Patents

Literature

37results about How to "Avoid peeling off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

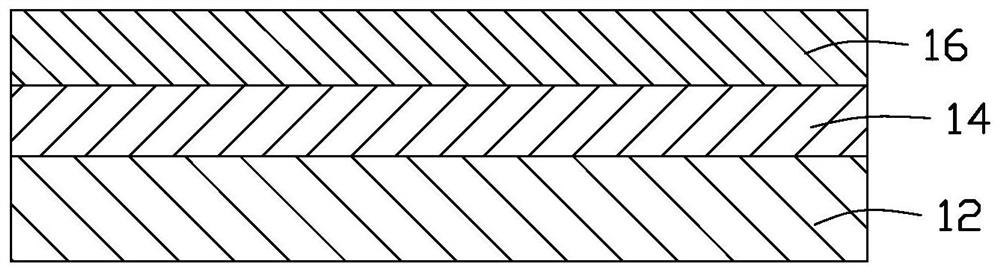

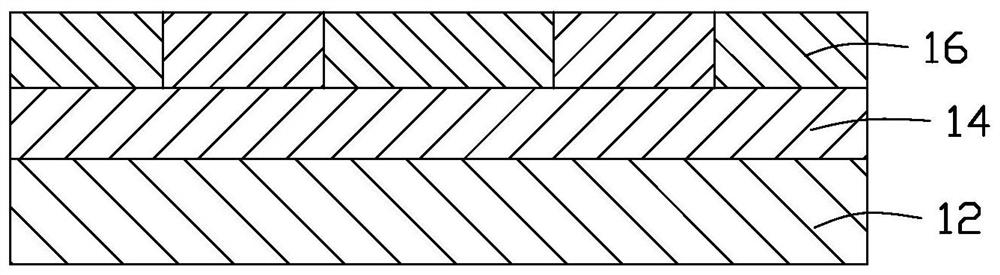

Multifunctional graphene electrothermal paste, multifunctional electrothermal film prepared by same, preparation method and application

ActiveCN107682943AImprove machinabilityFast heat conductionChemical industryHeating element materialsCross-linkAviation

The present invention discloses multifunctional graphene electrothermal paste, a multifunctional electrothermal film prepared by the same, a preparation method and application. The preparation methodcomprises the following steps that: (1) graphene nanoplatelets are modified by introducing inducible lipidation and cross-linking reaction groups; (2) the modified graphene, a lipidizable and cross-linking reaction emulsion and various kinds of additives are subjected to liquid phase mixing, the above dispersion liquid is induced to undergo in-situ esterification and cross-linking reaction, so that graphene-based homogeneous electrothermal paste can be formed; (3) an electrothermal paste loading matrix is modified, so that the interfacial property of the electrothermal paste and the matrix material can be enhanced; and (4) the graphene electrothermal paste can be combined with different base materials, so that electrothermal products can be prepared. The graphene electrothermal material ofthe invention has the advantages of adjustable resistivity, adjustable use voltage, adjustable heating efficiency, far infrared heating function, flame retardancy, wide application range, high safety, energy-saving performance and the like, and can be applied to home building material manufacturing, human body care, aviation equipment, medical equipment, transportation pipelines, automobiles andother fields.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

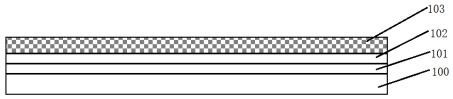

Passivation layer of IC chip

ActiveCN101304023AAvoid peeling offImprove yieldSemiconductor/solid-state device detailsSolid-state devicesSilicon dioxideMetal

The invention provides a passivant layer of an integrated circuit chip, which comprises at least a first silicon dioxide layer and a silicon nitride layer, wherein the first silicon dioxide is positioned under the silicon nitride layer; the invention is characterized in that the passivant layer also comprises a second silicon dioxide layer which is positioned between the first silicon dioxide layer and the silicon nitride layer. The passivant layer of the invention can effectively avoid a peeling off and dropping off between the passivant layer and a metal layer, between the metal layer and a medium insulating layer, thus improving yield of integrated circuit chips.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

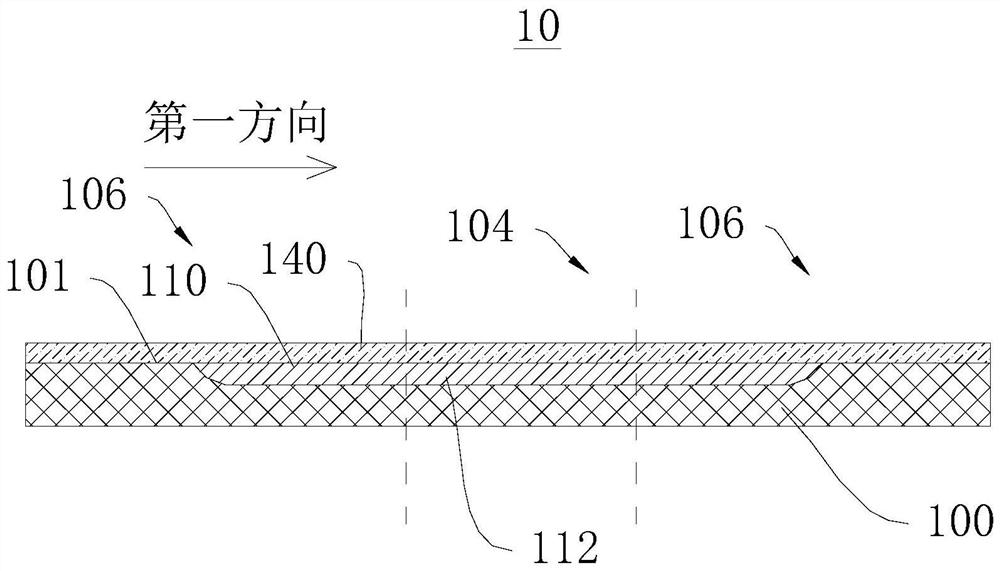

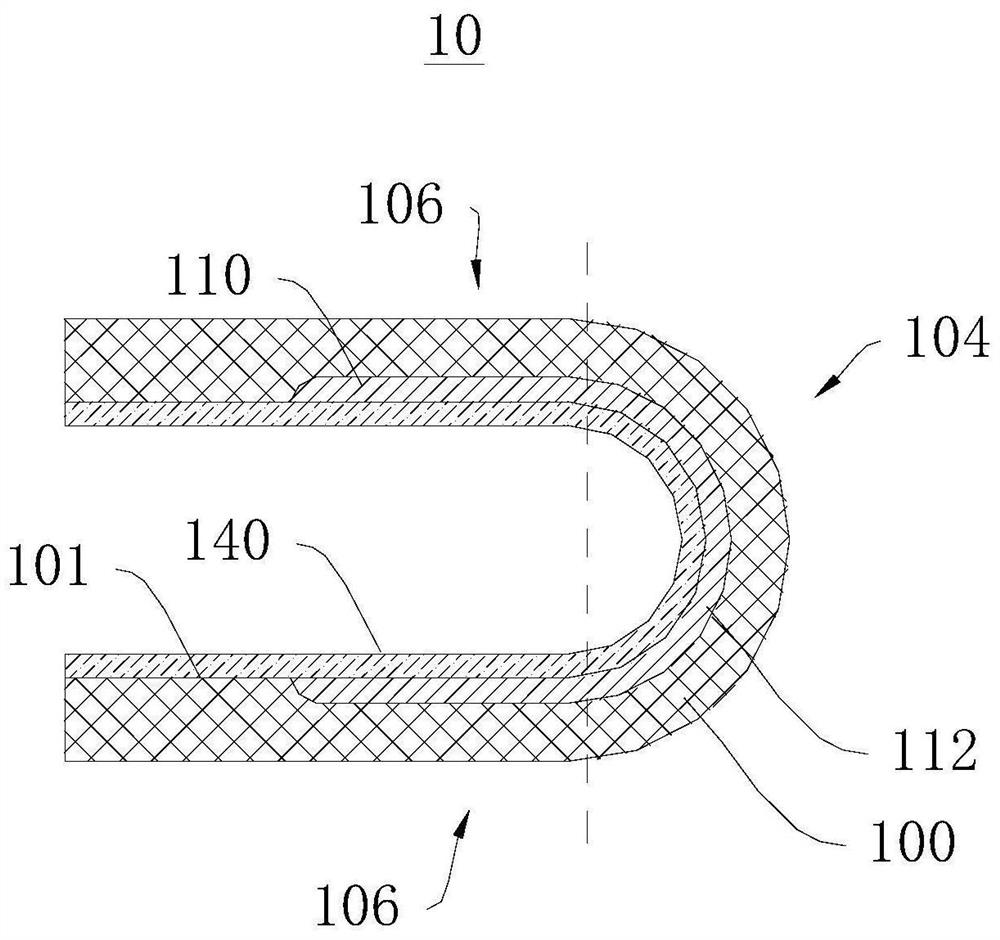

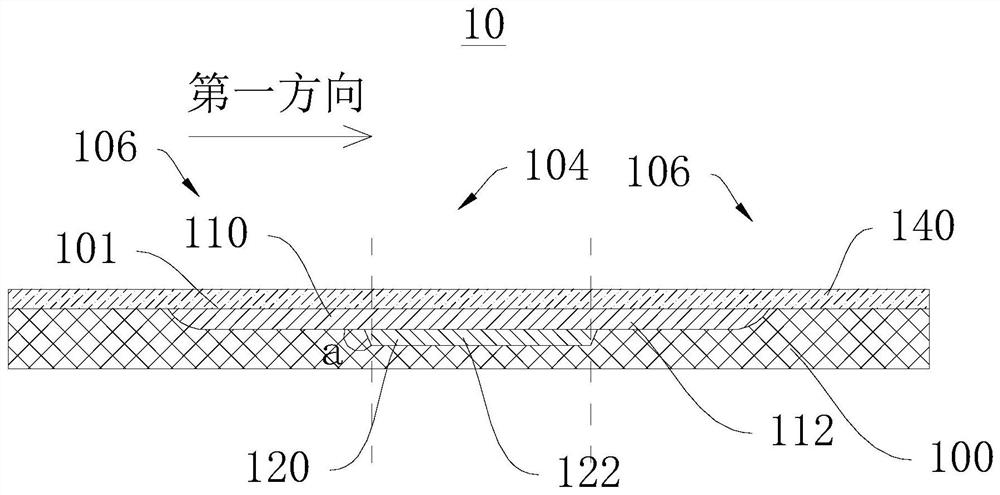

Folding cover plate and display device

PendingCN113888982AExtended service lifeAvoid peeling offIdentification meansDisplay deviceEngineering

The invention relates to a folding cover plate and a display device. A first surface of a substrate is provided with a first groove in a bending area. When the folding cover plate is in a horizontal unfolding state, the maximum width of the first groove is larger than the width of the bending area in the first direction. At least one of the two ends of the first groove is located in the non-bending area. The first flexible layer is arranged in the first groove. When the cover plate is bent and folded through the bending area, the curvature radius corresponding to the bending area is decreased. And the deformation of the part of the first flexible layer in the bending area is greater than the deformation of the part of the first flexible layer in the non-bending area. In the first direction, at least one of the two ends of the first flexible layer is located in the non-bending area. At least one of the two ends of the first groove is located in the non-bending area, so that the situation that at least one of the two ends, located at the first groove, of the first flexible layer is stripped and falls off from the first groove in the repeated bending process of the folding cover plate can be prevented, and therefore the service life of the folding cover plate is prolonged.

Owner:HEFEI VISIONOX TECH CO LTD

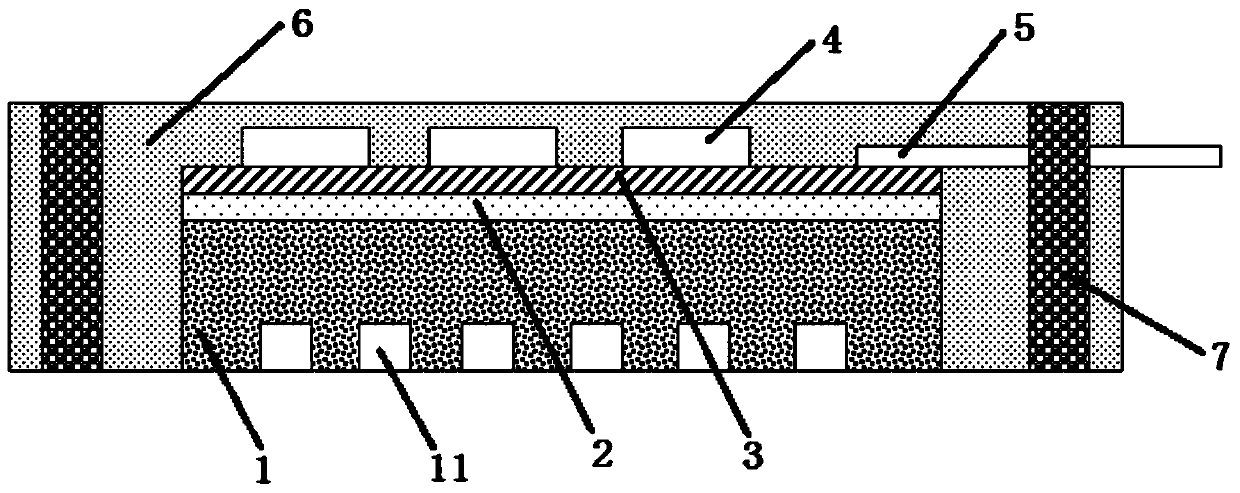

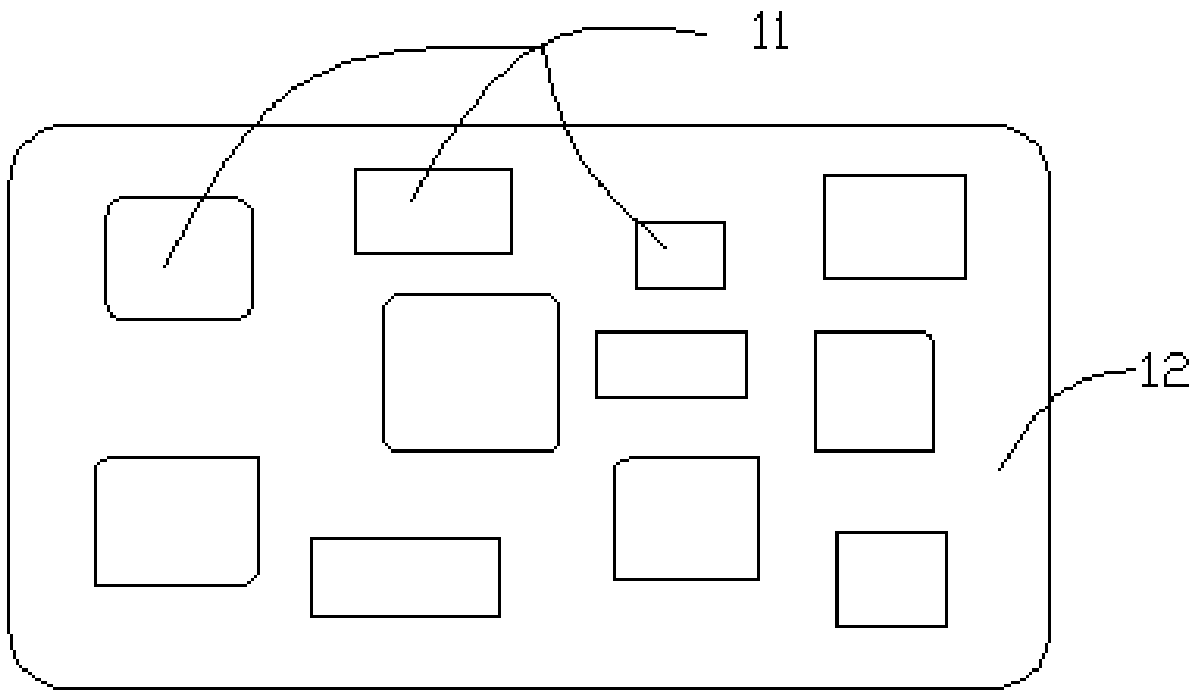

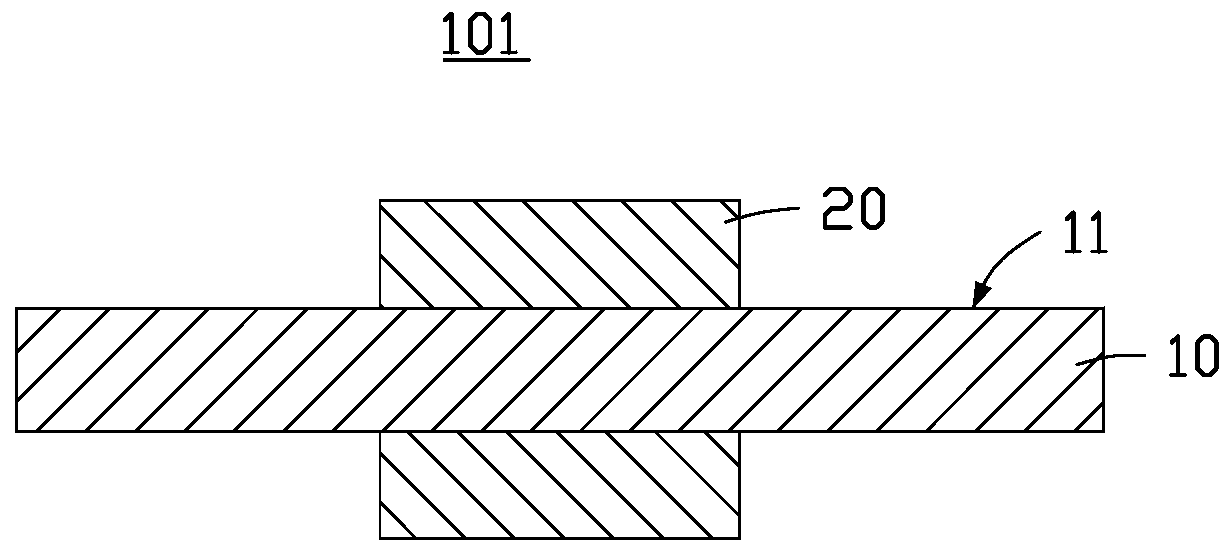

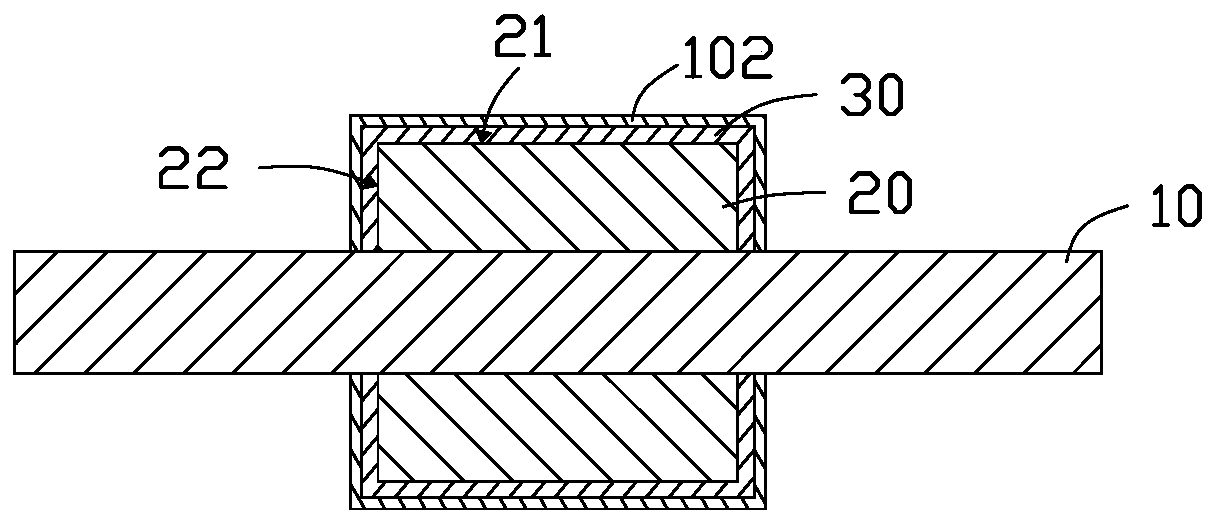

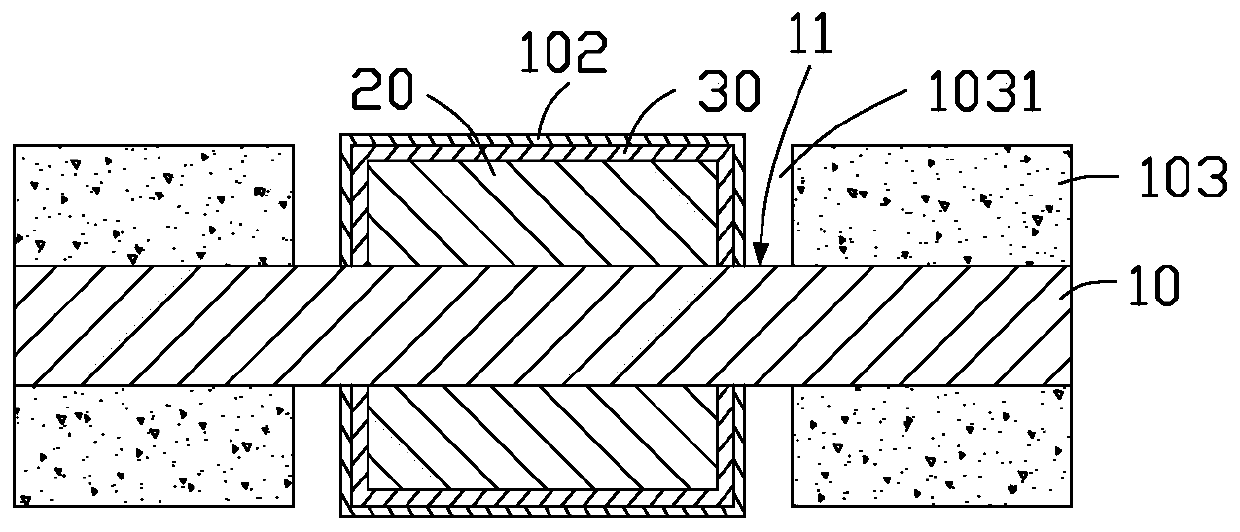

Packaging component and preparation method thereof

ActiveCN111341739AAvoid peeling offImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesHemt circuitsEngineering

