Display panel and preparation method thereof

A display panel and metal technology, which is applied in the direction of electrical components, transistors, electric solid devices, etc., can solve the problem of low adhesion between the metal oxide layer and the Cu film, achieve the effect of preventing peeling off and improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

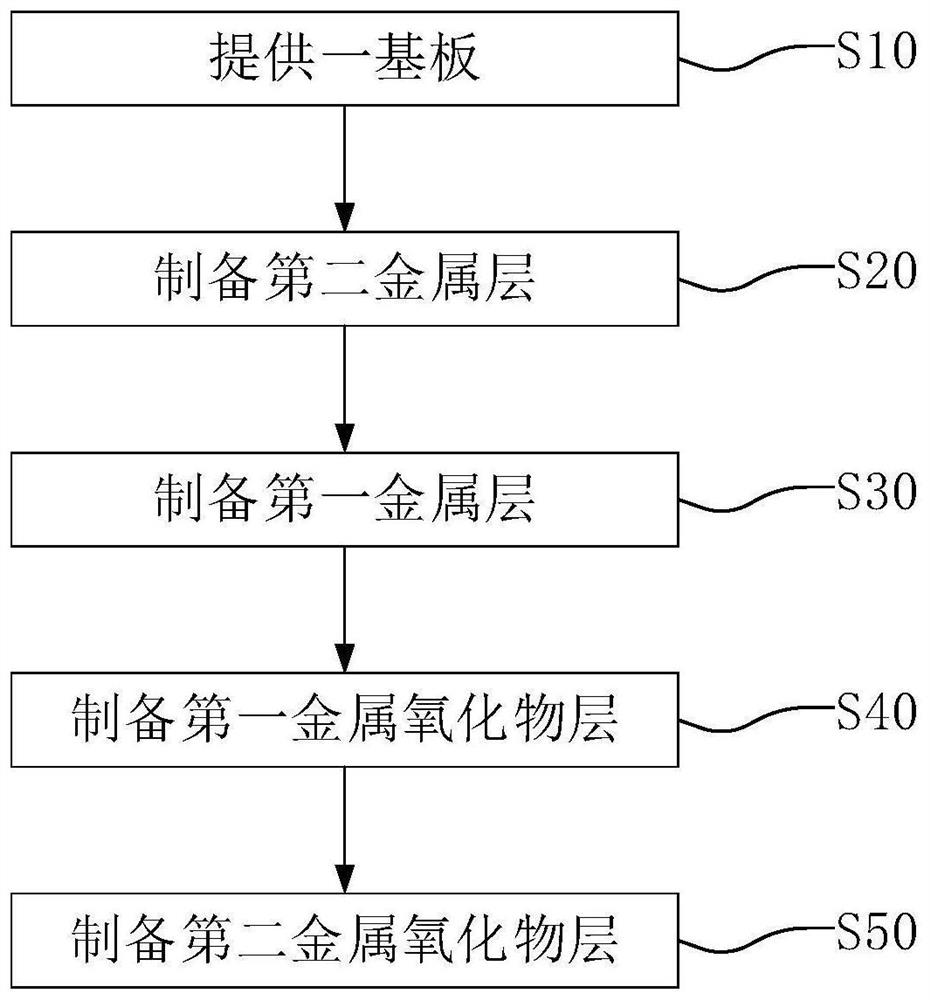

Method used

Image

Examples

Embodiment 1

[0044] An embodiment of the present invention provides a display device, which has a display panel 100, and the display panel 100 is used to provide a display image for the display device. The display device can be any product or component with a display function, such as a mobile phone, a tablet computer, a notebook computer, and the like.

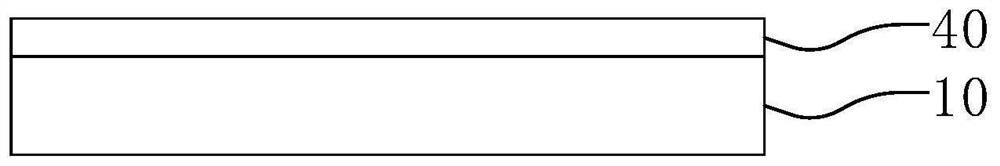

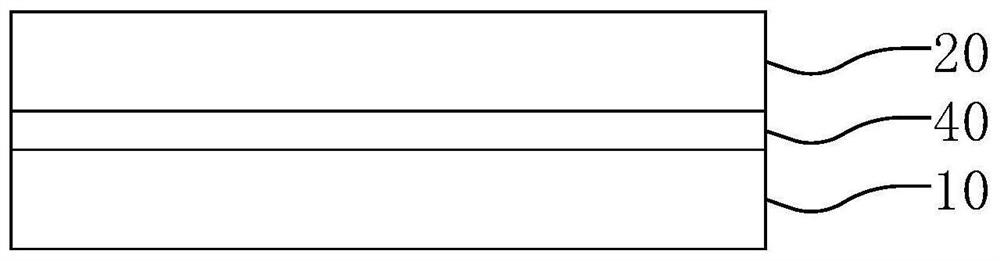

[0045] like Figure 5 As shown, the display panel 100 has a substrate 10 , a first metal layer 20 , a second metal layer 40 and a metal oxide layer 30 .

[0046] The substrate 10 is used to protect the overall structure of the display panel 100 , which may be an insulating substrate such as a glass substrate or a quartz substrate.

[0047] The first metal layer 20 is disposed on a surface of the substrate 10 and is used for transmitting electric energy for devices in the display panel 100 . The first metal layer 20 is made of a metal material with excellent electrical conductivity, and the metal material may be copper.

[0048] The secon...

Embodiment 2

[0064] An embodiment of the present invention provides a display device, which has a display panel 100, and the display panel 100 is used to provide a display image for the display device. The display device can be any product or component with a display function, such as a mobile phone, a tablet computer, a notebook computer, and the like.

[0065] like Figure 9 As shown, the display panel 100 has a substrate 10 , a first metal layer 20 and a metal oxide layer 30 .

[0066] The substrate 10 is used to protect the overall structure of the display panel 100 , which may be an insulating substrate such as a glass substrate or a quartz substrate.

[0067] The first metal layer 20 is disposed on the substrate 10 and is used for transmitting electric energy for devices in the display panel 100 . The first metal layer 20 is made of a metal material with excellent electrical conductivity, and the metal material may be copper.

[0068] The metal oxide layer 30 is disposed between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com