Composite polymer emulsion high-strength interface agent for vitrified brick and preparation thereof

A polymer emulsion and composite technology, applied in the field of interface agent, can solve the problems of high density, difficulty in laying vitrified tiles, low water absorption, etc., achieve high-strength adhesion, solve stability, and improve compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

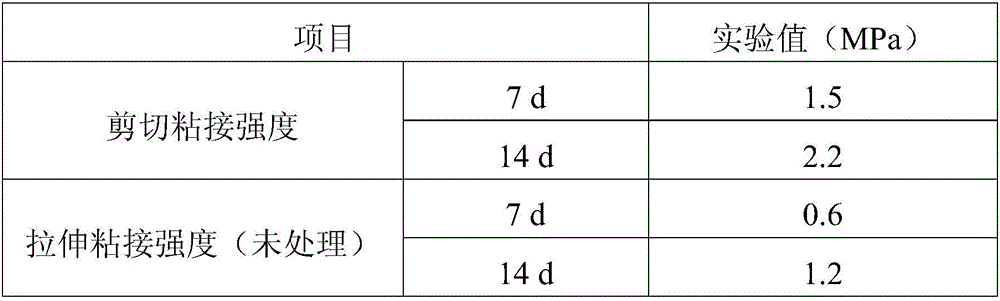

Embodiment 1

[0026] A composite polymer emulsion high-strength interface agent suitable for vitrified tiles, including the following components by mass fraction: 65% of small particle size styrene-acrylic emulsion; 20% of pure acrylic emulsion; 10% of small particle size styrene-butadiene emulsion; Efficacy agent 0.3%; dispersant 0.1%; wetting agent 0.5%; the rest water.

[0027] Wherein, the concentration of the small particle diameter styrene-acrylic emulsion is 55wt%, and the particle diameter scope of the small particle diameter styrene-acrylic emulsion is preferably between 30~60nm; The diameter range is preferably between 50 and 120nm; the dispersant is 5040; the wetting agent is LCN407; the synergist: including 15wt% D-mannose, 30wt% wetting and viscosifying agent SM-20, 10wt% D-glucose It is obtained by mixing uronic acid, 1.0 wt% pyruvic acid and the rest being water.

[0028] Mix the above components evenly to obtain a composite polymer emulsion high-strength interface agent sui...

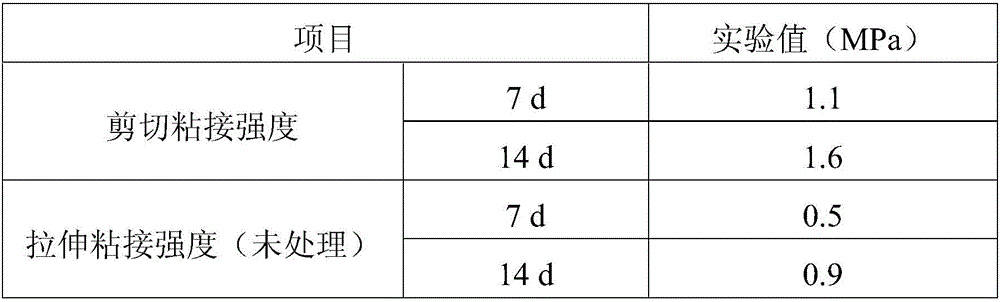

Embodiment 2

[0034] A composite polymer emulsion high-strength interface agent suitable for vitrified tiles, including the following components by mass fraction: 45% of small particle size styrene-acrylic emulsion; 20% of pure acrylic emulsion; 10% of small particle size styrene-butadiene emulsion; Efficacy agent 0.3%; dispersant 0.1%; wetting agent 0.5%; the rest water.

[0035] Wherein, the concentration of the small particle diameter styrene-acrylic emulsion is 55wt%, and the particle diameter scope of the small particle diameter styrene-acrylic emulsion is preferably between 30~60nm; The diameter range is preferably between 50 and 120nm; the dispersant is 5040; the wetting agent is LCN407; synergist: including 20wt% D-mannose, 25wt% wetting and tackifier, 10wt% D-glucuronic acid , 1.5wt% pyruvic acid, and the rest are obtained by mixing components of water.

[0036] Mix the above components evenly to obtain a composite polymer emulsion high-strength interface agent suitable for vitrif...

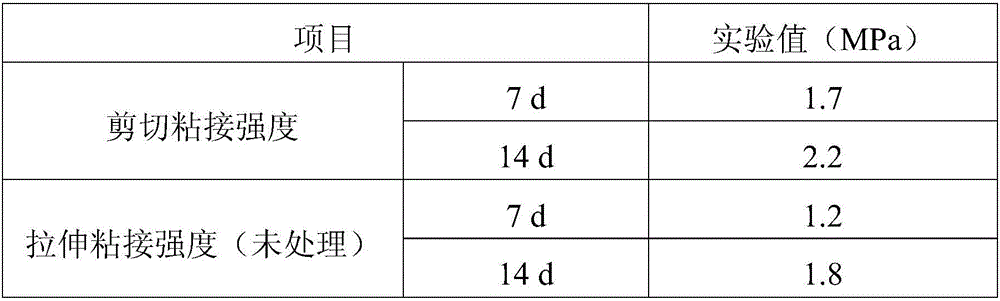

Embodiment 3

[0043] A composite polymer emulsion high-strength interface agent suitable for vitrified tiles, including the following components by mass fraction: 55% of small particle size styrene-acrylic emulsion; 20% of pure acrylic emulsion; 8% of small particle size styrene-butadiene emulsion; Efficacy agent 0.3%; dispersant 0.1%; wetting agent 0.5%; the rest water.

[0044]Wherein, the concentration of the small particle diameter styrene-acrylic emulsion is 55wt%, and the particle diameter scope of the small particle diameter styrene-acrylic emulsion is preferably between 30~60nm; The diameter range is preferably between 50 and 120nm; the dispersant is 5040; the wetting agent is LCN407; synergist: including 18wt% D-mannose, 27wt% wetting and tackifier, 15wt% D-glucuronic acid , 1.2wt% pyruvic acid, and the rest are water.

[0045] Mix the above components evenly to obtain a composite polymer emulsion high-strength interface agent suitable for vitrified tiles.

[0046] Paint it direc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com