The invention relates to a packaging component and a preparation method thereof. The method comprises the following steps of providing a heat dissipation substrate, and etching the second surface of the heat dissipation substrate to form a plurality of concave holes; forming an insulating layer and a circuit wiring layer on the first surface of the heat dissipation substrate; mounting a pluralityof semiconductor elements and a plurality of conductive pins on the circuit wiring layer; forming a packaging colloid; forming a plurality of through holes at the periphery of the packaging colloid atintervals, wherein the through holes penetrate through the packaging colloid; providing a plurality of metal conductive columns, and forming a plurality of through holes penetrating through the metalconductive columns on the side surfaces of the metal conductive columns, embedding the plurality of metal conductive columns into the corresponding through holes respectively, and performing a thermal compression bonding process on the packaging colloid to enable part of the packaging colloid to be embedded into the through holes of the metal conductive columns.

Owner:深圳市之诺微电子有限公司

Circuit board and manufacturing method thereof

ActiveCN110049619AAvoid peeling offTightly boundPrinted circuit aspectsConductive pattern reinforcementOptoelectronicsCopper

Disclosed is a circuit board. The circuit board comprises a substrate, wherein the substrate has at least one first surface, and the circuit board further comprises a conductive body and a nickel layer, wherein the conductive body is combined with the first surface, and the nickel layer wraps the surface of the conductive body; the circuit board further comprises a non-metal conductive film and agold layer; the non-metal conductive film is combined on the first surface and is arranged adjacent to the nickel layer; and the gold layer wraps the nickel layer and the non-metal conductive film atthe same time. A dense protection interface formed by combining the gold layer and the non-metal conductive film is formed on the side surface, close to the substrate, of the nickel layer in the circuit board, so that corrosive gas can be effectively prevented from entering a gap between the nickel layer and the substrate, a nickel-gold interface and a nickel-copper interface can be effectively prevented from forming an original battery effect, and therefore the nickel layer and the electric conductor can be prevented from being corroded due to the original battery effect, and the gold layer can be effectively prevented from being stripped off. In addition, the invention further provides a manufacturing method of the circuit board.

