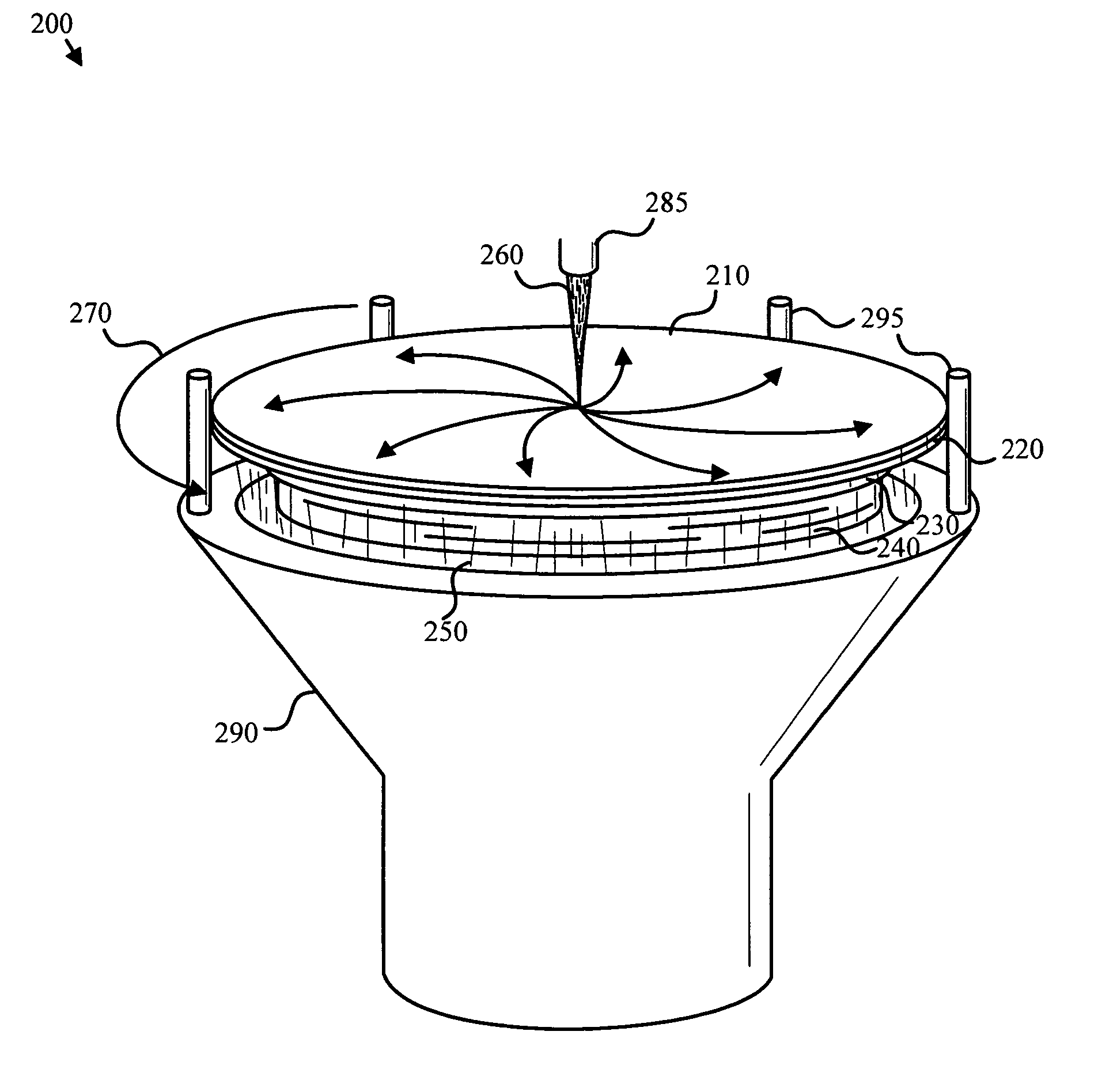

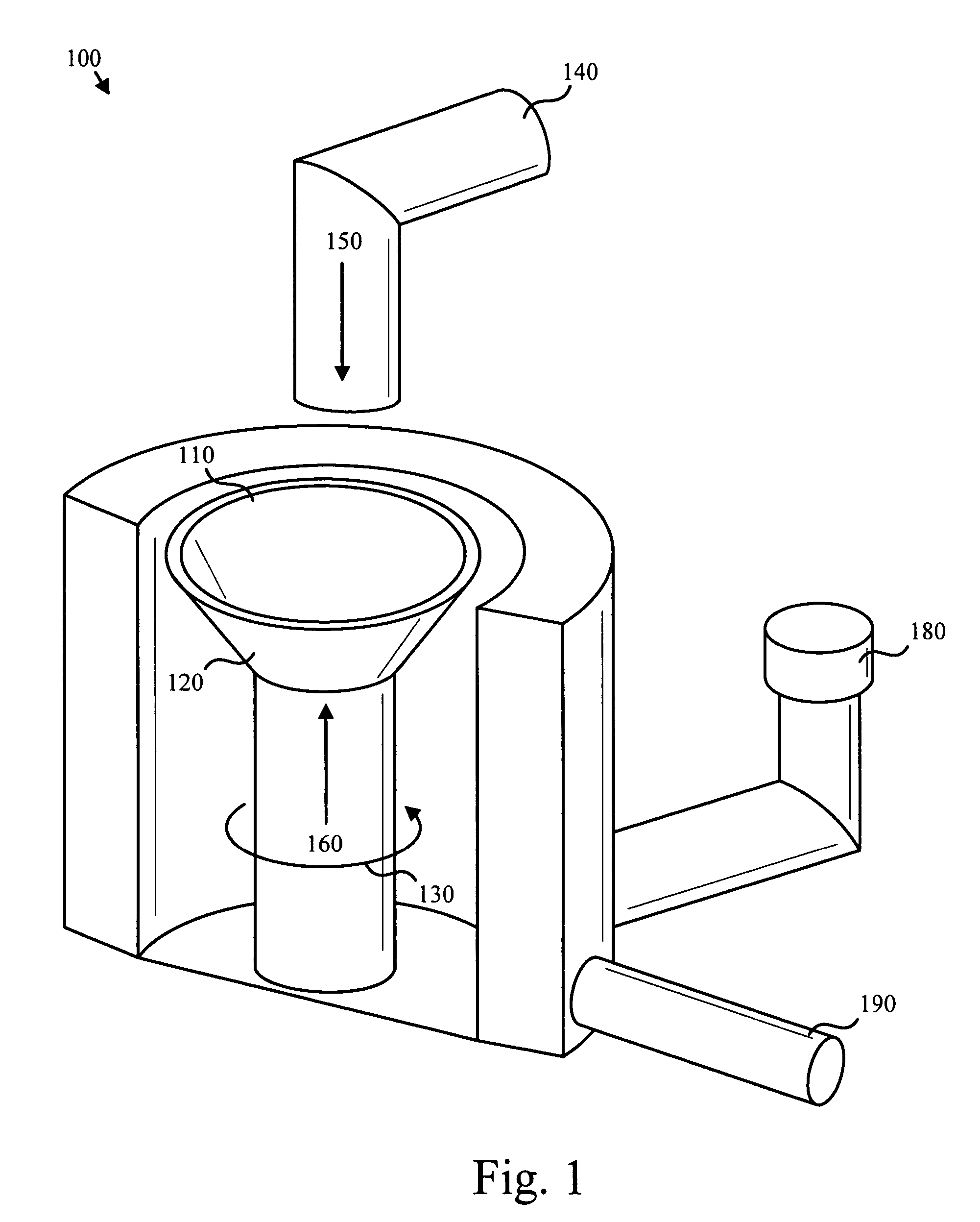

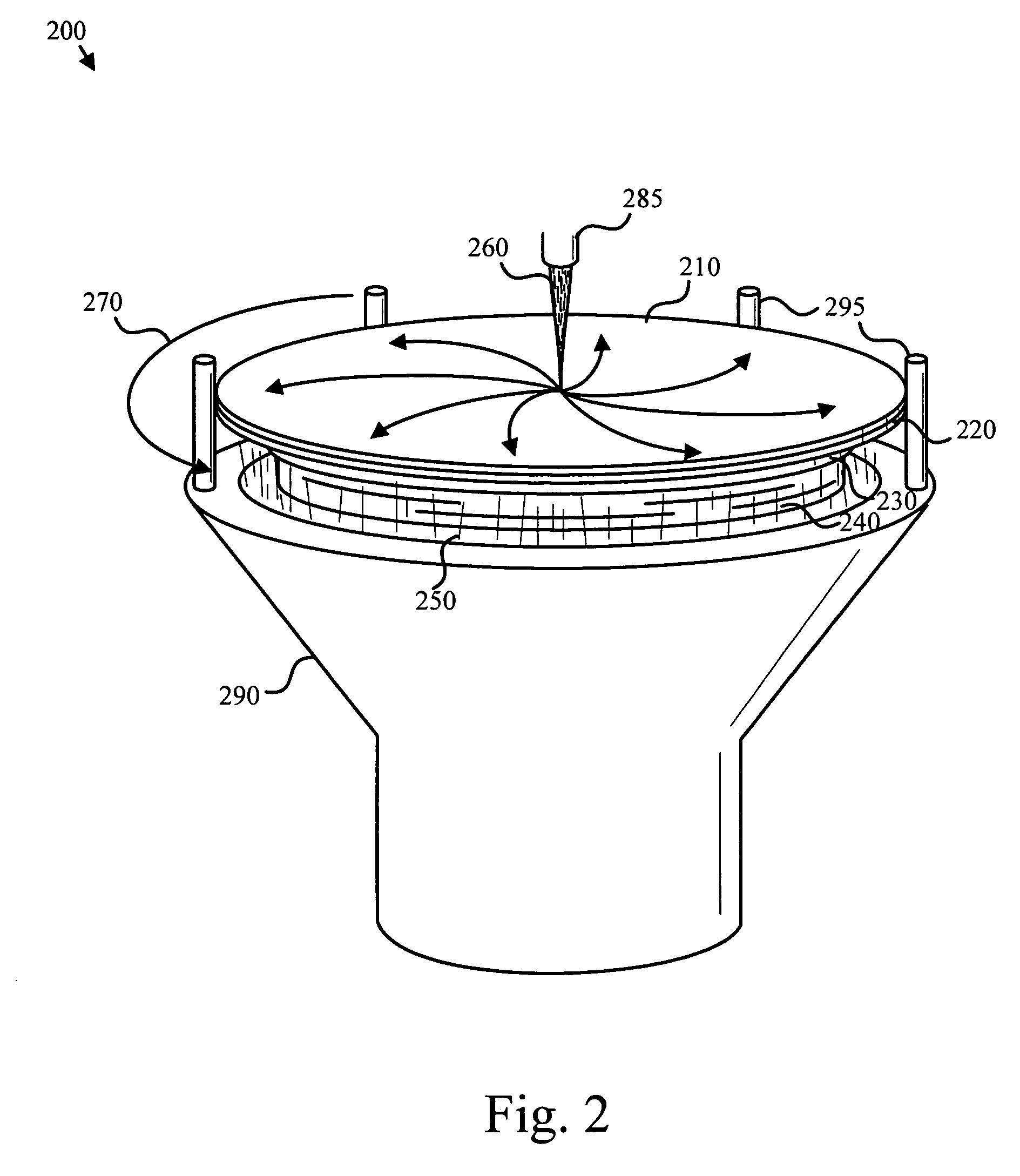

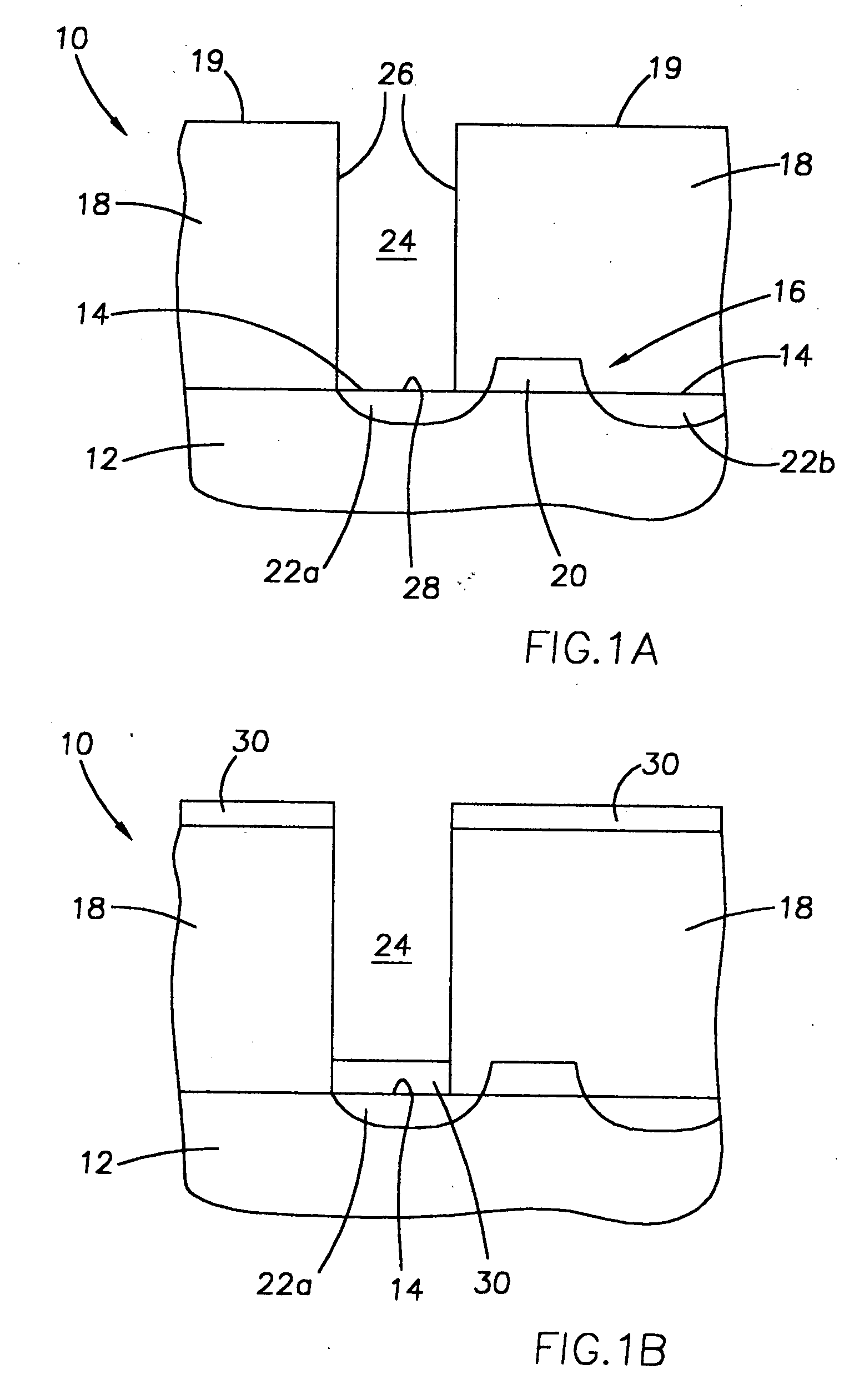

Apparatus, system, and method for reducing integrated circuit peeling

InactiveUS20060170076A1Eliminates integrated circuit peelingEfficient removalSemiconductor/solid-state device detailsSolid-state devicesHydrogen fluorideEngineering

An apparatus, system, and method are disclosed for reducing integrated circuit peeling. This invention reduces integrated circuit peeling by providing a wafer with a solventphilic layer and removing unwanted film using a solvent that is philic to the solventphilic layer. In one embodiment, a boundary is provided to reduce the rotation speed precision required to reach the desired etching distance. In certain embodiments, a wet edge etching process is used to remove unwanted film from the perimeter of the solventphilic layer. In certain embodiments, the solventphilic layer comprises a hydrophilic layer such as silicon nitride, and the solvent comprises a solution of water and hydrogen fluoride.

Owner:LSI CORPORATION

Hot dip silver coating /silver halides reference electrode and method for making same

ActiveCN101308111AImprove potential stabilityExtended service lifeWeather/light/corrosion resistanceMaterial electrochemical variablesDip-coatingMaterials processing

The invention relates to a thermal dip-coating silver / silver halide reference electrode and a method for the production thereof, the reference electrode is composed of silver and silver halide insoluble salt, silver halide is formed on a silver matrix by adopting a thermal dip-coating method for combining with the matrix well, then part of silver halide is transformed into metallic silver through reduction so as to form a silver / silver halide reference electrode body, the silver / silver halide electrode body is packaged in an electrode sleeve processed by insulation materials, thereby forming a solid reference electrode component. The reference electrode of the invention has rather high electric potential stability, the combination between the formed silver halide coating and the matrix is firm due to the adoption of the fusing and dip-coating method, the problem of pulverization or stripping can be eliminated, and the reference electrode has a long service life owing to sufficient dip-coating amount. The reference electrode can be used to measure the metal structure electrode electric potential of mediums in seawater.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

