Patents

Literature

31results about How to "Has anti-ultraviolet effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame-resistant and uvioresistant polyester composite material and method for preparing same

ActiveCN101735578AFlame retardant hasHas anti-ultraviolet effectFlame-proof filament manufactureMonocomponent polyesters artificial filamentLow vacuumEsterification reaction

The invention relates to a flame-resistant and uvioresistant polyester composite material and a method for preparing the same. The composite material is prepared by performing an esterification reaction on ethylene glycol, terephthalic acid, uvioresistant agent pulp and a flame retardant and then performing low-vacuum condensation polymerization and high-vacuum condensation polymerization, wherein the added amounts of the uvioresistant agent pulp and the flame retardant are between 0.1 and 20 weight percent and between 0.1 and 20 weight percent respectively; the esterification reaction is performed at the temperature of between 200 and 290 DEG C and under a pressure of between 0.1 and 0.6 MPa for 1 to 4 hours; the low-vacuum condensation polymerization is performed at the temperature of between 200 and 290 DEG C and under the pressure of between 100,000 and 500 Pa for 10 to 90 minutes; the high-vacuum condensation polymerization is performed at the temperature of between 250 and 300 DEG C and under the pressure of between 500 and 50 Pa for 1 to 4 hours; and the uvioresistant agent pulp consists of 5 to 30 weight percent of inorganic nano-oxide and the ethylene glycol. Flame-resistant and uvioresistant polyester fiber fabrics prepared from the material have flame resistance and uvioresistant effect.

Owner:PETROCHINA CO LTD

Short fiber of polyethylene terephthalate and method for producing same

ActiveCN101525782AImprove performanceImprove breathabilityMelt spinning methodsMonocomponent polyesters artificial filamentFiberPolyester

The invention discloses short fiber of polyethylene terephthalate and a method for producing the same. A raw material for preparing the polyethylene terephthalate is glycol, wherein a carbon element of the glycol comes from a biological material. The cutting length of the short fiber obtained by adopting a conventional pre-spinning and post-spinning process is between 4 and 10 mm; the titer is between 6.5 and 6.8 dtex; the strength is between 3.0 and 4.0 cN / dtex; and the elongation is between 20 and 40 percent. Compared with the prior short fiber, the preparation of the short fiber of the polyethylene terephthalate utilizes bio-based glycol to replace glycol as a conventional petroleum source, reduces dependence on petroleum, relieves energy crisis, simultaneously improves the utilization of crops and achieves the effects of increment and profit generation.

Owner:TORAY IND INC

Flame-resistant and uvioresistant polyester composite material and method for preparing same

ActiveCN101735578BFlame retardant hasHas anti-ultraviolet effectFlame-proof filament manufactureMonocomponent polyesters artificial filamentLow vacuumEsterification reaction

The invention relates to a flame-resistant and uvioresistant polyester composite material and a method for preparing the same. The composite material is prepared by performing an esterification reaction on ethylene glycol, terephthalic acid, uvioresistant agent pulp and a flame retardant and then performing low-vacuum condensation polymerization and high-vacuum condensation polymerization, wherein the added amounts of the uvioresistant agent pulp and the flame retardant are between 0.1 and 20 weight percent and between 0.1 and 20 weight percent respectively; the esterification reaction is performed at the temperature of between 200 and 290 DEG C and under a pressure of between 0.1 and 0.6 MPa for 1 to 4 hours; the low-vacuum condensation polymerization is performed at the temperature of between 200 and 290 DEG C and under the pressure of between 100,000 and 500 Pa for 10 to 90 minutes; the high-vacuum condensation polymerization is performed at the temperature of between 250 and 300 DEG C and under the pressure of between 500 and 50 Pa for 1 to 4 hours; and the uvioresistant agent pulp consists of 5 to 30 weight percent of inorganic nano-oxide and the ethylene glycol. Flame-resistant and uvioresistant polyester fiber fabrics prepared from the material have flame resistance and uvioresistant effect.