Owner:QING DING PRECISION ELECTRONICS HUAIAN CO LTD +1

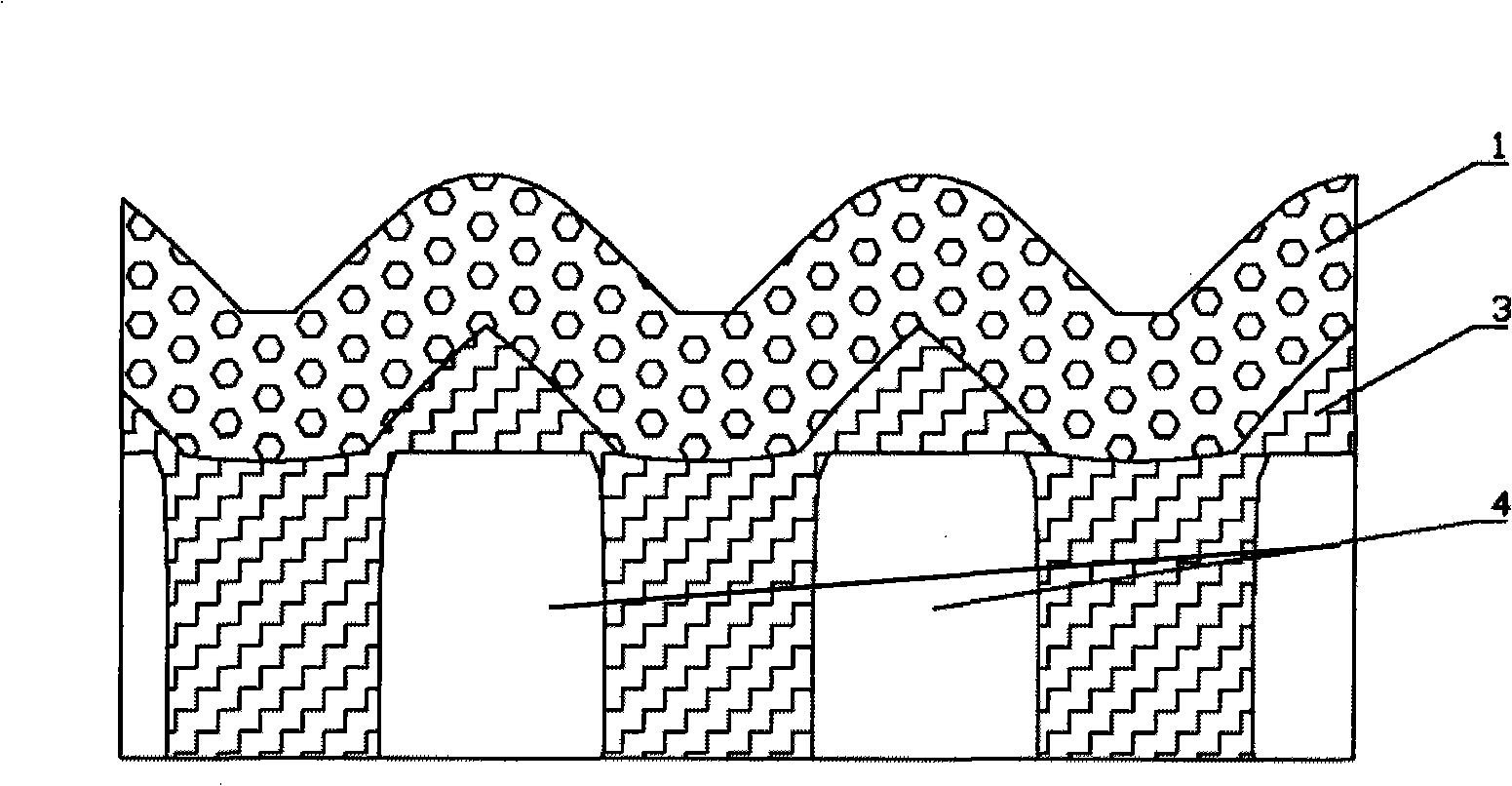

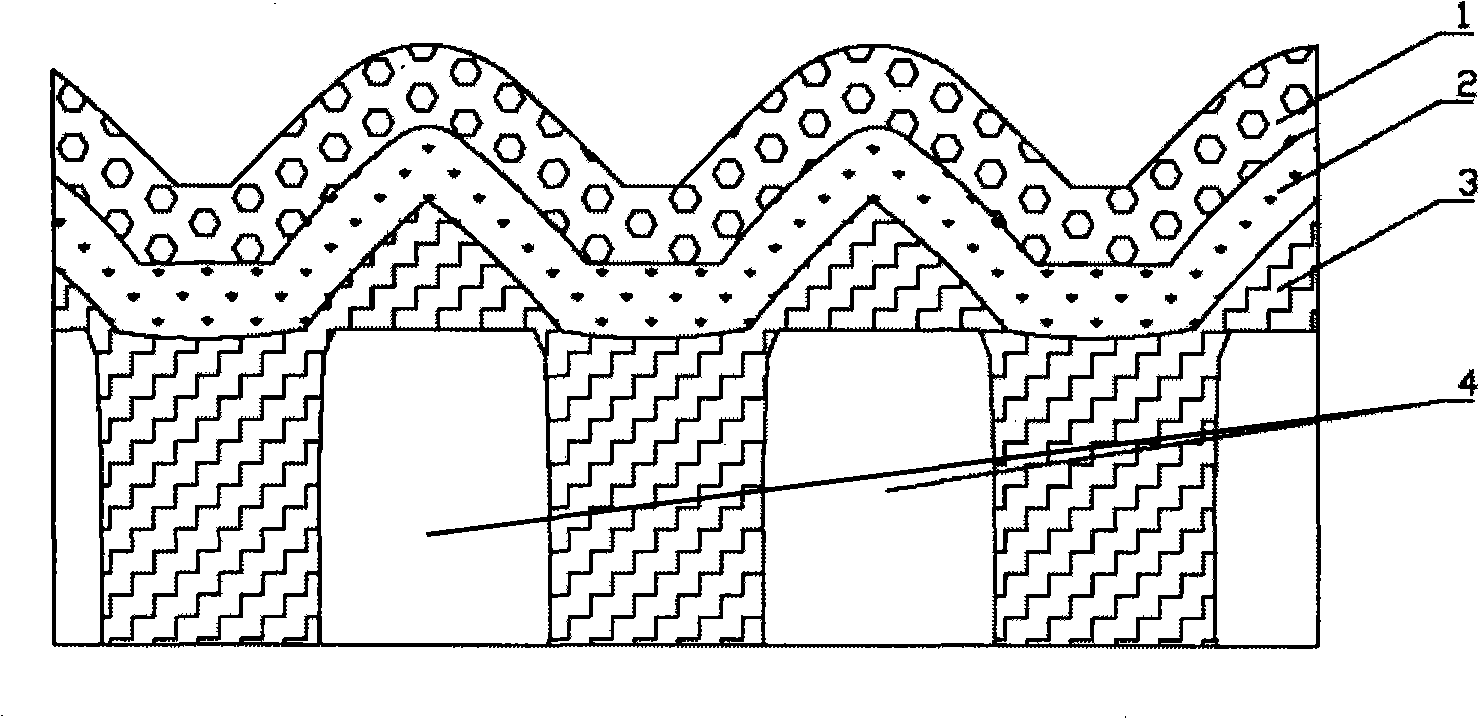

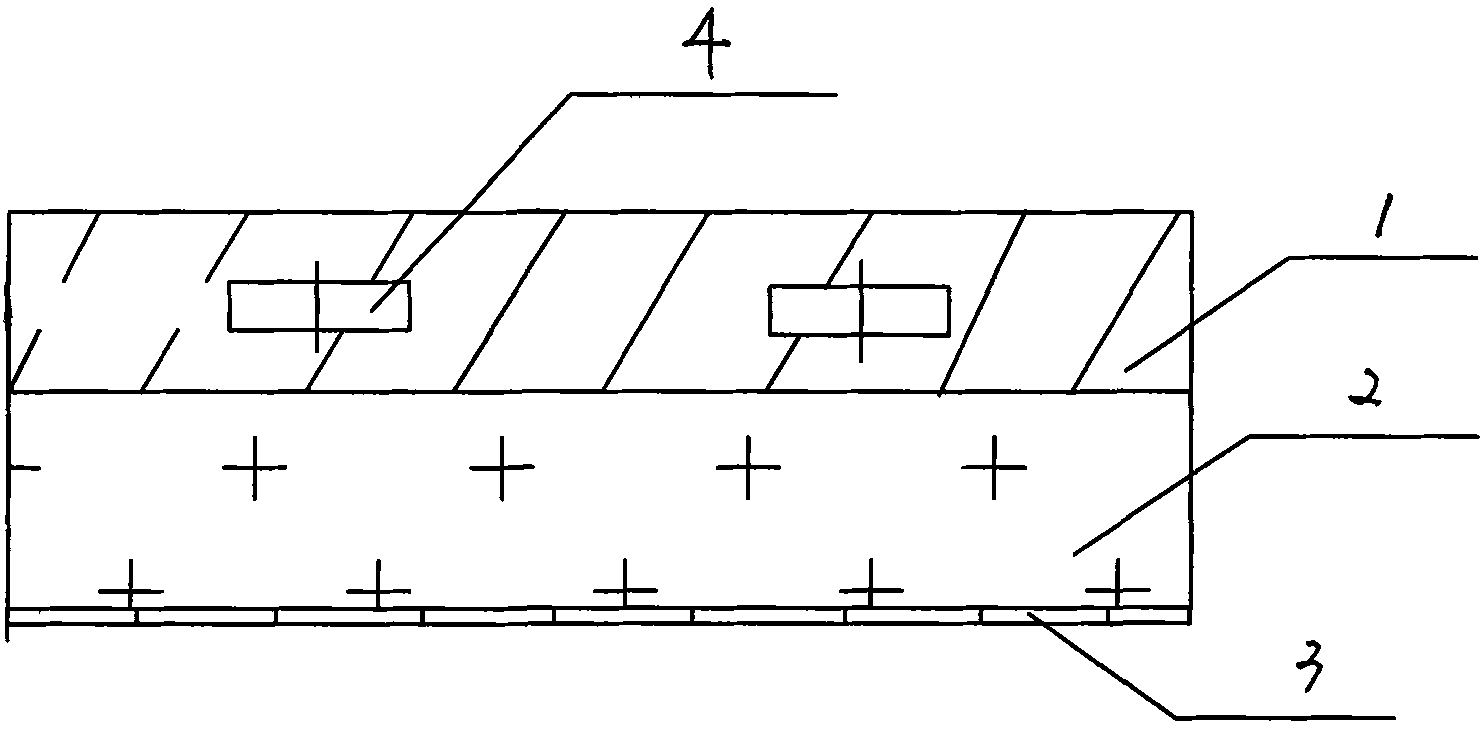

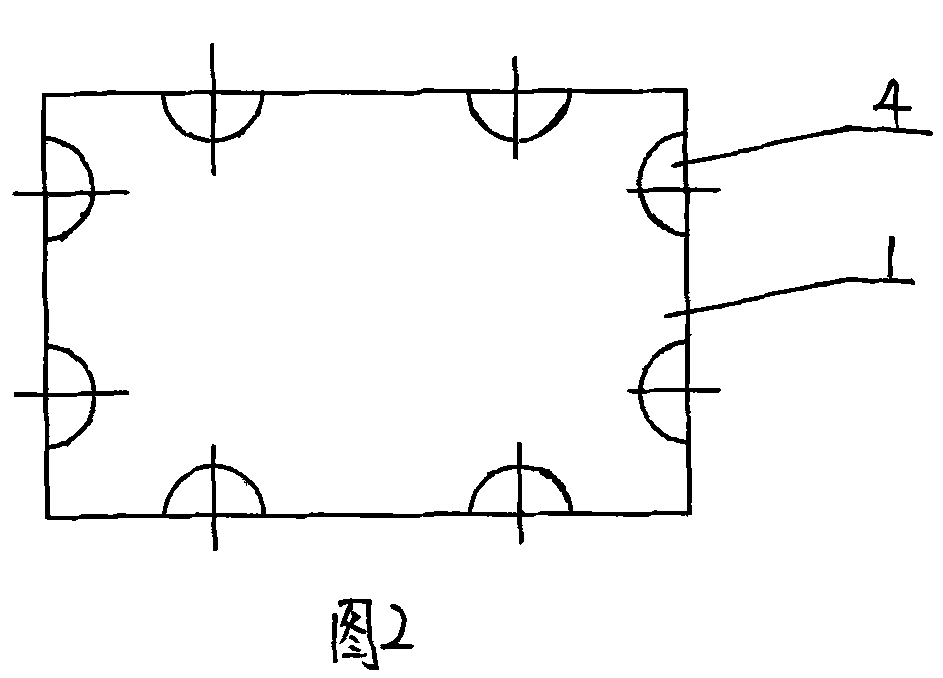

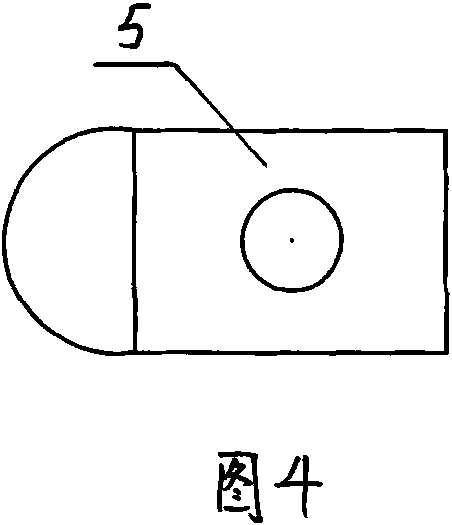

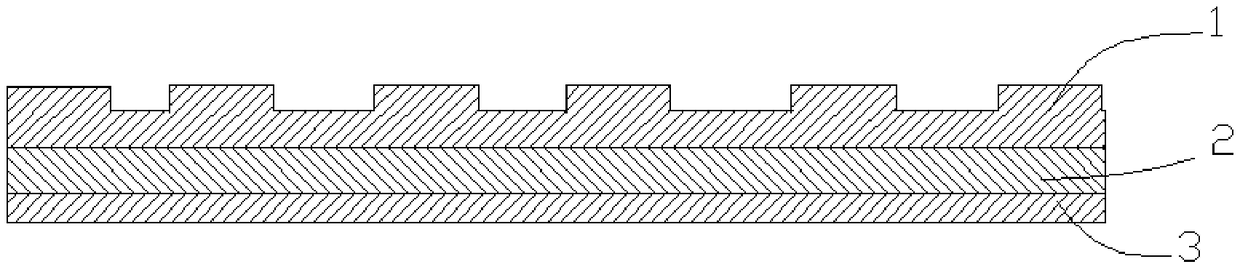

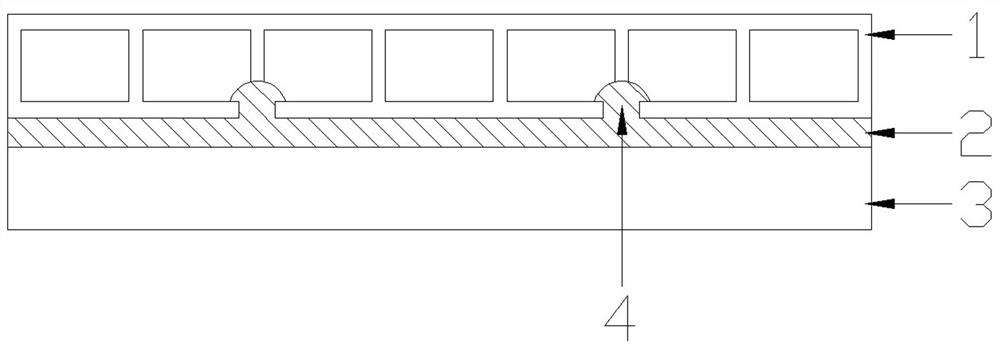

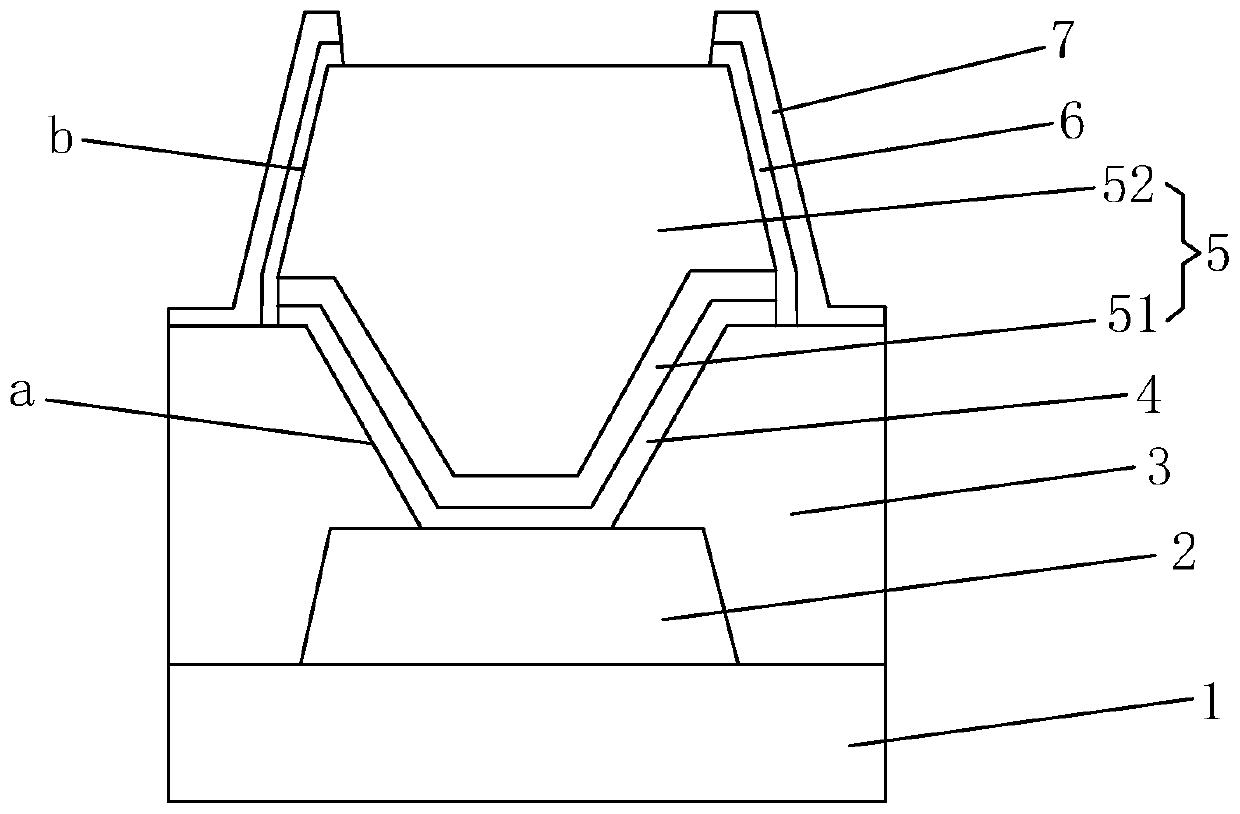

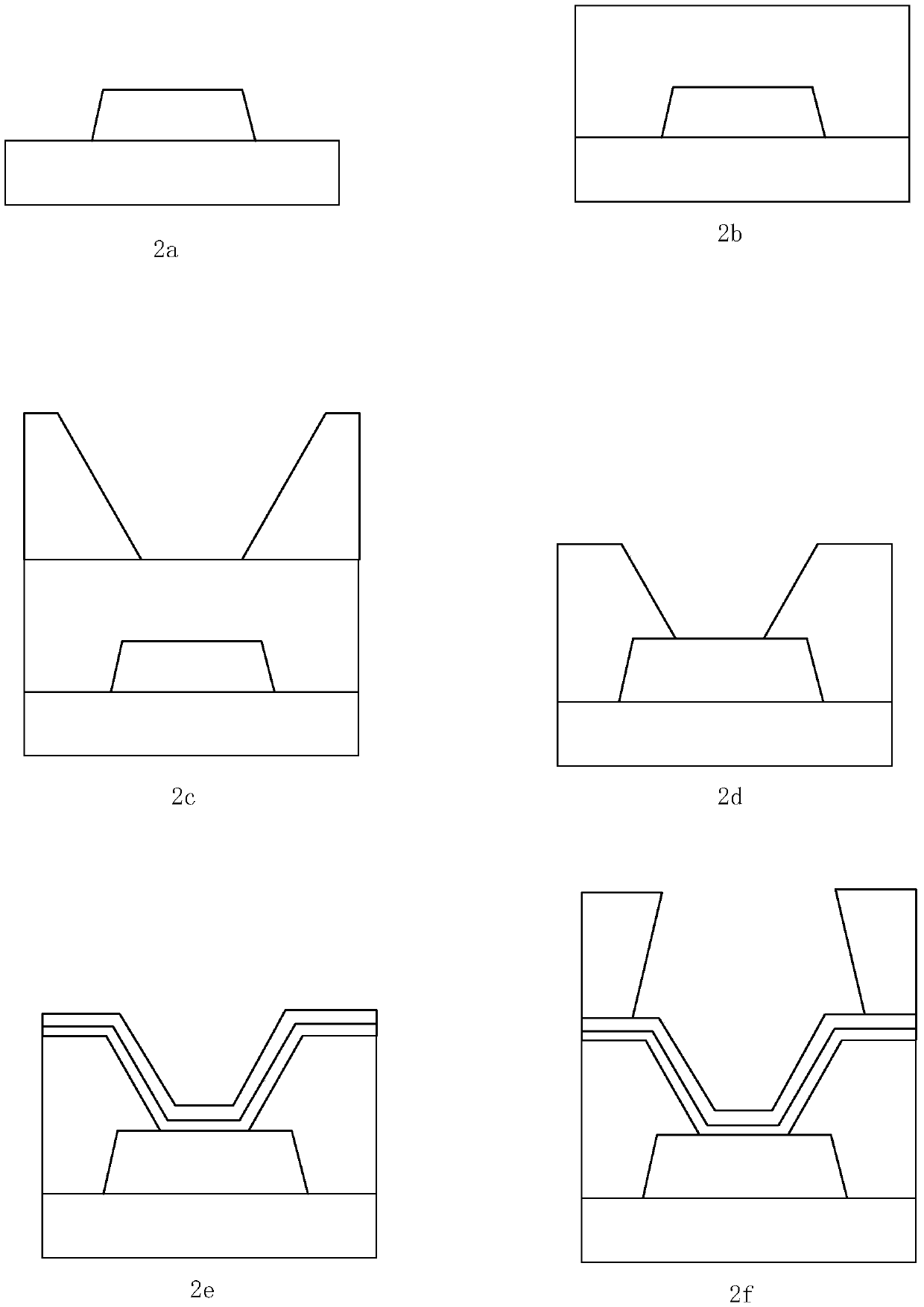

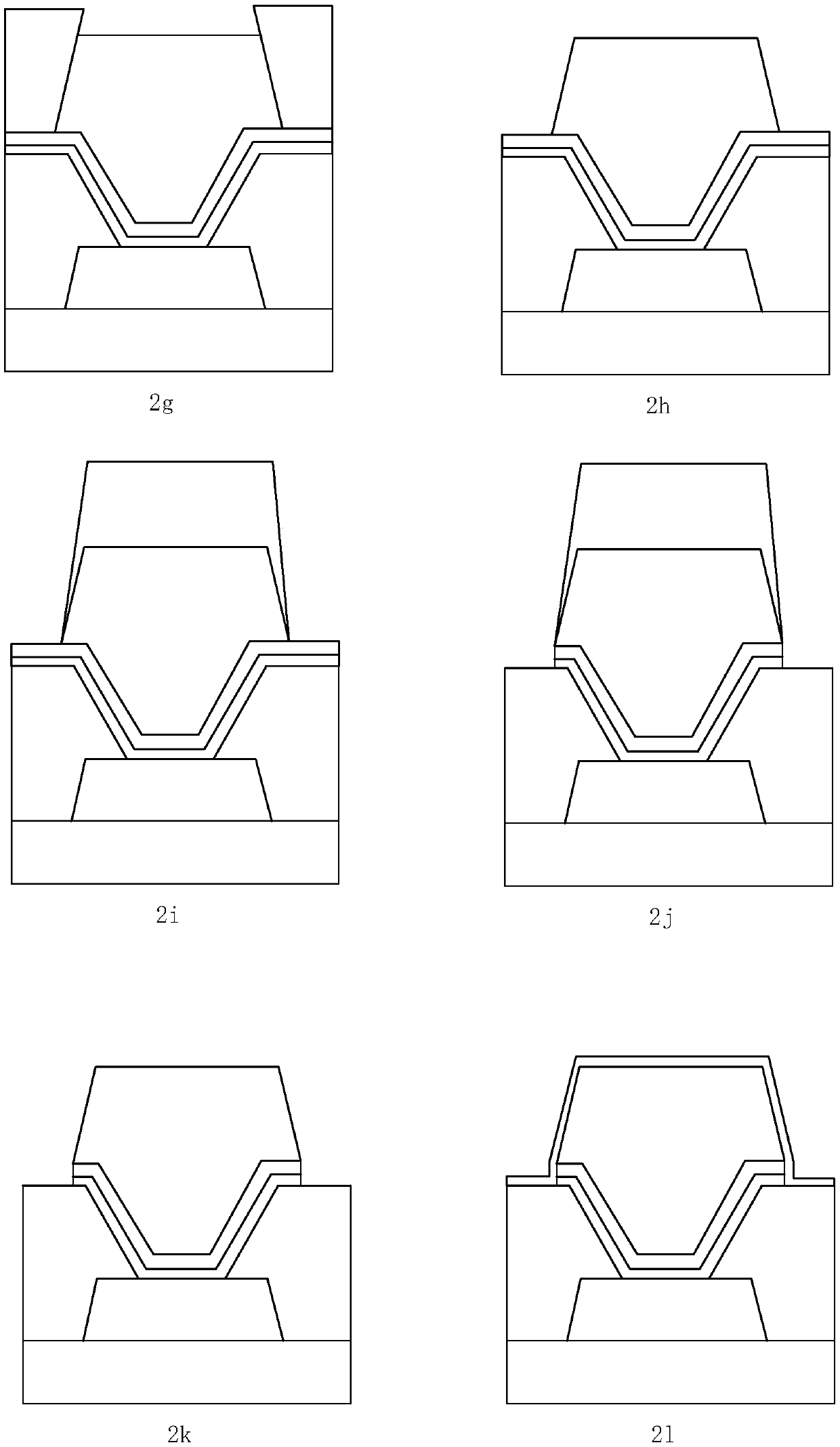

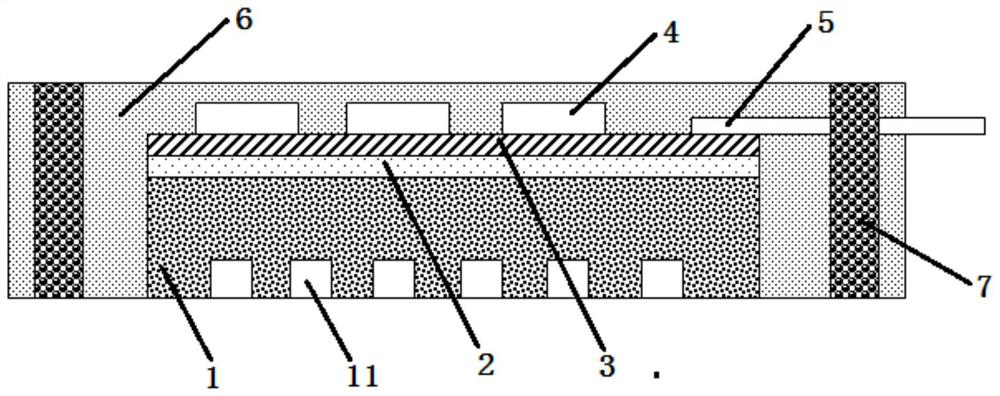

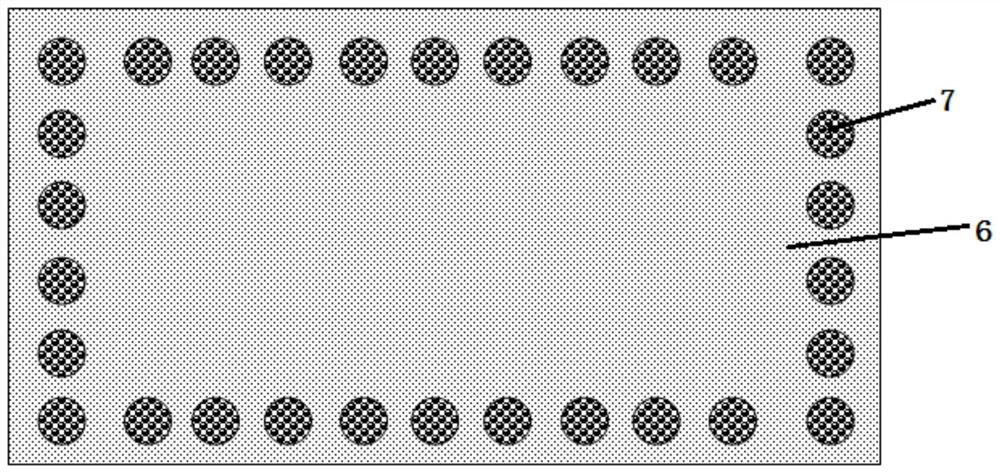

Decorative heat preservation composite board with lugs and construction method thereof

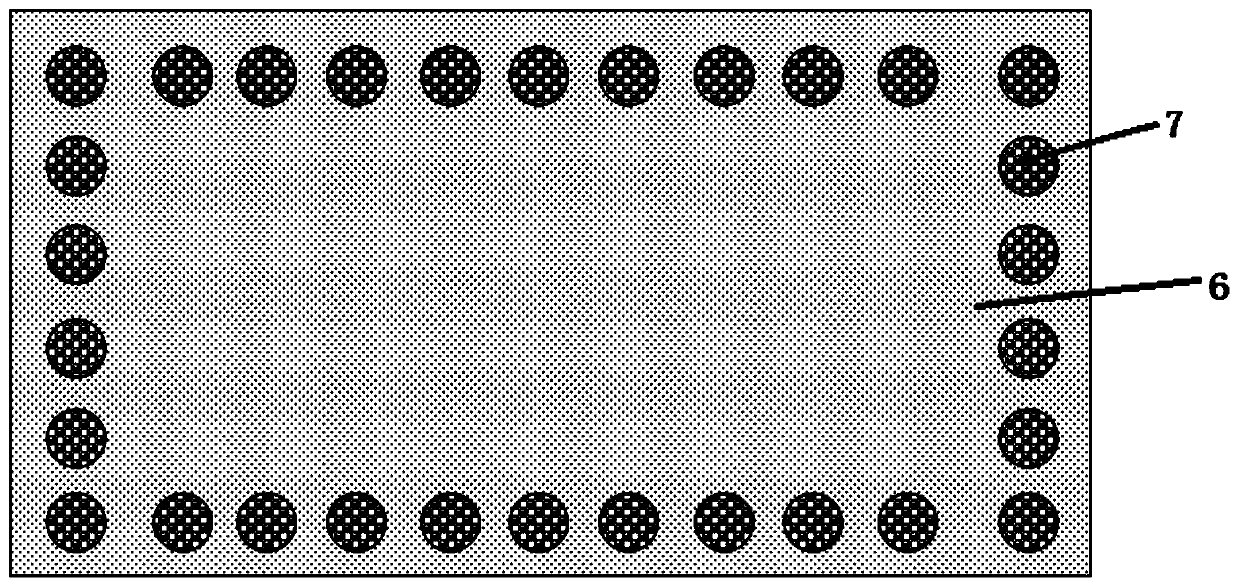

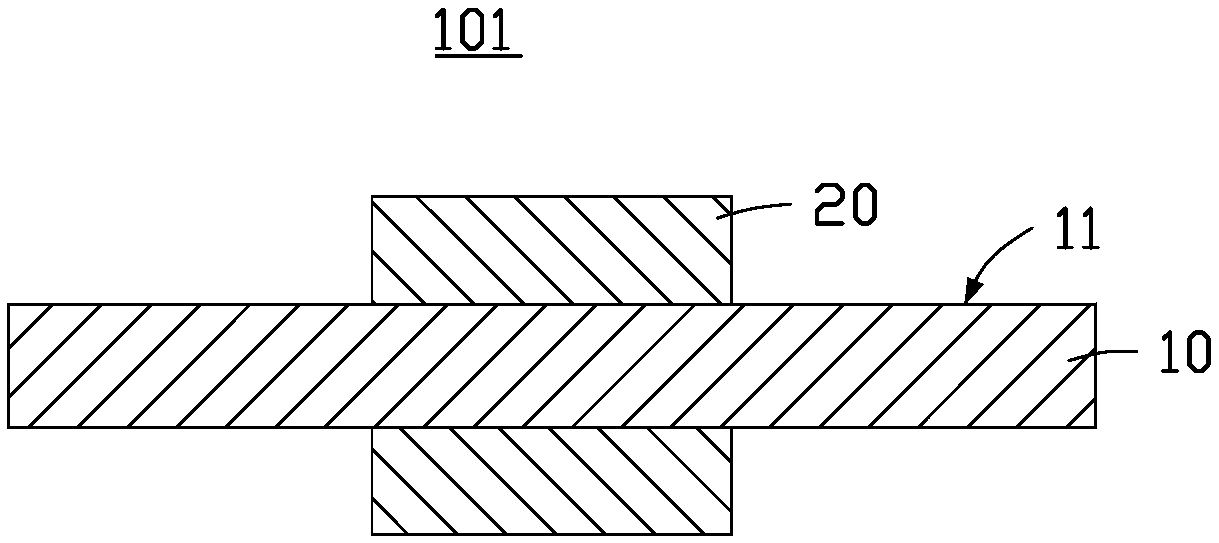

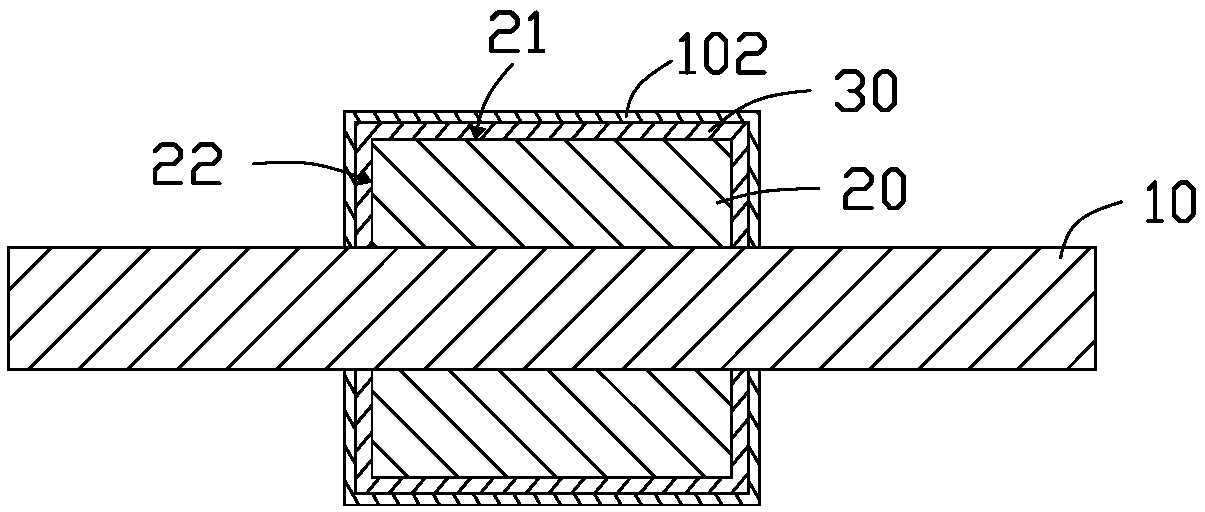

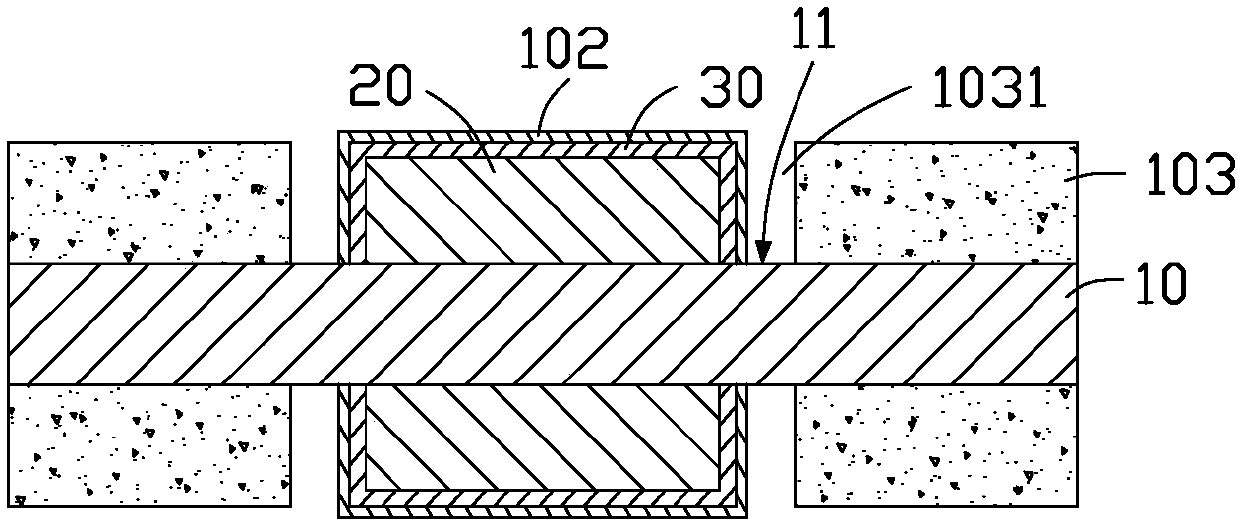

InactiveCN101349094BAvoid peeling offEliminates the problem of poor insulationCovering/liningsInterface layerWeather proofing