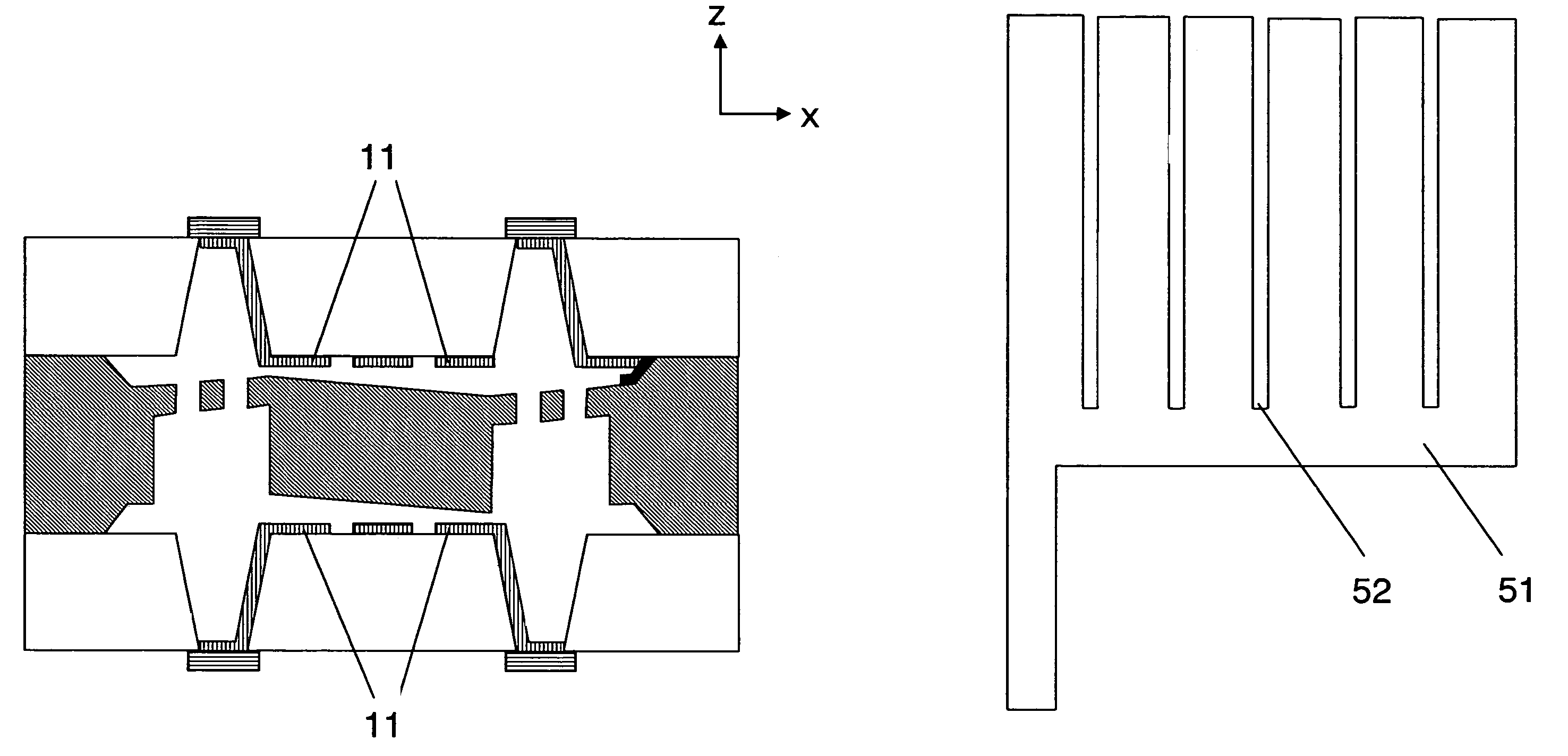

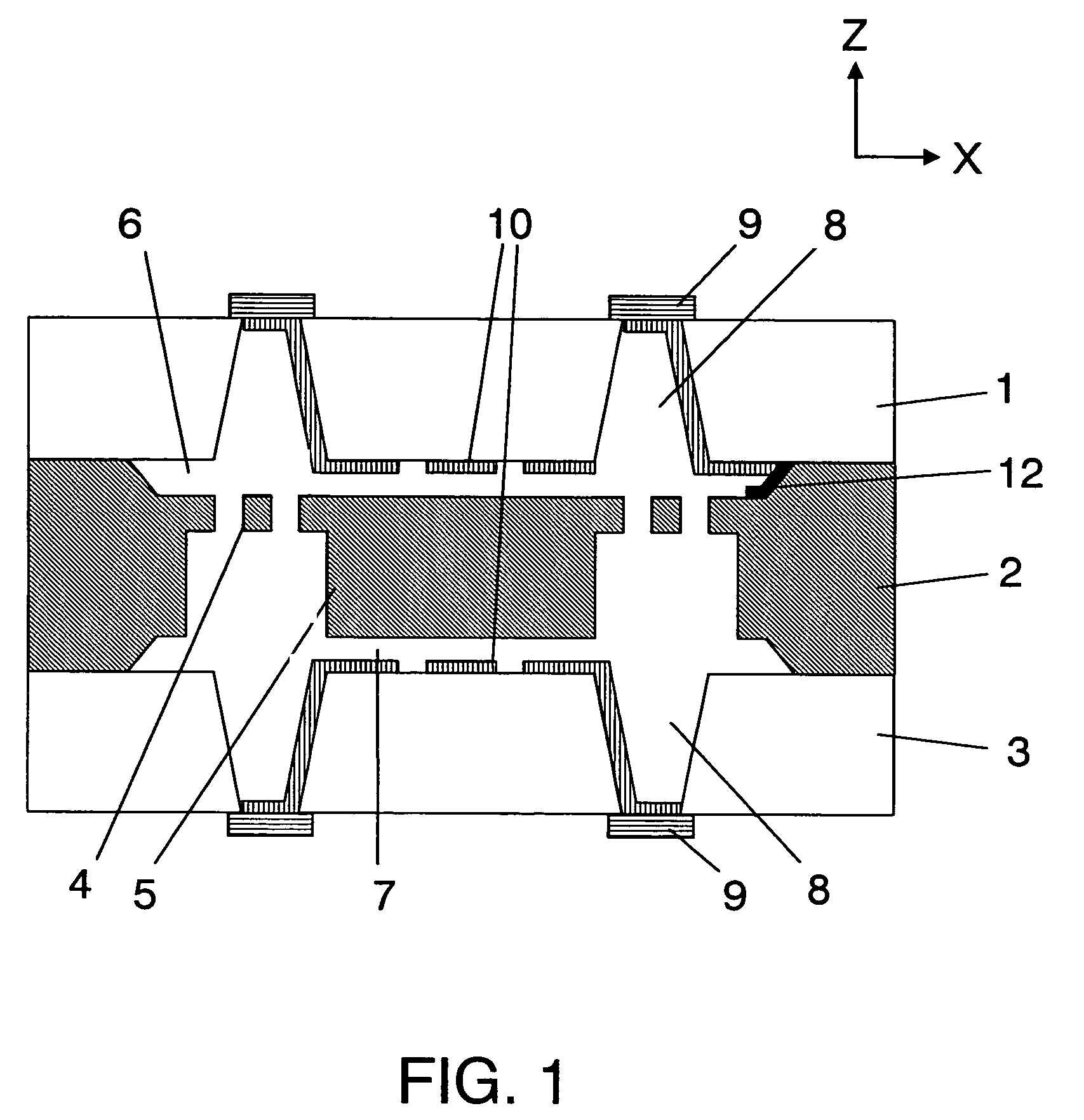

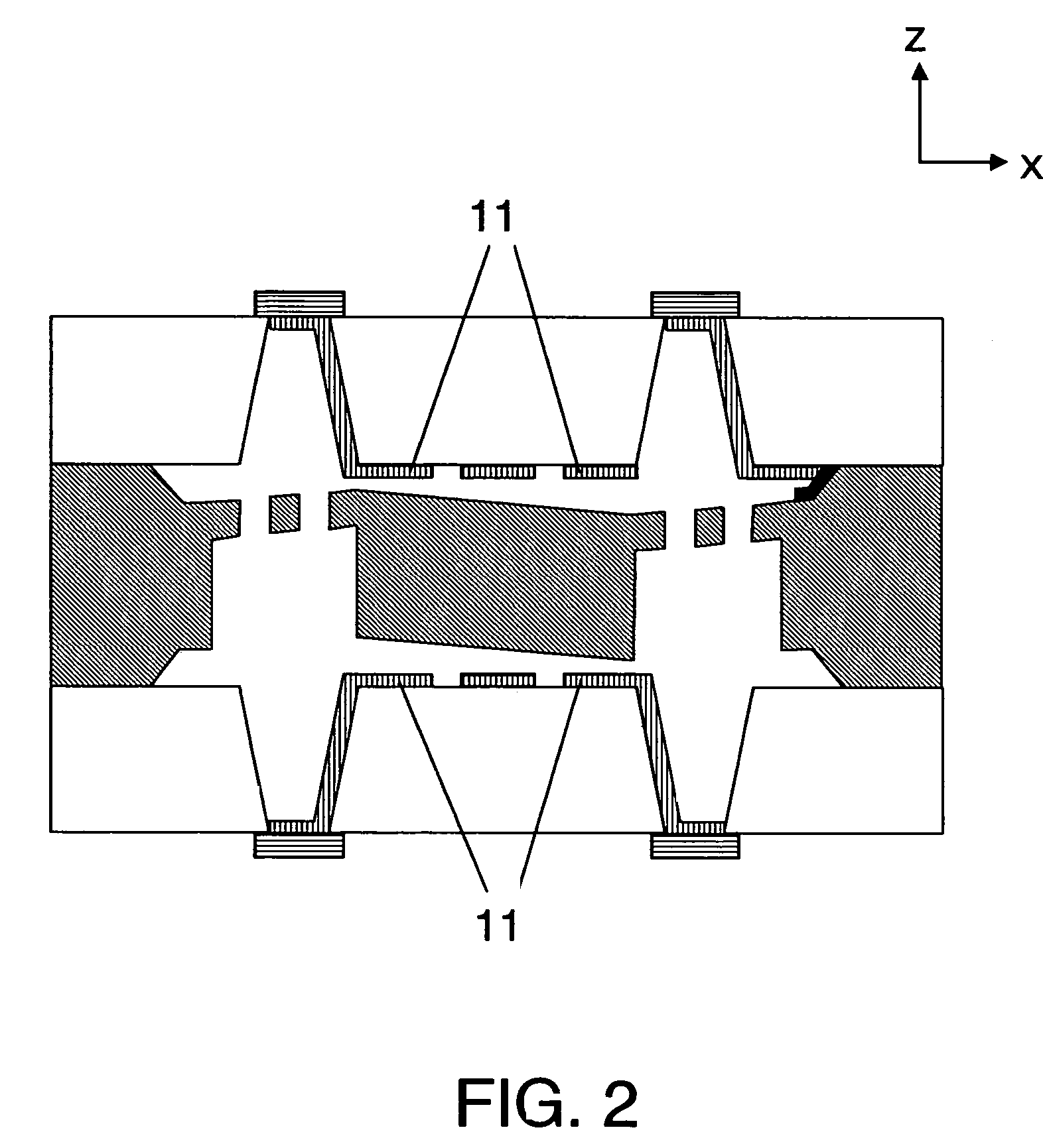

Capacitance type dynamic quantity sensor

ActiveUS7225675B2Prevent surfaceImprove reliabilitySpeed measurement using gyroscopic effectsAcceleration measurementCapacitanceAngular velocity

A capacitance type dynamic quantity sensor has a first substrate, a second substrate disposed over the first substrate, and first and second electrodes each disposed on a main surface of a respective one of the first and second substrates. Each of the first and second electrodes has through-holes formed in a portion thereof. A third substrate is disposed between and connected to the main surface of each of the first and second substrates. A vibration member is mounted on the third substrate so as to confront the first and second electrodes with gaps therebetween. The vibration member is mounted on the third substrate to undergo vibrational movement in response to application of an acceleration or an angular velocity to the vibration member so that the capacitance type dynamic quantity sensor detects a dynamic quantity in accordance with a change in capacitance between the first and second electrodes due to vibrational movement of the vibration member.

Owner:ABLIC INC

Method of forming a conductive contact

InactiveUS6888252B2Promote resultsLower Level RequirementsSemiconductor/solid-state device detailsSolid-state devicesIntegrated circuitAluminium

Conductive contacts in a semiconductor structure, and methods for forming the conductive components are provided. The method comprises depositing a conductive material over a substrate to fill a contact opening, removing excess material from the substrate leaving the contact within the opening, and then heating treating the contact at a high temperature, preferably with a rapid thermal anneal process, in a reactive gas to remove an undesirable component from the contact, for example, thermal annealing a TiCl4-based titanium nitride in ammonia to remove chlorine from the contact, which can be corrosive to an overlying aluminum interconnect at a high concentration. The contacts are useful for providing electrical connection to active components in integrated circuits such as memory devices. In an embodiment of the invention, the contacts comprise boron-doped and / or undoped TiCl4-based titanium nitride having a low concentration of chlorine. Boron-doped contacts further possess an increased level of adhesion to the insulative layer to eliminate peeling from the sidewalls of the contact opening and cracking of the insulative layer when formed to a thickness of greater than about 200 angstroms in a high-aspect-ratio opening.

