A kind of anti-scratch PE composite pipe and preparation method thereof

A composite pipe, anti-scratch technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of lack of protective layer, displacement, falling off, high low temperature brittleness, etc., to prevent the melt viscosity from rising, The effect of avoiding peeling off and improving production continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

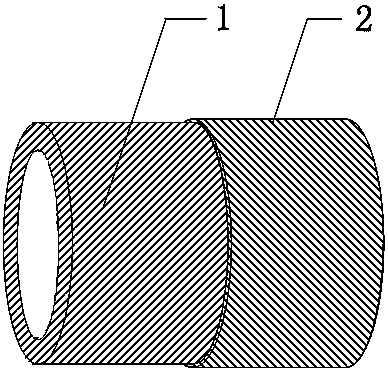

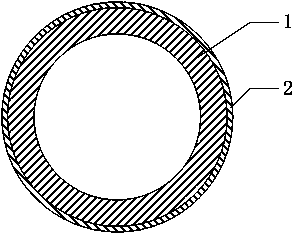

[0035] The thickness of the cross-linked polyethylene protective layer 2 is 10% of the wall thickness of the homogeneous polyethylene pipe main body 1, and the cross-linked polyethylene protective layer 2 is made of the following raw material components in parts by weight:

[0036] 90 parts of cross-linked polyethylene, 0.05 parts of polydimethylsiloxane, 0.1 part of sodium carboxymethyl cellulose, 10100.1 parts of antioxidant, 0.1 part of antioxidant 168, 2 parts of linear low density polyethylene;

[0037] Its preparation method is as follows: Stir each component of the material of the cross-linked polyethylene protective layer 2 evenly according to the proportion, then add it into the extruder and adopt the reactive extrusion process, and place it outside the homogeneous polyethylene pipe main body 1 at a temperature of 140-230°C. A layer of cross-linked polyethylene protective layer 2 with a cross-linking degree of 15% is co-extruded to form a tightly composited integrated ...

Embodiment 2

[0039] The thickness of the cross-linked polyethylene protective layer 2 is 15% of the wall thickness of the homogeneous polyethylene pipe main body 1, and the cross-linked polyethylene protective layer 2 is made of the following raw material components in parts by weight:

[0040] 100 parts of cross-linked polyethylene, 0.2 parts of polydimethylsiloxane, 0.5 parts of sodium carboxymethylcellulose, 0.5 parts of antioxidant 10100, 0.1 part of antioxidant 168, 6 parts of linear low density polyethylene;

[0041] The preparation method is the same as in Example 1, and the crosslinking degree of its light crosslinking is 12%.

Embodiment 3

[0043]The thickness of the cross-linked polyethylene protective layer 2 is 12% of the wall thickness of the homogeneous polyethylene pipe main body 1, and the cross-linked polyethylene protective layer 2 is made of the following raw material components in parts by weight:

[0044] 92 parts of cross-linked polyethylene, 0.08 parts of polydimethylsiloxane

[0045] Sodium carboxymethyl cellulose 0.4 parts Antioxidant 1010 0.4 parts

[0046] Antioxidant 168 0.2 parts Linear low density polyethylene 5 parts.

[0047] The preparation method is the same as in Example 1, and the crosslinking degree of its light crosslinking is 14%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com