Technique method of metallization annealing of IGBT back face

A technology of backside metallization and process method, which is applied in the field of IGBT backside metallization and annealing, and can solve the problems of backside metal peeling and falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

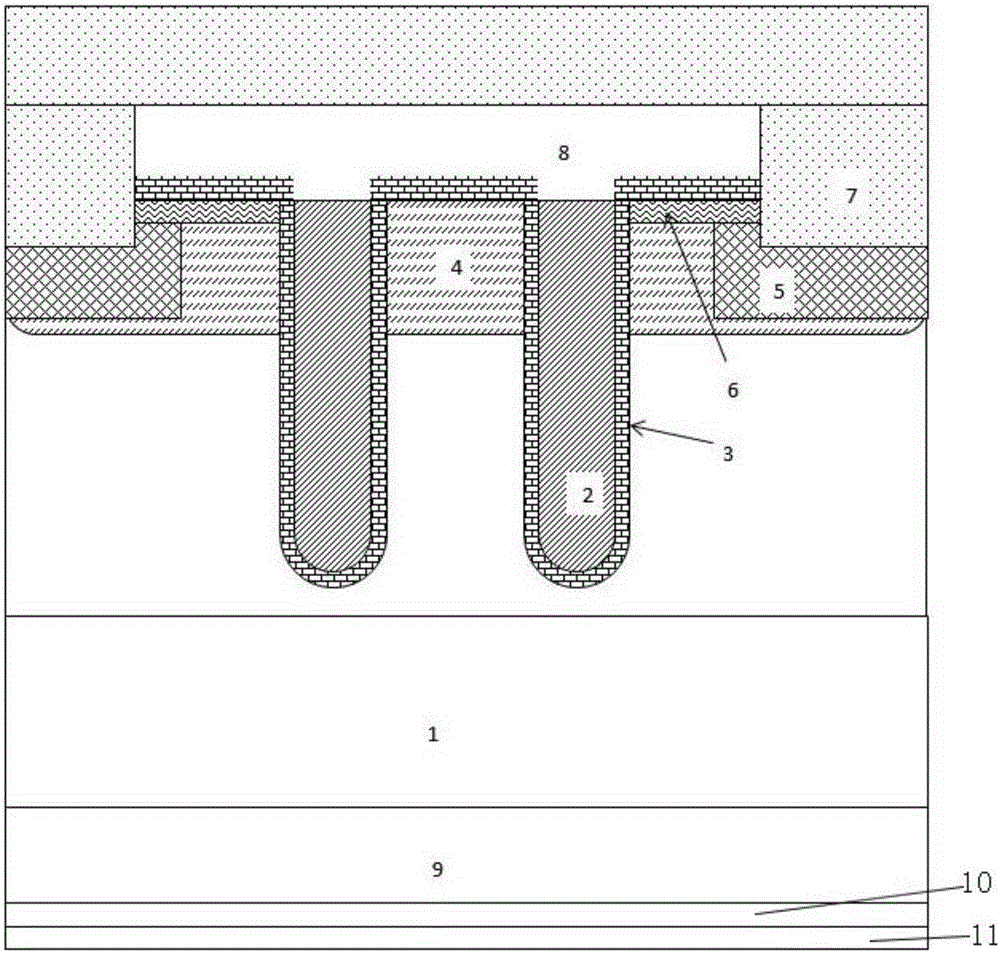

[0020] The metallization and annealing process on the back of the IGBT described in the present invention is applicable to all IGBT products of the non-TAIKO process, but not applicable to the wafers of the TAIKO process.

[0021] This process method comprises the following steps:

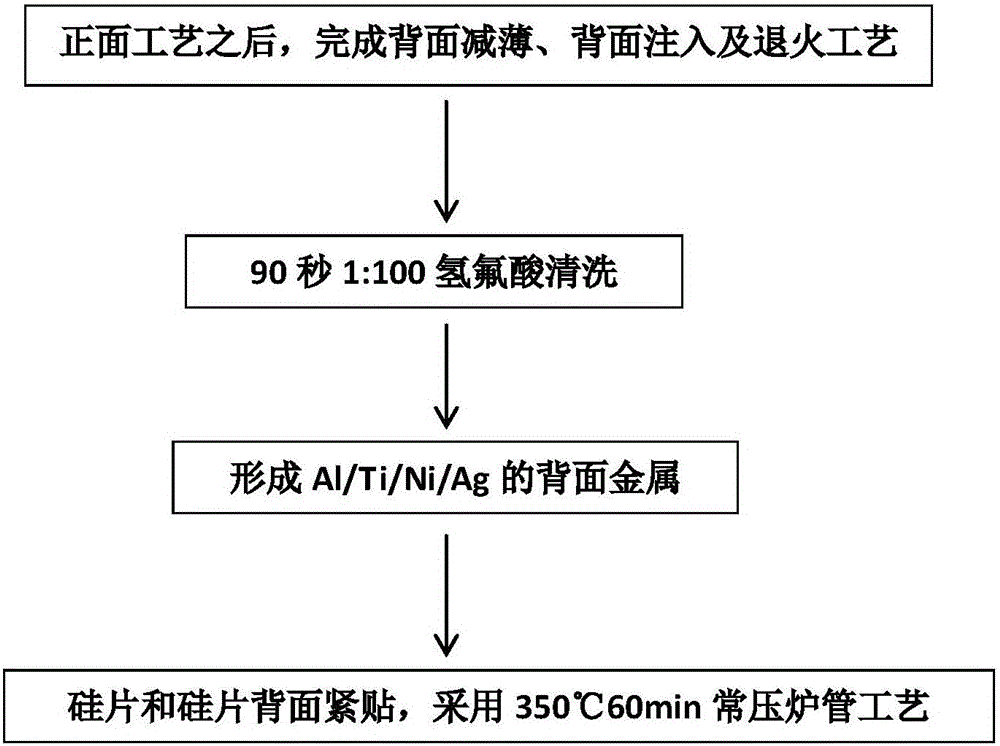

[0022] The first step is to select a suitable substrate to complete the front pattern process, including the cell area and the voltage protection ring area. After the front-side process is completed, thinning, back-side ion implantation, and back-side laser annealing processes are performed on the back side of the silicon wafer.

[0023] The second step is to clean the back of the silicon wafer with 1:100 buffered hydrofluoric acid for 90 seconds.

[0024] The third step is to deposit the back metal, that is to form the back metal of Al, Ti, Ni and Ag. Typical thicknesses correspond to 2000 angstroms, 2000 angstroms, 2000 angstroms, and 8000 angstroms, respectively.

[0025] In the fourth step, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com