Owner:MICRON TECH INC

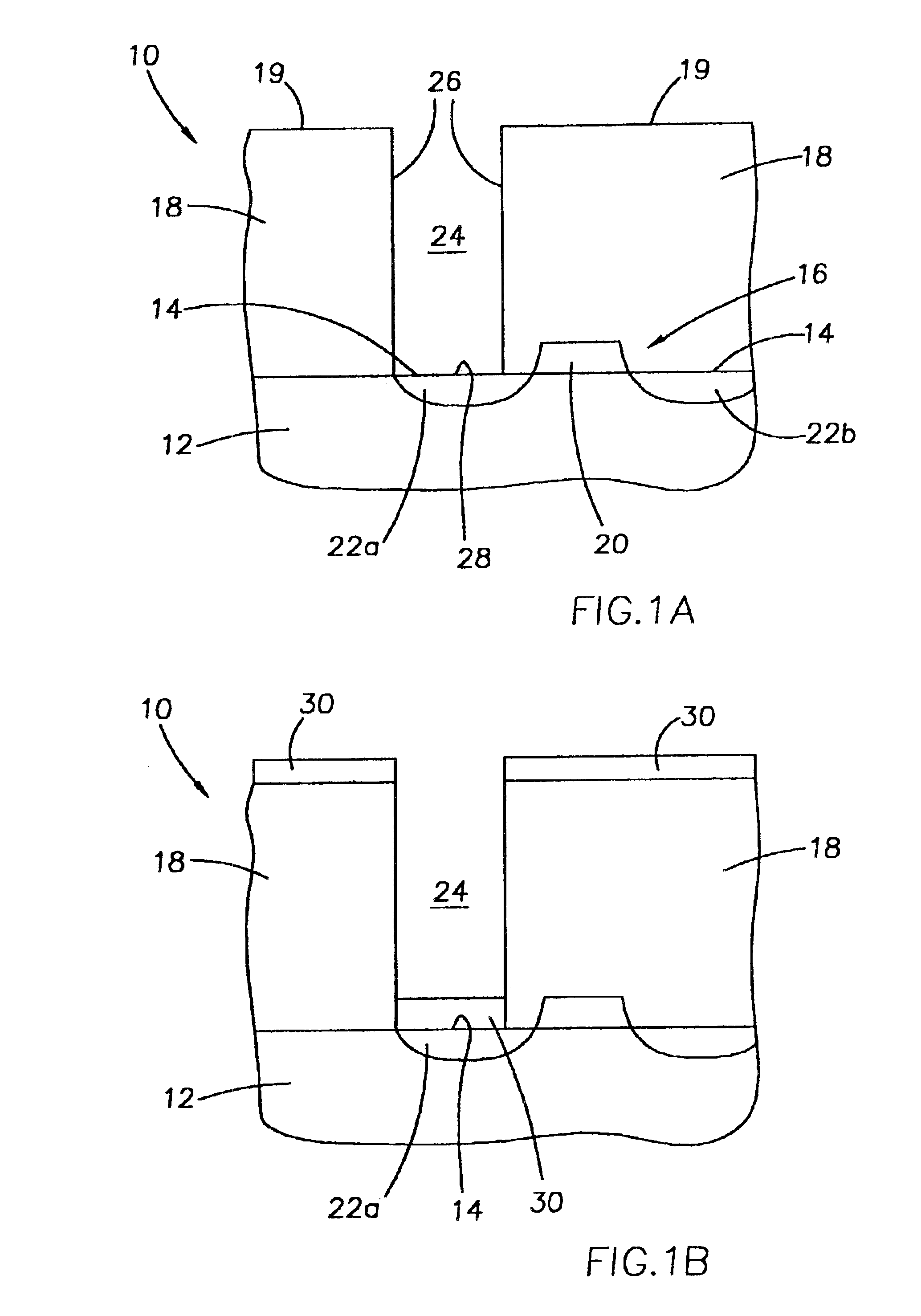

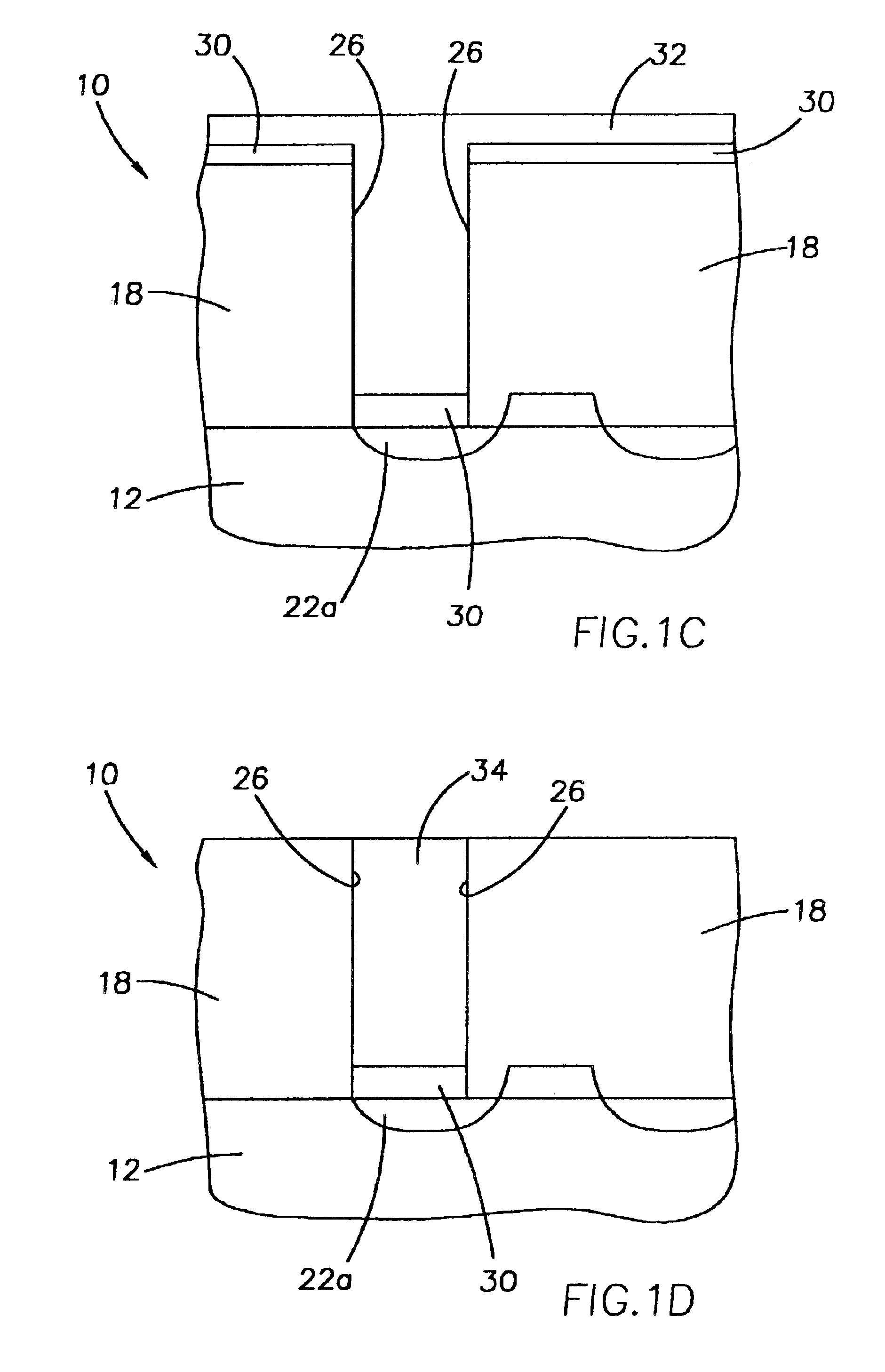

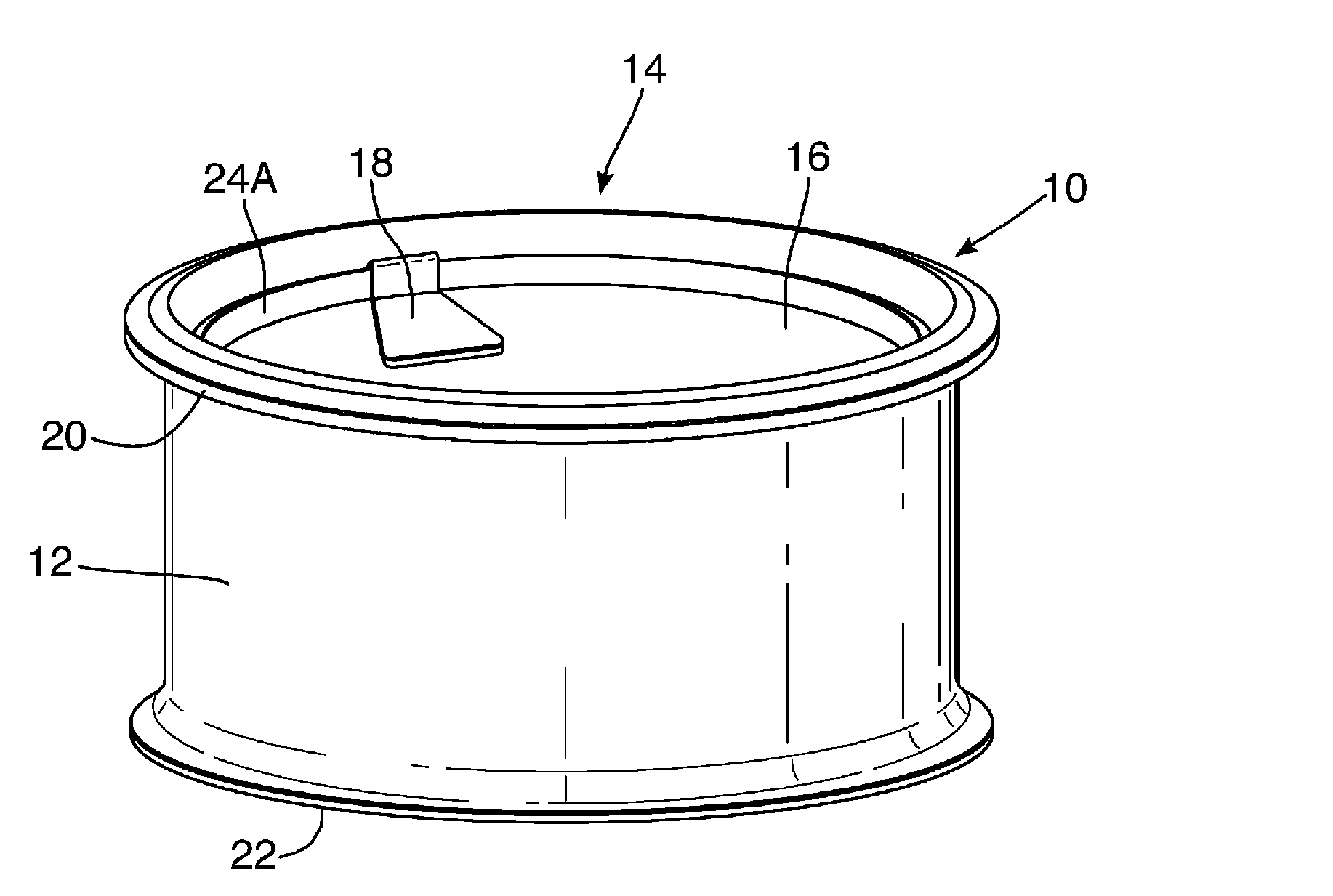

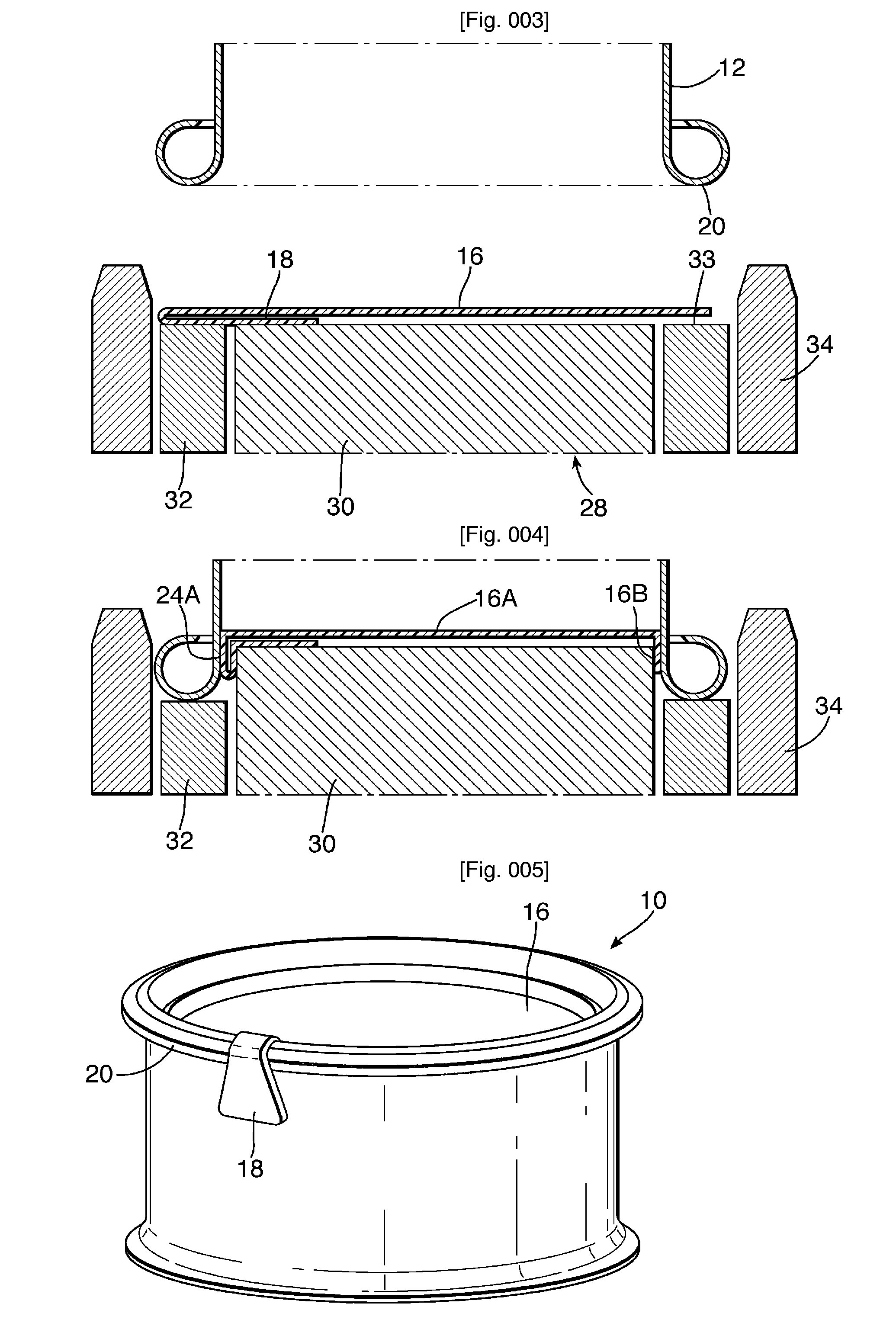

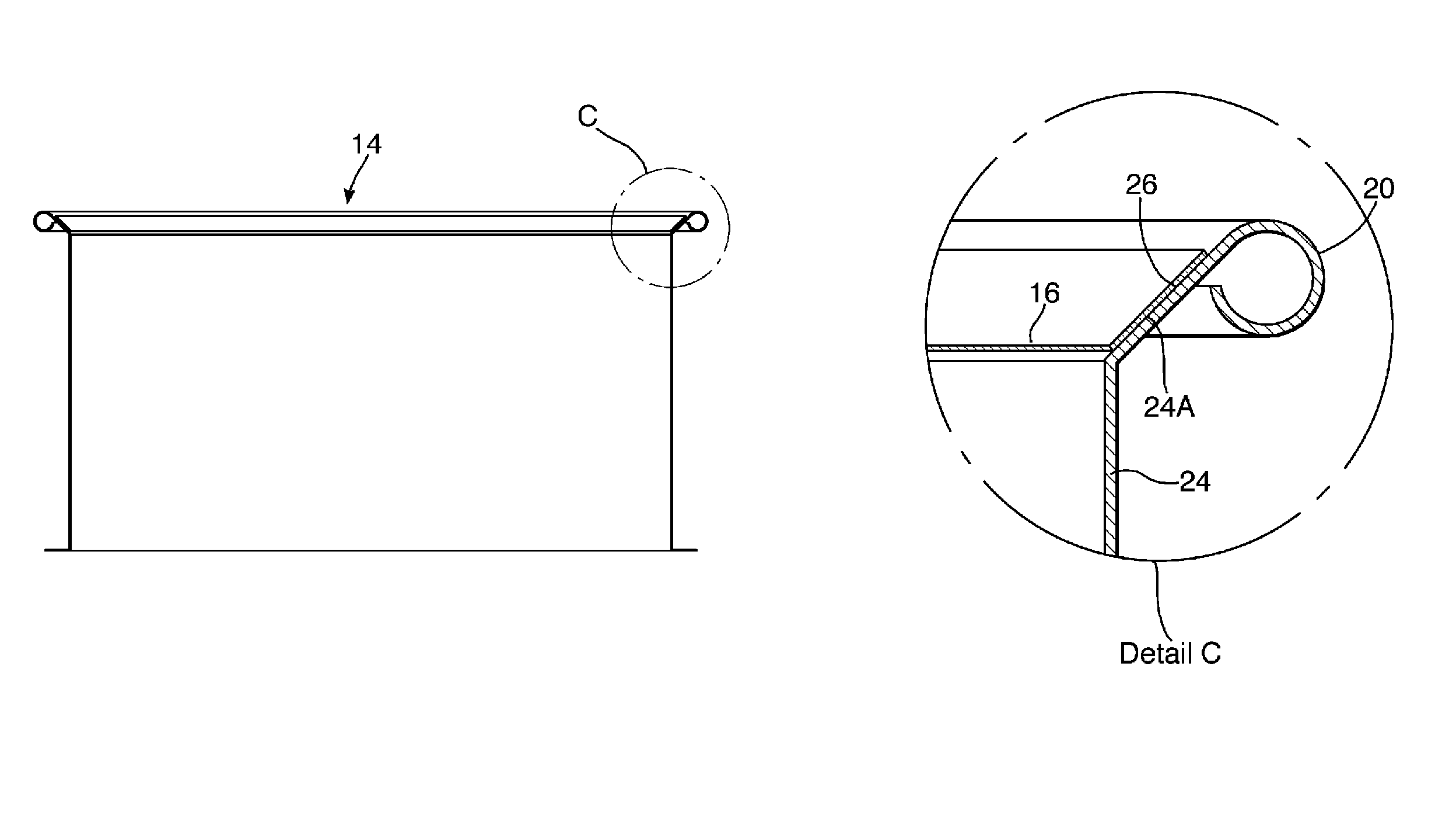

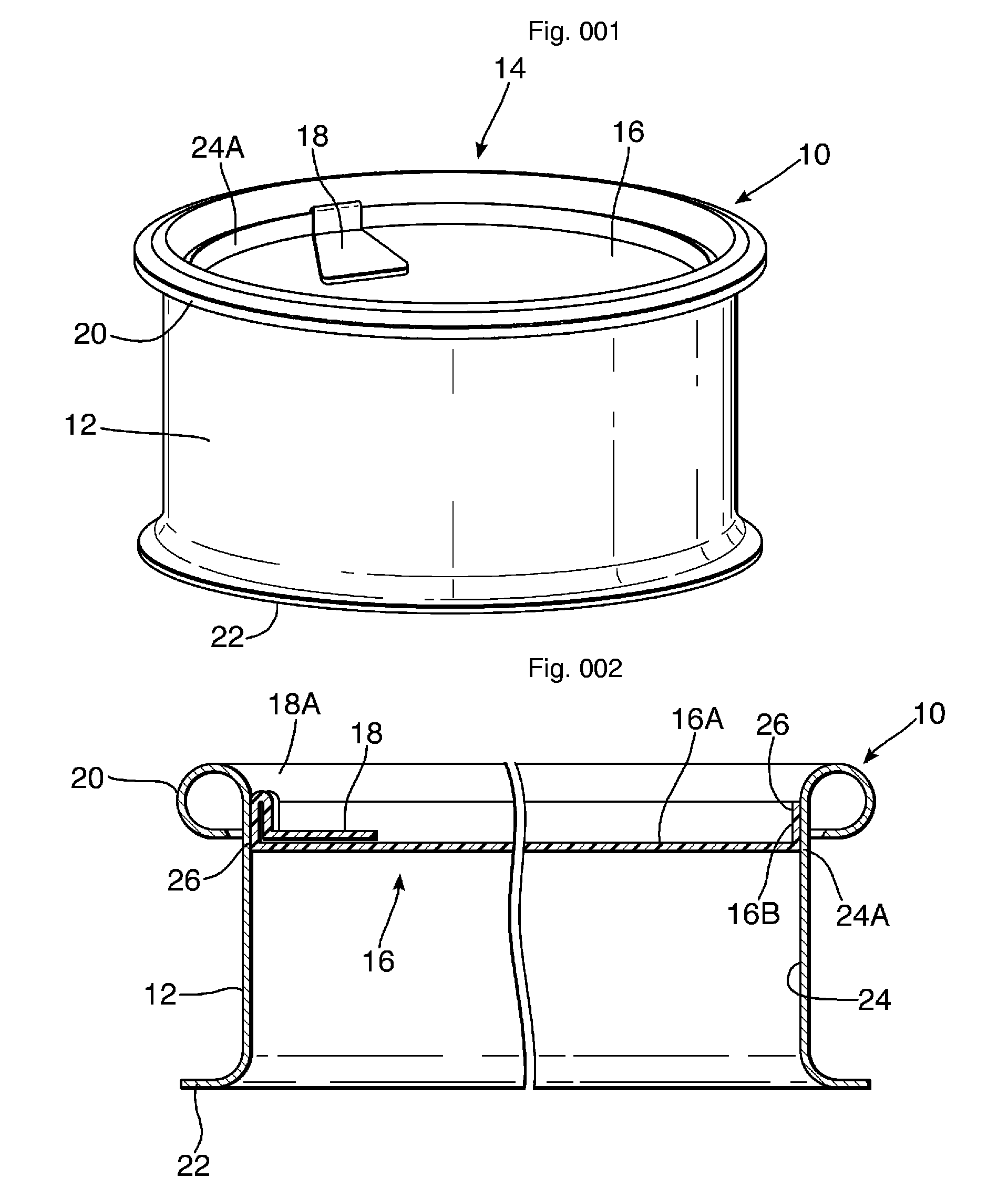

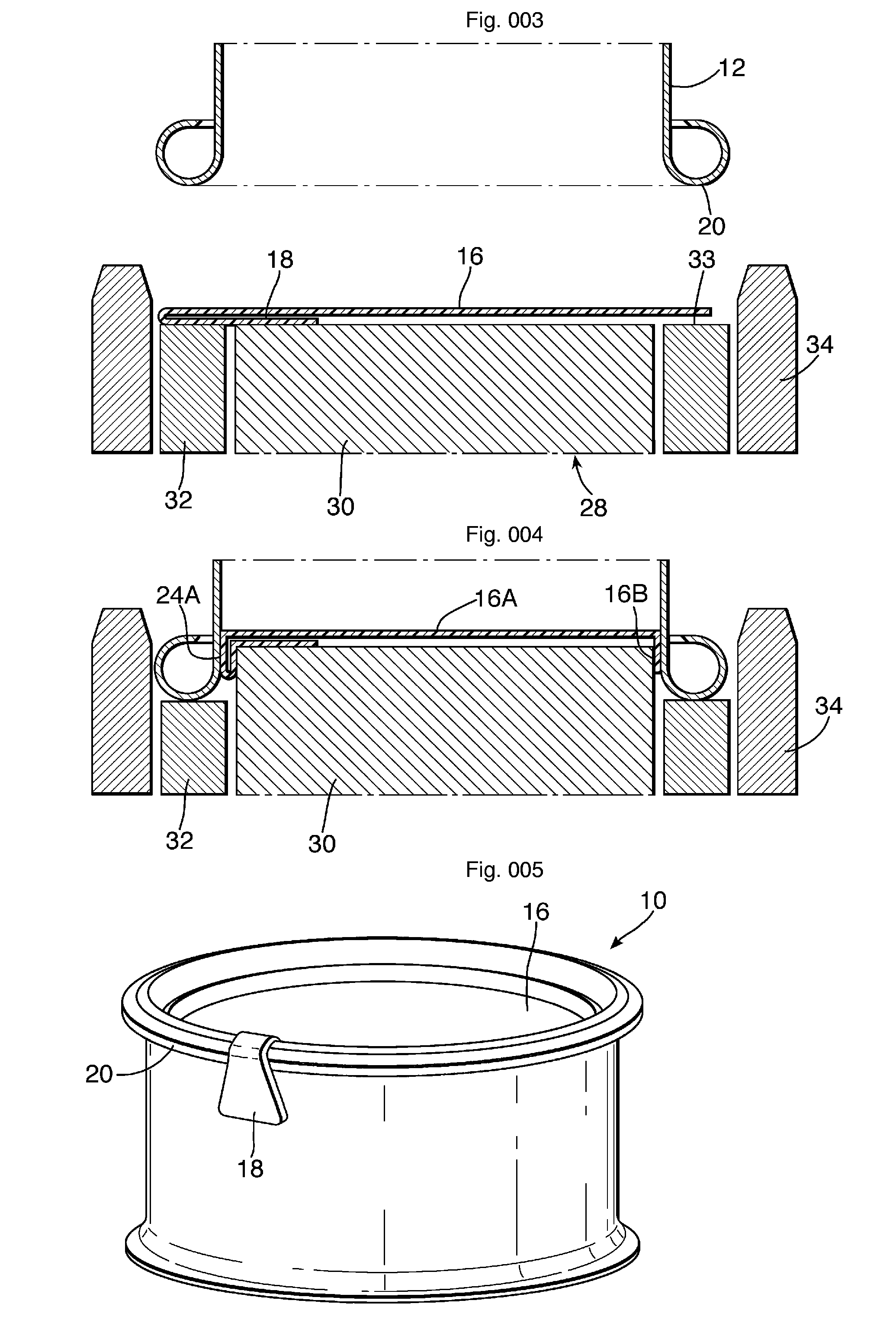

Packaging Can and Method and Apparatus for Its Manufacture

ActiveUS20090022861A1Easy to openReduce morbidityReady-for-oven doughsInternal framesBiomedical engineeringMetal

