Chitosan nanofiber composite membrane for adsorption and separation of heavy metal ions and its preparation method and application

A technology of chitosan nanometer and heavy metal ions is applied in the application field of adsorption materials and nanomaterials, which can solve the problems of low use efficiency and poor mechanical properties, and achieve the effects of reducing energy loss, overcoming poor strength and improving adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

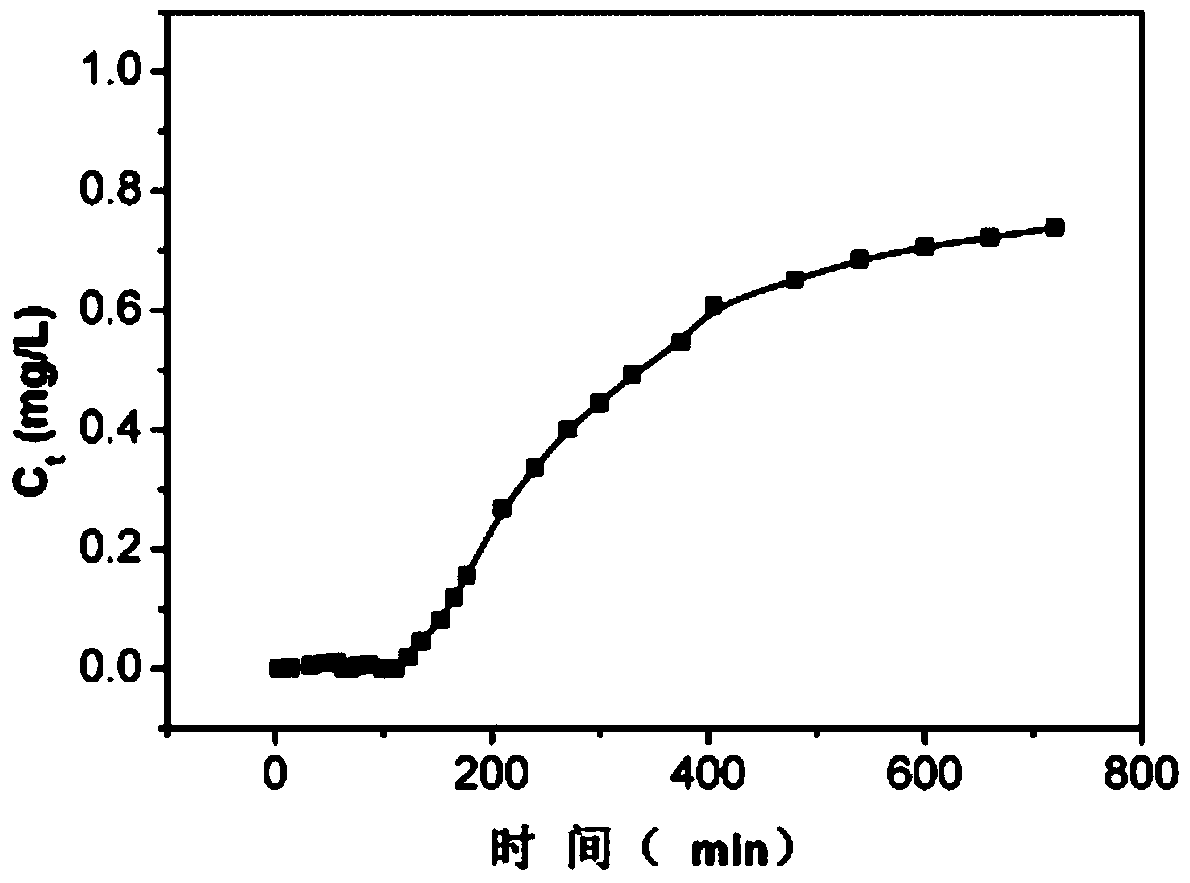

[0057] 1) Dissolving 3g of chitosan with a deacetylation degree of 90% and a molecular weight of 200,000 in acetic acid solution of 90% by mass fraction in 57g was stirred and dissolved for 12h to obtain a uniform spinning solution with a mass fraction of 5%; Chitosan nanofibers were prepared by electrospinning. The electrospinning process was as follows: voltage 23kV, spinning distance 6cm, liquid supply speed 1mL / h; gram weight 34g / m 2 The polyester non-woven fabric is used as the base, the diameter of the polyester fiber is 20 μm, and the pore size of the non-woven fabric is 114 μm; the chitosan nanofiber is electrospun on the non-woven fabric substrate to obtain the chitosan nanofiber / polyester Non-woven composite material. The mean diameter of chitosan fiber in the composite material prepared is 60-120nm (as figure 1 shown), the weight of chitosan fiber is 2g / m 2 , the pore size of the composite material was 0.56 μm; the prepared composite material was put into a desicc...

