Glass microballoon with dual-layer function membrane

A technology of glass microbeads and functional film, applied in the field of glass microbeads, can solve the problems of increasing the consumption of traffic signs and other markers, poor binding force, short service life, etc., to eliminate peeling phenomenon, prolong service life, reduce The effect of production costs

Inactive Publication Date: 2008-10-15

單岩崑

View PDF0 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

There are two defects in the actual use of ordinary glass beads in markers: 1. Because glass beads have moisture absorption characteristics, they are prone to agglomeration after moisture absorption, and the glass beads cannot work normally after agglomeration. used; 2. existing glass microspheres have poor binding force with adhesives such as other glass microspheres and paints, especially only physically bonded and poorly bonded with environmentally friendly water-soluble marking paints. It is easy to peel off, causing traffic markings and other markers to lose their reflective function; 3. The existing markers such as traffic markings mixed with glass beads are easy to fall off due to glass beads, and their service life is short, thus increasing traffic markings, etc. The consumption of markers increases the cost of use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

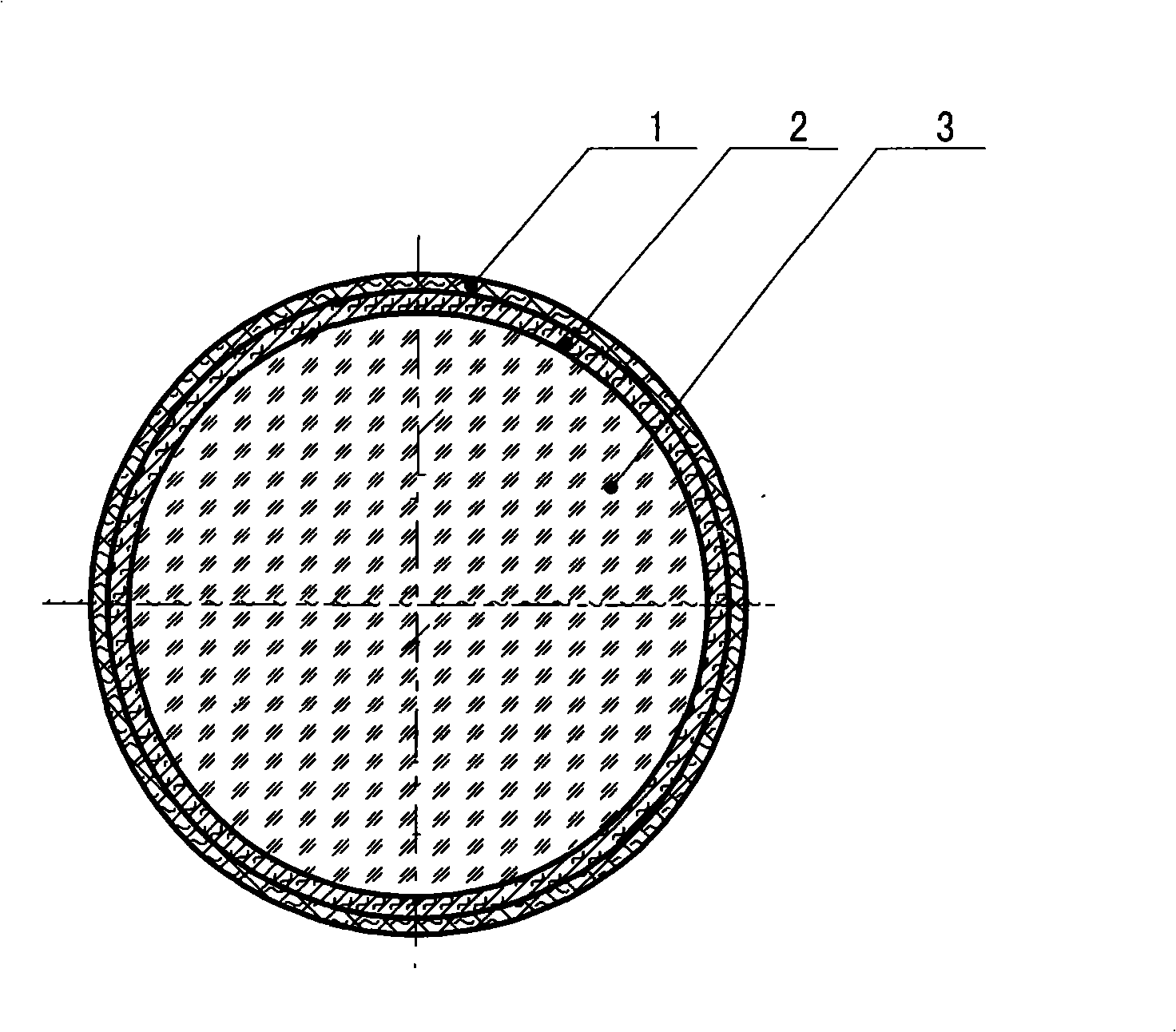

The invention relates to a glass bead with double-layer functional films, and is mainly and technically characterized in that the outer surface of the glass bead body is evenly coated with an inner layer of the functional film and an outer layer of the functional film, the inner layer of the functional film adopts organosilicon materials which have affinity toward the glass bead and adhesives such as oil paint, etc., and the outer layer of the functional film adopts organosilicon materials with hydrophobic performance. The invention forms double layers of the functional films with the unique function on the surface of the glass bead, so as to enable the glass bead to have efficacies of moisture proof and anti-caking, and the original pure physical binding of the glass bead and the substrate of markers such as traffic marker lines, etc., are changed into molecule bonding plus physical binding, thereby greatly improving the mutual binding force, prolonging the service life, reducing the manufacturing cost and being applicable to the combination with the environment friendly water-soluble marker paint. The technology fills the domestic blank, and reaches the international leading level.

Description

Glass beads with double-layer functional film technical field The invention relates to a glass microsphere with reflective effect applicable to the field of traffic safety, in particular to a glass microsphere with a double-layer functional film. Background technique In order to enhance the reflective effect of markers (such as reflective signboards, traffic sign lines, etc.), glass beads are usually evenly added to the matrix of markers. The purpose is to use the reflective properties of glass beads to improve the reflective performance of markers. At present, the glass microspheres commonly used are solid glass spheres made of ordinary glass materials and their diameters are about 50-1000 μm. There are two defects in the actual use of ordinary glass beads in markers: 1. Because glass beads have moisture absorption characteristics, they are prone to agglomeration after moisture absorption, and the glass beads cannot work normally after agglomeration. used; 2. existing gl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03C17/34C03C17/32C09K9/00

Inventor 單岩崑

Owner 單岩崑

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com