Owner:CROWN PACKAGING TECH

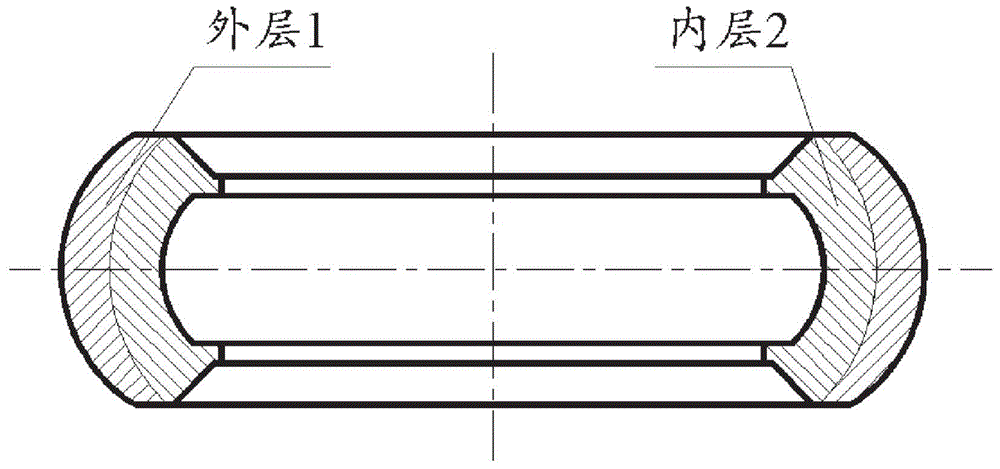

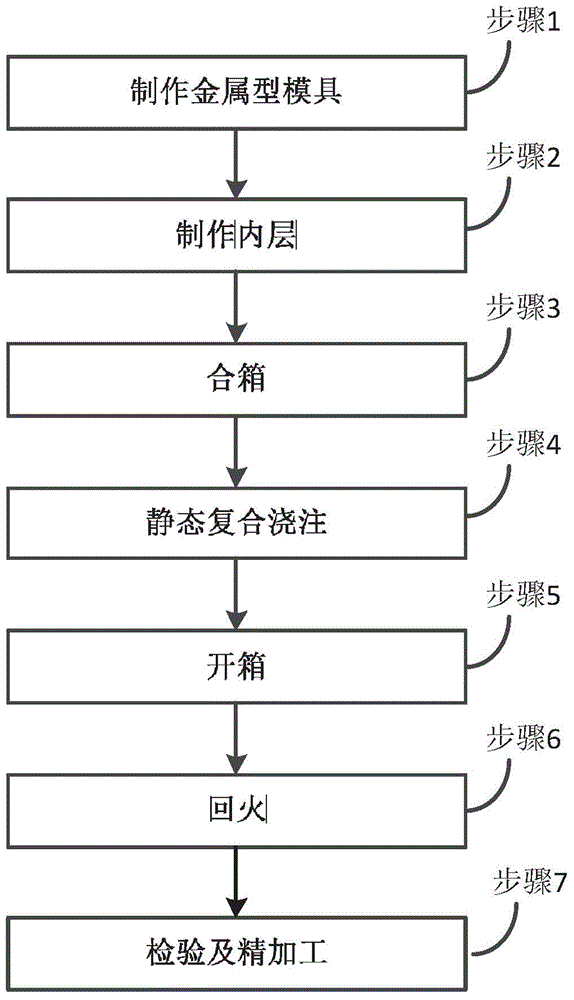

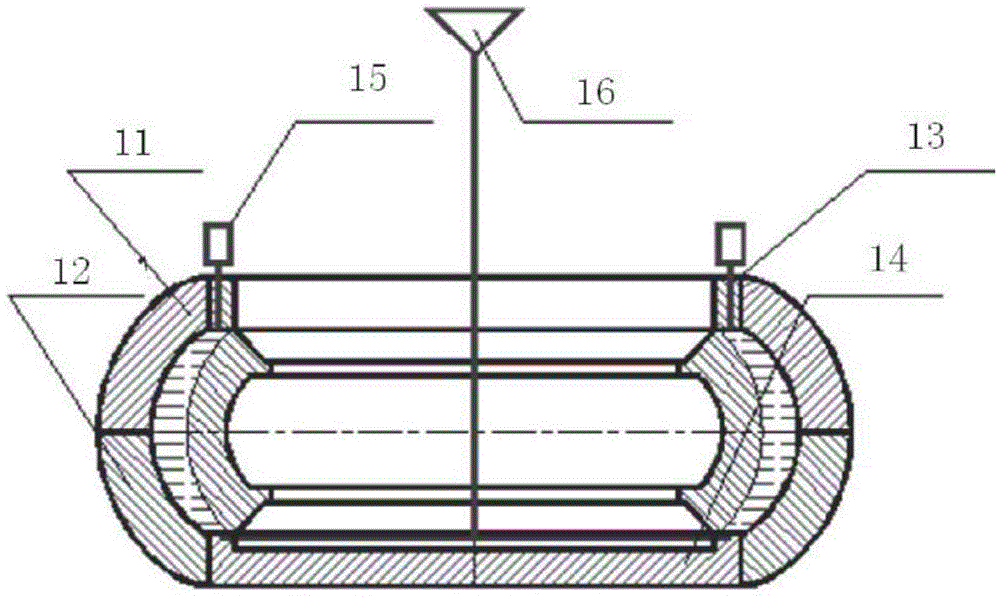

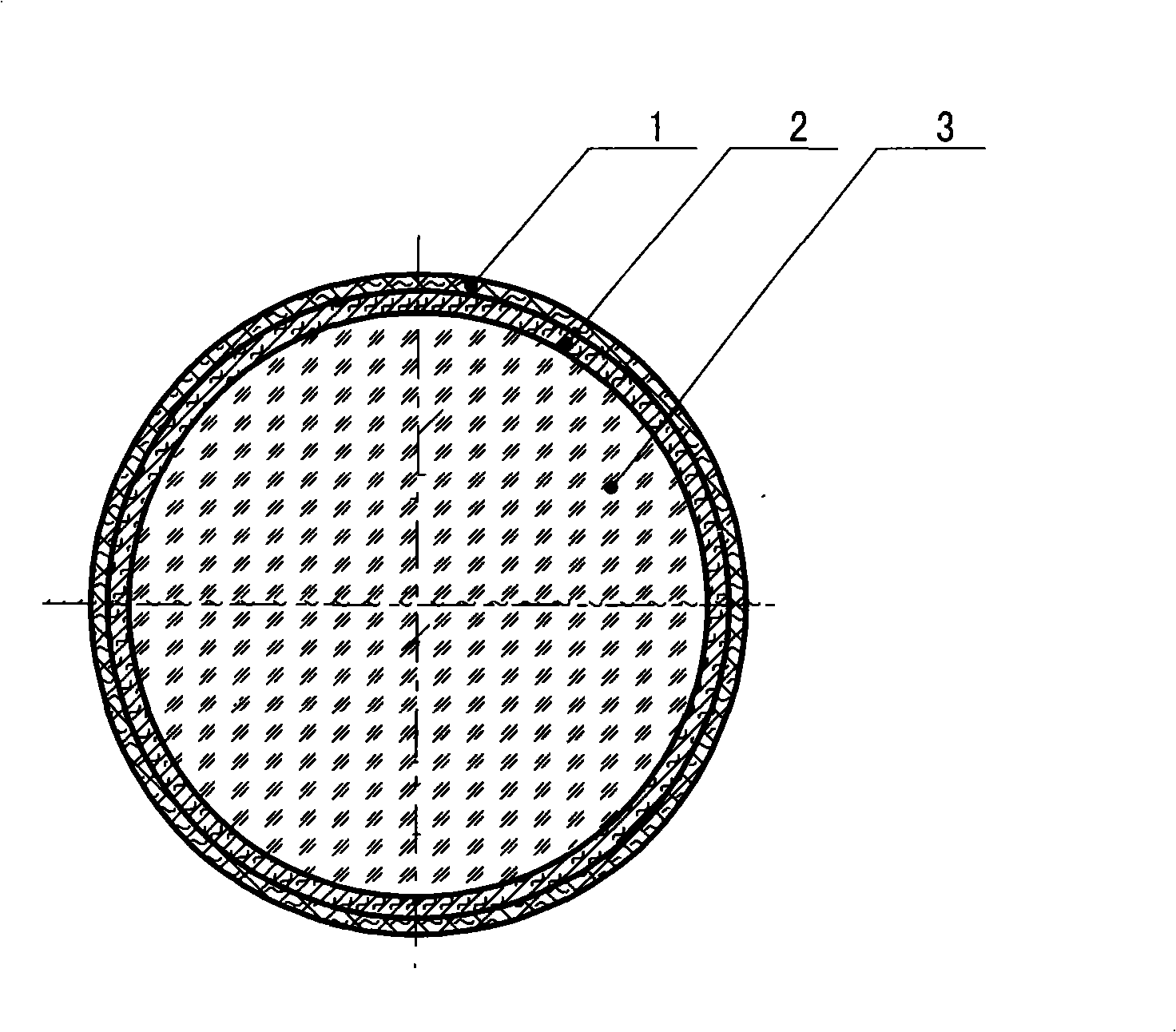

Super wear-resistant compound vertical mill roller shell and manufacture method thereof

The invention discloses a super wear-resistant compound vertical mill roller shell. The super wear-resistant compound vertical mill roller shell comprises a dual-layer structure including a super wear-resistant outer layer and a high toughness inner layer, wherein the outer layer is the super wear-resistant cast iron of which the metallurgical melting content is greater than 35% of carbide particle, the inner layer is the high toughness medium carbon low alloy steel, the super wear-resistant outer layer and the high toughness inner layer are bonded together in a metallurgical bonding mode, the wear-resistant cast iron is the super wear-resistant cast iron comprising carbon element more than ordinary level and various alloy elements with ultrahigh content. The working layer molten iron is tightly surrounded by the inner layer which is heated to 930 DEG C under the static pressure, with washing action of the molten iron, the outer surface forming boundary of the inner layer jacket with deep sharp lines of 2mm is melted, and the outer layer and the inner layer can be bonded together in the metallurgical bonding mode along the reduction of the temperature; the failure mode as piece dropping and spalling due to the welding of micro cracks can be thoroughly eliminated and the maintenance-free is achieved for life.

Owner:天津泰铭医疗技术股份有限公司

Glass microballoon with dual-layer function membrane

InactiveCN101284712AImprove Molecular Coupling PerformanceImprove adhesionTenebresent compositionsAdhesiveWater soluble

The invention relates to a glass bead with double-layer functional films, and is mainly and technically characterized in that the outer surface of the glass bead body is evenly coated with an inner layer of the functional film and an outer layer of the functional film, the inner layer of the functional film adopts organosilicon materials which have affinity toward the glass bead and adhesives such as oil paint, etc., and the outer layer of the functional film adopts organosilicon materials with hydrophobic performance. The invention forms double layers of the functional films with the unique function on the surface of the glass bead, so as to enable the glass bead to have efficacies of moisture proof and anti-caking, and the original pure physical binding of the glass bead and the substrate of markers such as traffic marker lines, etc., are changed into molecule bonding plus physical binding, thereby greatly improving the mutual binding force, prolonging the service life, reducing the manufacturing cost and being applicable to the combination with the environment friendly water-soluble marker paint. The technology fills the domestic blank, and reaches the international leading level.