Embodiment 2

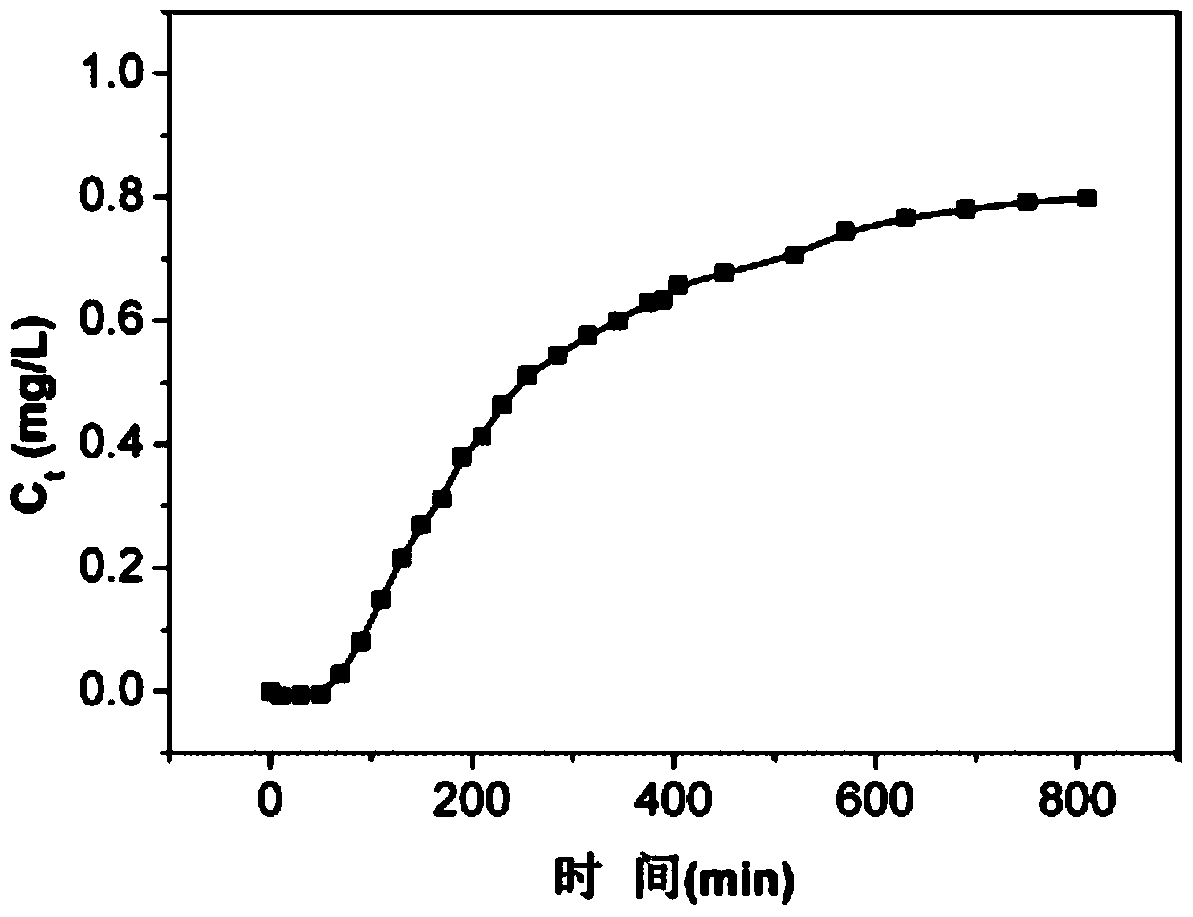

[0061] 1) Dissolving 1.5g of chitosan with a deacetylation degree of 95% and a molecular weight of 150,000 in 50g of trifluoroacetic acid was stirred and dissolved for 4h to obtain a uniform spinning solution with a mass fraction of 3%; using the electrospinning method Chitosan nanofibers were prepared; among them, the electrospinning process was: voltage 15kV, spinning distance 10cm, liquid supply speed 0.5mL / h; the gram weight was 27g / m 2 The polypropylene fiber non-woven fabric is used as the base, and the chitosan nanofiber is electrospun on the base to obtain the chitosan / polypropylene non-woven fabric composite material; the average diameter of the chitosan fiber in the prepared composite material is 70- 150nm, the weight of chitosan fiber is 1g / m 2 , the pore size of the composite material was 1.03 μm; the prepared composite material was put into a desiccator filled with 20mL glyoxal solution, and the glyoxal vapor was cross-linked for 12 hours to obtain a cross-linked ...

Embodiment 3

[0065] 1) 3g deacetylation degree is 70%, the chitosan that molecular weight is 300,000 is dissolved in the acetic acid solution that 57g mass fraction is 85%, stirring and dissolving 12h, obtaining the uniform spinning solution that mass fraction is 5%; Utilize Chitosan nanofibers were prepared by electrospinning; the electrospinning process was as follows: voltage 30kV, spinning distance 15cm, liquid supply speed 1.5ml / h; gram weight 34g / m 2 The polyamide non-woven fabric is the substrate, the diameter of the polyamide fiber is 10 μm, and the pore size of the non-woven fabric is 68 μm; the chitosan nanofiber is electrospun on the substrate to obtain the chitosan nanofiber / polyamide non-woven fabric Composite material; the average diameter of chitosan fiber in the prepared composite material is 70-200nm, and the gram weight of chitosan fiber is 0.5g / m 2 , the pore size of the composite material was 3.2 μm; the prepared composite material was put into a desiccator filled with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com