Two-slice wheel

A two-piece, wheel technology, used in rims, vehicle parts, transportation and packaging, etc., can solve problems such as falling off, single appearance, waste, etc., and achieve the effects of improved mechanical performance, rich and diverse appearance, and reduced cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

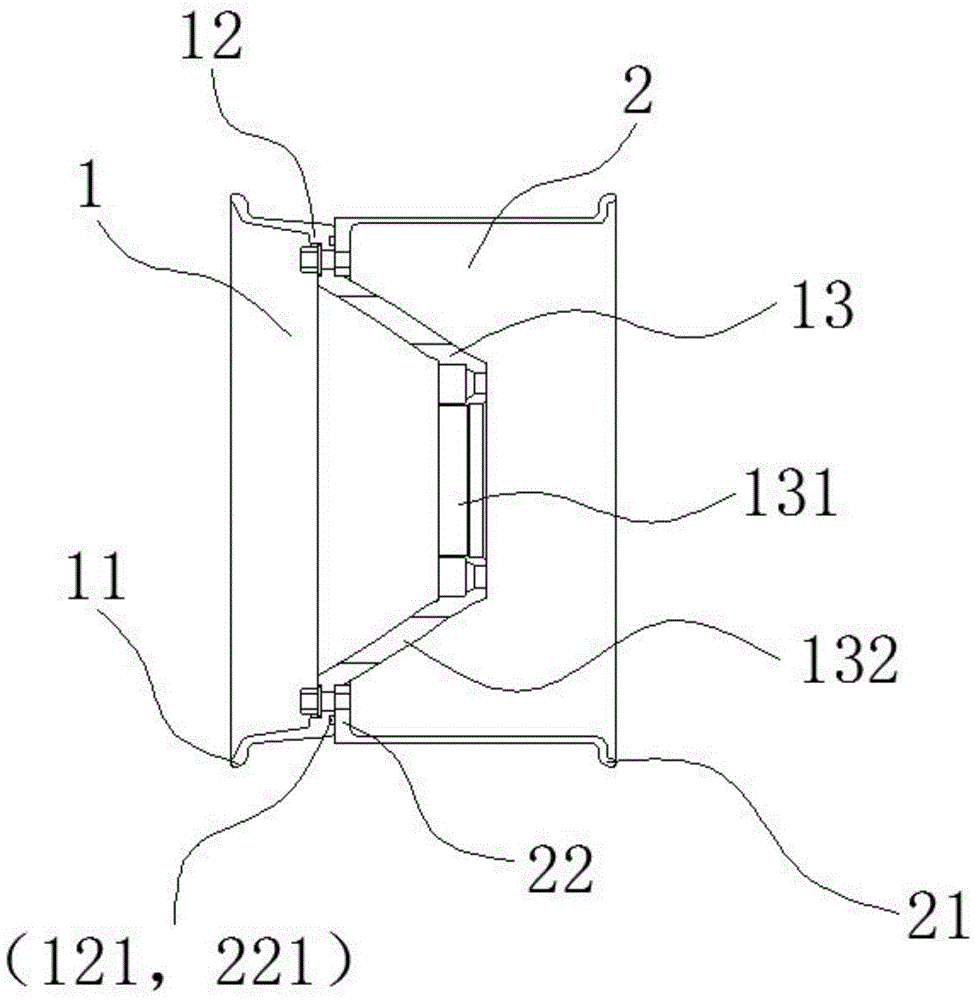

[0013] A two-piece wheel, including a hub, the hub includes a front rim 1 and a rear rim 2, the front rim 1 is an aluminum alloy front rim 1, and the front rim 1 is integrally formed parts; the rear rim 2 is an aluminum alloy rear rim 2, and the rear rim 2 is an integrally formed piece; the front rim 1 and the rear rim 2 are fixedly connected into one body by bolts, and the front rim The rim 1 is in the shape of a tapered cylinder. The front rim 1 includes an outer rim 11, a first annular mounting portion 12 and a spoke 13. The first annular mounting portion 12 is provided with a positioning slot 121 and a mounting Screw holes; the center of the spoke 13 is provided with a central through hole 131, and the inclined surface of the spoke 13 is provided with an air hole 132 parallel to the axis line of the spoke 13; one side of the rear rim 2 is provided with The second annular mounting part 22 is provided with a mounting through hole corresponding to the mounting screw hole and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com