Owner:單岩崑

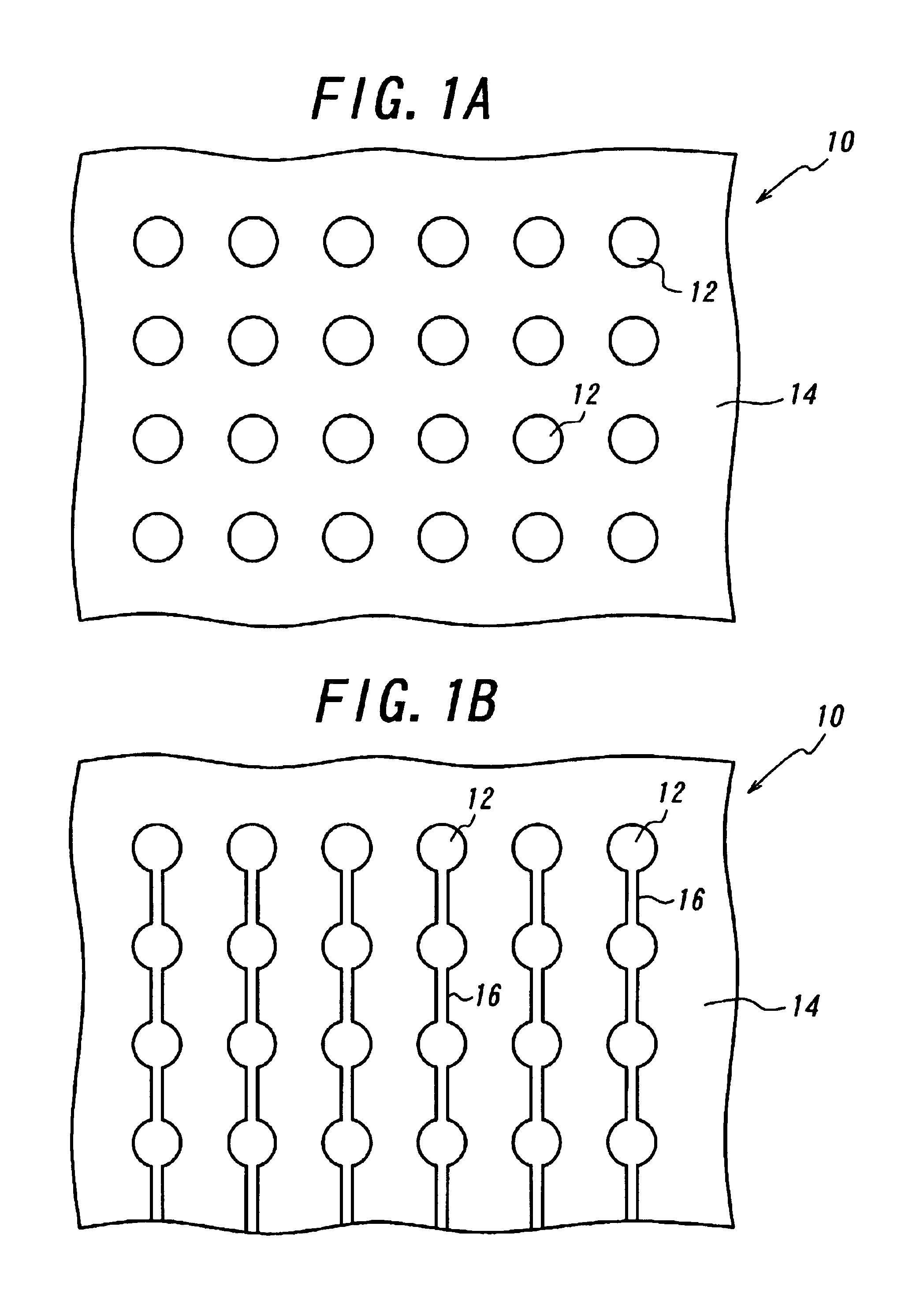

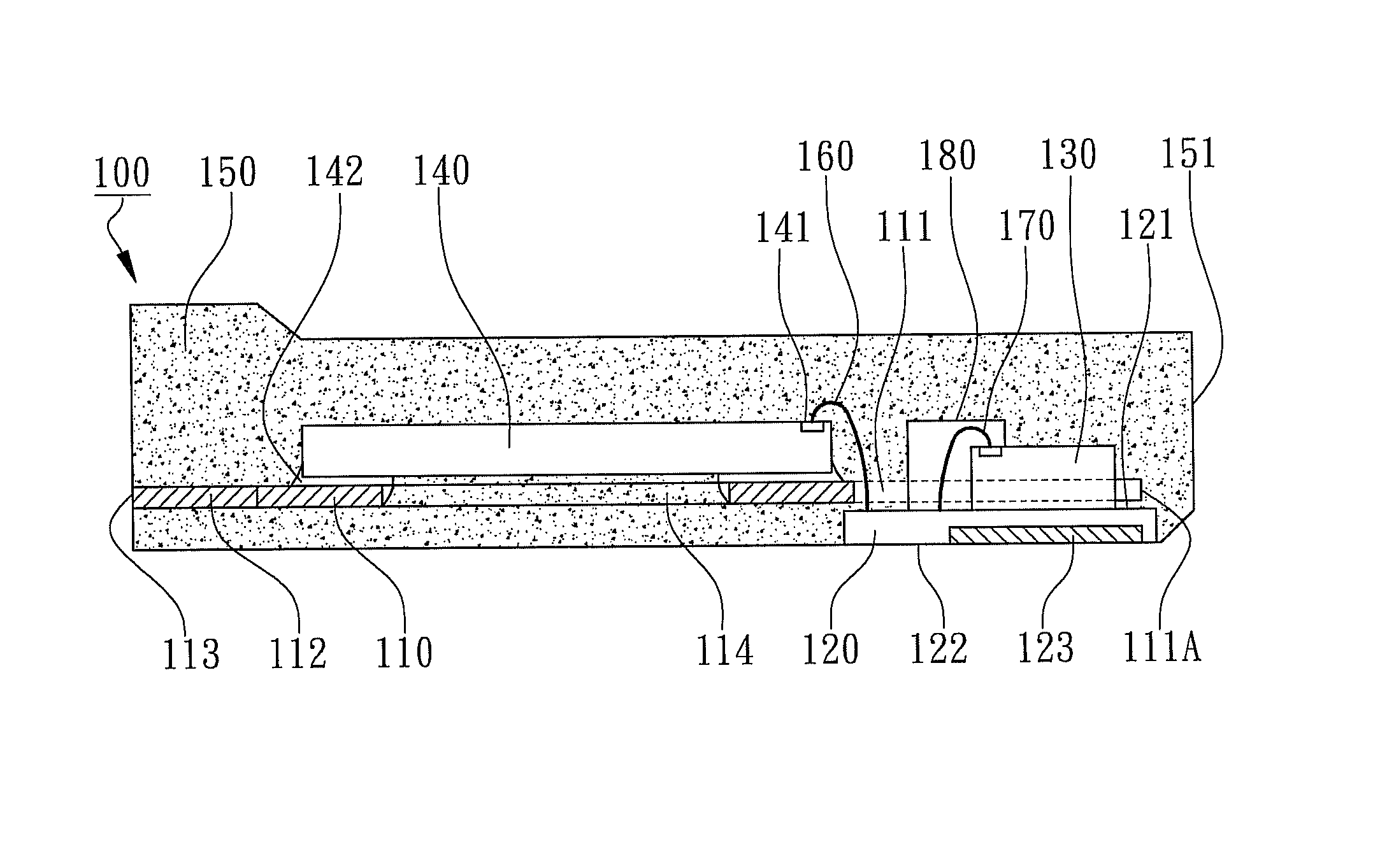

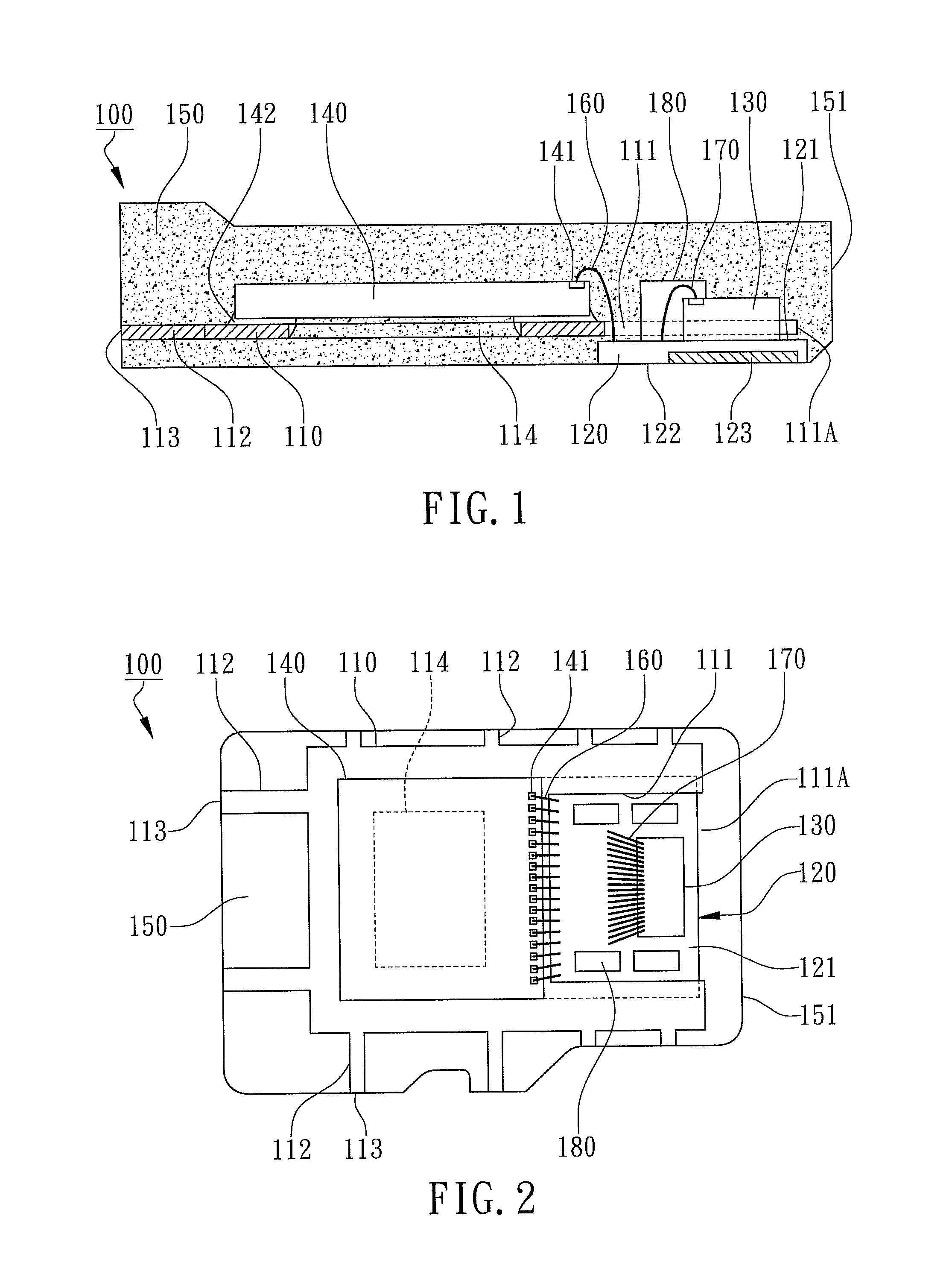

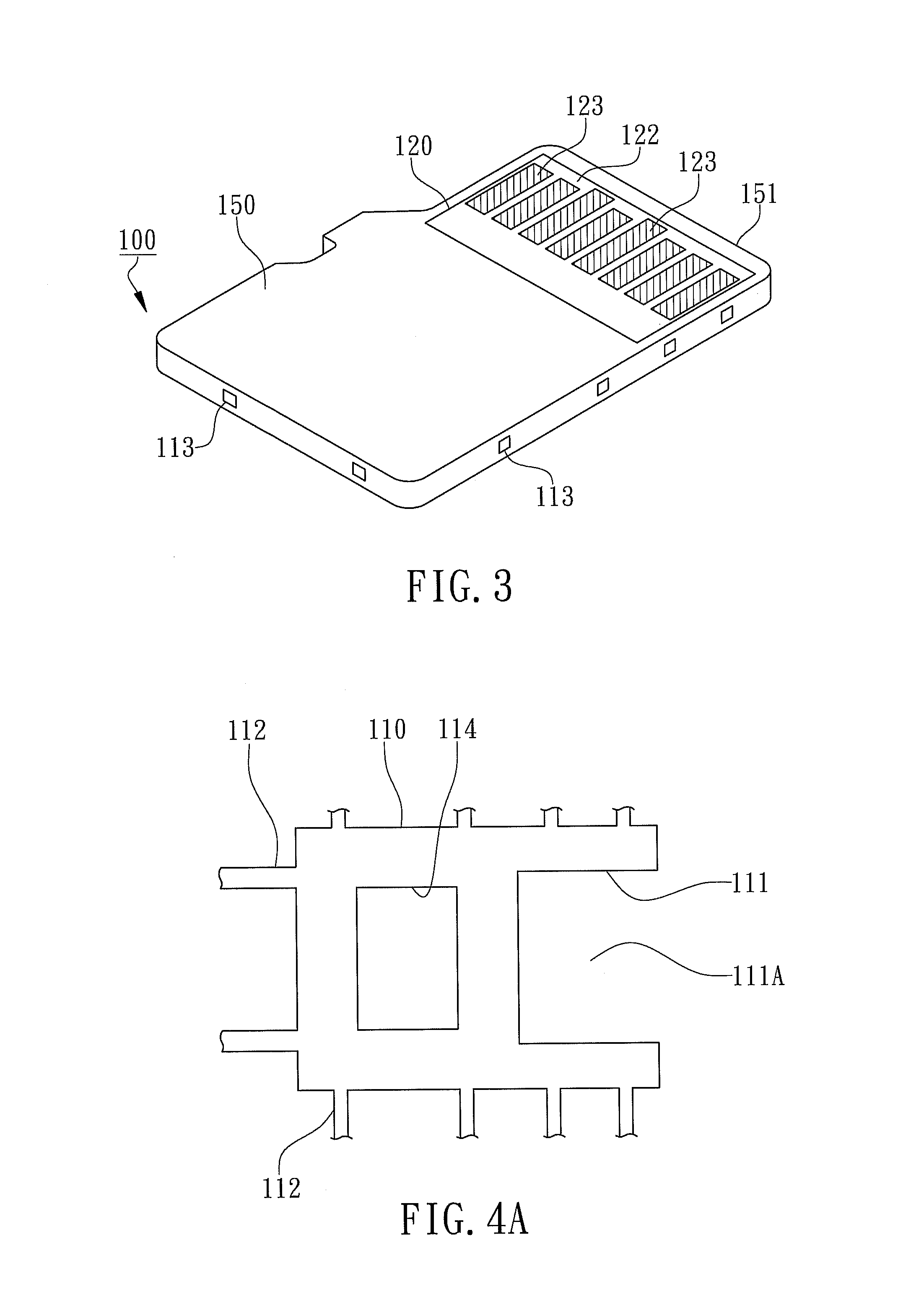

Multi-chip memory package with a small substrate

ActiveUS8368192B1Eliminate peelingLower substrate costSemiconductor/solid-state device detailsSolid-state devicesSealantElectrical and Electronics engineering

Disclosed is a multi-chip memory package with a small substrate by using a die pad having an opening to substitute the chip-carrying function of a conventional substrate so that substrate dimension can be reduced. A substrate is attached under the die pad. A first chip is disposed on the substrate located inside the opening. A second chip is disposed on the die pad. An encapsulant encapsulates the top surface of the die pad, the top surface of the substrate, the first chip, and the second chip. The dimension of the substrate is smaller than the dimension of the encapsulant. In a preferred embodiment, a plurality of tie bars physically connect to the peripheries of the die pad and extend to the sidewalls of the encapsulant to have a plurality of insulated cut ends exposed from the encapsulant.

Owner:POWERTECH TECHNOLOGY

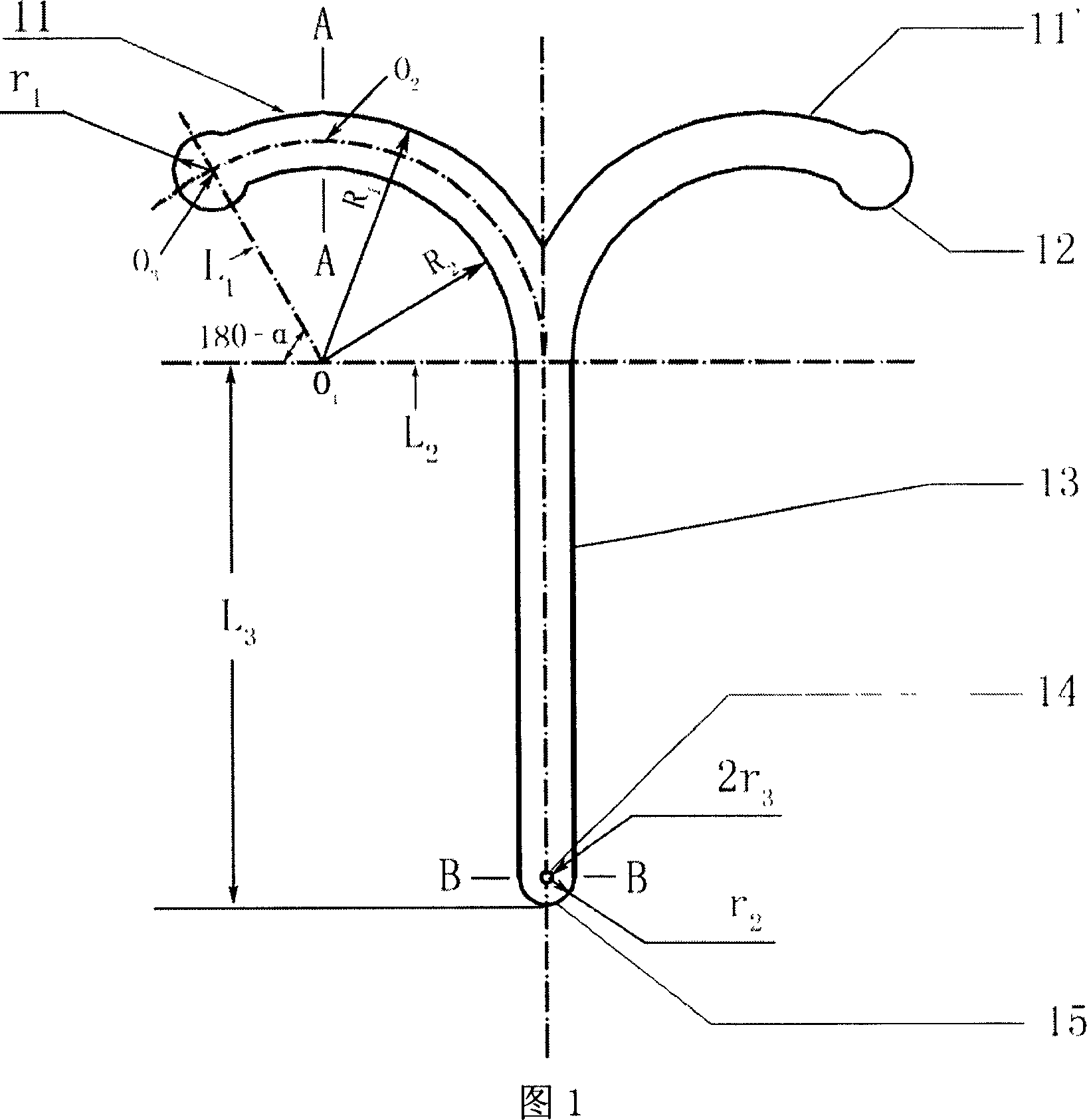

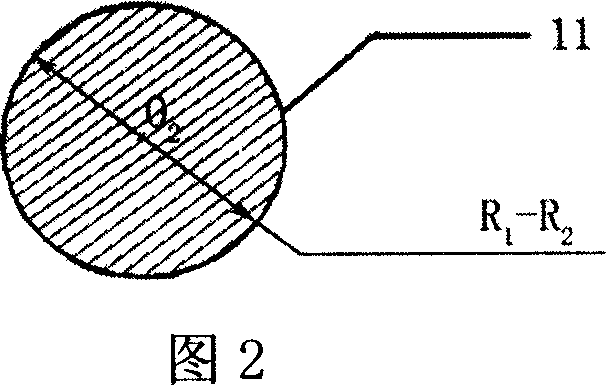

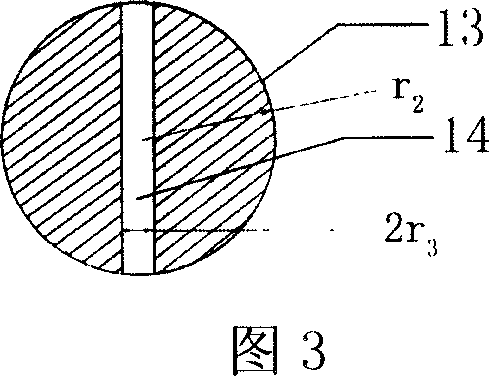

Intrauterine device of composite material

InactiveCN1931113AImprove effective utilizationMorphologicallyOrganic active ingredientsFemale contraceptivesEndocervixSide effect

The intrauterine device (IUD) of composite material consists of one vertical arm and two arc arms distributed symmetrically about the top of the vertical arm, and has also two spheres in the external ends of two arc arms and one semi-sphere in the bottom of the vertical arm and with anal filament hole in the center. It has the shape between T and Gamma, accords with the morphologic and dynamic requirements of women's uterine. Compared with available IUD, the present invention has simple setting operation without need of dilatation, no damage on endocervix and less pain, bleeding and other side effects.

Owner:湖北大禹医疗器械有限责任公司

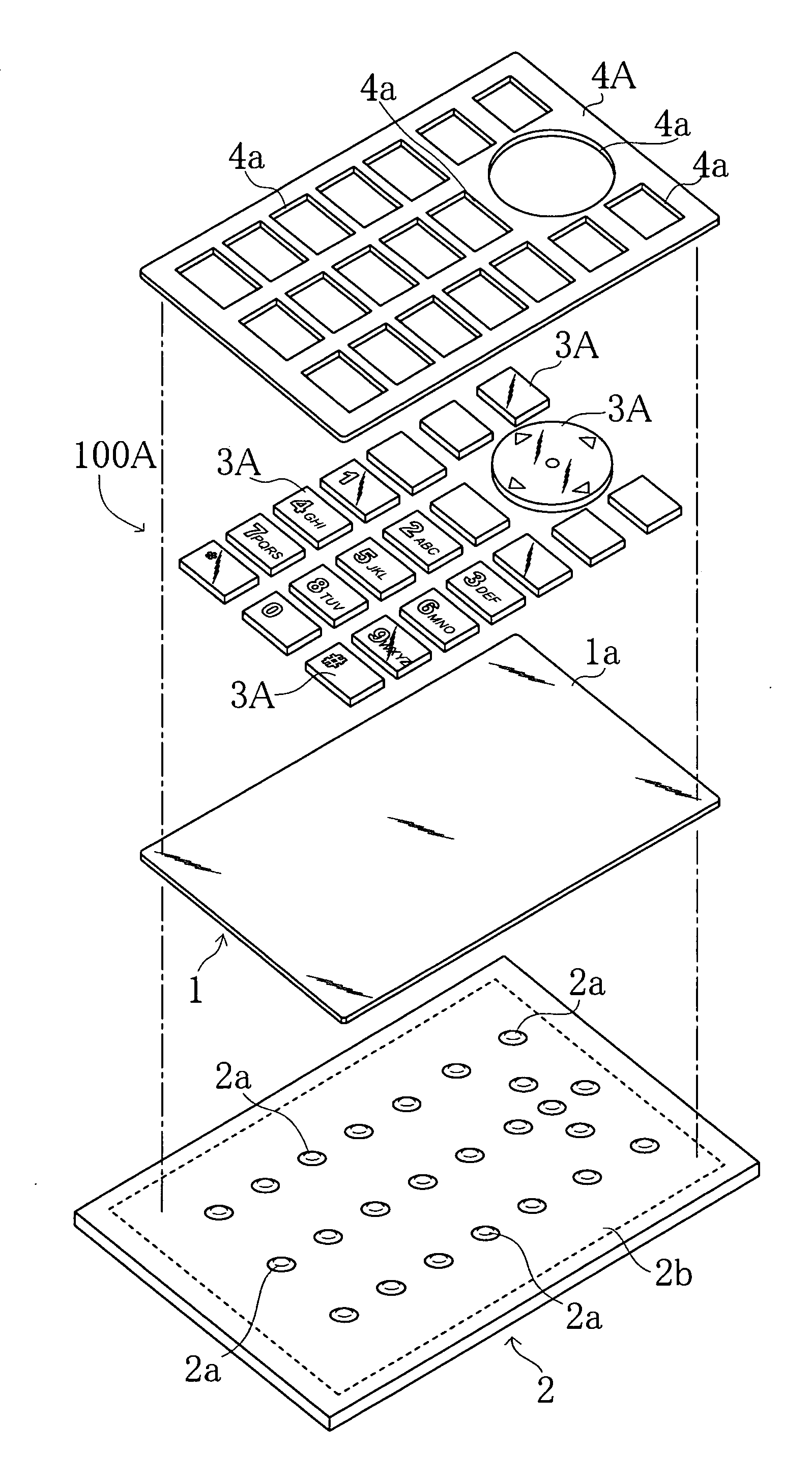

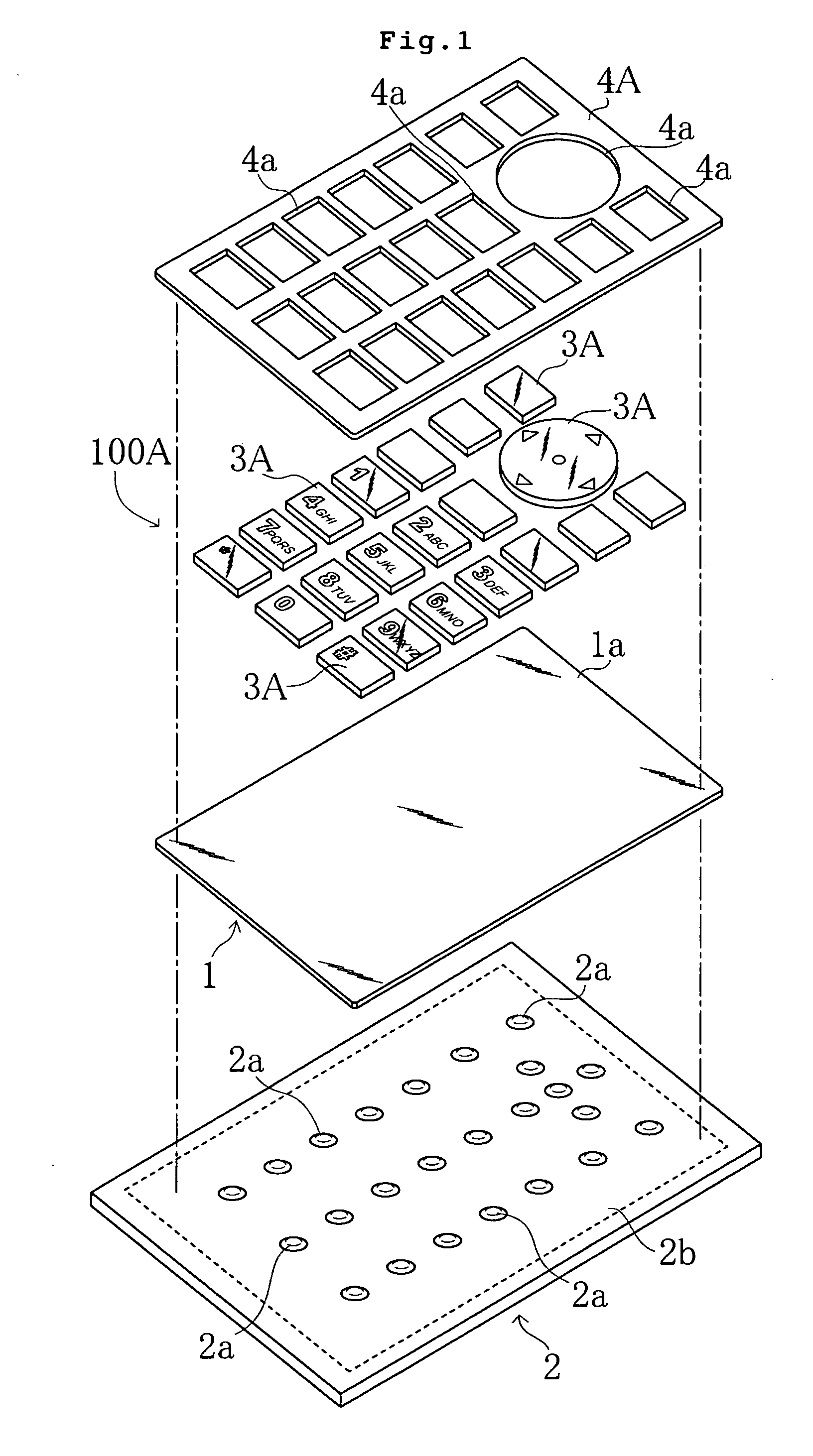

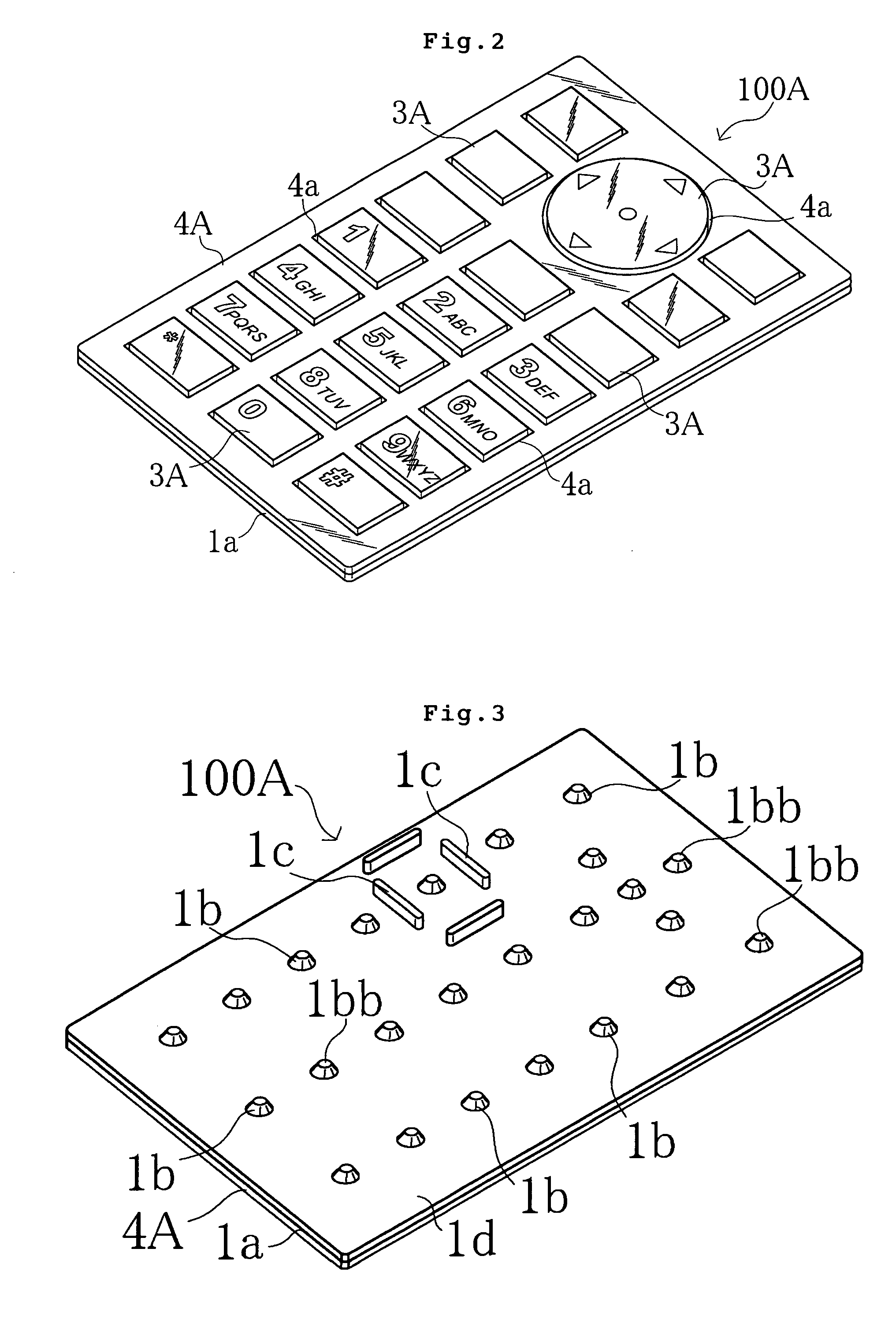

Key Base, Key Sheet and Method of Forming Key Base

InactiveUS20090057121A1Key base can be thinnedWithout usingEmergency actuatorsElectric switchesEngineeringMechanical engineering

Owner:SUNARROW CO LTD

Packaging can and method and apparatus for its manufacture

ActiveUS8746488B2Easy to openReduce morbidityReady-for-oven doughsCapsEngineeringBiomedical engineering

A can for packaging food, comprising a metal can body and a diaphragm lid (16) formed of lidding material which comprises a multilayer structure with at least an aluminum layer of from 6 to 90 microns thickness and a bond layer for fixing the lid (16) directly to the can body. One method for forming the can forms the lidding material by using an outwardly extending curl (20) at one end of the metal can body as the draw die. Lidding material which is carried by the body maker punch is drawn around the curl of the can body draw die so as to form the lidding material into a cup shape.