The invention discloses a decorative heat preservation compound plate provided with hanging ears and a construction method thereof. The compound plate comprises a facing layer(1), a heat preservation layer(2) and a reinforced interface layer(3), and the compound plate is formed by the combination of the three layers. The compound plate is characterized in that all side surfaces of the facing layer(1) are provided with hanging ear holes(4), and the hanging ears(5) are embedded in the hanging ear holes(4) and fixed on the facing layer(1) as a whole to form products. The construction method comprises the steps of the base wall treatment, gluing of the compound plate on the base wall surface, arrangement of a cold-hot bridge distance plate, the connection of base wall surfaces and the ear hanging, the filling of polyurethane rigid foams in between the adjacent compound plates for the melting-joint polyurethane welding and the filling of decorative weather proofing sealants in joints, etc., and the construction method also has the characteristics of simple construction, quickness and convenience and low cost, etc.

Owner:孟真

Fan-out package with antenna and preparation method thereof

ActiveCN114204249AAvoid peeling offImprove joint tightnessSemiconductor/solid-state device detailsAntenna supports/mountingsMetal nanowiresSemiconductor package

The invention relates to a fan-out package with an antenna and a preparation method thereof, and relates to the field of semiconductor package. The first antenna structure and the second antenna structure are formed in the first preset antenna pattern and the second preset antenna pattern in a mode of spin-coating the metal nanowire solution, and the implementation of the preparation process is convenient for improving the bonding tightness of the antenna structures and the flexible resin packaging layer, so that the antenna structures can be prevented from stripping and falling off. Furthermore, the first antenna structure and the second antenna structure are stacked and electrically connected with each other, so that the signal transmitting strength of the antenna structure or the signal receiving capability of the antenna structure is effectively improved, and the functionality of fan-out packaging is improved.

Owner:WEIHAI IDEACODS ELECTRONICS TECH CO LTD

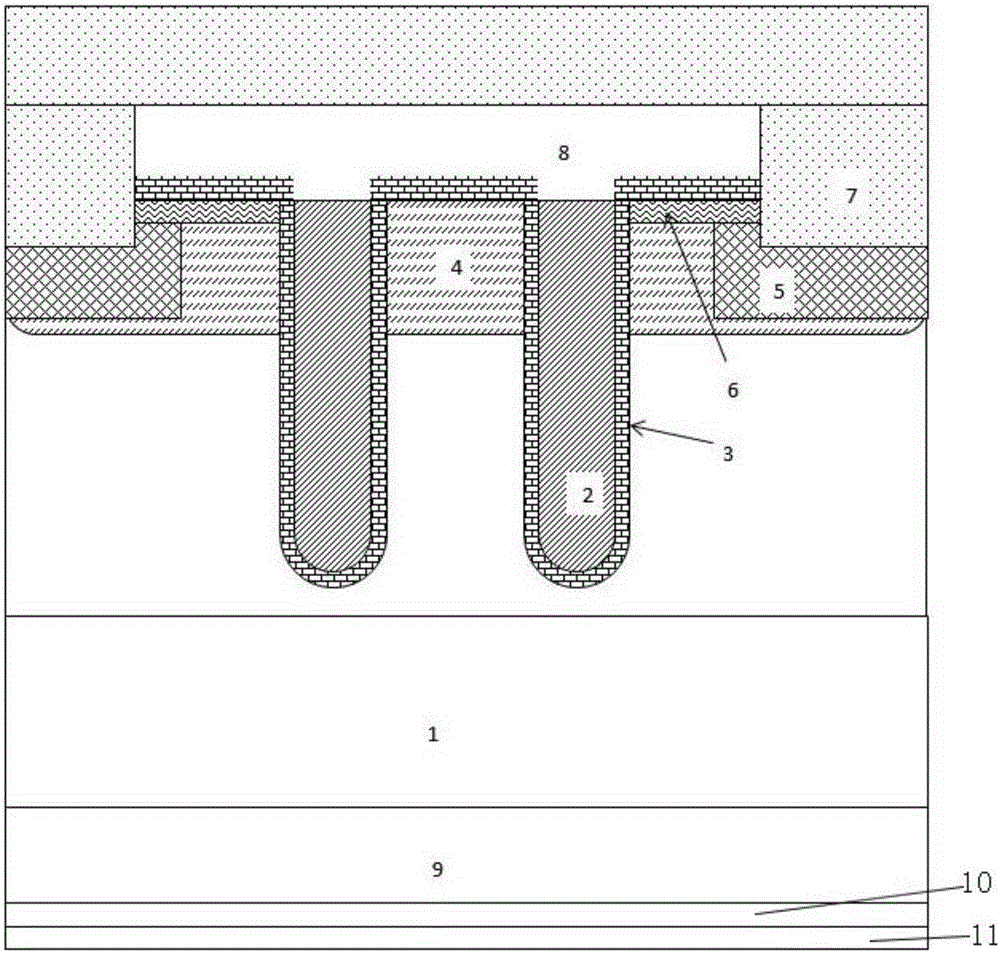

NAND memory and manufacturing method thereof

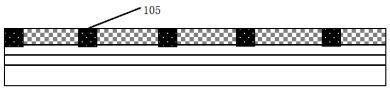

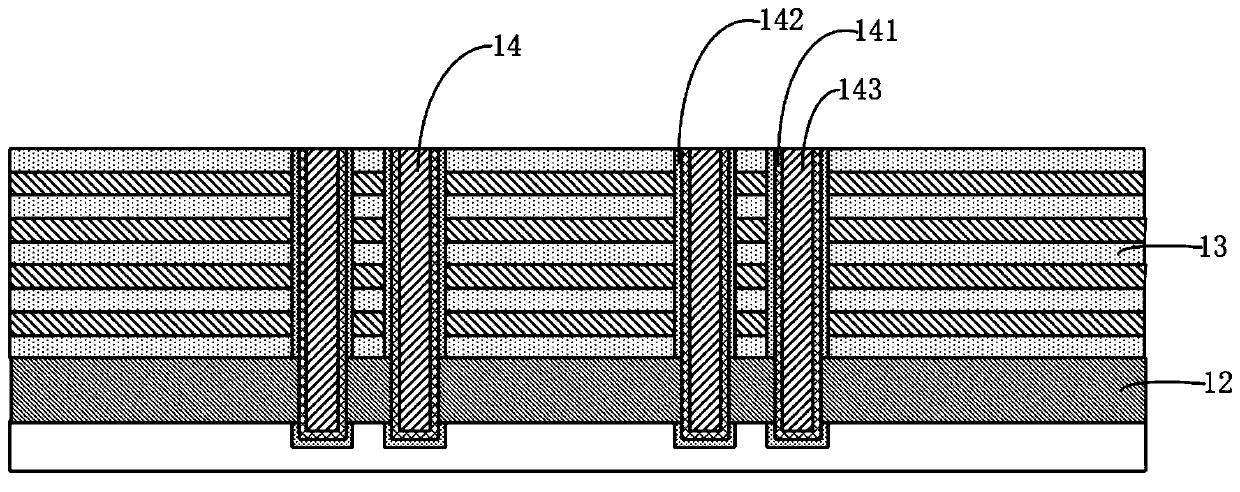

InactiveCN111048517AEnsure stabilityAvoid partial collapseSolid-state devicesSemiconductor devicesEngineeringSemiconductor

The invention relates to an NAND memory and a manufacturing method thereof. The manufacturing method comprises the following steps that: a first semiconductor layer is formed on a substrate; selectiveregion doping is performed on the first semiconductor layer, so that a doped region and a non-doped region located at the periphery of the doped region can be formed; a stack structure is formed on the first semiconductor layer which has been subjected to the selective region doping, wherein the stack structure comprises a plurality of sacrificial layers and a plurality of second insulating layers which are alternately stacked along a vertical direction; channel structures which penetrate through the stack structure and the non-doped region of the first semiconductor layer to directly reach the substrate are formed, wherein each channel structure comprises a second semiconductor layer and a storage function layer; grid line gaps passing through the stack structure are formed; the non-doped region in the first semiconductor layer are removed through the grid line gaps, so that a doped semiconductor column body and a gap region between the channel structures can be formed; and an epitaxial layer is grown in the gap region. Therefore, when the channel structures are eroded, the doped semiconductor column body positioned below the stack structure can provide auxiliary support, and therefore, the stability of the stack structure is ensured.

Owner:YANGTZE MEMORY TECH CO LTD

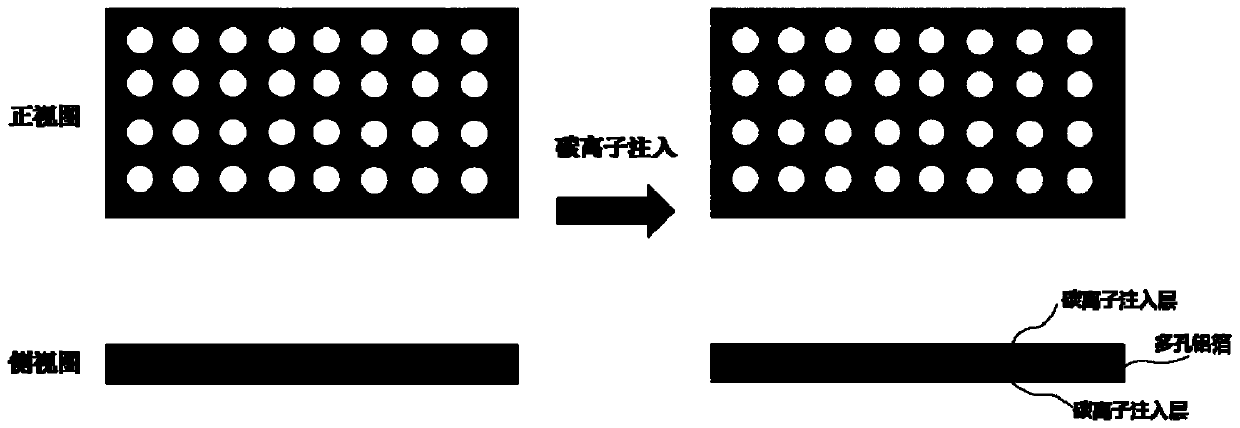

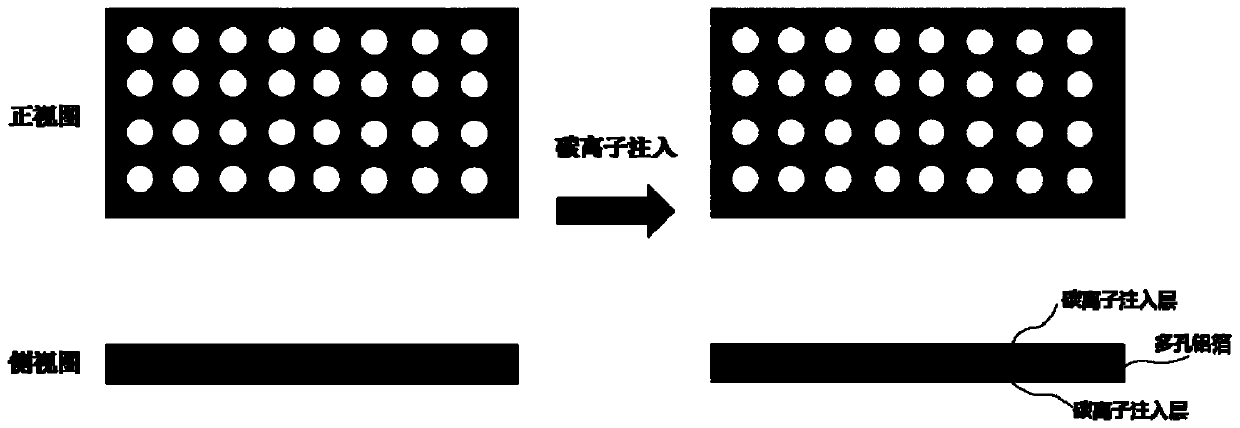

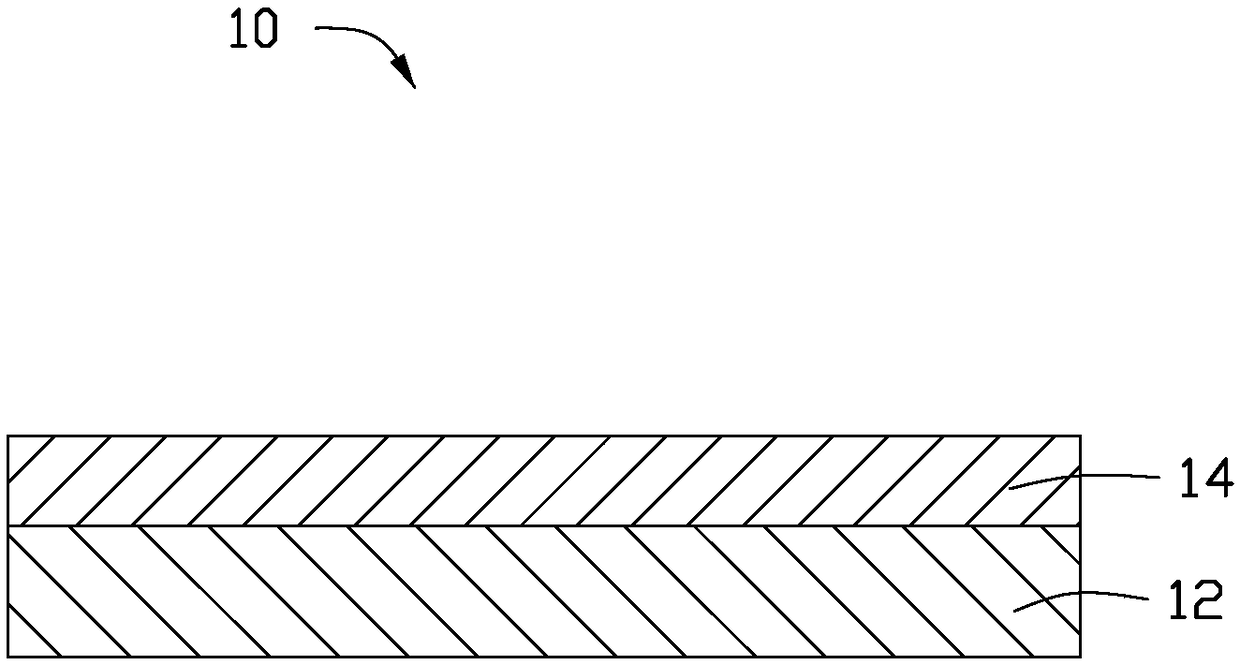

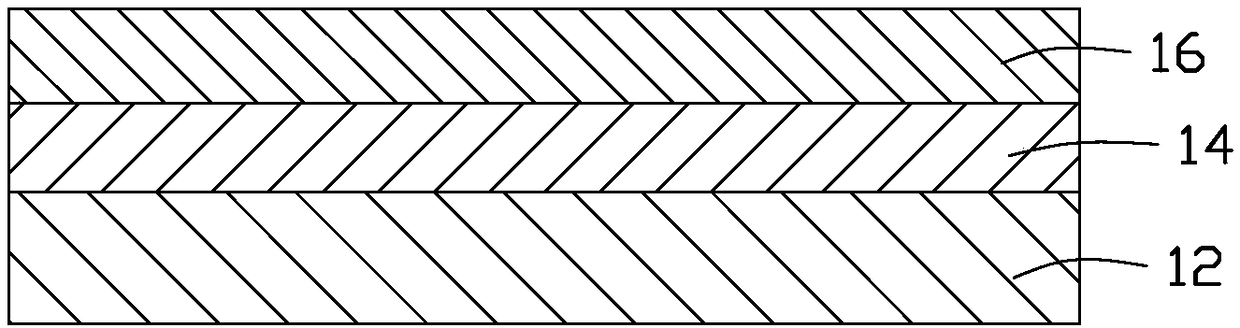

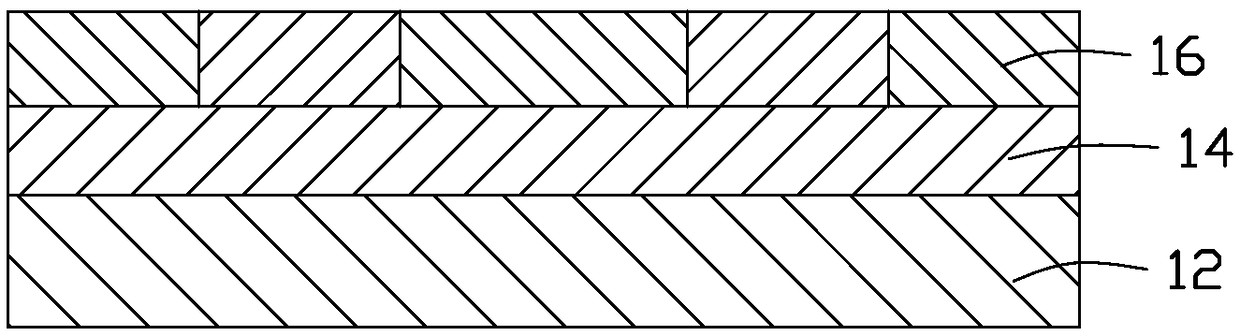

Lithium ion battery, preparation method thereof and application of porous aluminum-carbon composite material

InactiveCN109713289AImprove conductivityLow costFinal product manufactureCell electrodesCarbon compositesLithium-ion battery

The invention relates to a lithium ion battery, a preparation method thereof and the application of a porous aluminum-carbon composite material. The preparation method of the lithium ion battery comprises the following steps: providing a positive electrode, a diaphragm and an electrolyte; carrying out carbon ion implantation on a porous aluminum foil to obtain a negative electrode; assembling andprocessing the positive electrode, the diaphragm, the negative electrode and the electrolyte to obtain the lithium ion battery. The inventor of the invention creatively adopts a specific porous aluminum-carbon composite material. Namely, a porous aluminum foil injected with carbon ions is used as a negative electrode. The porous aluminum foil can serve as an active negative electrode material anda current collector at the same time. The problems of volume expansion, poor conductivity after lithium intercalation and the like in the metal aluminum negative electrode circulation process can be effectively solved. The circulation performance and the rate capability are improved. Meanwhile, the porous aluminum foil can effectively improve the energy density of a battery when serving as a negative electrode due to higher gram volume, lighter mass and thinner thickness.