Owner:PETROCHINA CO LTD

New type wash articles

InactiveCN1916145AImprove product performancePromote absorptionOrganic detergent compounding agentsNon-surface-active detergent compositionsChemistryPollutant

This invention discloses a new detergent. The detergent is prepared by mixing basic cleaning material with functional additive (at least one of water-soluble chitosan, chitosan hydrochloride, chitosan citrate and chitosan lactate). The content of the functional additive is 0.1-5 wt. %. The functional additive has good moisture-retaining, antibacterial, film-forming and radiation-resisting properties, and can accelerate the adsorption of nutritious components by human body cells. When the functional additive is added in the detergent, it can remove grease and pollutants on human skin or hair by physical adsorption, and can complex with heavy metals on human skin without any stimulation to skin.

Owner:NINGBO UNIV

Uvioresistant type biomass polyester fiber and preparation method thereof

ActiveCN103668538AImprove protectionPromote sustainable developmentMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterTitanium nitride

The invention discloses an uvioresistant type biomass polyester fiber and a preparation method of the uvioresistant type biomass polyester fiber. The uvioresistant type biomass polyester fiber is characterized in that the uvioresistant type biomass polyester fiber is prepared from the following raw materials in percentage by weight: 1-5% of uvioresistant type master batches and the balance of biomass polyester chips. The preparation method comprises the step of performing melt spinning on the uvioresistant type master batches and the biomass polyester chips to obtain the uvioresistant type biomass polyester fiber. The bio-based polyester raw material is prepared from bio-based ethylene glycol and bio-based 1, 3-propylene glycol through biological fermentation and purification, the traditional petroleum base ethylene glycol is replaced, environment protection and sustainable development are facilitated, and nano titanium nitride has small grain diameter and large specific surface area and has the efficacy on ultra violent resistance.

Owner:TIANE CHEM FIBER GROUP CORP BAODING +1

Anti-ultraviolet lotion

InactiveCN107028832AMaintain normal functionAnti-UV safe and effectiveCosmetic preparationsToilet preparationsUltravioletProtection Skin

