Preparation method of solar photovoltaic glass with micro-nano anti-reflection layer

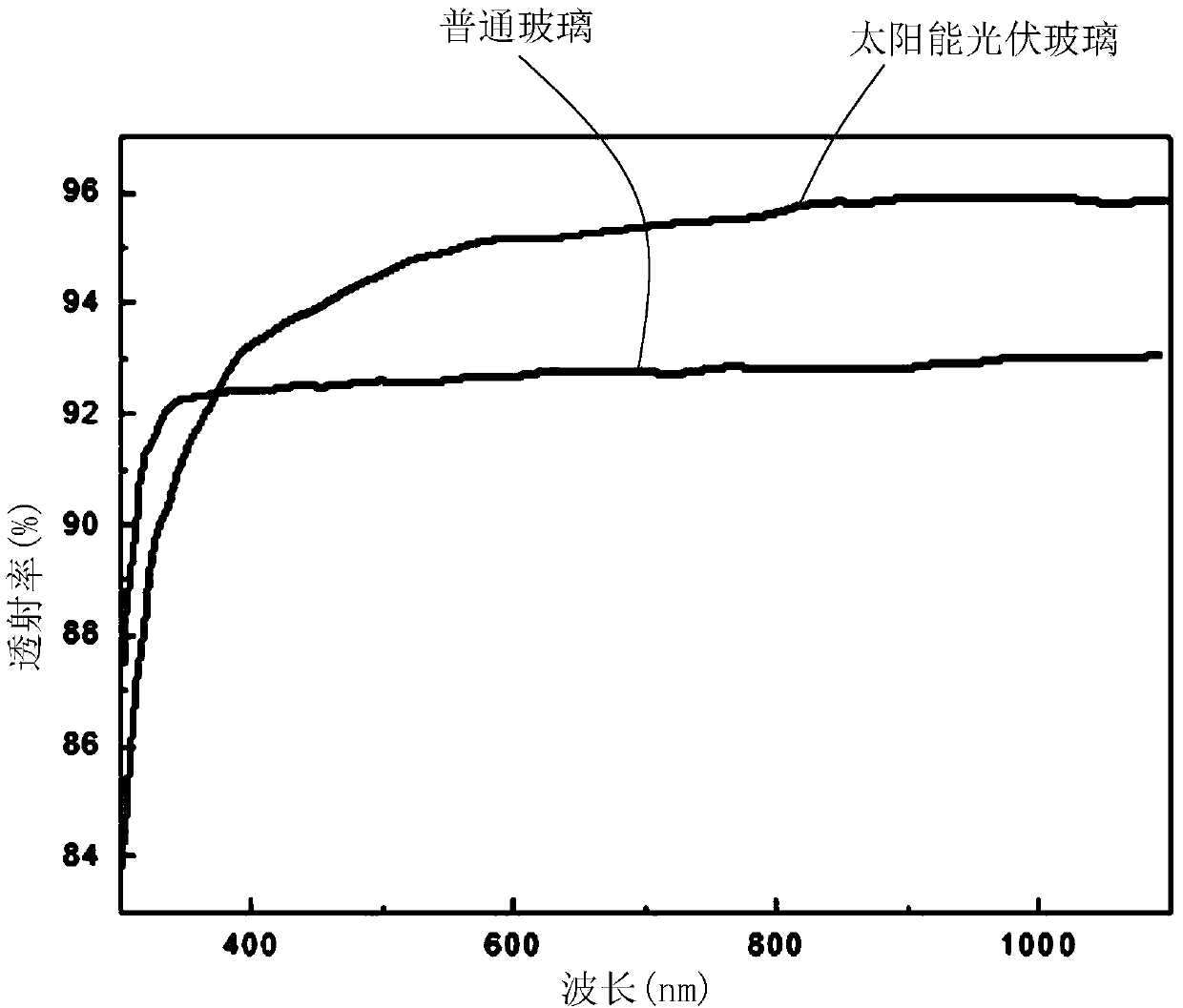

A solar photovoltaic and anti-reflection layer technology, applied in photovoltaic power generation, coatings, semiconductor devices, etc., can solve the problems of unsuitability for large-scale production, complex preparation process, poor resolution, etc., and achieve high resolution and high light conversion efficiency Performance, simple process, and the effect of improving light conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

