Cross-linked polyethylene lined composite pipe and production method thereof

A technology of cross-linked polyethylene and production methods, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve problems such as many production control links, affect the application of oil pipes, and complicated processes, so as to improve product quality and avoid Peeling off, good composite effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

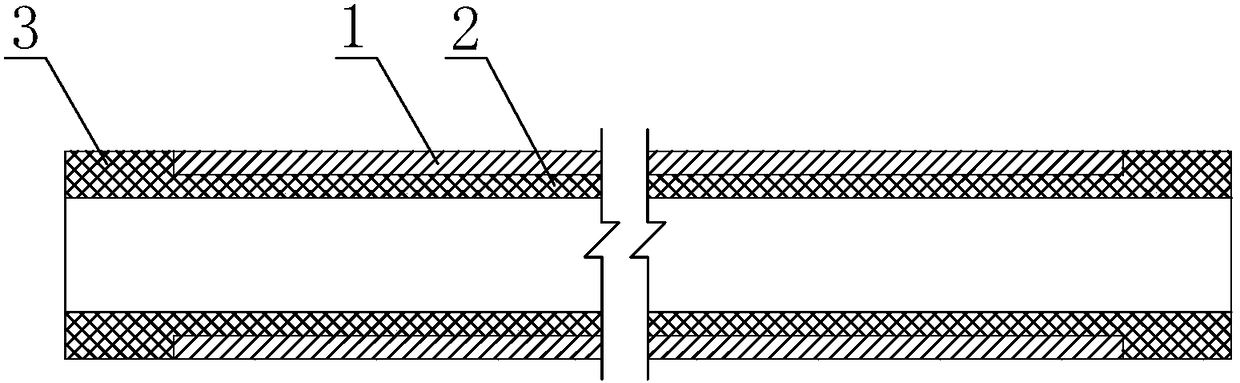

[0048] The cross-linked polyethylene lined pipe selected in this example has an outer diameter of 63-63.6mm and a wall thickness of 3.0-3.4mm; The gauge length is 1200mm.

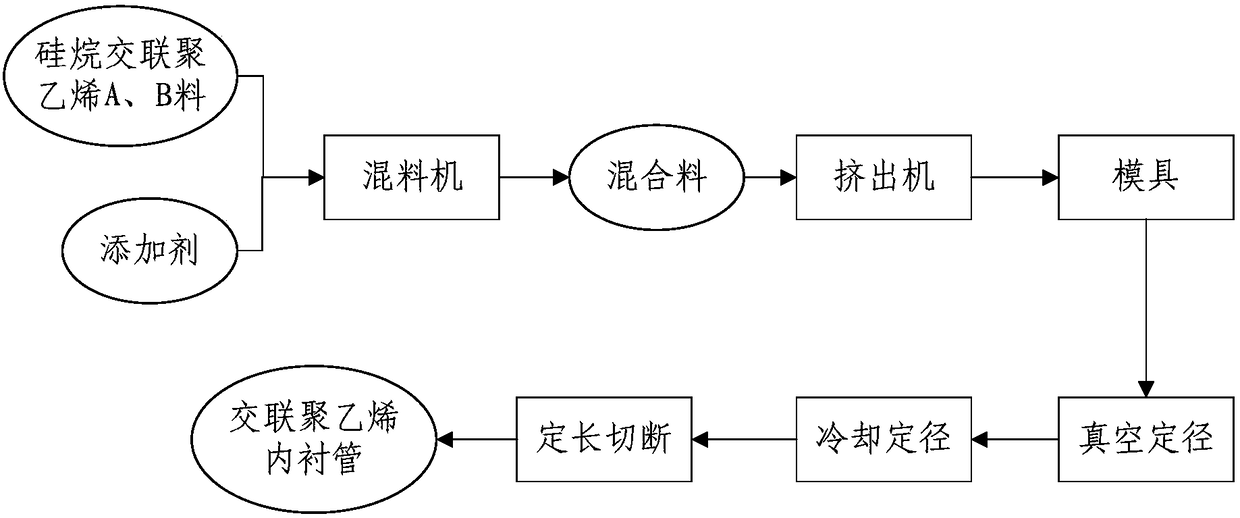

[0049] Among them, the cross-linked polyethylene lining pipe is made of the following components by weight ratio: 90 parts of cross-linked polyethylene raw materials; 0.05 parts of silicone external lubricating additives; 0.5 parts of telechelic hydrophilic group polymer additives; Antioxidant 1010 is 0.15 parts; antioxidant 168 is 0.5 parts; linear low density polyethylene powder is 2 parts.

