Silica gel composite bath towel and a preparation method thereof

A technology for silica gel and bath towels, which is applied in chemical instruments and methods, sanitary equipment, lamination, etc. It can solve the problems of weak bonding force between silica gel and bath towel cloth, silica gel affecting performance, and silica gel layer is easy to fall off. Wide range, excellent transparency, the effect of avoiding peeling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

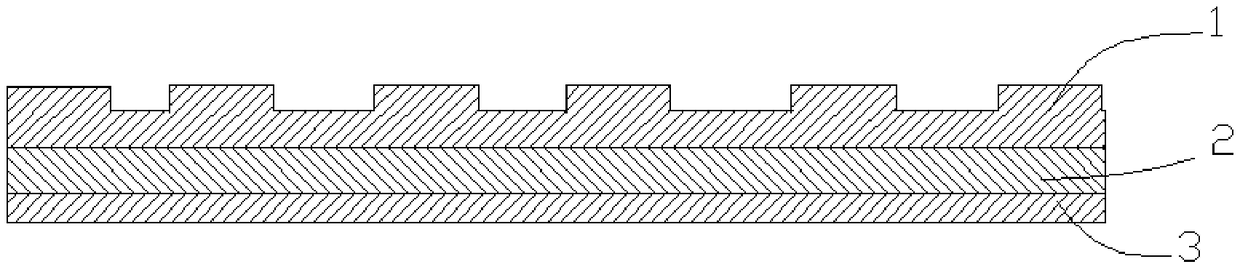

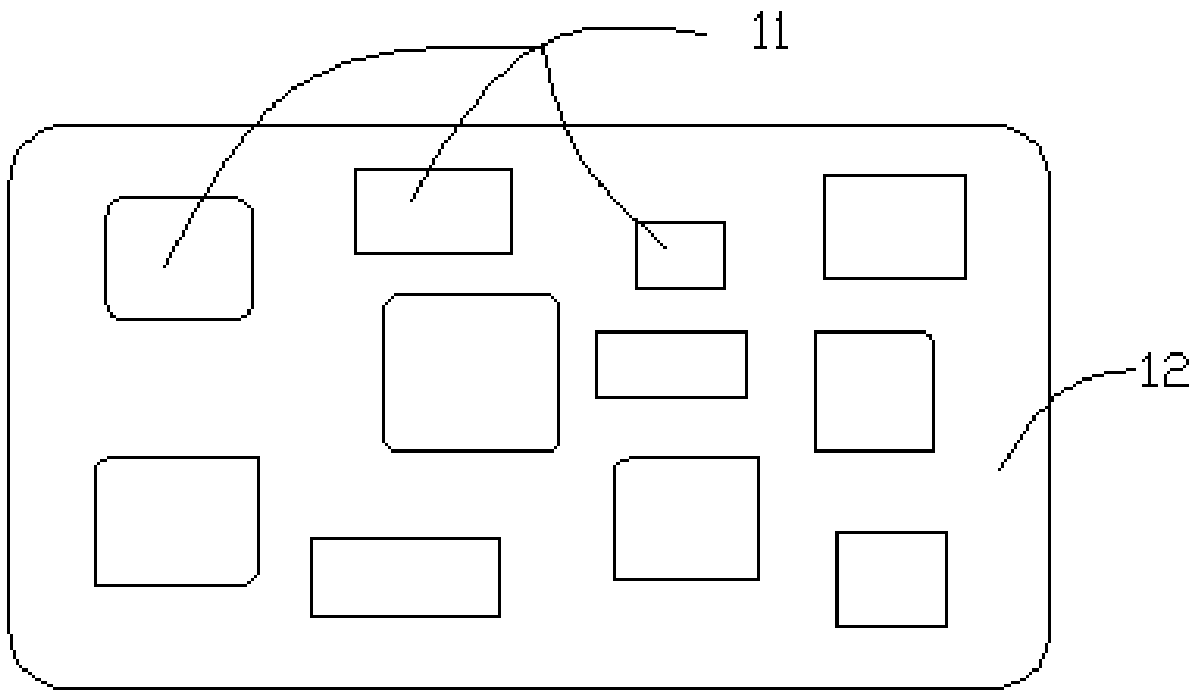

[0033] The silica gel composite bath towel includes a silica gel composite layer 1, a water-absorbing layer 2, and a lining layer 3 arranged sequentially from top to bottom. The coating material layer 11 is higher than the thickness of the matrix material layer 12 and is 0.8mm, and the area of the hanging coating material layer 11 is 50% of the area of the matrix material layer 12, and the matrix material is a bath towel;

[0034] The hanging coating material includes the following raw materials in parts by weight: 100 parts of liquid silica gel, 1 part of cyclopolydimethylsiloxane and 1 part of fumed white carbon black;

[0035] The liquid silica gel includes A component and B component, and the weight ratio of the A component and B component is 1:1,

[0036] The A component includes the following raw materials in parts by weight: 12 parts of polymethylvinylsiloxane, 13.965 parts of hydroxyl polydimethylsiloxane, 25 parts of vinyl MQ silicone resin and 0.03 parts of plati...

Embodiment 2

[0043] The silica gel composite bath towel includes a silica gel composite layer 1, a water-absorbing layer 2 and a lining layer 3 arranged sequentially from top to bottom. The thickness of the hanging coating material layer 11 higher than the base material layer 12 is 0.6mm, and the area of the hanging coating material layer 11 is 80% of the area of the base material layer 12, and the base material is bath towel cloth;

[0044] The hanging coating material includes the following raw materials in parts by weight: 100 parts of liquid silica gel, 45 parts of cyclopolydimethylsiloxane and 1 part of fumed white carbon black;

[0045] The liquid silica gel includes A component and B component, and the weight ratio of the A component and B component is 1:1,

[0046] The A component includes the following raw materials in parts by weight: 15 parts of polymethylvinylsiloxane, 15 parts of hydroxyl polydimethylsiloxane, 20 parts of vinyl MQ silicone resin and 0.015 parts of platinum...

Embodiment 3

[0053] The silica gel composite bath towel includes a silica gel composite layer 1, a water-absorbing layer 2 and a lining layer 3 arranged sequentially from top to bottom. The thickness of the hanging coating material layer 11 higher than the base material layer 12 is 0.8mm, and the area of the hanging coating material layer 11 is 80% of the base material layer 12 area, and the base material is bath towel cloth, and the described bath towel cloth is shuttle fabric;

[0054] The hanging coating material includes the following raw materials in parts by weight: 100 parts of liquid silica gel, 15 parts of cyclopolydimethylsiloxane and 1 part of fumed white carbon black;

[0055] The liquid silica gel includes A component and B component, and the weight ratio of the A component and B component is 1:1,

[0056] The A component includes the following raw materials in parts by weight: 14 parts of polymethylvinylsiloxane, 12 parts of hydroxyl polydimethylsiloxane, 24 parts of vinyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com