Owner:CROWN PACKAGING TECH

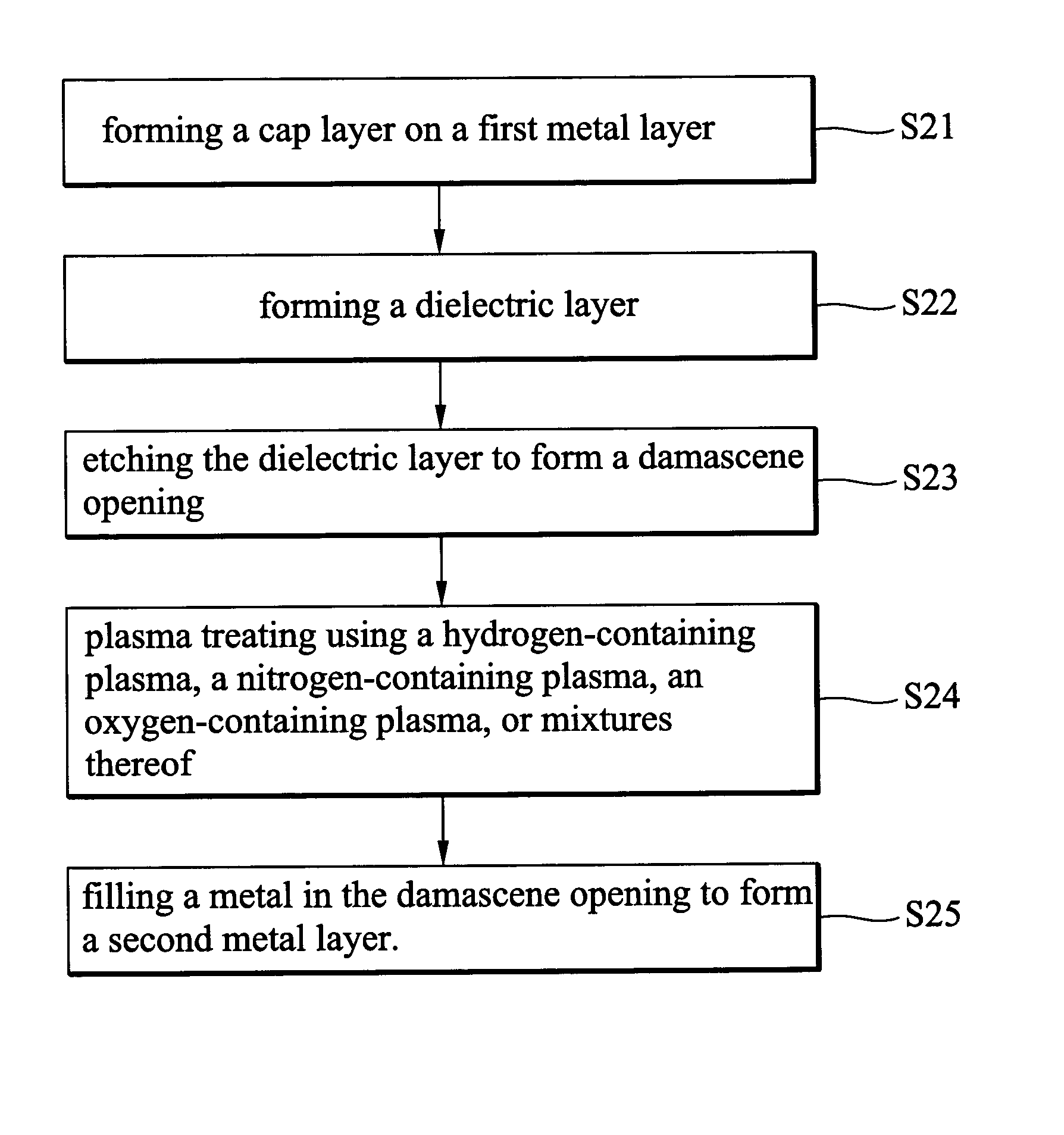

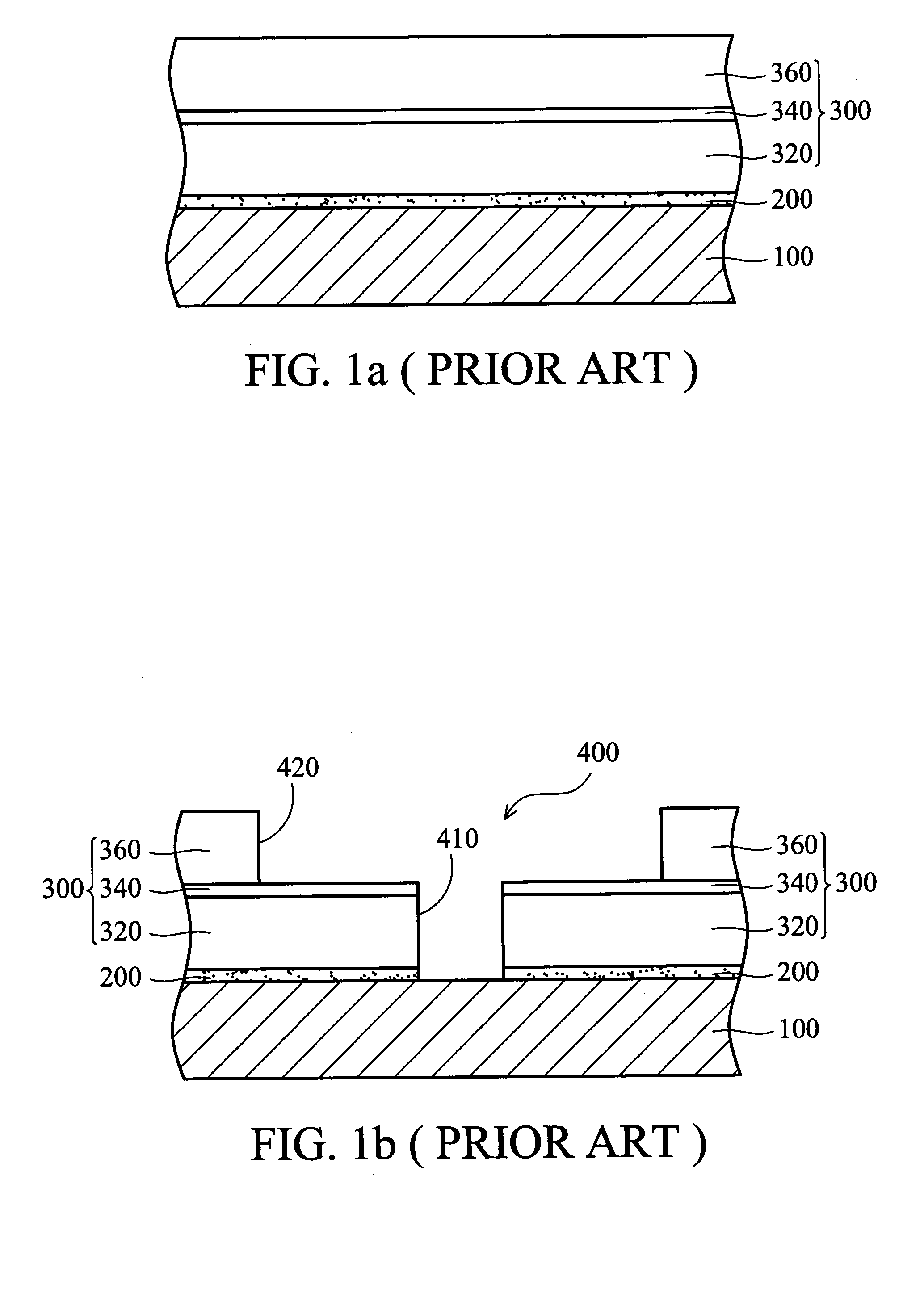

Process for forming metal damascene structure to prevent dielectric layer peeling

InactiveUS20050059233A1Eliminates peelGood adhesionSemiconductor/solid-state device manufacturingSemiconductor devicesPlasma treatmentFiller metal

A process for forming a metal damascene structure. First, a cap layer is formed on a first metal layer, and a dielectric layer is formed on the cap layer. Next, the dielectric layer is etched to form a damascene opening. Next, hydrogen-containing plasma, nitrogen-containing plasma, oxygen-containing plasma, or a mixture thereof is used to perform the plasma treatment. Next, a metal is filled in the damascene opening to form a second metal layer. Peeling of the dielectric layer due to remaining impurities is eliminated by the plasma treatment after etching of the damascene opening.

Owner:TAIWAN SEMICON MFG CO LTD

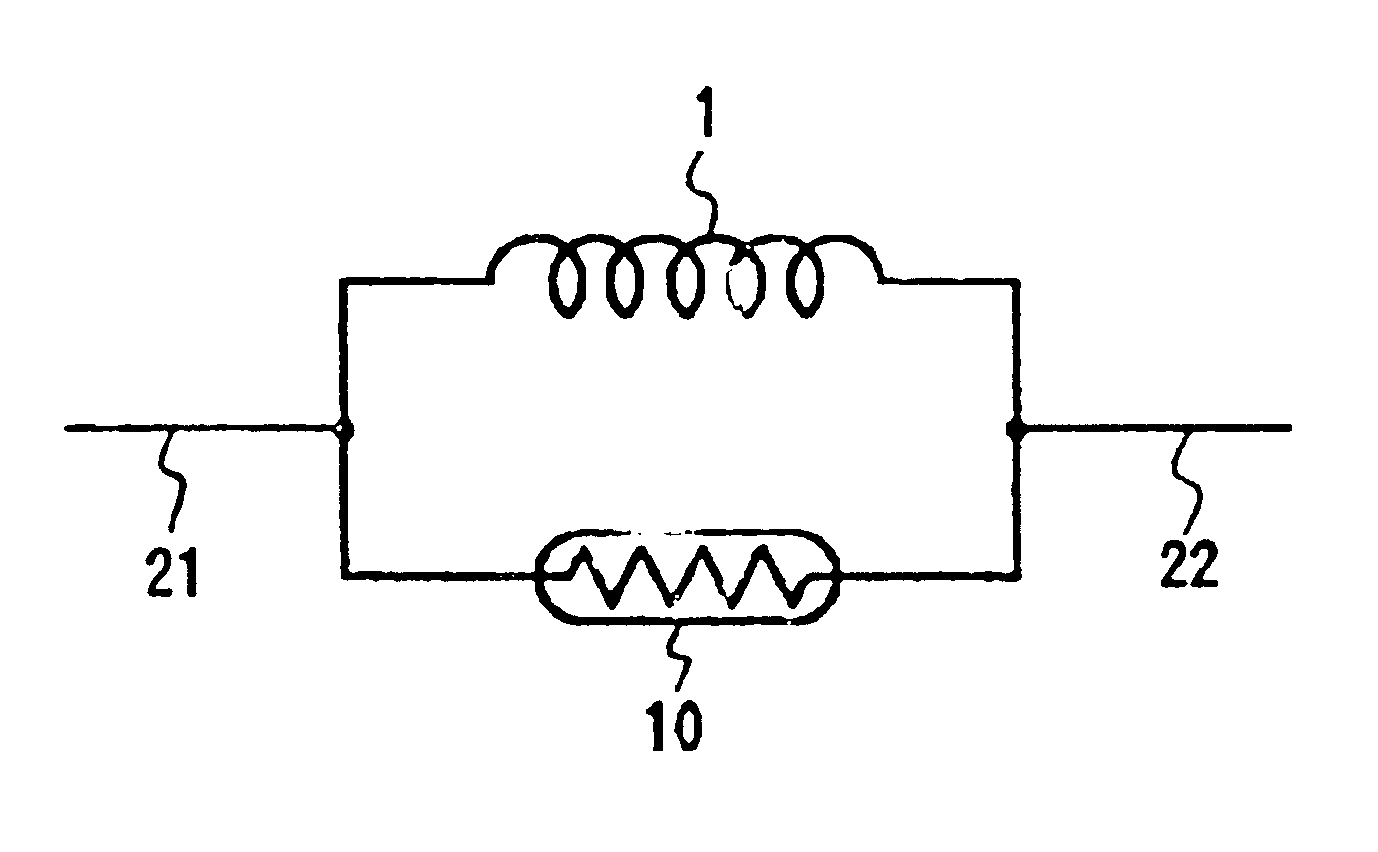

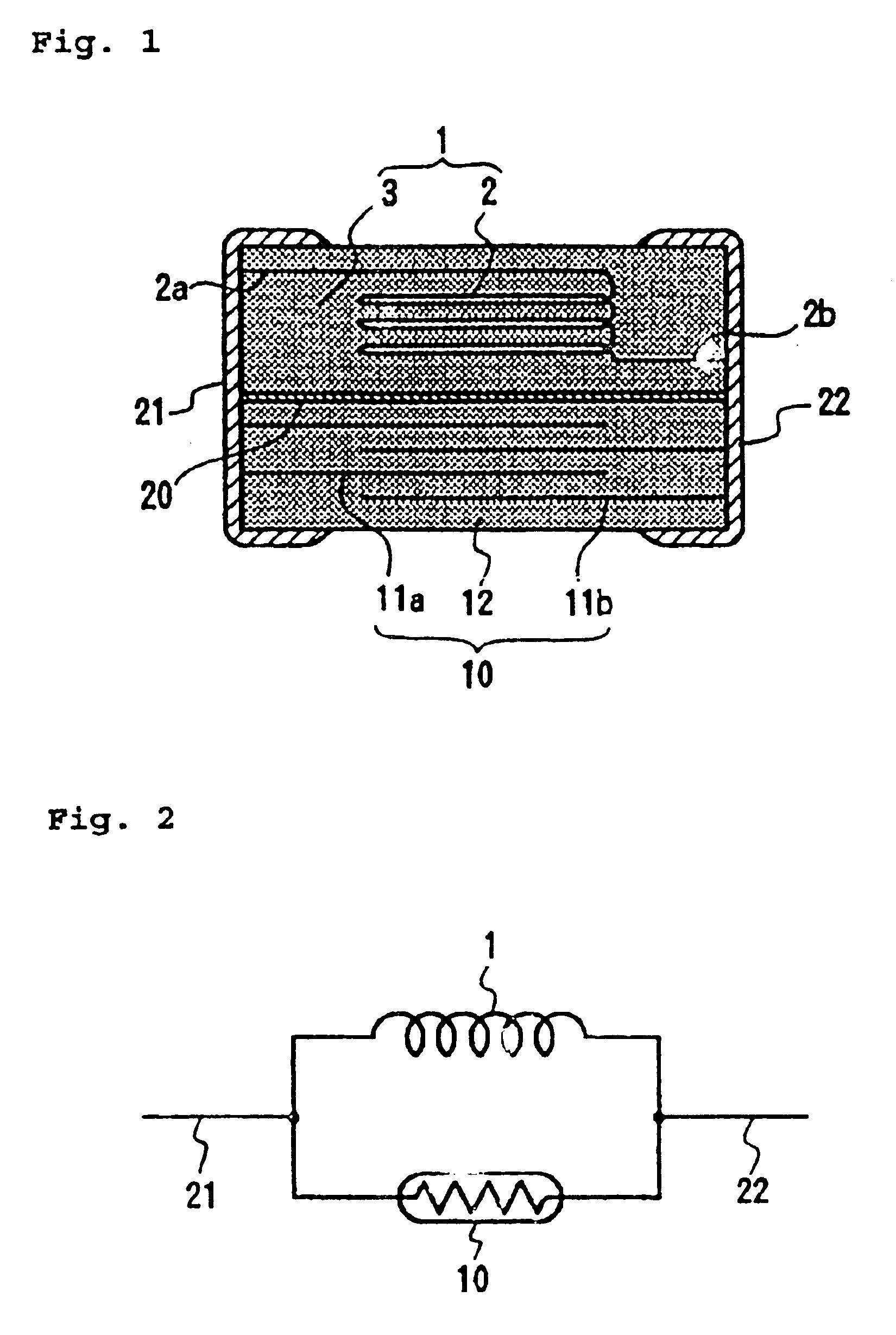

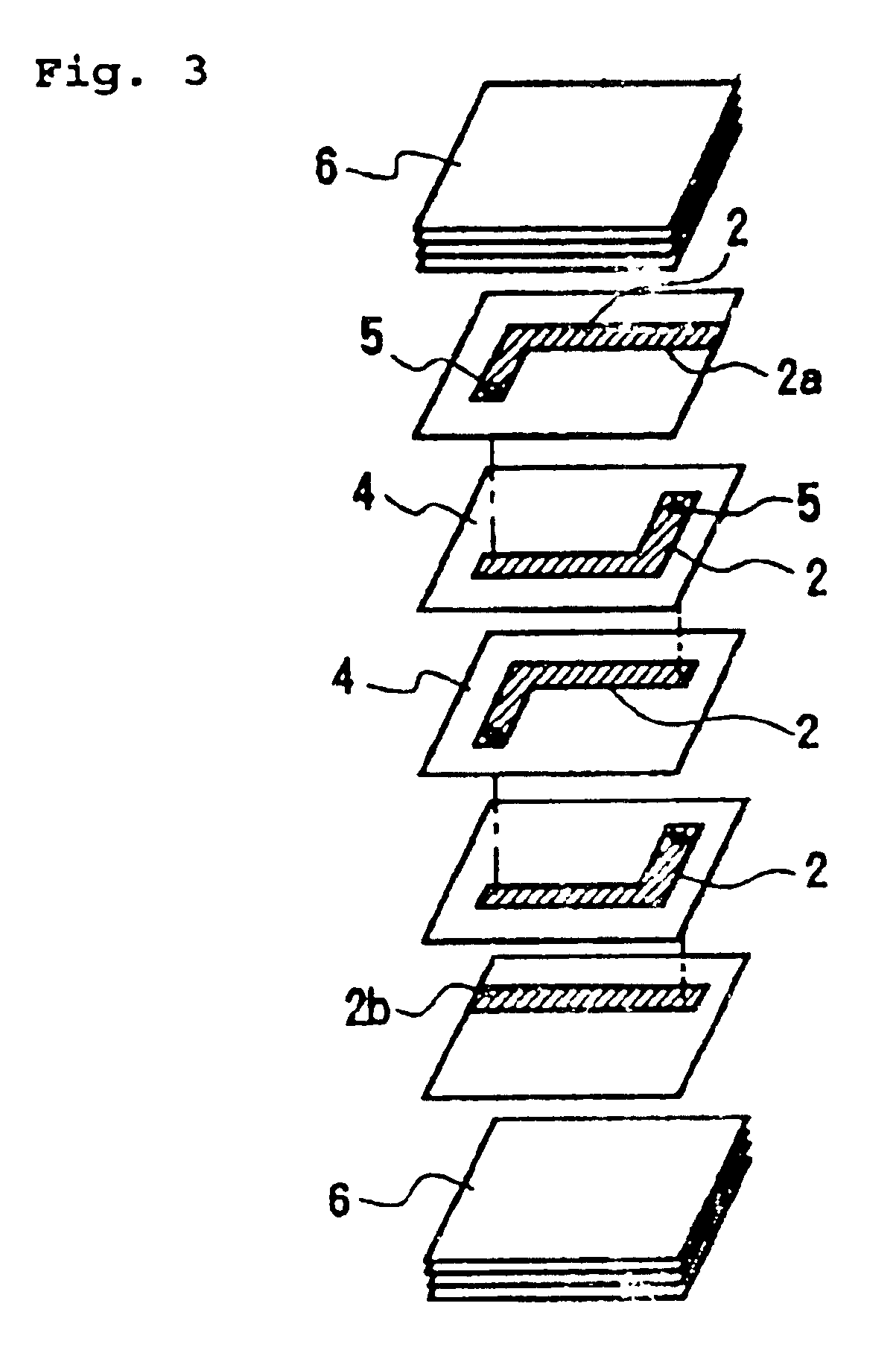

Chip-type composite electronic component and manufacturing method thereof

InactiveUS6846693B2Impedance stabilityEliminate peelingOther resistor networksTransformers/inductances coils/windings/connectionsElectrical conductorInductor

An inductor obtained by laminating a plurality of ceramic layers having an internal coil conductor, and a thermistor obtained by laminating a plurality of ceramic layers having internal electrodes and having a predetermined resistance-temperature characteristic are laminated via an intermediate insulating layer. Both ends of the internal coil conductor of the inductor and the internal electrodes of the thermistor are connected to a pair of external electrodes. Thus, the inductor and the thermistor are connected in parallel.