Owner:SOUNDON NEW ENERGY TECH CO LTD

Circuit board and manufacturing method thereof

ActiveCN109429428BReduce gapAvoid peeling offPrinted circuit aspectsElectrical connection printed elementsEngineeringMechanical engineering

The invention relates to a circuit board, which comprises an insulating layer, a conductive structure formed on the surface of the insulating layer, a nickel plating layer formed on the upper surface and side surfaces of the conductive structure, and a nickel plating layer formed on the upper surface and side surfaces of the nickel plating layer. A gold layer, the conductive structure includes a plurality of conductive patterns, the conductive pattern includes a quadrangle whose upper base length is equal to the lower base length and a protruding edge located at least on one side of the quadrangle, and the height of the protruding edge is less than or equal to The height of the quadrilateral. The present invention also provides a manufacturing method of the above-mentioned circuit board.

Owner:HONGQISHENG PRECISION ELECTRONICS (QINHUANGDAO) CO LTD +1

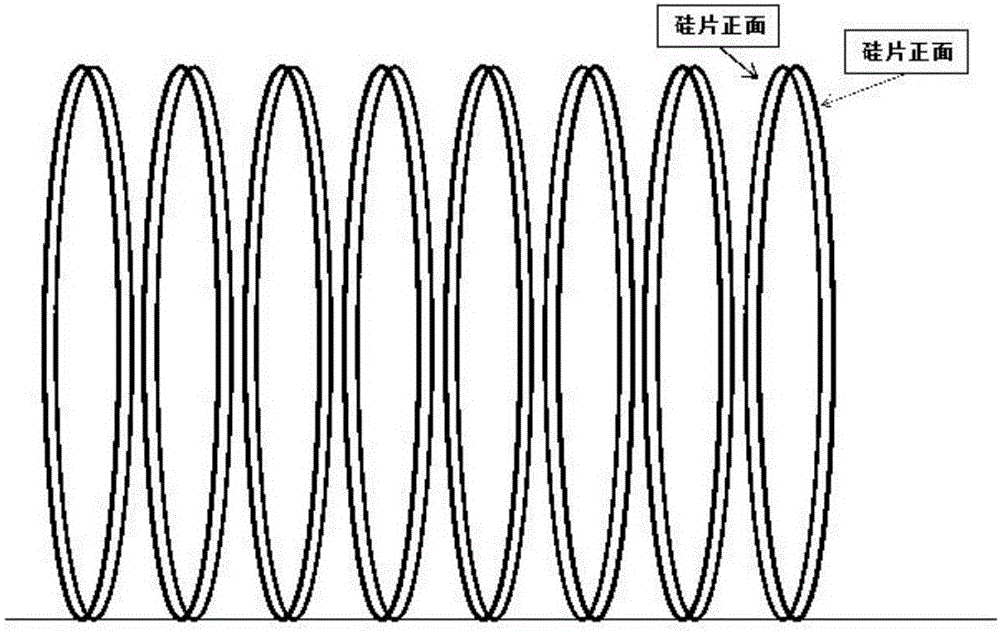

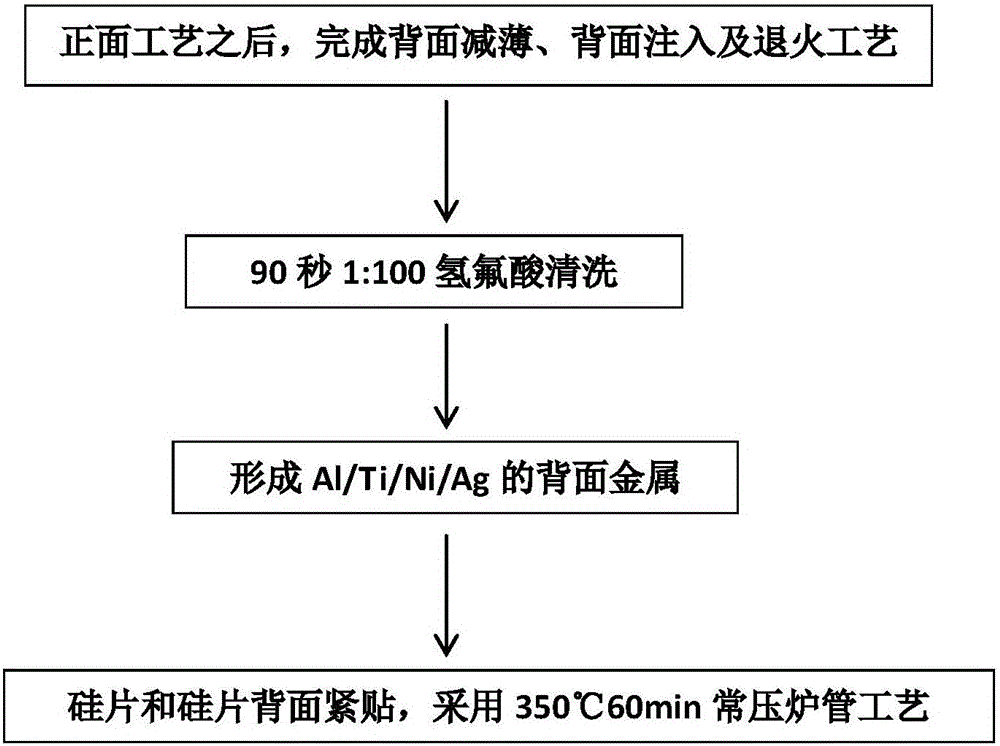

Technique method of metallization annealing of IGBT back face

ActiveCN104992965AReduce contact resistanceAvoid peeling offSemiconductor devicesHydrofluoric acidThinning

The invention discloses a technique method of metallization annealing of an IGBT back face. The technique method comprises steps of performing back face thinning, ion implantation and annealing technique after a front face technique is finished; performing 1:100 buffering hydrofluoric acid cleaning for 90 seconds; forming back face metal of Al, Ti, Ni and Ag; and tightly pasting a silicon sheet to a silicon sheet back face by using ordinary-pressure furnace tube technique of 350 DEG C for 60 minutes. According to the invention, while lower contact resistance of the back face metal of the silicon sheet is ensured, metal stripping is avoided, so an IGBT device is provided higher reliability.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

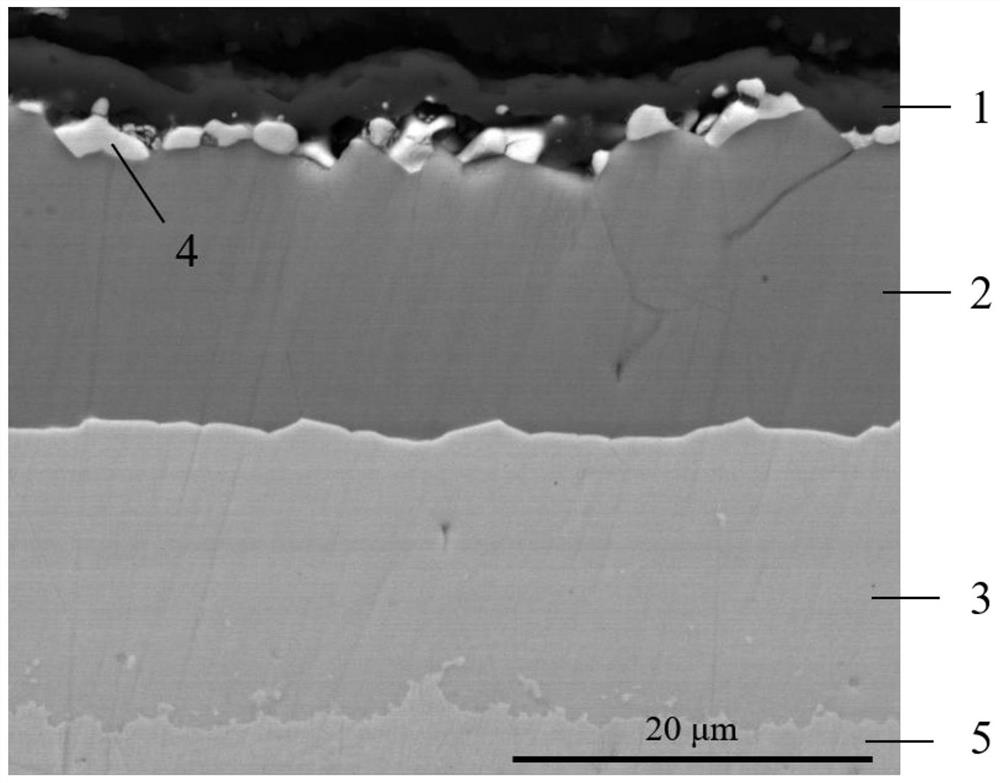

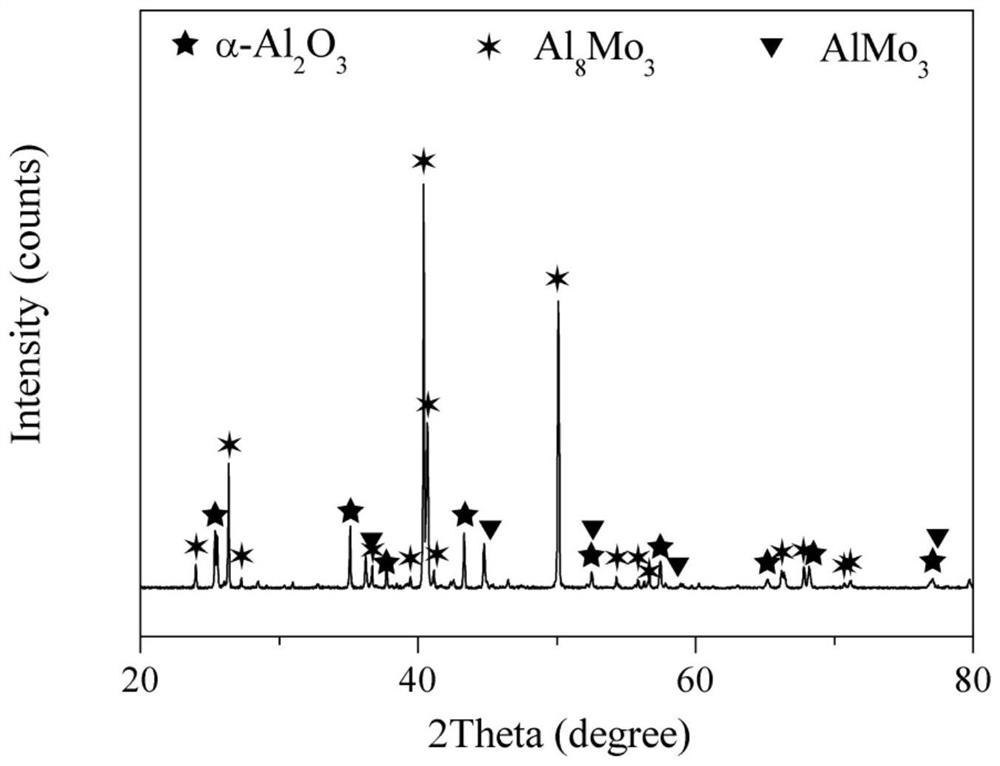

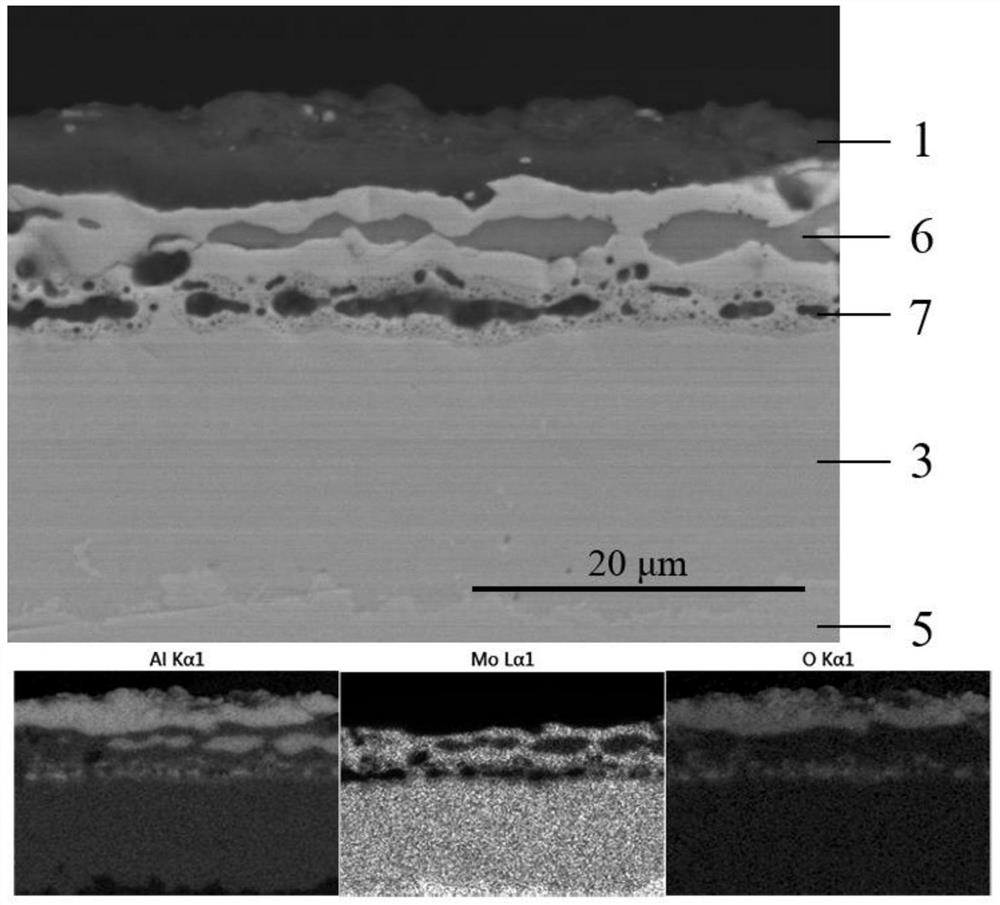

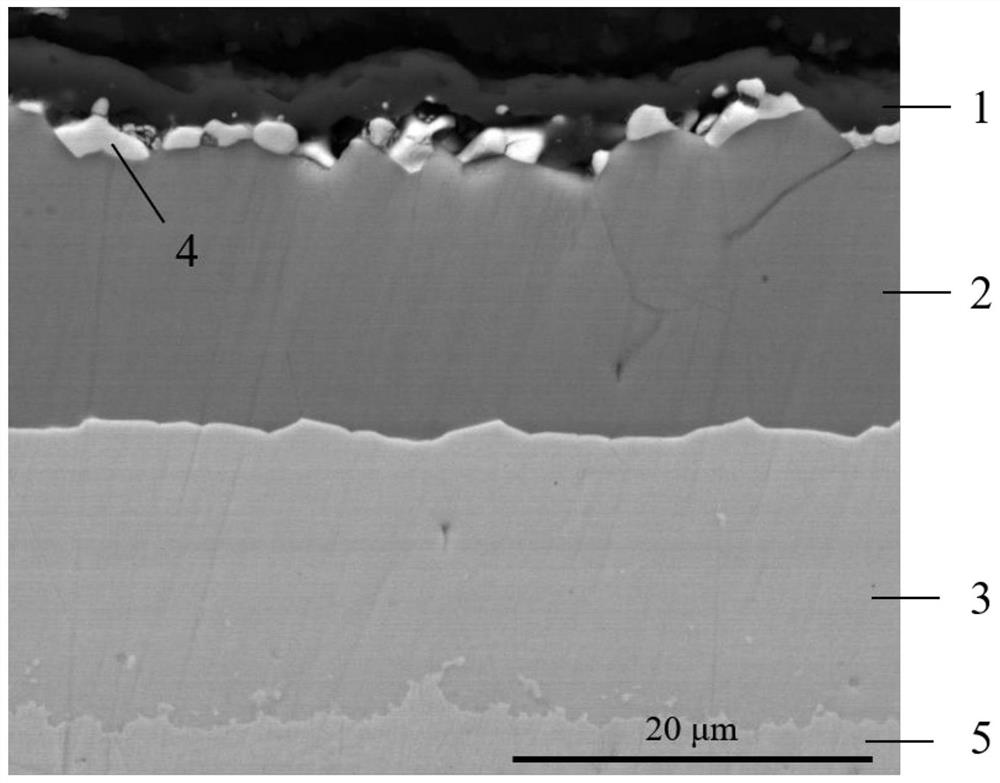

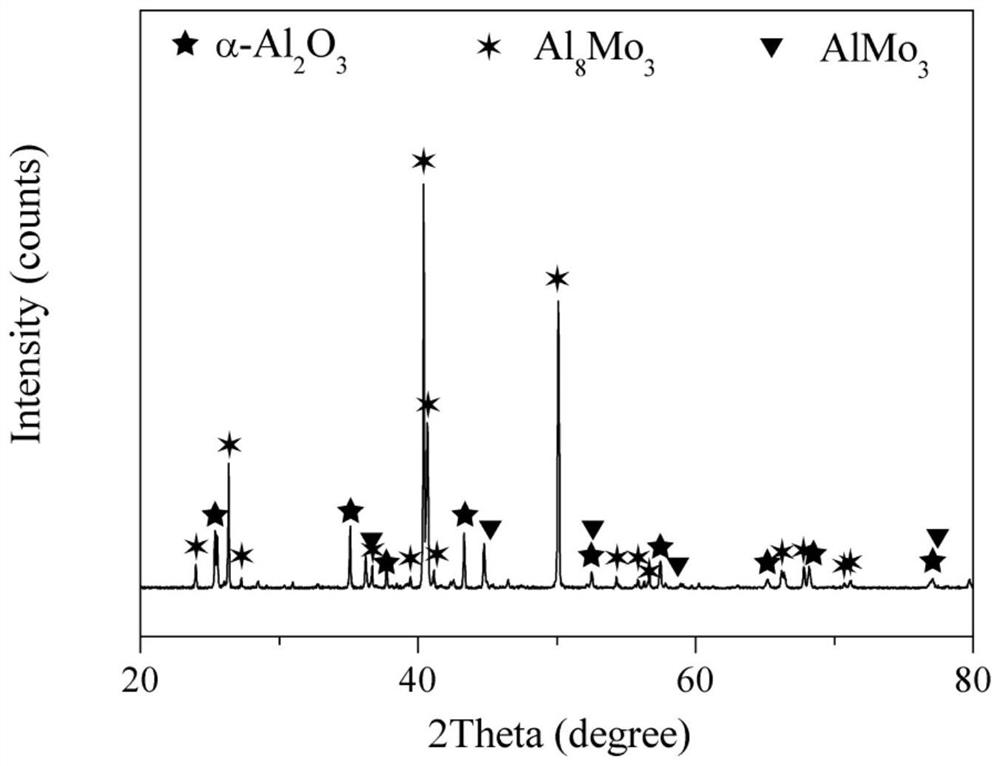

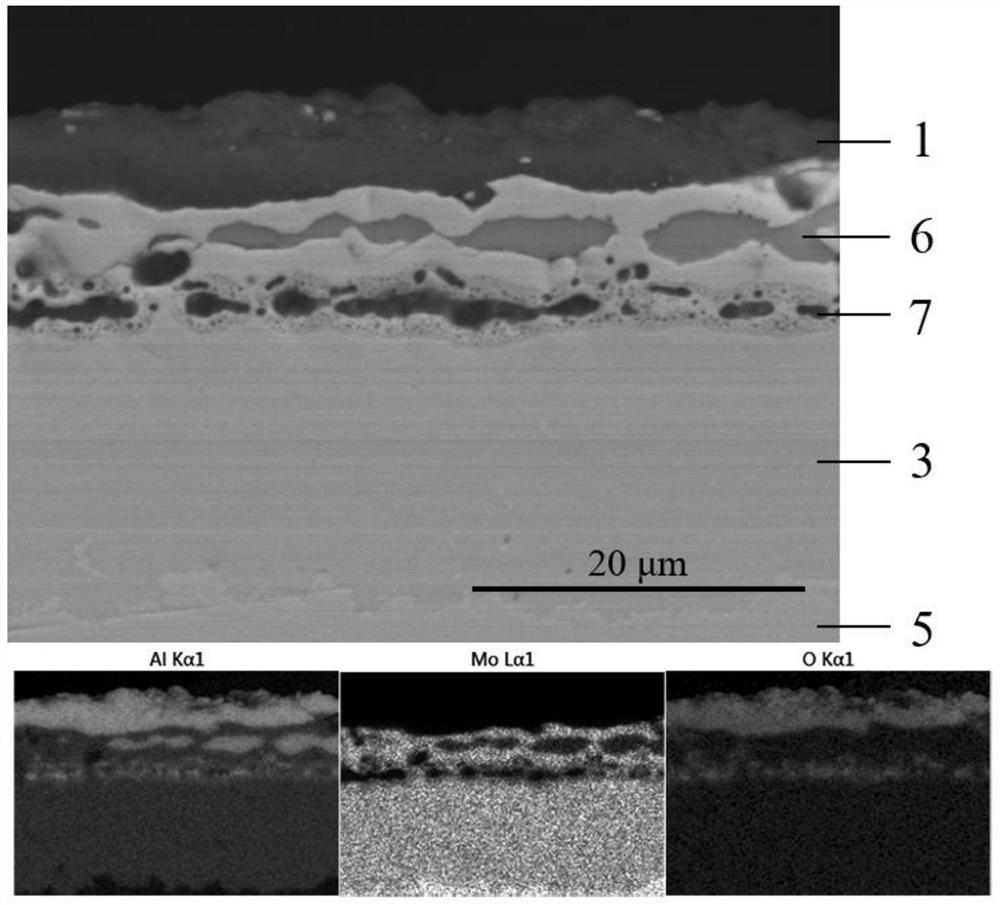

Ablation-resistant and corrosion-resistant protective coating on surface of molybdenum metal mold core and preparation method

