Plastic hollow plate bonding method

A bonding method and empty board technology, which is applied in the field of bonding, can solve problems such as affecting appearance and scars, and achieve the effects of preventing peeling off, reducing impact, and increasing bonding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solutions of the present invention will be clearly and completely described below in conjunction with the drawings and embodiments, but the embodiments should not be construed as limiting the present invention.

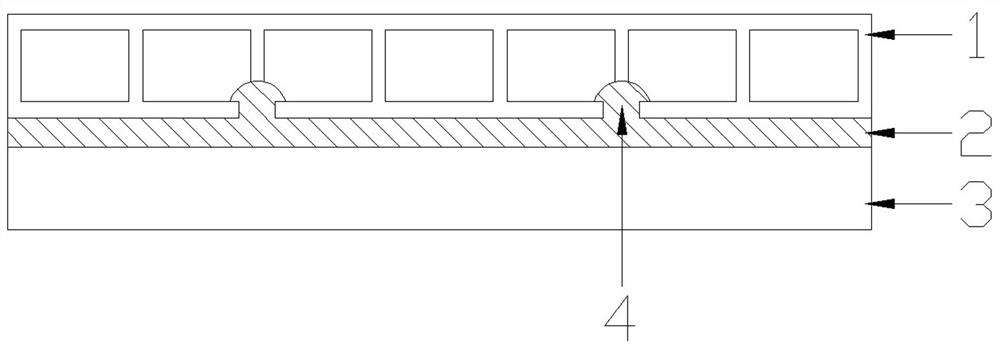

[0011] The present invention as figure 1 Shown: a plastic hollow board bonding method, the bonding surface of the plastic hollow board 1 forms a blind hole 4 by punching, and the bonding surface of the plastic hollow board 1 is coated with an adhesive 2 and pasted with the adhered part 3 By applying pressure, the adhesive 2 penetrates into the interior of the plastic hollow plate 1 through the blind hole 4, and forms a glue riveting structure after curing, increasing the bonding area, thereby effectively preventing the parts from peeling off without changing the appearance of the product.

[0012] It should be noted that a plurality of support plates are arranged at equal intervals inside the plastic hollow plate 1, and the best position of the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com