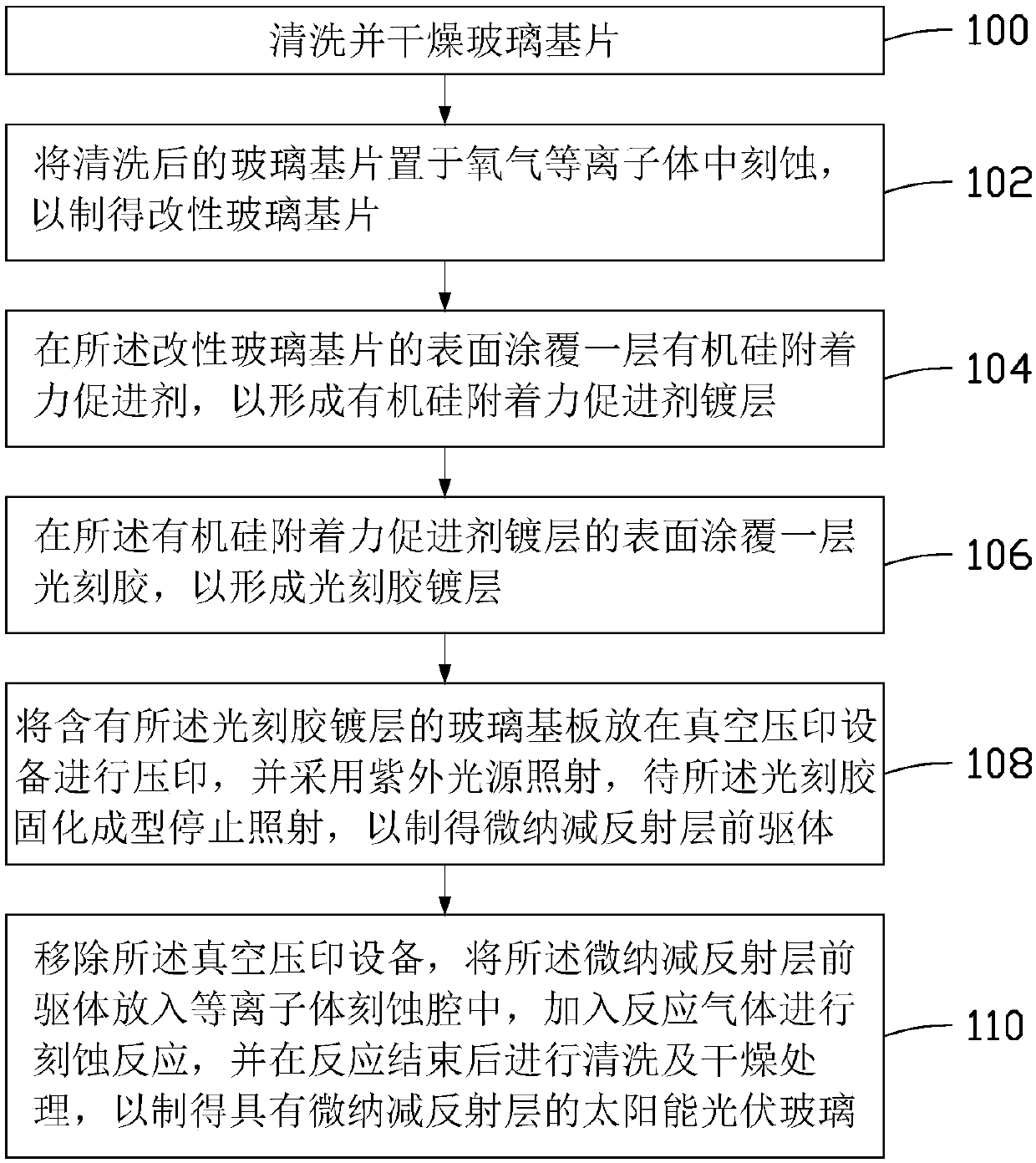

[0032] see figure 1 , the preparation method of the solar photovoltaic glass with micro-nano anti-reflection layer of the present invention, it comprises the steps:

[0033] Step 100, cleaning and drying the glass substrate.

[0034] Specifically, the glass substrate is placed in an ultrasonic cleaning machine, and an appropriate amount of cleaning agent is added for ultrasonic cleaning for 5-10 minutes (min); the cleaned glass substrate is taken out, soaked with a solvent for a period of time, and then cleaned with an inert gas blow dry.

[0035] Wherein, the thickness of the glass substrate is 0.3-0.5 nanometer (nm). It can be understood that the purpose of cleaning the glass substrate is to remove the pollutants on the glass substrate, thereby avoiding the scattering and absorption of incident light by the pollutants, thereby improving the light conversion rate of the solar photovoltaic glass. The cleaning agent for cleaning the glass substrate is an organic solvent. Th...

Embodiment 1

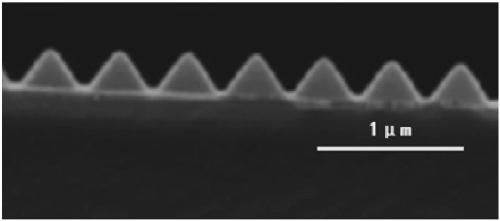

[0057] Put the glass substrate with a thickness of 0.4nm into an ultrasonic cleaning machine, and use absolute ethanol to ultrasonically clean it for about 5-10 minutes, so as to remove the pollutants on the glass substrate. The glass substrate was taken out, soaked with deionized water for 2 minutes, and the chemical reagents remaining on the surface were removed, and then the glass was blown dry with nitrogen gas. Put the cleaned glass substrate into an oxygen plasma and etch for 4 minutes to prepare a modified glass substrate. Put the modified glass substrate into a 200°C oven and bake for 30 minutes to remove the reactant formed by the reaction between the reaction gas and the glass substrate in oxygen plasma etching, and cool it to room temperature. The silicone adhesion promoter was coated on the surface of the cover glass by a spin coating process, wherein the spin coating speed was 4000rpm, and the spin coating time was 60s, so as to form a coating of the silicone adh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com