ActiveCN112024818AReduce the probability of spreadingImprove anti-ablation performanceFoundry mouldsSolid state diffusion coatingMetal moldAlonizing

The invention discloses an ablation-resistant and corrosion-resistant protective coating on the surface of a molybdenum metal mold core and a preparation method. At first, by means of an embedded dialysis technology, an aluminide coating is prepared on a pure molybdenum base body or a molybdenum alloy base body, then the aluminide coating is subjected to in-situ oxidation, thus an oxide / aluminidecomposite coating is prepared, the composite coating is composed of three phases alpha-Al2O3, Al8Mo3 and AlMo3, and the total thickness of the coating is 15-70 micrometers. A continuous compact alpha-Al2O3 layer is arranged on the outermost layer of the coating, and the remarkable ablation-resisting and corrosion-resisting protective effect on the molybdenum metal mold core can be achieved. Firm metallurgical bonding is formed between an aluminum oxide layer and an aluminide layer of the coating and between the aluminide layer and base body metal, and the situation that in the preparation anduse process, due to the stress effect, the coating is stripped and falls off can be effectively avoided.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

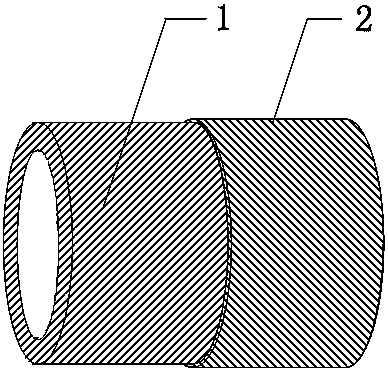

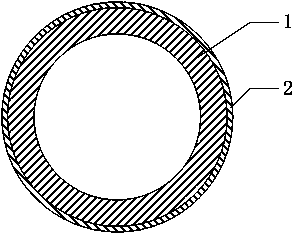

A kind of anti-scratch PE composite pipe and preparation method thereof

ActiveCN105542271BIncrease melt viscosityPrevent cross-linking reactionRigid pipesComposite effectCross-linked polyethylene

The invention provides an anti-scratch PE clad pipe and a preparation method, and belongs to the field of tubing preparation technology. The clad pipe comprises a homogeneous polyethylene pipe main body which is moulded by a common polyethylene material, a layer of crosslinked polyethylene protection layer is added on the surface of the homogeneous polyethylene pipe main body, and the layer is characterized in that the thickness of the crosslinked polyethylene protection layer is 10-15% of the thickness of the homogeneous polyethylene pipe main body wall. The prepared novel anti-scratch PE clad pipe has a good composite effect, the crosslinked polyethylene protective layer and the homogeneous polyethylene pipe main body are better combined into an integrated body, so that the phenomenon of peeling and shedding of the inner pipe and the outer pipe during trenchless construction is avoided; the method has the advantages of excellent processing property, relatively low technology difficulty coefficient, and high production efficiency; the clad pipe prepared by the production technology has the advantages of high qualified rate of product, improved product quality, spatial network structure formed by the external layer crosslinked polyethylene protective layer, improved integral anti-scratch performance of the pipe, and long usage period.

Owner:LINHAI WEIXING NEW BUILDING MATERIALS CO LTD

Silica gel composite bath towel and a preparation method thereof

ActiveCN108773118AImprove breathabilityImprove liquidityBathroom accessoriesLaminationSkin surfaceHardness

The invention provides a silica gel composite bath towel and a preparation method thereof. The silica gel composite bath towel comprises a silica gel composite layer, a water absorbing layer and a lining layer which are sequentially arranged from top to bottom. A coating material layer penetrates through a base material layer to prepare the silica gel composite layer. The thickness of the coatingmaterial layer is higher than the base material layer by 1 mm or less, and the area of the coating material layer is 50% and above of the area of the base material layer. The coating material of the silica gel composite bath towel and a polar functional group on the surface of the base material can generate intermolecular force, and under the action of high pressure in the preparation process, thecoating material and the base material can achieve good compounding, and the coating material can be uniformly applied onto the base material. The silica gel composite bath towel obtained by the invention has moderate hardness, can easily remove dirt on skin surface, does not harm the skin, and has excellent air permeability. The preparation method of the invention has the following advantages: operation is simple; mass production of the product can be achieved; coating thickness is uniform, and the coating material layer is not easy to fall off.

Owner:王延民

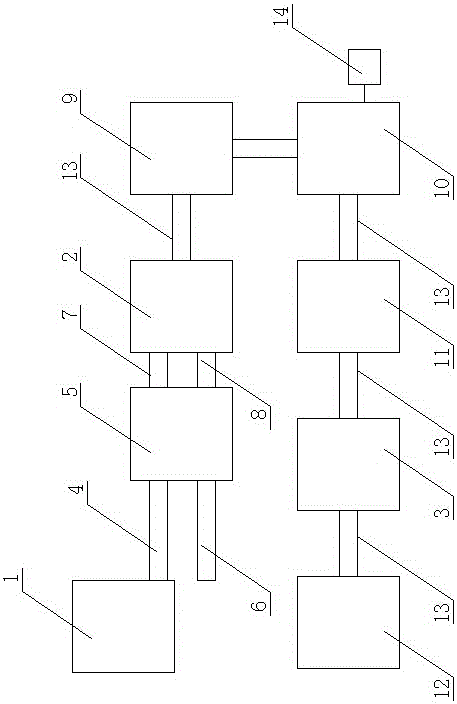

Production method and device of ultra-high molecular weight polyethylene lined composite pipe

The invention discloses an ultrahigh molecular weight polyethylene lining composite pipe production method and device, and relates to the field of composite pipe production method and device equipment. The ultrahigh molecular weight polyethylene lining composite pipe production method comprises the steps of pretreatment, material selection, composition, destressing, constant length cut and flanging. The ultrahigh molecular weight polyethylene lining composite pipe production device is characterized in that an outlet of a size reducing machine is provided with a lining pipe conveying device to be connected with one inlet of a cleaning machine, the other inlet of the cleaning machine is provided with a steel pipe conveying device, the cleaning machine is provided with a lining pipe outlet and a steel pipe outlet which are connected with corresponding inlets of a composite mold machine, the composite mold machine, a placement table, a heating box, a constant length cutting machine, a flanging machine and a coupling screw-on machine are connected in sequence, and a composite pipe conveying device is arranged between every two adjacent devices. The ultrahigh molecular weight polyethylene lining composite pipe production method is simple, the lining composition effect is good, the phenomenon that an outer pipe is stripped or disengaged from an inner pipe is avoided, the technological difficulty degree is low, working efficiency is high, the product percent of pass is high, the product quality is improved, the product has the ultrahigh wear resistance, and manufactured composite pipes are long in using period.

Owner:大庆高新区法尔文得新材料有限公司

Circuit board and manufacturing method thereof

ActiveCN109429428AReduce gapAvoid peeling offPrinted circuit aspectsElectrical connection printed elementsEngineeringNickel

The invention relates to a circuit board. The circuit board comprises an insulating layer, a conductive structure formed on the surface of the insulating layer, a nickel plating layer formed on the upper surface and the side surface of the conductive structure, and a gold layer formed on the upper surface and the side surface of the nickel plating layer, wherein the conductive structure comprisesa plurality of conductive patterns; and the conductive patterns comprise a quadrilateral with the upper bottom length equal to the lower bottom length, and a protruding edge at least located on one side surface of the quadrilateral, wherein the height of the protruding edge is smaller than or equal to that of the quadrilateral. The invention further provides a manufacturing method of the circuit board.

Owner:HONGQISHENG PRECISION ELECTRONICS (QINHUANGDAO) CO LTD +1

Multi-chip package with antenna structure and preparation method thereof

ActiveCN114551251AAvoid peeling offImprove joint tightnessSemiconductor/solid-state device detailsSolid-state devicesMetal nanowiresSemiconductor chip

The invention relates to a multi-chip package with an antenna structure and a preparation method thereof. The first antenna structure, the second antenna structure, the third antenna structure and the fourth antenna structure are formed in the first preset antenna pattern, the second preset antenna pattern, the third preset antenna pattern and the fourth preset antenna pattern in a spin-coating mode of the metal nanowire solution, through the preparation process, the connection tightness of the antenna structures and the flexible resin packaging layer can be improved conveniently, and then stripping and falling of the antenna structures can be avoided. Furthermore, the first antenna structure and the third antenna structure are stacked, and the second antenna structure and the fourth antenna structure are stacked, so that the signal transmitting strength of the antenna structure or the signal receiving capability of the antenna structure is effectively improved. Meanwhile, due to the arrangement of the first isolation structure and the second isolation structure, interference between the antenna structures, between the semiconductor chips and between redistribution lines can be effectively avoided, and then the function stability of multi-chip packaging is guaranteed.

Owner:WEIHAI IDEACODS ELECTRONICS TECH CO LTD

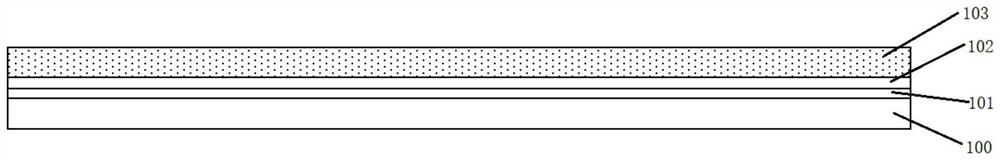

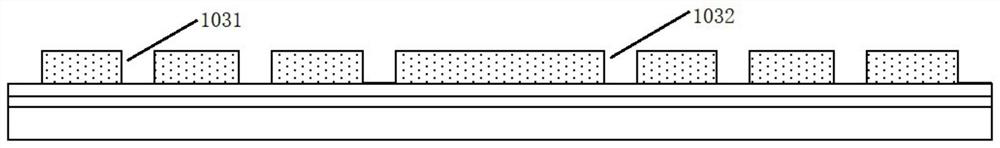

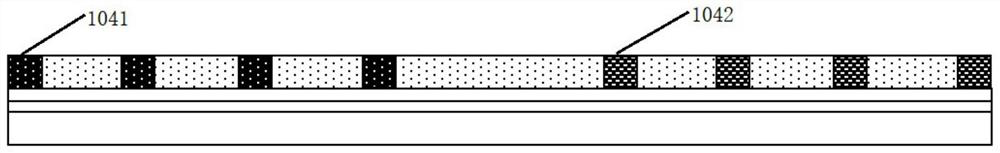

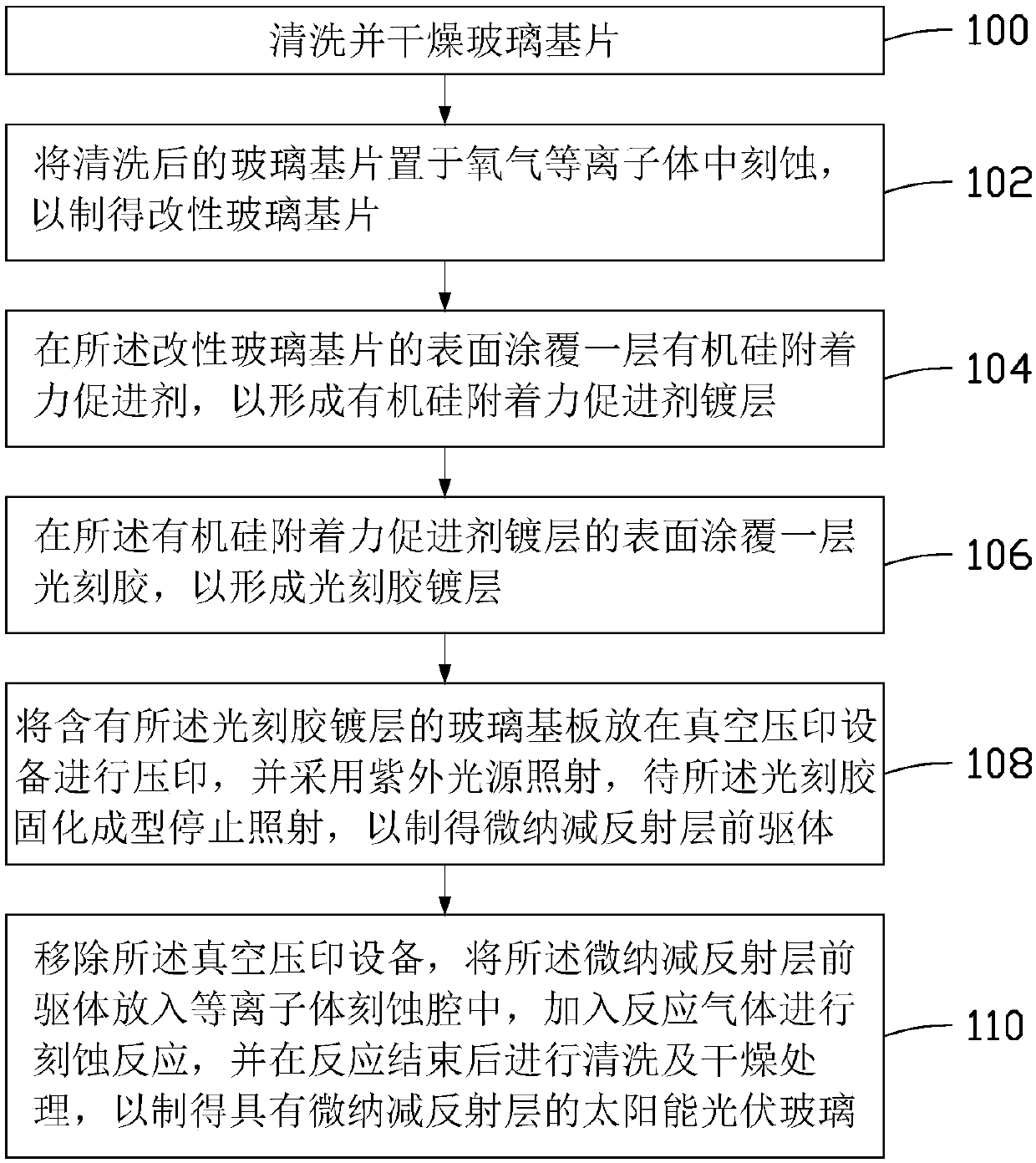

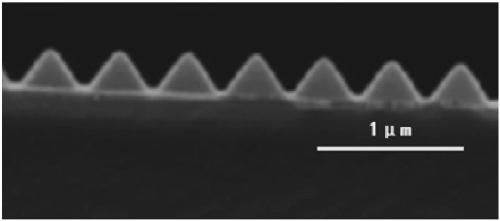

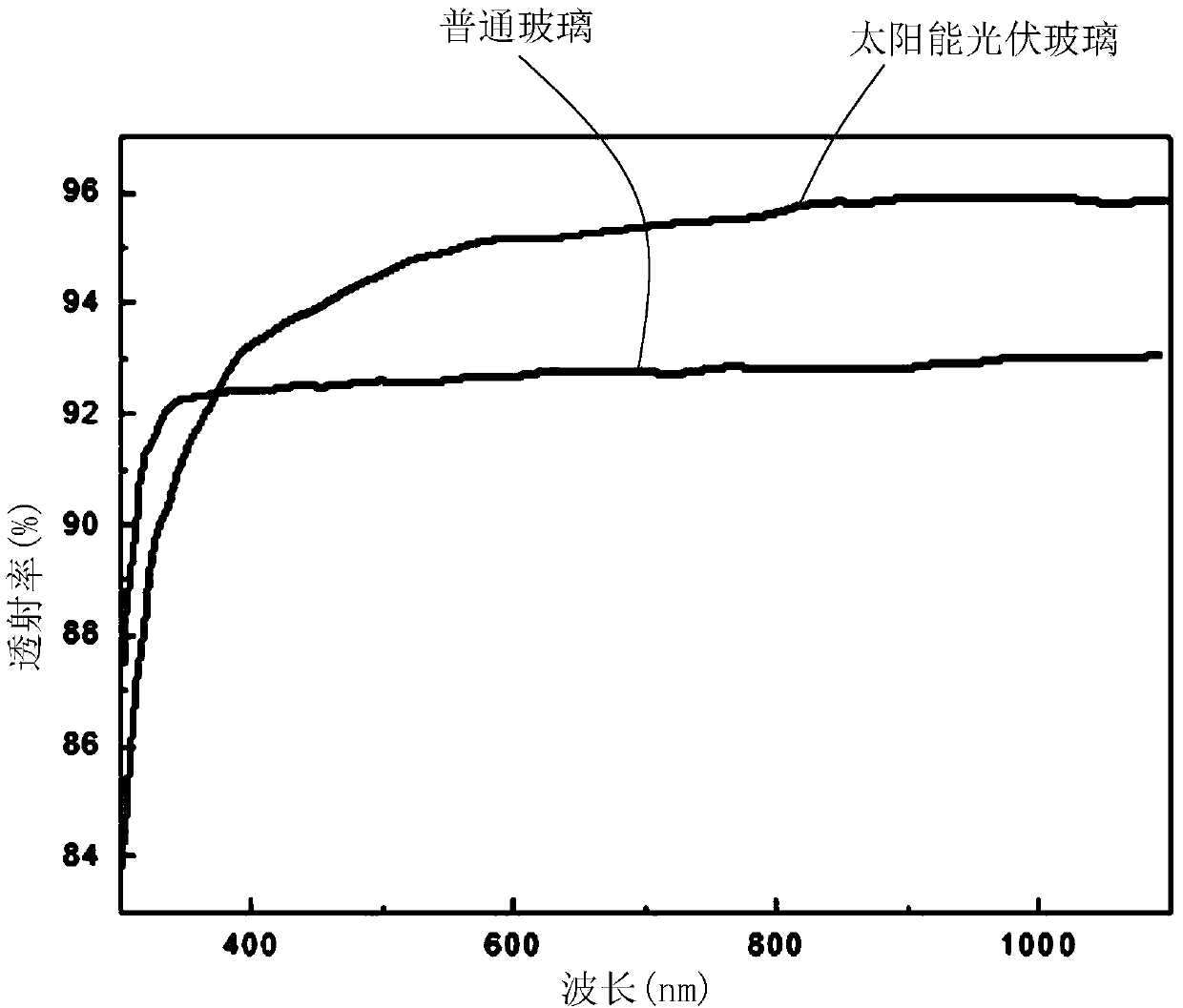

Preparation method of solar photovoltaic glass with micro-nano anti-reflection layer