Owner:MURATA MFG CO LTD

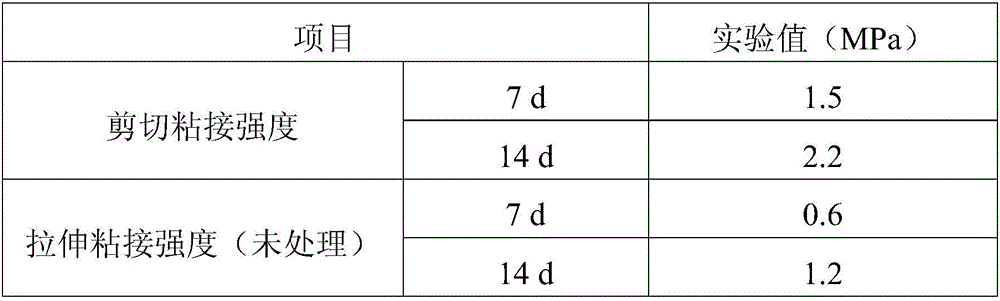

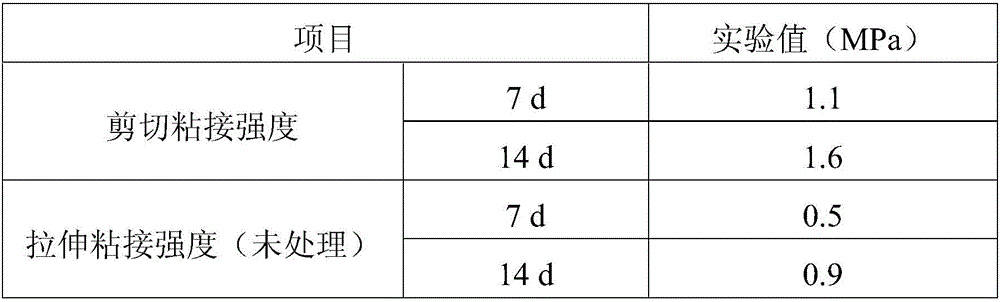

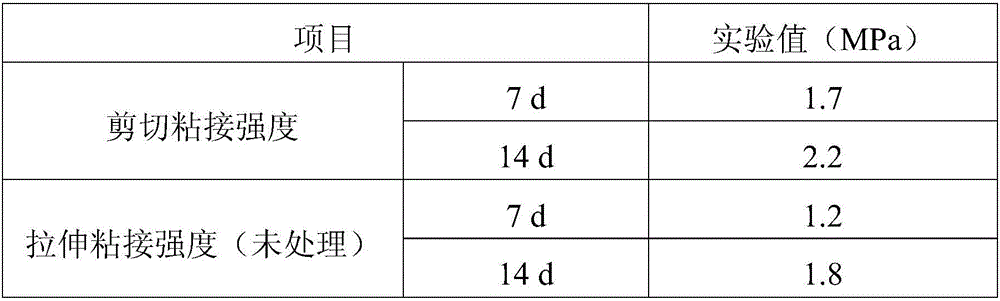

Composite polymer emulsion high-strength interface agent for vitrified brick and preparation thereof

The invention belongs to the technical field of interface agent, and discloses a composite polymer emulsion high-strength interface agent for a vitrified brick and a preparation method thereof. The interface agent comprises the following components by the mass fraction: 45-65% of a small-particle-size styrene-acrylic emulsion, 15-25% of a pure acrylic emulsion, 5-10% of a small-particle-size styrene-butadiene emulsion, 0.2-0.5% of a synergistic agent, 0.1-0.3% of a dispersant, 0.3-1.0% of a wetting agent, and the balance water. With adopting of the small-particle-size styrene-acrylic emulsion, with cooperation of the smaller-particle-size styrene-butadiene emulsion as a penetrating agent, and with collocation use of the water-based synergistic agent, the water solubility of the two kinds of emulsions are effectively improved, the compatibility of the emulsions is improved, the adhesion force and stability of an interface material are increased, the effect of penetrating into the back of a brick with low water absorption rate can be realized, the pulling strength of the material is also increased, the comprehensive effect of an acrylic emulsion is fully played, two-way permeability is achieved, and the adhesion force of a cement-based material is fully played.

Owner:广东亿固壁安粘贴技术有限公司

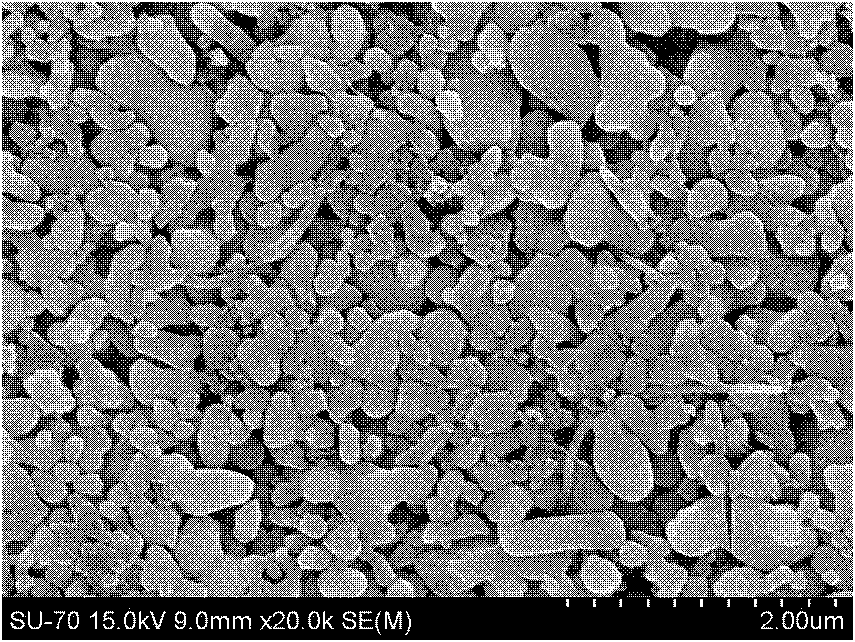

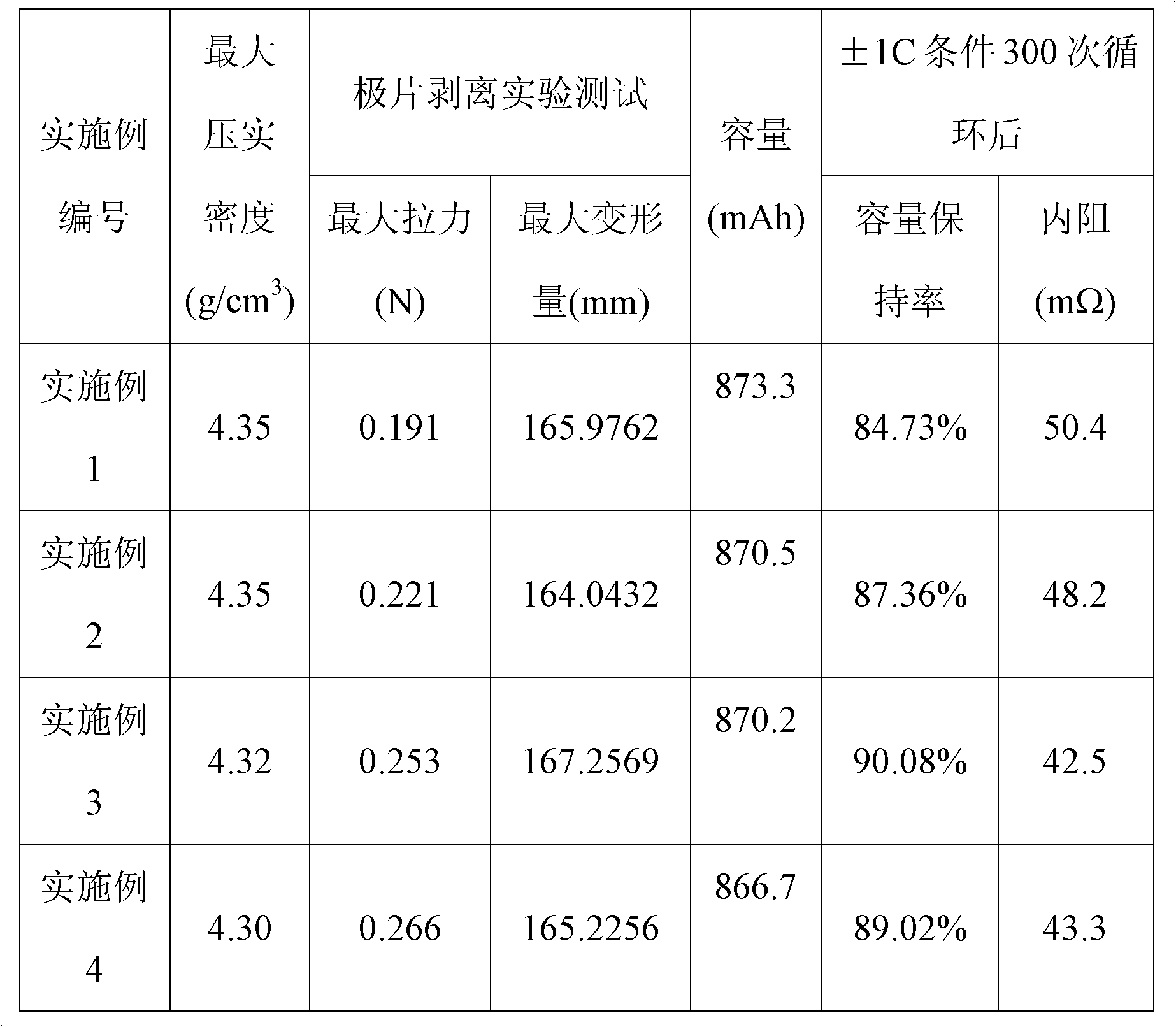

Paste for nonaqueous lithium ion battery positive electrode

The invention relates to paste for a nonaqueous lithium ion battery positive electrode. The paste comprises a positive electrode active substance, a conductive agent, a bonding agent and a solvent, wherein the proportioning ratio of the total mass of the three components, namely the positive electrode active substance, the conductive agent and the bonding agent to the mass of the solvent is 100:(40-130); and the content by percentage of each of the positive electrode active substance, the conductive agent and the bonding agent in the total mass of the three components is 92.5-97.6%, 1.9-3.5% and 0.5-4.0% respectively. By adopting the paste for the positive electrode provided by the invention, the peeling phenomenon between a coated layer and the foil layer of a current collector can be eliminated to a greater extent, the bonding property of the prepared lithium ion battery can be improved, the inner resistance of the battery can be reduced, and the capacity of the battery can be improved.

Owner:HUNAN FENGYUAN YESHINE KINGCO NEW ENERGY

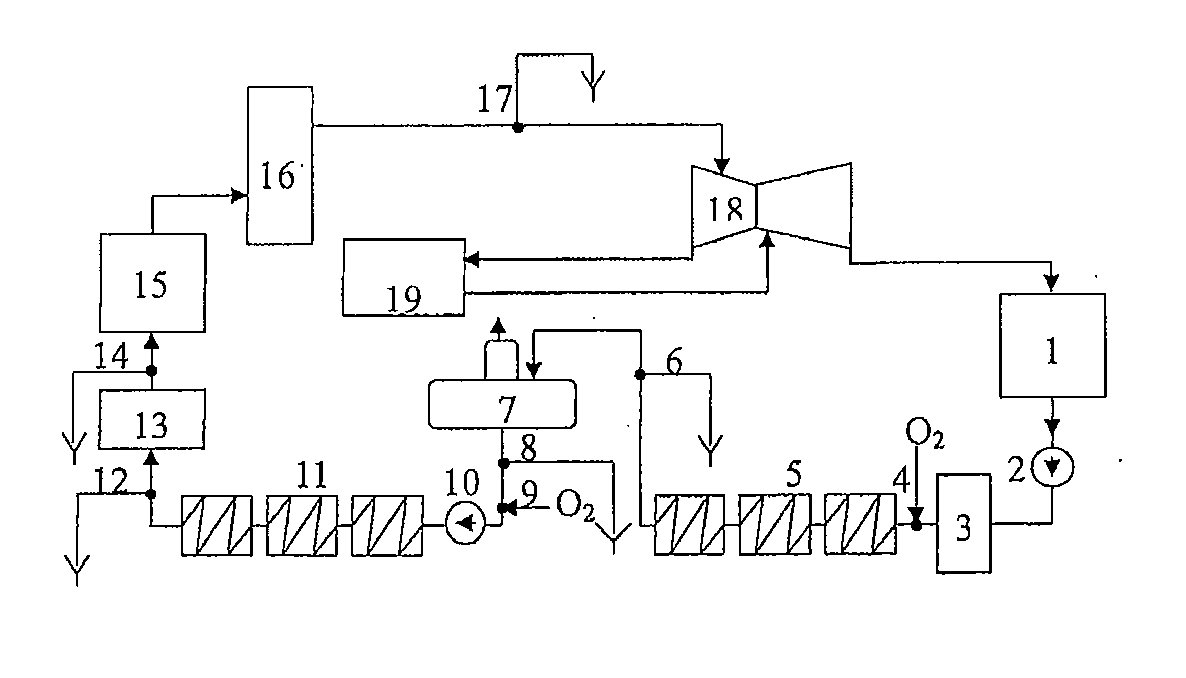

Process for feed-water oxygenating treatment in boiler in power station

ActiveUS20140042104A1Lower iron levelsReduce the amount of oxygenWater treatment parameter controlSteam generation heating methodsPower stationEngineering

The present invention provides a process of oxygenated feed-water treatment of boilers in power station, carried out under an OT treatment process, suitable for both the monotube type boiler and the drum type boiler, and comprising an oxygenation stage comprising: a normal oxygenation converting stage and a decreased oxygenation film-supplementing stage; the normal oxygenation converting stage is a stage in which the feed water system is oxygenated both at the outlet of a condensate polishing system and at the inlet of a feed water pump of a high pressure feed water system, and the concentration of dissolved oxygen in the main steam is controlled to be ≦5 μg / L; the decreased oxygenation film-supplementing stage is a stage in which, after an oxide film is formed in the feed water system, the amount of oxygenation at the high pressure feed water system is decreased so that the amount of the oxygen added is only for supplementing and maintaining the oxide film, while the concentration of dissolved oxygen in the main steam is controlled to be ≦5 μg / L. It can ensure that a dense protection film can be formed and maintained on the metal surface of the pipes in a feed water system, thereby reducing the iron content in the feed water; excessive oxygen is prevented from entering the high temperature heating surface and causing the peeling off of the oxide skin; and the amount of oxygen consumed is significantly reduced, thereby decreasing the amount of maintenance.

