Lithium ion battery, preparation method thereof and application of porous aluminum-carbon composite material

A lithium-ion battery and carbon composite material technology, which is applied in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve the problems of difficult silicon carbon anode, high price, and difficulty in obtaining energy density lithium-ion batteries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A method for preparing a lithium-ion battery according to an embodiment of the present invention includes the following steps S1-S3:

[0022] S1. Provide positive electrode, separator and electrolyte.

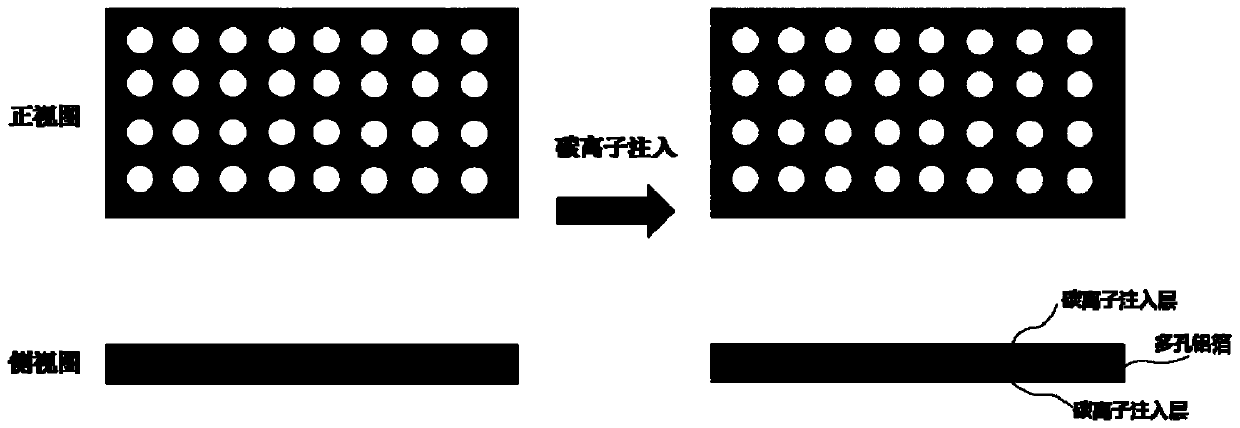

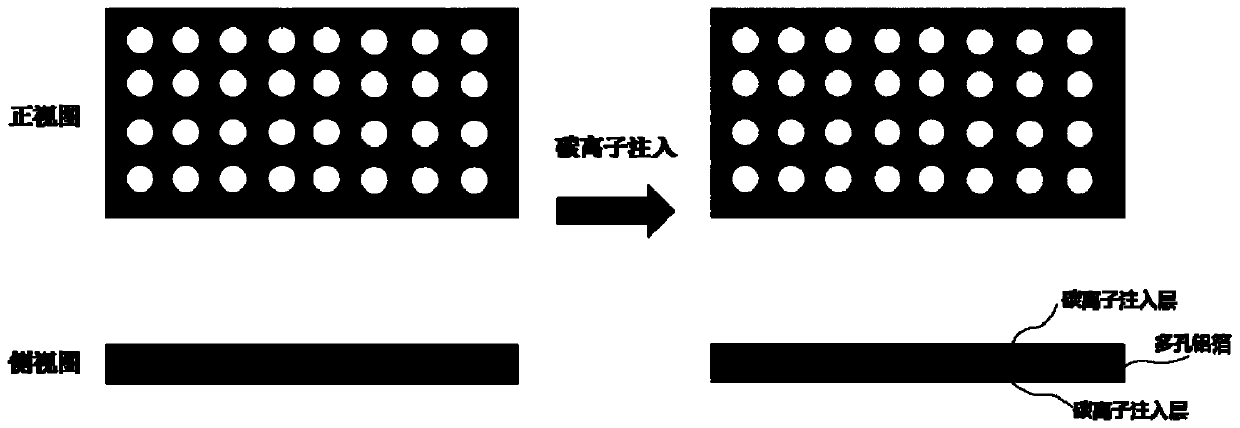

[0023] S2. Implanting the porous aluminum foil with carbon ions to obtain a negative electrode.

[0024] S3, assembling and processing the positive electrode, the separator, the negative electrode and the electrolyte to obtain the lithium ion battery.

[0025] Compared with graphite materials, metal aluminum (Al) has a higher theoretical specific capacity. When the LiAl structure is formed, the specific capacity can reach 993mAh / g. When the LiAl structure is formed, the specific capacity can reach 993mAh / g. 9 Al 4 materials, the specific capacity reaches 2235mAh / g, and the voltage platform is only 0.19V~0.45V (vs Li + / Li), and it has a smaller volume expansion than silicon materials, forming Li 9 A l4 , the volume expansion is only 97%, and the Al material also has...

Embodiment 1

[0036] The porous aluminum foil with a porosity of 10% and a thickness of 16 μm was ultrasonically cleaned in ethanol, acetone and deionized water to remove surface dirt, and then placed in a vacuum drying oven at 80°C for 20 minutes to dry. Take out the dried porous aluminum foil, place it in the ion implantation equipment, start vacuuming after sealing, and the vacuum degree reaches 1 × 10 -6 At torr, the energy density is 6μA / cm 2 Clean the surface of the porous aluminum foil for 20 minutes with a flow of argon ions. Then carbon ion implantation is carried out, and carbon ions are implanted into one side of the porous aluminum foil. After the single-sided ion implantation is completed, the above-mentioned ion implantation operation is repeated, and carbon ions are implanted into the other side of the aluminum foil to obtain a porous aluminum foil / carbon composite negative electrode. The carbon ion implantation energy is 1KeV, and the ion implantation dose is 1×10 -5 g / cm ...

Embodiment 2

[0040] The porous aluminum foil with a porosity of 20% and a thickness of 24 μm was ultrasonically cleaned in ethanol, acetone and deionized water to remove surface dirt, and then placed in a vacuum drying oven at 90°C for 10 minutes to dry. Take out the dried porous aluminum foil, place it in the ion implantation equipment, and start vacuuming after sealing, and the vacuum degree reaches 0.5×10 -6 At torr, the energy density is 7.5μA / cm 2 The surface of the porous aluminum foil was cleaned by the argon ion flow for 10 minutes. Then carbon ion implantation is carried out, and carbon ions are implanted into one side of the porous aluminum foil. After the single-sided ion implantation is completed, the above-mentioned ion implantation operation is repeated, and carbon ions are implanted into the other side of the aluminum foil to obtain a porous aluminum foil / carbon composite negative electrode. The carbon ion implantation energy is 1.5KeV, and the ion implantation dose is 1×10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com