ActiveCN107863393BHigh resolutionHigh light conversion rateCoatingsPhotovoltaic energy generationMicro nanoOxygen plasma

The invention discloses a preparation method of solar photovoltaic glass with a micro-nano antireflection layer. The preparation method comprises the following steps of a, putting a glass substrate into oxygen plasma to be etched to prepare a modified glass substrate; b, coating the surface of the modified glass substrate with a layer of organic silicon adhesion promoter to form an organic siliconadhesion promoter coating layer; c, coating the surface of the organic silicon adhesion promoter coating layer with a layer of photoresist to form a photoresist coating layer; d, putting the glass substrate comprising the photoresist coating layer into vacuum impressing equipment to be impressed, and performing irradiating by adopting an ultraviolet source, after the photoresist is cured and shaped, stopping irradiating to prepare an anti-reflection layer precursor; and e, removing the vacuum impressing equipment, putting the anti-reflection layer precursor into a plasma etching cavity, adding a reaction gas for performing an etching reaction to prepare the solar photovoltaic glass with the micro-nano antireflection layer. The preparation process is simple, and the prepared solar photovoltaic glass has high resolution and high optical conversion efficiency and performance.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

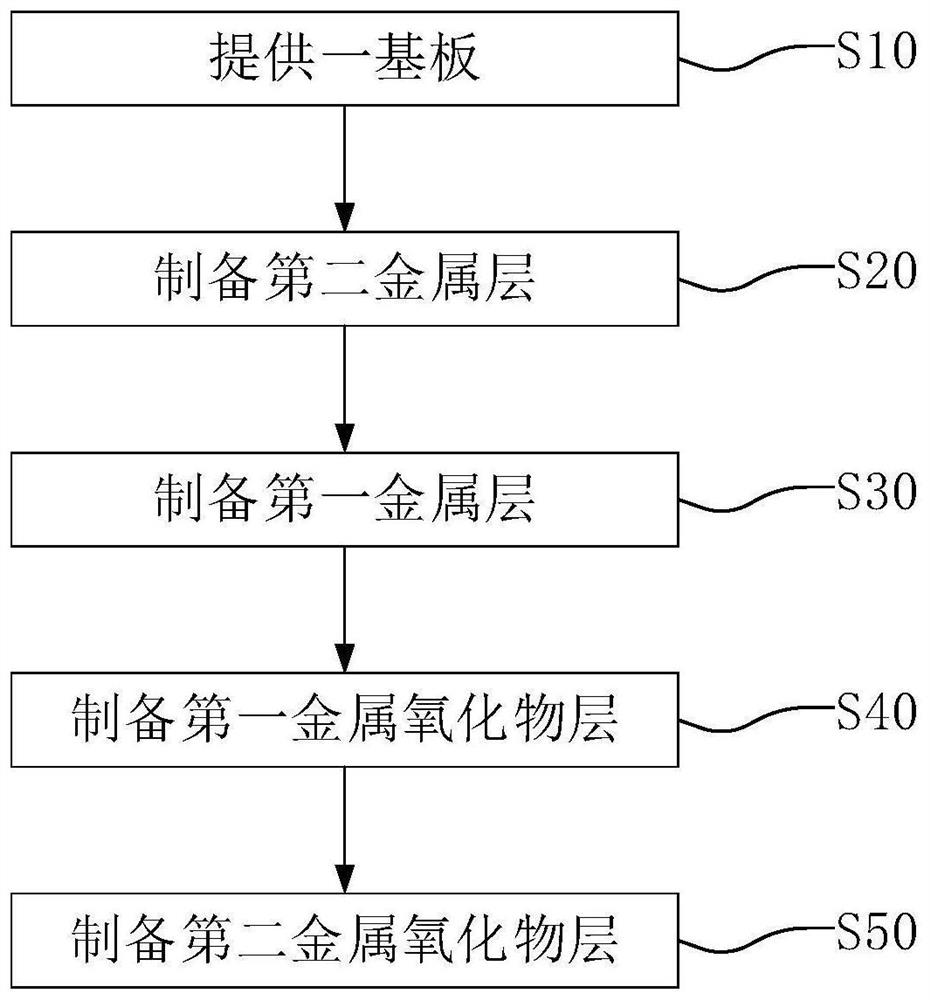

Display panel and preparation method thereof

ActiveCN112259557AImprove yield rateImprove adhesionTransistorSolid-state devicesPhysical chemistryOxygen atom

The invention provides a display panel and a preparation method thereof. The display panel comprises a first metal layer and at least two metal oxide layers. The metal oxide layers are stacked on onesurface of the first metal layer. In the metal oxide layers, the content of oxygen atoms in metal oxide gradually decreases from the side away from the metal layer to the side close to the metal layer.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

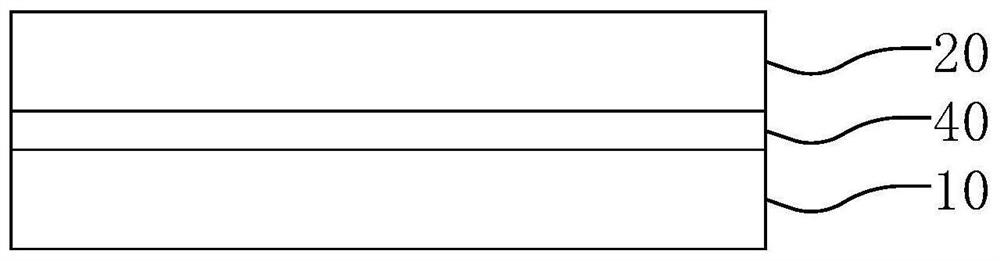

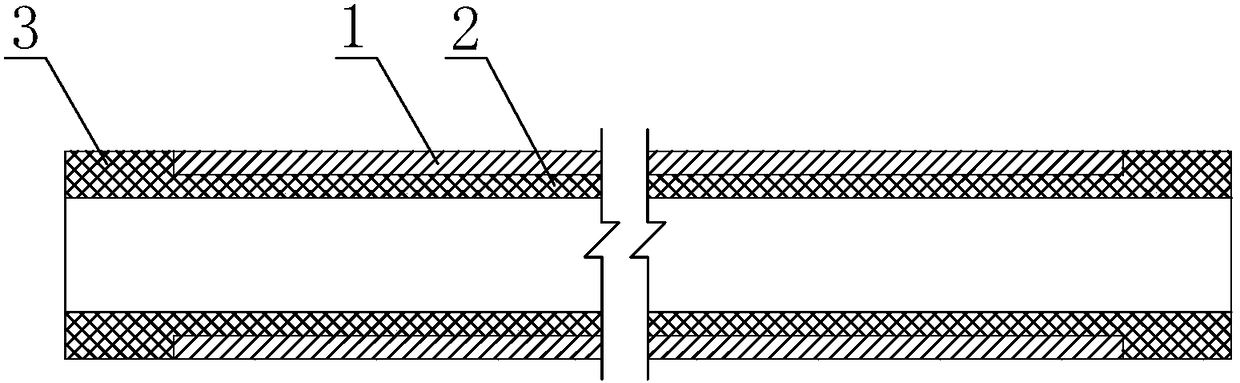

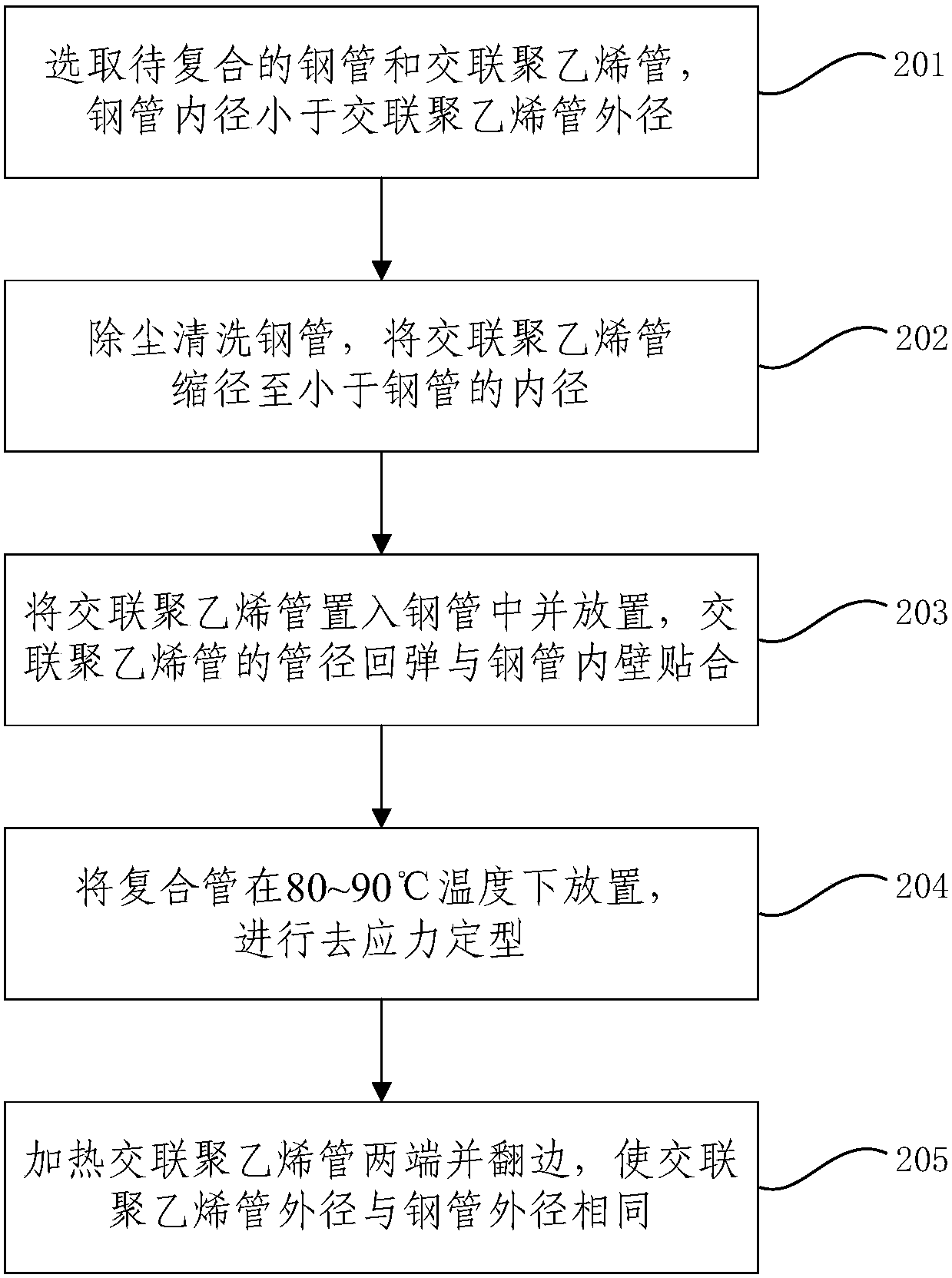

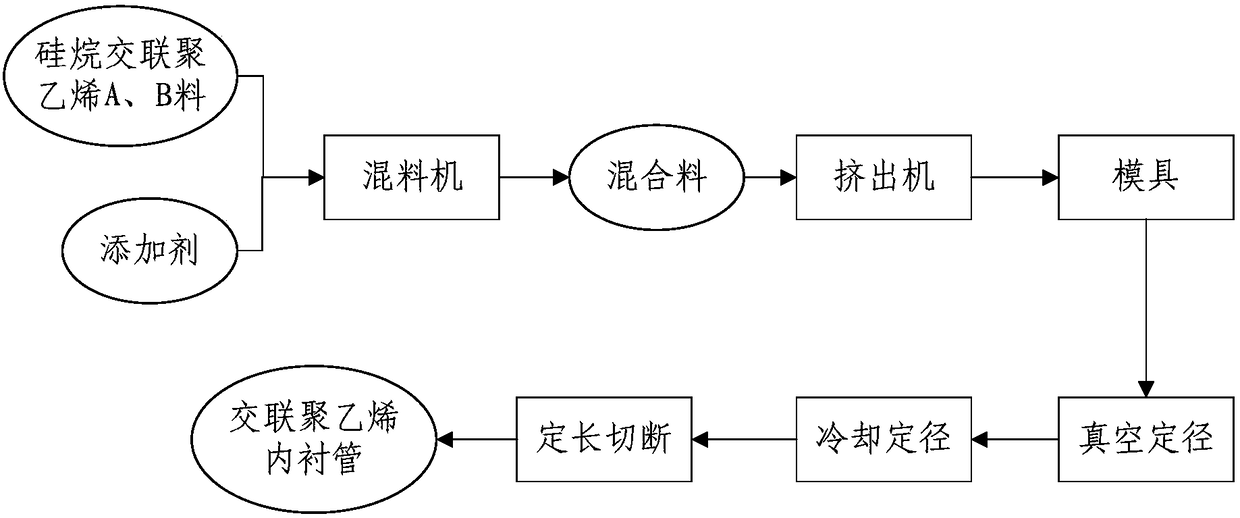

Cross-linked polyethylene lined composite pipe and production method thereof

ActiveCN105508749BImprove composite effectSimple production methodRigid pipesCross-linked polyethyleneMaterials science

The invention discloses a production method of a crosslinked polyethylene lining composite pipe. The production method comprises the following steps: a steel pipe and a crosslinked polyethylene pipe to be compounded are selected, wherein the inner diameter of the steel pipe is smaller than the outer diameter of the crosslinked polyethylene pipe; the dust removal cleaning is performed for the steel pipe, and the diameter reducing treatment is performed for the crosslinked polyethylene pipe, so that the outer diameter of the crosslinked polyethylene pipe is smaller than the inner diameter of the steel pipe; the crosslinked polyethylene pipe is put in the steel pipe for a period of time; and the pipe diameter of the crosslinked polyethylene pipe is returned to be tightly bonded with the inner wall of the steel pipe to obtain the crosslinked polyethylene lining composite pipe. The production method solves the pre-crosslinking phenomenon in the crosslinked polyethylene pipe production process, in particular in the large-caliber pipe extrusion production process, enables the inner and outer wall surfaces of the pipe to become smooth, and improves the production continuity. The produced lining composite pipe is excellent in compounding effect, prevents the generation of stripping phenomenon of an inner pipe and an outer pipe, is relatively lower in process difficulty coefficient, and is high in productivity.

Owner:ZHEJIANG WEIXING NEW BUILDING MATERIALS CO LTD

Plastic hollow plate bonding method

InactiveCN111892877AAvoid peeling offIncrease bonding areaAdhesive processes with surface pretreatmentAdhesive cementBonding strength

The invention provides a plastic hollow plate bonding method. The blind holes are formed in the bonding face of the plastic hollow plate, the bonding face of the plastic hollow plate and the bonded piece are bonded together through the adhesive, then the adhesive penetrates into the hollow plate through the blind holes after the plastic hollow plate and the bonded piece are pressed, and a glue riveting structure is formed after solidification. According to the method, the blind holes are formed in the bonding surface of the plastic hollow plate, and the state of the bonding surface is changedso that the adhesive goes deep into the plastic hollow plate, the bonding area is increased, the bonding strength is increased, and a product can be effectively prevented from being peeled off and falling off.

Owner:SHIYAN BOXING AUTOMOBILE DECORATIVE PROD

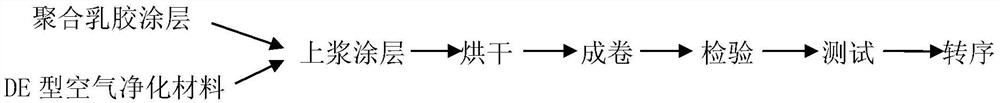

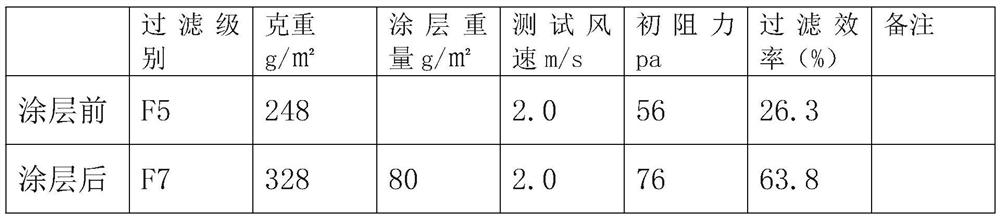

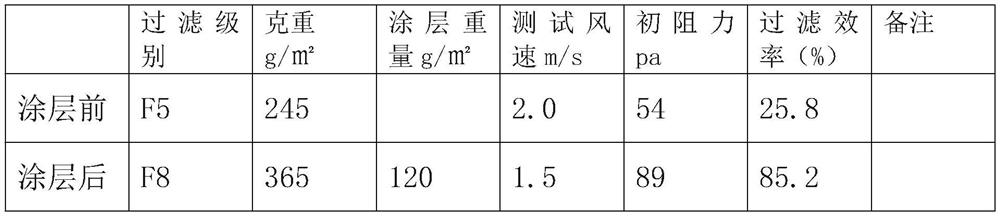

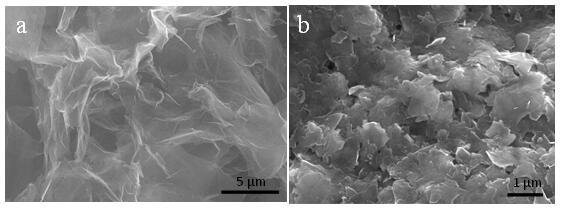

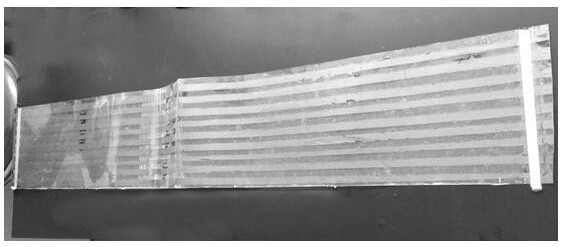

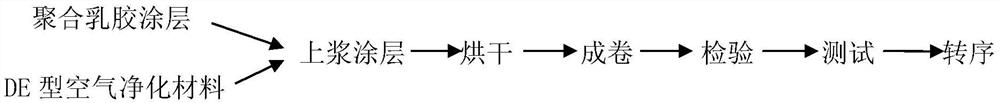

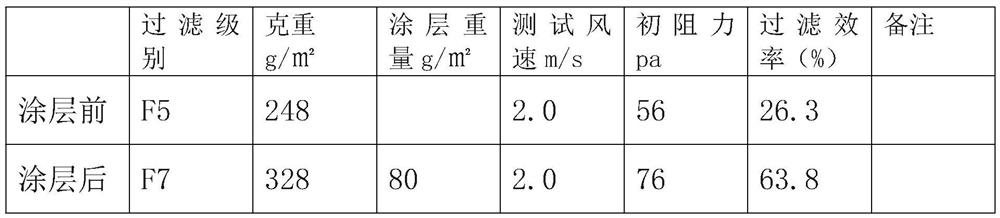

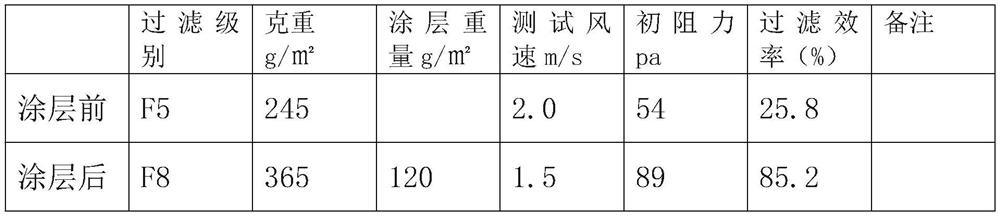

Multi-performance coating filter material and preparation method

ActiveCN113087857BImprove filtration efficiencySoft and smoothMembrane filtersFiltration separationCoated membraneEpoxy

The present invention is a kind of polymer latex coating, and the raw materials used are: 20-21 g of itaconic acid, 350-360 g of ethyl acrylate, 71-73 g of allyl polyoxyalkylene epoxy ether, 71-73 g of ethyl -2-methyl 1,3-dioxopentyl-4-yl acrylate 10-10.5g, methyl methacrylate 42-44g, fatty alcohol polyoxyethylene ether XL-90 2-2.3g, ammonium persulfate 1.9- 2.1g, deionized water 550-600g, mixed into a polymer emulsion. Take 80g of polymerization emulsion, add 17g of water and 3g of thickener, stir to thicken evenly, filter out the material to obtain the product. The coating film material can improve the filtration efficiency of the filter material while maintaining the original technical performance by coating the surface of the air outlet side.