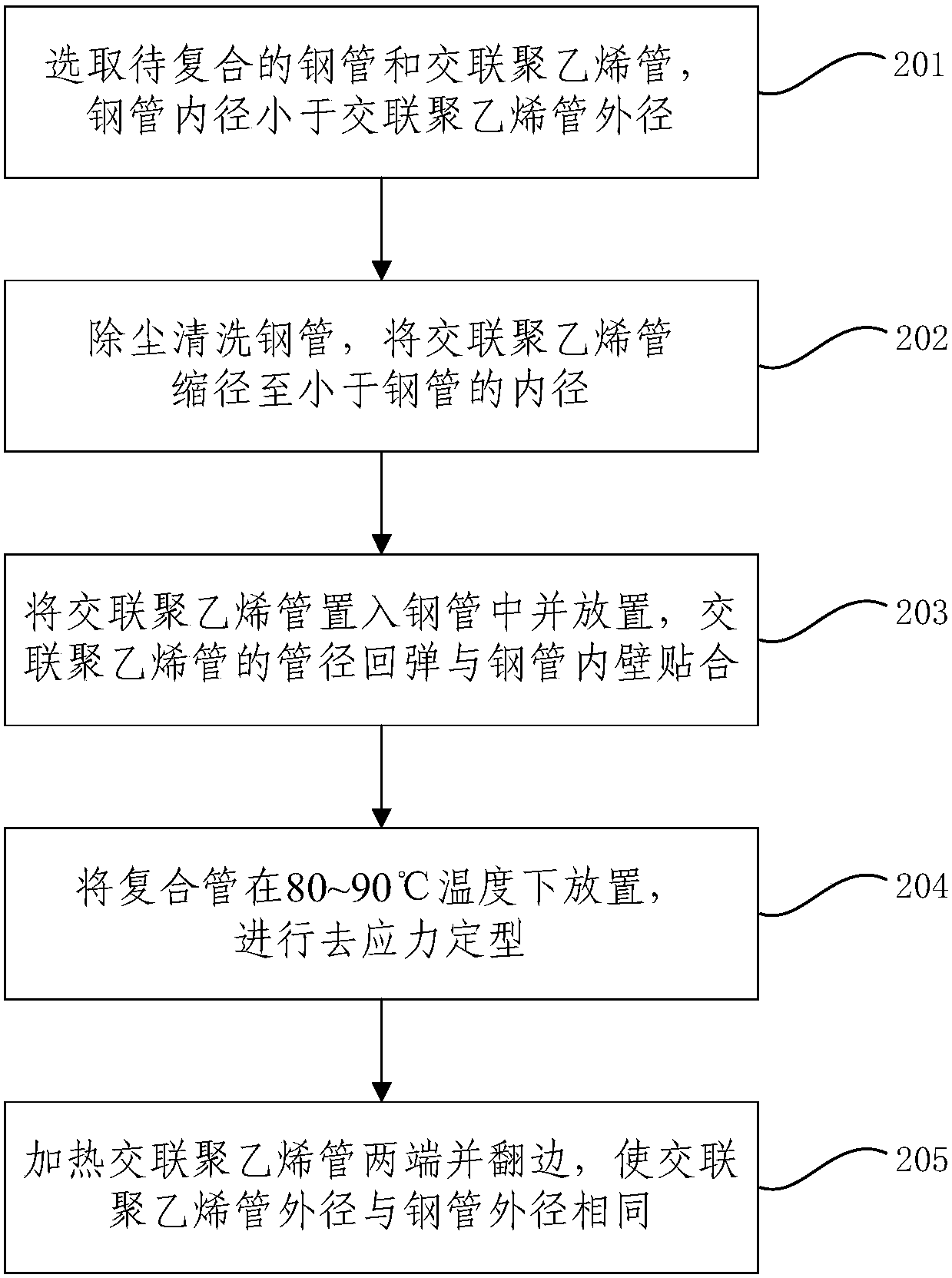

[0050] Use a reducing machine to reduce the outer diameter of the cross-linked polyethylene lined pipe to less than 54mm, insert it into the steel pipe, place it for 24 hours to restore the stress, and then place it at a constant temperature of 80°C for 3 hours to relieve the stress and shape it. Keep both ends of the cross-linked polyethylene lined pipe 20-25mm longer than the steel pipe, and heat the two ends of t...

Embodiment 2

[0052] The cross-linked polyethylene lining pipe selected in this example has an outer diameter of 91.5-92.4mm and a wall thickness of 4.5-5.0mm; The gauge length is 1200mm.

[0053] Among them, the cross-linked polyethylene lining pipe is made of the following components by weight: 100 parts of cross-linked polyethylene raw material; 0.1 part of silicone-based external lubricating additive; 0.25 part of telechelic hydrophilic group polymer additive; 0.1 part of antioxidant 1010; 0.1 part of antioxidant 168; 6 parts of linear low density polyethylene powder.

[0054] Use a reducing machine to reduce the outer diameter of the cross-linked polyethylene lined pipe to less than 86mm, insert it into the steel pipe, place it for 24 hours to recover the stress, and then place it at a constant temperature of 90°C for 2 hours to relieve the stress and shape it. Keep both ends of the lining pipe 20-25mm longer than the steel pipe, heat both ends to 200°C for 3 minutes, flanging until t...

Embodiment 3

[0056] The cross-linked polyethylene lining pipe selected in this example has an outer diameter of 160-161.5mm and a wall thickness of 3.0-3.4mm; The gauge length is 1200mm.

[0057] Among them, the cross-linked polyethylene lining pipe is made of the following components by weight ratio: 95 parts of cross-linked polyethylene raw materials; 0.2 parts of silicone-based external lubricating additives; 0.1 parts of telechelic hydrophilic group polymer additives; 0.5 parts of antioxidant 1010; 0.15 parts of antioxidant 168; 4 parts of linear low density polyethylene powder.

[0058] Use a reducing machine to reduce the outer diameter of the cross-linked polyethylene lined pipe to less than 152mm, insert it into the steel pipe, place it for 24 hours to restore the stress, and then place it at a constant temperature of 90°C for 2 hours to relieve the stress and shape it. Keep both ends of the lining pipe 20-25mm longer than the steel pipe, heat both ends to 200°C for 3 minutes, fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com