Owner:Z P EPC ELECTRIC POWER RES INST +1

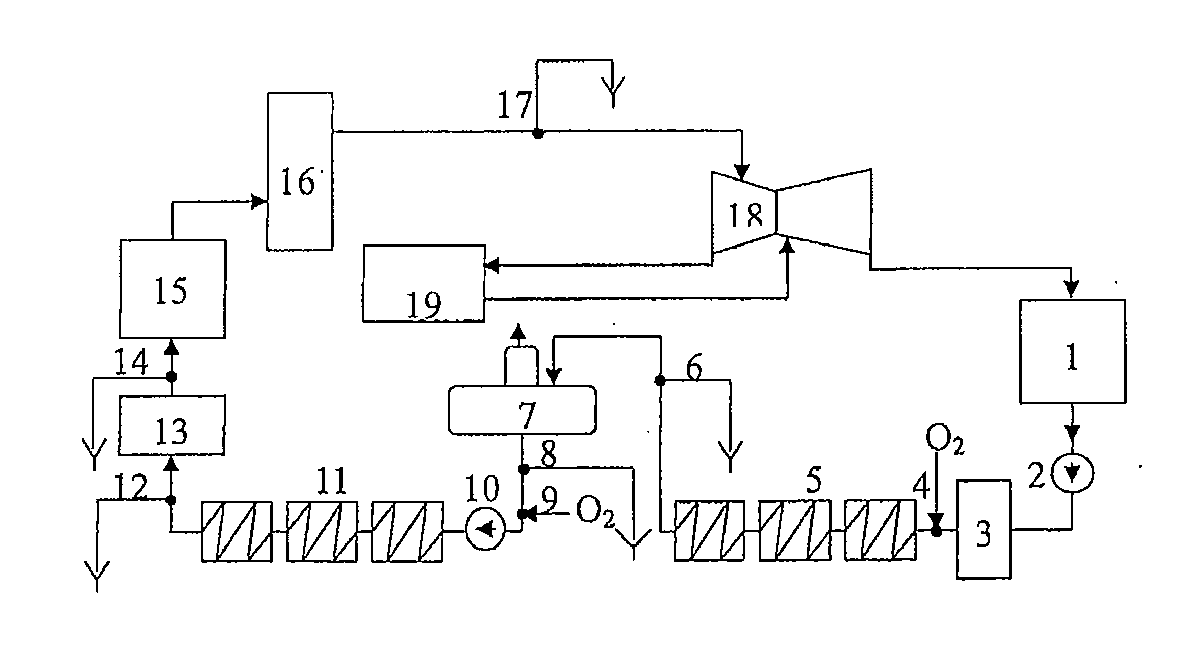

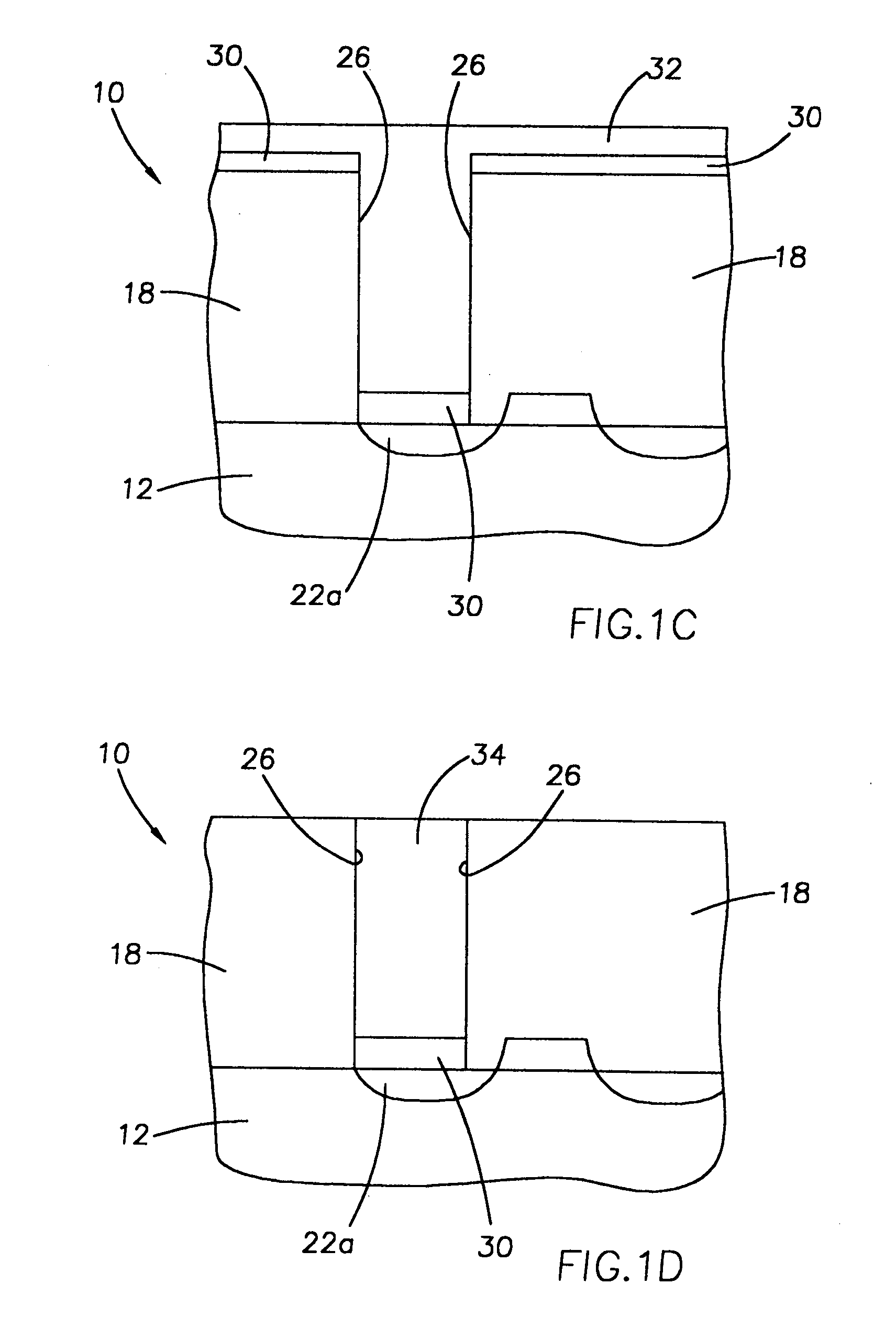

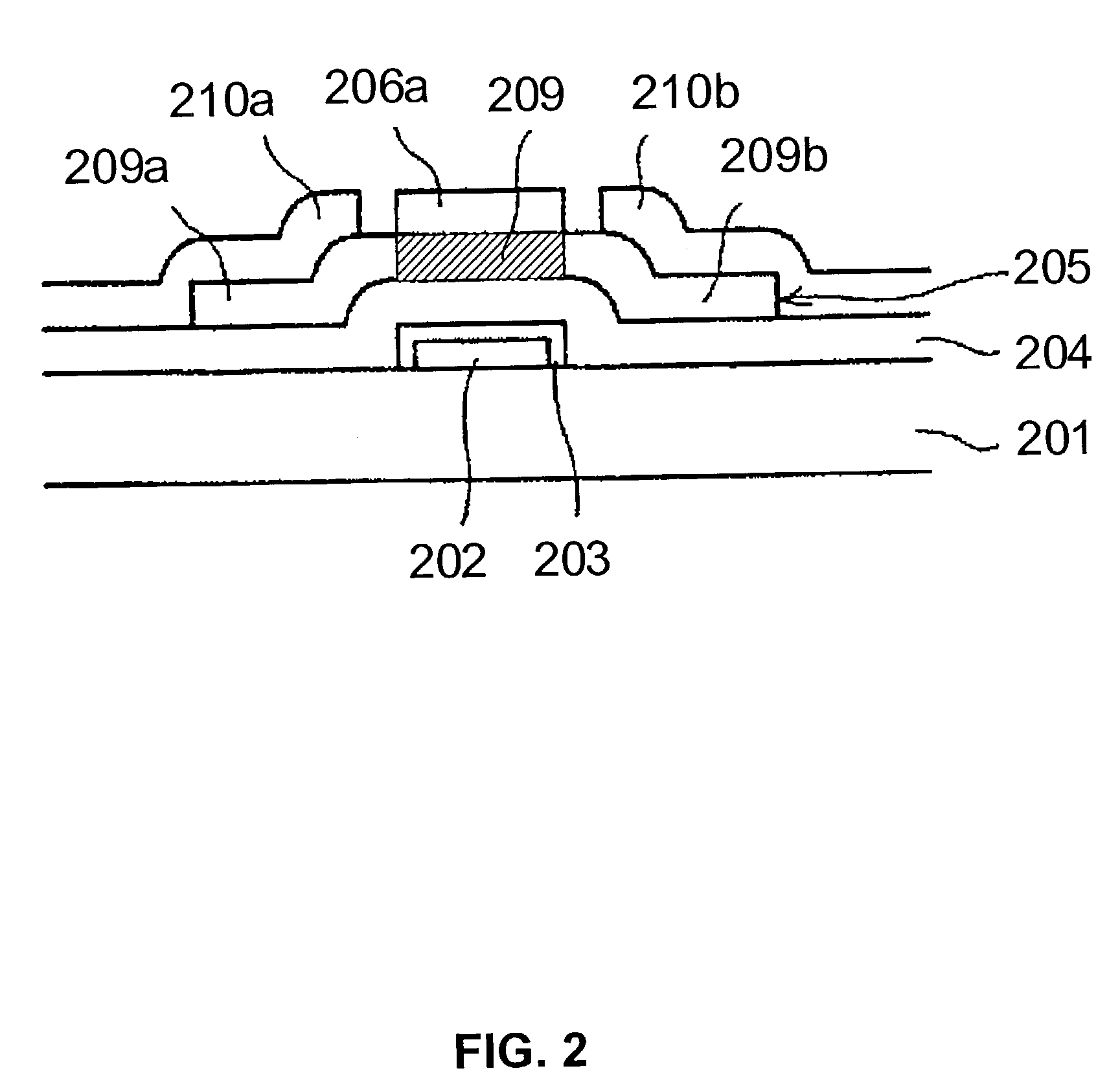

Low Temperature Process for TFT Fabrication

InactiveUS20080087960A1Added fabricationImprove adhesionTransistorSolid-state devicesHydrogenSilanes

Method of fabricating a thin-film transistor (TFT) in which a gate metal is deposited onto a substrate in order to form the gate of the thin-film transistor. The substrate may be an insulative substrate or a color filter. In a first method, the gate metal is subjected to an H2 plasma. After subjecting the gate metal to an H2 plasma, the gate insulating film is deposited onto the gate. In a second method, first and second layers of gate insulating film are respectively deposited on the gate at a first and second deposition rates. One layer is deposited under H2 or argon dilution conditions and has improved insulating conditions while the other layer serves to lower the overall compressive stress of the dual layer gate insulator. In a third method, an n+ silicon film is formed on a substrate by maintaining a flow of silane, phosphine and hydrogen gas into a processing chamber at substrate temperatures of about 300° C. or less.

Owner:APPLIED MATERIALS INC

Preparation method of low-zirconium mullite cast steel brick

The invention relates to a preparation method of a low-zirconium mullite cast steel brick, and belongs to the field of preparation of refractory materials. The raw material formula of the low-zirconium mullite cast steel brick provided by the invention comprises electrically smelted mullite, zirconium oxide, Guangxi white clay, andalusite, kyanite and lignin. According to the method provided by the invention, type and grain size of the raw materials are selected to be matched with the sintering temperature and time provided by the invention, so that the prepared low-zirconium mullite cast steel brick has the characteristics of excellent scouring resistance, high temperature resistance, small creep deformation, high compression strength, good thermal stability and the like, and is suitable for being used in large steel ingot casting in nuclear power products.

Owner:四川锦圆耐材有限公司

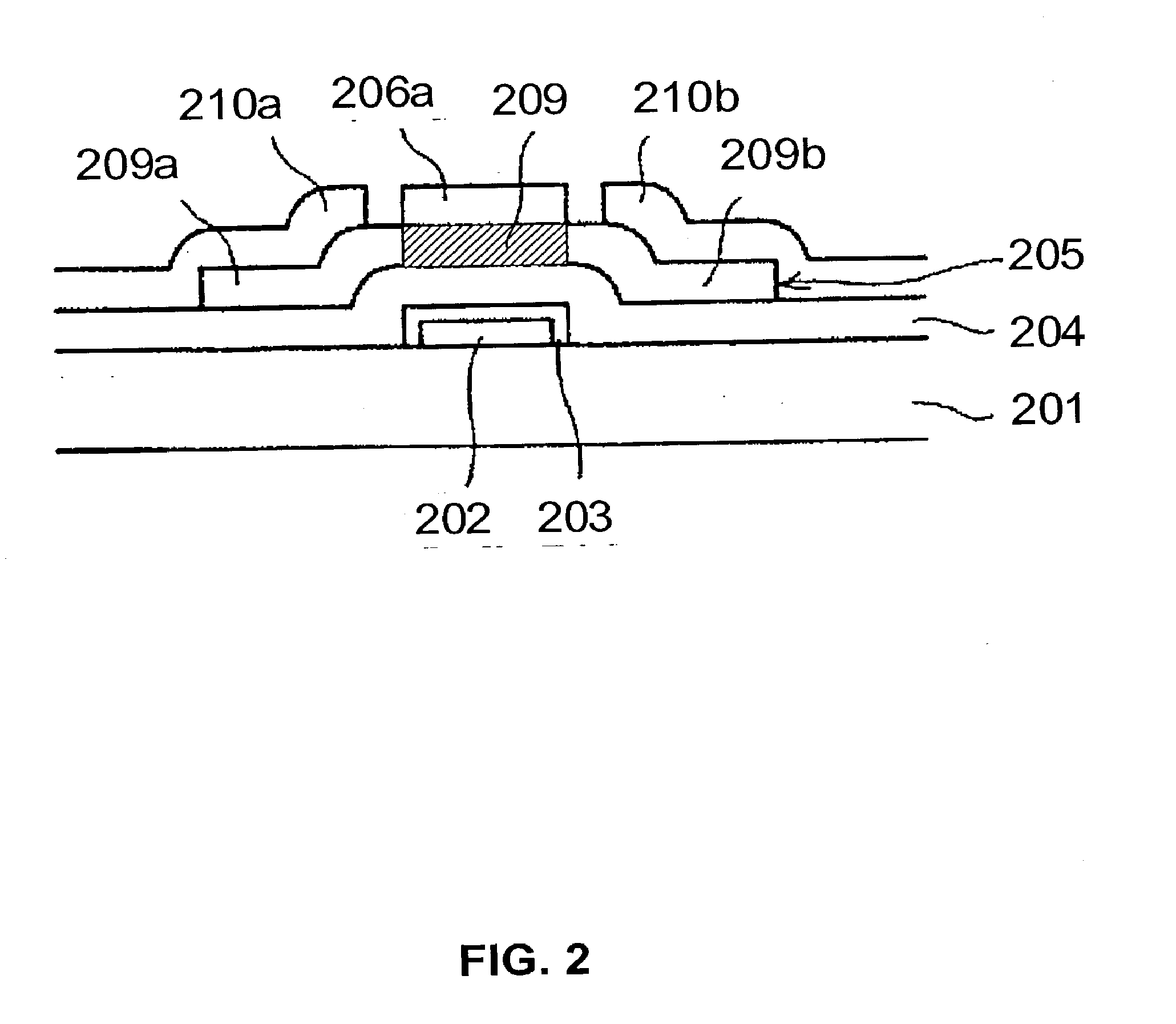

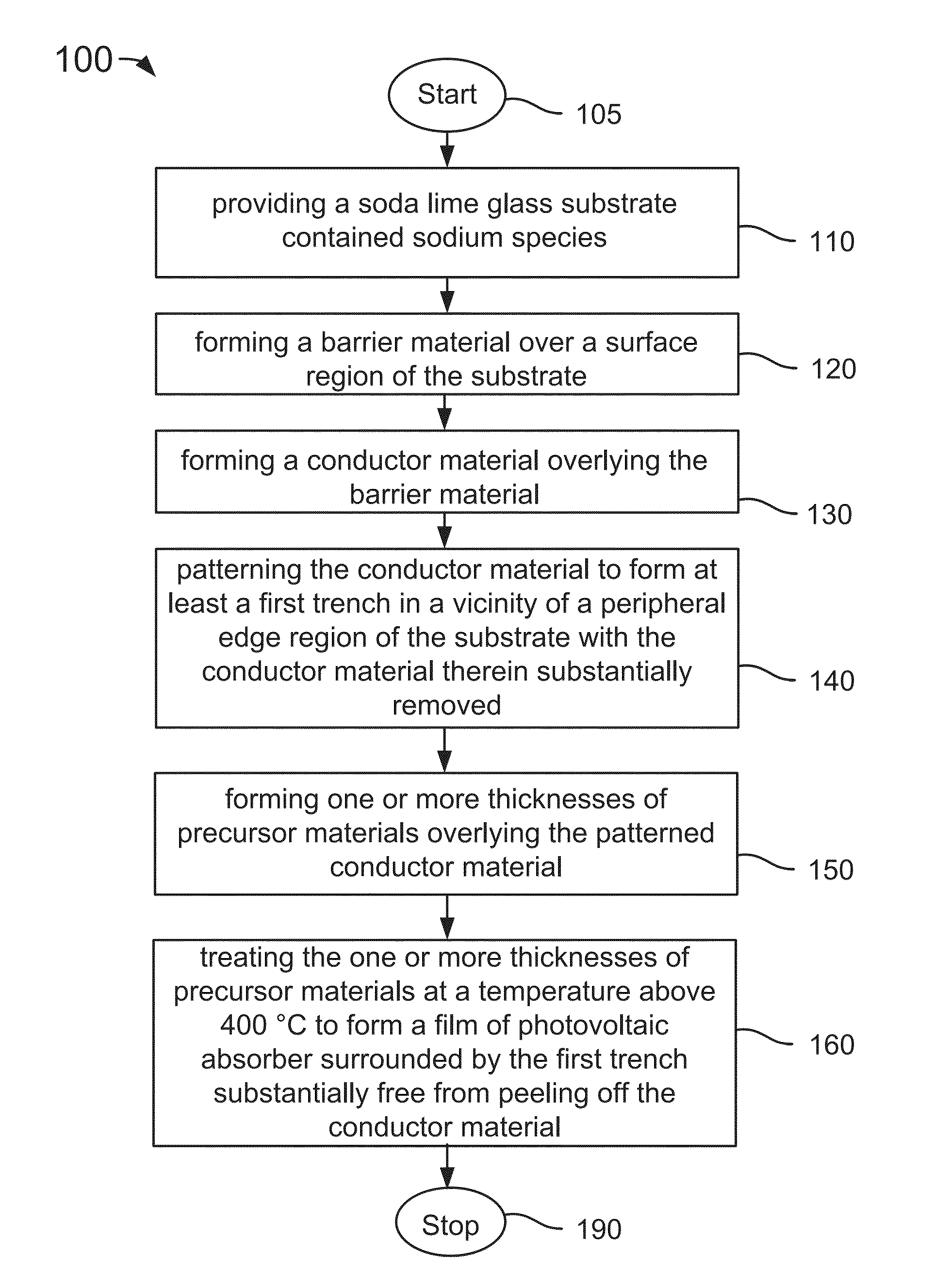

Method and structure for eliminating edge peeling in thin-film photovoltaic absorber materials

InactiveUS20130306150A1Eliminate peelingPrevent peelingFinal product manufactureSemiconductor/solid-state device manufacturingElectrical conductorOptoelectronics

A method for manufacturing a thin-film photovoltaic device includes providing a glass substrate contained sodium species. The glass substrate comprising a surface region and a peripheral edge region surround the surface region. The method further includes forming a barrier material overlying the surface region and partially overlying the peripheral edge region and forming a conductor material overlying the barrier material. Additionally, the method includes forming at least a first trench in a vicinity of the peripheral edge region to remove substantially the conductor material therein and forming precursor materials overlying the patterned conductor material. Furthermore, the method includes thermally treating the precursor materials to transform the precursor materials into a film of photovoltaic absorber. The first trench is configured to maintain the film of photovoltaic absorber substantially free from peeling off the conductor material.

Owner:CM MFG

Quartz damage repair method for high-end mask

InactiveUS7045256B2Improve repair accuracyEliminate peelingPhotomechanical apparatusSemiconductor/solid-state device manufacturingIon beamDamage repair

Owner:TAIWAN SEMICON MFG CO LTD

Method of forming a conductive contact

InactiveUS20060246714A1Improve mechanical propertiesNo impact on its conductive propertySemiconductor/solid-state device detailsSolid-state devicesHigh concentrationSemiconductor structure

Conductive contacts in a semiconductor structure, and methods for forming the conductive components are provided. The method comprises depositing a conductive material over a substrate to fill a contact opening, removing excess material from the substrate leaving the contact within the opening, and then heating treating the contact at a high temperature, preferably with a rapid thermal anneal process, in a reactive gas to remove an undesirable component from the contact, for example, thermal annealing a TiCl4-based titanium nitride in ammonia to remove chlorine from the contact, which can be corrosive to an overlying aluminum interconnect at a high concentration. The contacts are useful for providing electrical connection to active components in integrated circuits such as memory devices. In an embodiment of the invention, the contacts comprise boron-doped and / or undoped TiCl4-based titanium nitride having a low concentration of chlorine. Boron-doped contacts further possess an increased level of adhesion to the insulative layer to eliminate peeling from the sidewalls of the contact opening and cracking of the insulative layer when formed to a thickness of greater than about 200 angstroms in a high-aspect-ratio opening.

Owner:MICRON TECH INC

Low temperature process for TFT fabrication

Method of fabricating a thin-film transistor (TFT) in which a gate metal is deposited onto a substrate in order to form the gate of the thin-film transistor. The substrate may be an insulative substrate or a color filter. In a first method, the gate metal is subjected to an H2 plasma. After subjecting the gate metal to an H2 plasma, the gate insulating film is deposited onto the gate. In a second method, first and second layers of gate insulating film are respectively deposited on the gate at a first and second deposition rates. One layer is deposited under H2 or argon dilution conditions and has improved insulating conditions while the other layer serves to lower the overall compressive stress of the dual layer gate insulator. In a third method, an n+ silicon film is formed on a substrate by maintaining a flow of silane, phosphine and hydrogen gas into a processing chamber at substrate temperatures of about 300° C. or less.

Owner:APPLIED MATERIALS INC

Heat-insulation magnesium casting material and preparation method thereof

The invention relates to a heat-insulation magnesium casting material and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps: evenly mixing 20-50 wt% of magnesite, 33-63 wt% of mesitite, 0.9-7 wt% of silicon dioxide fine powder, 0.1-2 wt% of sodium polyphosphate and 3-8 wt% of water, thereby obtaining the heat-insulation magnesium casting material. The magnesite is more than one of fused magnesite grains, sintered magnesite grains, fused magnesite fine powder and sintered magnesite fine powder. The invention has the advantages of abundant raw material storage and simple preparation technique; and the prepared heat-insulation magnesium casting material basically has no crack or peel phenomenon, has the advantages of low heat conductivity, high strength, strong alkaline dust and slag corrosion resistance, high melting point and strong alkaline solid and gas slag corrosion resistance, and is beneficial to energy saving and consumption reduction. The heat-insulation magnesium casting material provided by the invention is suitable for liners of high-temperature industrial kilns and containers.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com