Coal mine protective clothing fabric and preparation method thereof

A technology for protective clothing and coal mines, applied in the field of clothing fabrics, can solve the problems of poor wear resistance, fast burning speed, poor vapor permeability, and poor moisture permeability, so as to improve wearing comfort, ensure life safety, and achieve good anti-fouling performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

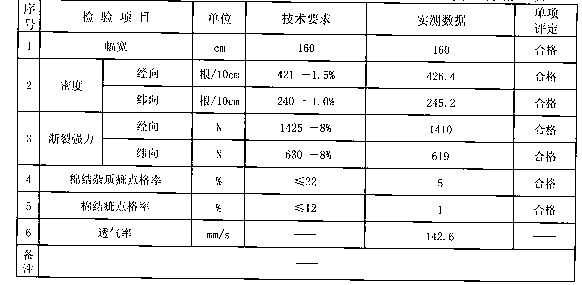

[0054] 1. Product specifications

[0055] 160cm, MVS(CM18.2tex×2)×MVS CM32.4tex, 421 pieces / 10cm×240 pieces / 10cm

[0056] 2. Selection of raw materials

[0057] (1) Selection and matching of warp and weft cotton yarn raw materials

[0058] In order to make the 18.2tex and 32.4tex cotton yarns of vortex spinning have sufficient strength to meet the production needs of the subsequent processes, the cotton is selected from 2-3 grades of fine-staple cotton.

[0059] (2) Selection of conductive filament

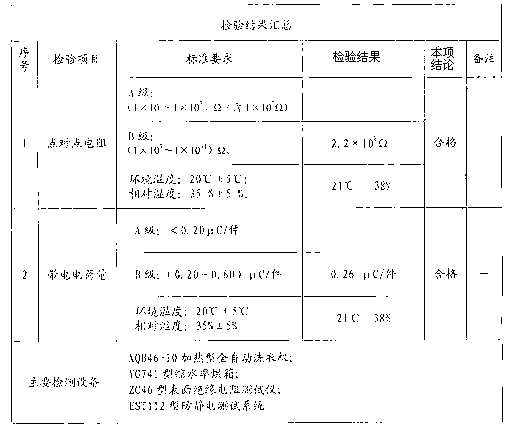

[0060] The conductive filament is polyester PET100D / 48F FDY full-drawn yarn, the strength is 2.5-3CN / D, the elongation at break is 30-50%, and the length resistance ratio is 10 1 Ω / cm-10 4 Ω / cm.

[0061] 3. Production process

[0062] 1. Spinning process

[0063] FA009 reciprocating plucking machine——FA125 heavy object separator——FA105 single-axis flow cotton opener——FA029 multi-compartment blending machine——FA116 main impurity removal machine——FGY-80D foreign fiber detecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com