Owner:丹东天皓净化材料有限公司 +1

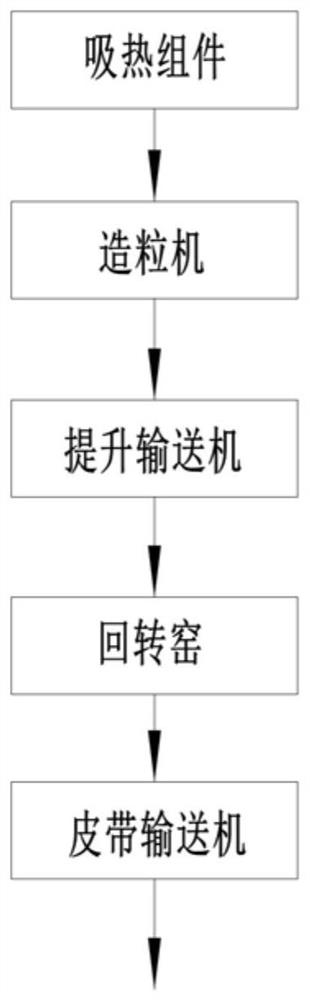

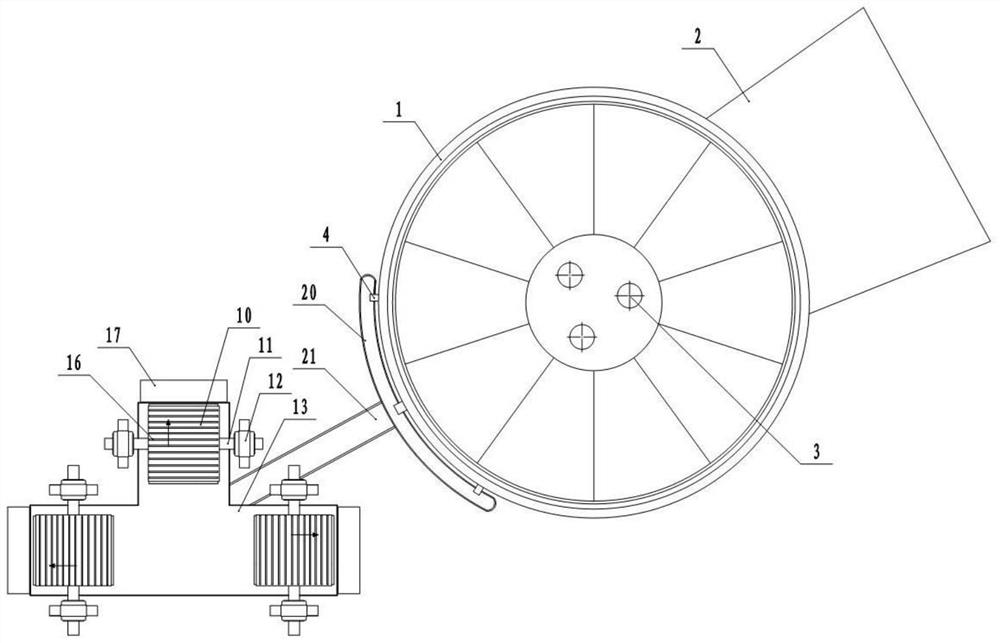

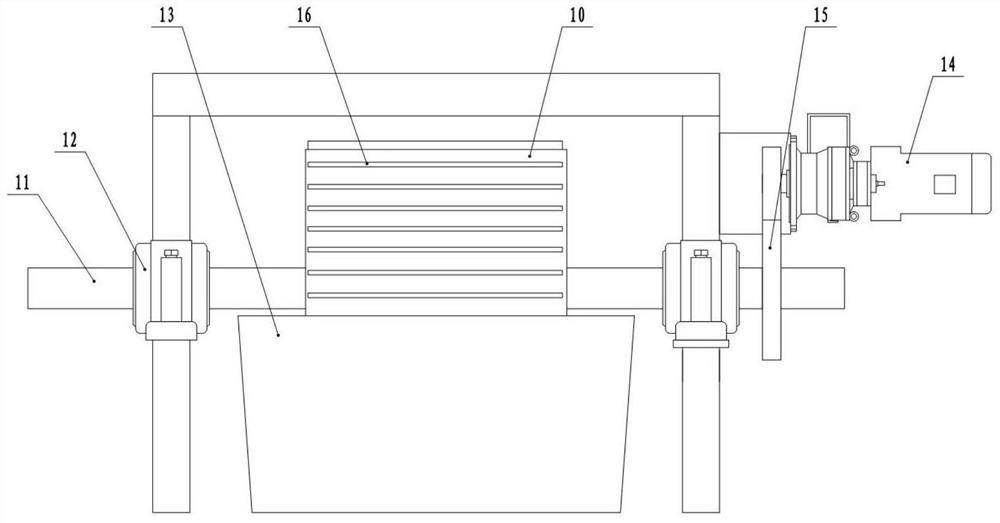

Waste heat recovery system for smelting of calcium carbide

InactiveCN112665396ASolve waste heat recoveryNot easy to peel offCharge manipulationIncreasing energy efficiencyThermodynamicsSlag

The invention relates to the technical field of waste heat recovery equipment, and particularly discloses a waste heat recovery system for smelting of calcium carbide. The waste heat recovery system is connected with a plurality of discharging openings of a calcium carbide smelting furnace, and comprises a rack, a heat absorption assembly, a slag cylinder, a granulator, a lifting conveyor, a secondary heat exchange system and a belt conveyor, wherein the heat absorption assembly comprises a heat absorption head; the heat absorption head comprises a hollow roller and two hollow shafts; the slag cylinder is arranged below the roller; the rack is further provided with a flow guide assembly; the flow guide assembly comprises an arc-shaped groove and a flow guide groove; the arc-shaped groove is located below the three discharging openings; the flow guide groove is connected with the arc-shaped groove and the slag cylinder; the roller is provided with a plurality of blocking bars; the top of the granulator is provided with slag receiving hoppers; and the slag receiving hoppers are arranged close to the rollers of the heat absorption head respectively. The waste heat recovery system provided by the patent of the invention abandons the mode of transferring by using a trolley in the prior art, and solves the problem that waste heat recovery of calcium carbide liquid is affected because the carbide liquid in a trolley quickly forms a calcium carbide layer on the surface due to a relatively high solidification speed of the calcium carbide liquid.

Owner:重庆岩昱节能科技有限公司

A kind of anti-ablation and anti-corrosion protective coating on the surface of molybdenum metal core and its preparation method

ActiveCN112024818BReduce the probability of spreadingImprove anti-ablation performanceFoundry mouldsSolid state diffusion coatingAlloy substrateAlonizing

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

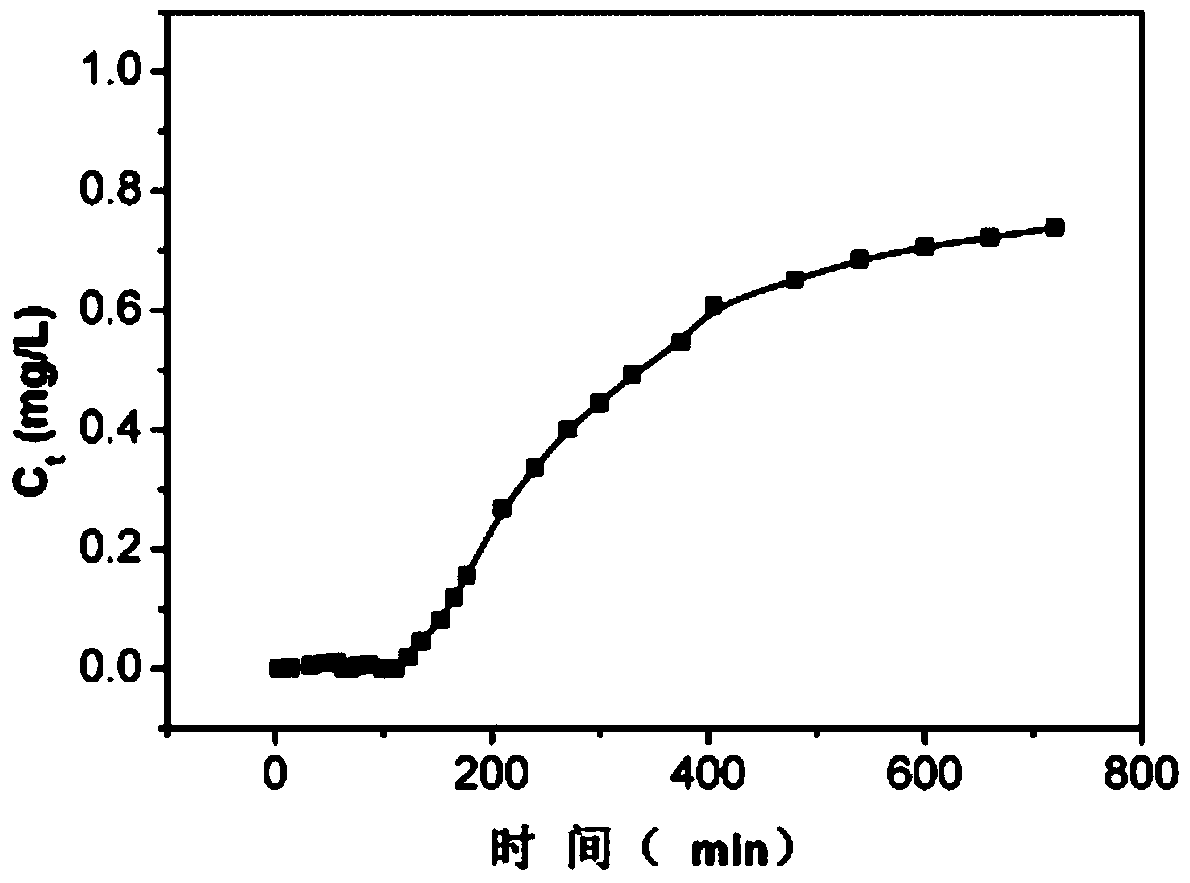

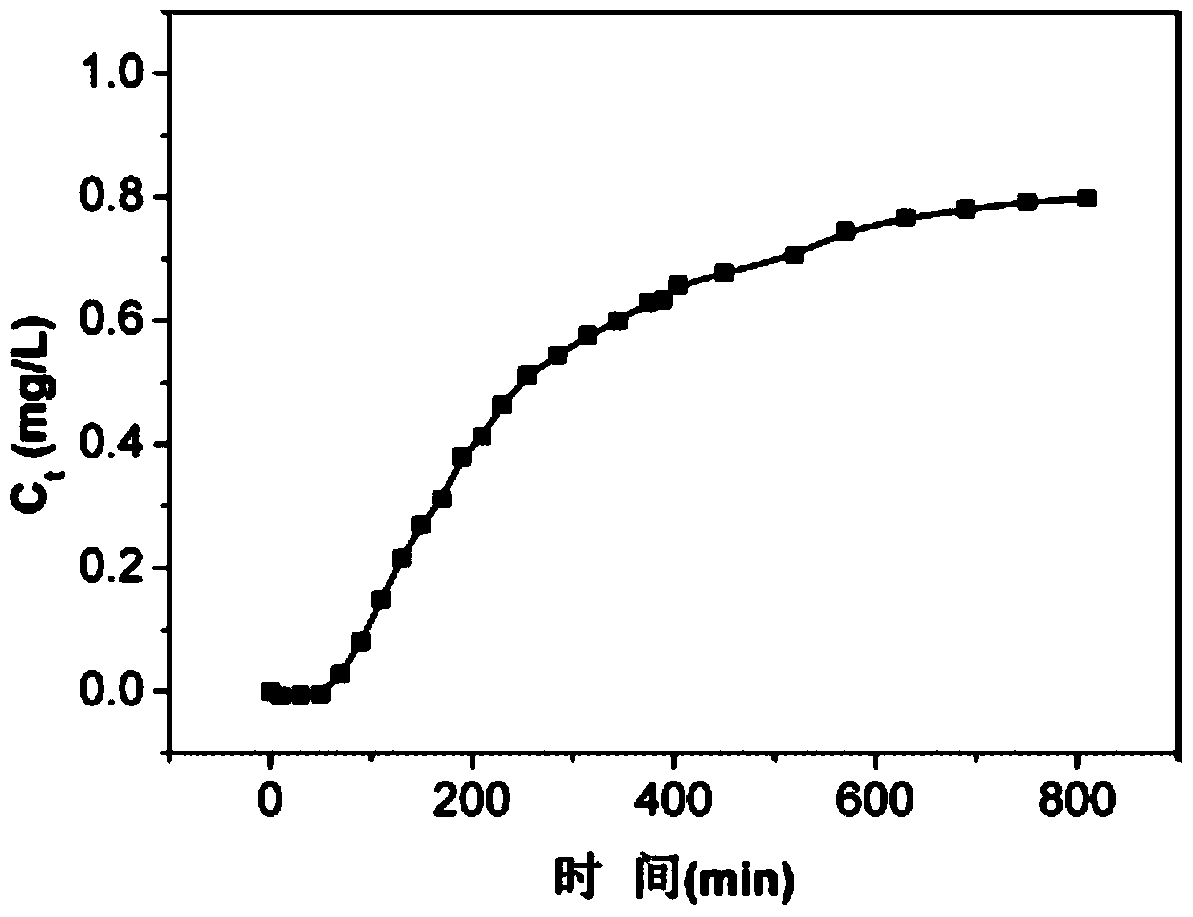

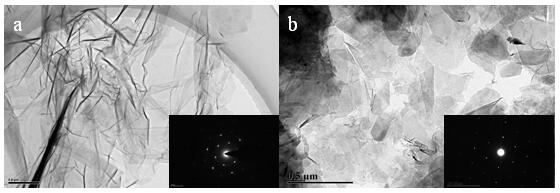

Chitosan nanofiber composite membrane for adsorption and separation of heavy metal ions and its preparation method and application

ActiveCN106311165BStrong penetrating powerIncrease the adsorption areaSemi-permeable membranesOther chemical processesSpinningElectrospun nanofibers

The invention relates to a chitosan nanofiber composite film for adsorbing and separating heavy metal ions and a preparation method and application thereof. The composite film is a chitosan electrospun nanofiber / non-woven fabric base composite film. The method for preparing the composite film comprises the following steps: performing electro-spinning on chitosan on a non-woven fabric base through an electrostatic spinning method, thereby obtaining a composite fiber film; and combining multiple composite fiber film layers in different manners, thereby preparing an adsorption and separation medium. The adsorption and separation medium is filled in a filter separator and can be used for dynamically adsorbing and filtering to remove heavy metal ions in water. The composite film disclosed by the invention is simple and convenient in preparation method, green, environmental-friendly, low in cost, easy to popularize and apply, high in heavy metal wastewater treatment efficiency and high in selectivity, can be used for purifying and treating heavy metals in industrial and domestic wastewater, and has important social and economical benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Circuit board and manufacturing method thereof

ActiveCN110049619BAvoid peeling offTightly boundPrinted circuit aspectsConductive pattern reinforcementGalvanic cellGold layer

Disclosed is a circuit board. The circuit board comprises a substrate, wherein the substrate has at least one first surface, and the circuit board further comprises a conductive body and a nickel layer, wherein the conductive body is combined with the first surface, and the nickel layer wraps the surface of the conductive body; the circuit board further comprises a non-metal conductive film and agold layer; the non-metal conductive film is combined on the first surface and is arranged adjacent to the nickel layer; and the gold layer wraps the nickel layer and the non-metal conductive film atthe same time. A dense protection interface formed by combining the gold layer and the non-metal conductive film is formed on the side surface, close to the substrate, of the nickel layer in the circuit board, so that corrosive gas can be effectively prevented from entering a gap between the nickel layer and the substrate, a nickel-gold interface and a nickel-copper interface can be effectively prevented from forming an original battery effect, and therefore the nickel layer and the electric conductor can be prevented from being corroded due to the original battery effect, and the gold layer can be effectively prevented from being stripped off. In addition, the invention further provides a manufacturing method of the circuit board.

Owner:QING DING PRECISION ELECTRONICS HUAIAN CO LTD +1

Metal layer of compound semiconductor and preparation method thereof

ActiveCN107275380BImprove adhesionImprove air tightnessSemiconductor/solid-state device manufacturingSemiconductor devicesWaferingEngineering physics

The invention discloses a compound semiconductor metal layer and a manufacturing method thereof. A first metal layer and an insulating layer are arranged on a compound semiconductor wafer successively, an opening is arranged above the first metal layer on the insulating layer, two sides of the opening are inclined inwardly for 45 DEG to 75 DEG, and a TiW layer covers the bottom part and the side wall of the opening and extends to the top surface of the insulating layer around; a second metal layer is formed on the TiW layer and fills the opening and is convex above the opening, and two sides of the convex part are inclined outwardly for 75 DEG to 85 DEG; a Ti layer covers the side wall of the TiW layer and the surface of the second metal layer, and a connection port is opened at the top surface of the second metal layer; and a protection layer covers the Ti layer and the surface of the insulating layer. Through the arrangement of the above structure, the metal layer structure meets technological requirements, the connection stability and the device reliability are improved, the yield of the process and the service life of the product are improved, promotion of an electroplating process in metal layer manufacturing is facilitated, and the cost is reduced.

Owner:XIAMEN SANAN INTEGRATED CIRCUIT

A kind of multifunctional graphene electrothermal slurry and its multifunctional electrothermal film and its preparation method and application

ActiveCN107682943BImprove machinabilityFast heat conductionChemical industryHeating element materialsSlurryGraphene

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Multi-performance coating filtering material and preparation method thereof

ActiveCN113087857AImprove filtration efficiencySoft and smoothMembrane filtersFiltration separationCoated membraneEpoxy

The invention relates to a polymerized emulsion coating which is prepared by mixing the following raw materials by weight: 20 to 21 g of itaconic acid, 350 to 360 g of ethyl acrylate, 71 to 73 g of allyl polyoxy alkyl epoxy ether, 10 to 10.5 g of ethyl-2-methyl 1, 3-dioxopentyl-4-yl acrylate, 42 to 44 g of methyl methacrylate, 2 to 2.3 g of fatty alcohol-polyoxyethylene ether XL-90, 1.9 to 2.1 g of ammonium persulfate and 550 to 600 g of deionized water, and the raw materials are mixed into a polymerized emulsion. 80g of the polymerized emulsion is taken, 17g of water and 3g of a thickening agent are added, stirred and thickened uniformly, and filtered and discharged to obtain the product. According to the coating film material, the surface of the air outlet side is covered with a film, so that the filtering efficiency of the filtering material is improved while the original technical performance is kept.

Owner:丹东天皓净化材料有限公司 +1

A packaging component and its preparation method

ActiveCN111341739BAvoid peeling offImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesHemt circuitsEngineering

The present invention relates to a packaging component and a manufacturing method thereof. The method comprises the following steps: providing a heat dissipation substrate, etching the second surface of the heat dissipation substrate to form a plurality of concave holes; An insulating layer and a circuit wiring layer are formed on the first surface of the circuit wiring layer; a plurality of semiconductor elements and a plurality of conductive pins are installed on the circuit wiring layer; an encapsulation compound is formed; a plurality of intervals are formed around the encapsulation compound The perforations penetrate the encapsulant; provide a plurality of metal conductive pillars, and then form a plurality of through holes penetrating through the metal conductive pillars on the side of each of the metal conductive pillars, and multiple metal conductive pillars are formed. The conductive pillars are respectively embedded into the corresponding through-holes, and then the encapsulation compound is subjected to a thermocompression bonding process, so that part of the encapsulation compound is embedded in the through holes of the metal conduction pillars.

Owner:深圳市之诺微电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com