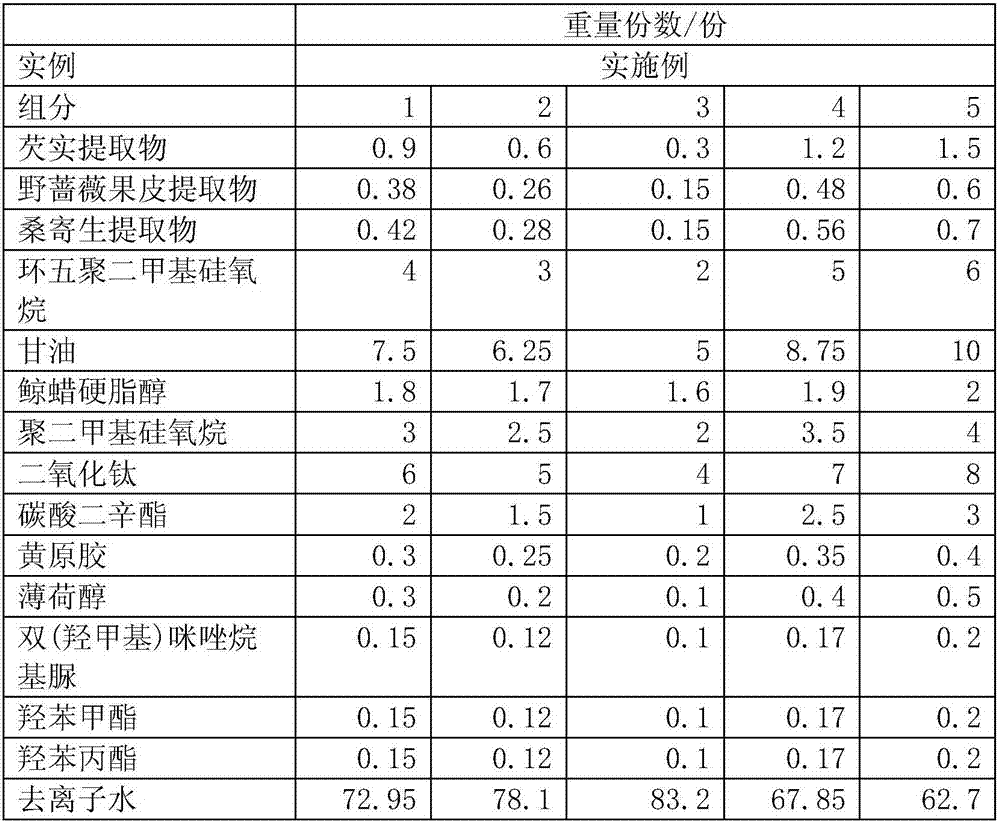

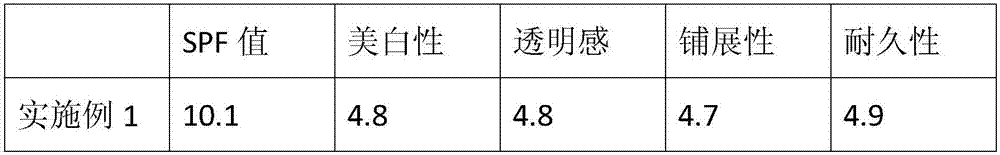

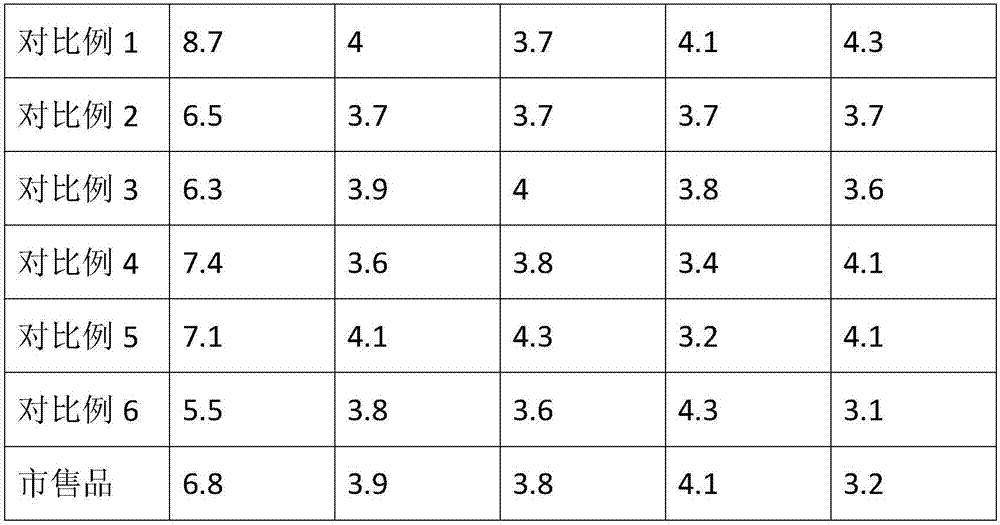

The invention discloses an anti-ultraviolet lotion. The anti-ultraviolet lotion comprises a plant composition at a weight percentage of 0.6-2.8%; the plant composition is a mixture from gordon euryale extract, multiflora rose peel extract and Chinese taxillus herb extract at a weight ratio of (6-15): (3-6): (4-7). The anti-ultraviolet lotion can protect telomere DNA (deoxyribonucleic acid) of skin cells from influence of UV (ultraviolet) rays as well as further damage and can effectively clean hydroxyl radicals, hydrogen peroxide, DPPH (1,1-dyphenyl-2-picrylhydrazyl) radicals, O2 radicals and ABTS+ (2, 2'-azino-bis(3-ethylbenzothiazoline-6-sulfonic) radicals; under the premise of maintaining the normal physiological metabolism and functions of skin and through reasonable combination and synergetic combination of components, the anti-ultraviolet lotion achieve the effect of protecting the skin cells from ultraviolet rays.

Owner:GUANGZHOU BARBURLY COSMETIC

A kind of anti-ultraviolet type biomass polyester fiber and preparation method thereof

ActiveCN103668538BImprove protectionPromote sustainable developmentMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterTitanium nitride

The invention discloses an uvioresistant type biomass polyester fiber and a preparation method of the uvioresistant type biomass polyester fiber. The uvioresistant type biomass polyester fiber is characterized in that the uvioresistant type biomass polyester fiber is prepared from the following raw materials in percentage by weight: 1-5% of uvioresistant type master batches and the balance of biomass polyester chips. The preparation method comprises the step of performing melt spinning on the uvioresistant type master batches and the biomass polyester chips to obtain the uvioresistant type biomass polyester fiber. The bio-based polyester raw material is prepared from bio-based ethylene glycol and bio-based 1, 3-propylene glycol through biological fermentation and purification, the traditional petroleum base ethylene glycol is replaced, environment protection and sustainable development are facilitated, and nano titanium nitride has small grain diameter and large specific surface area and has the efficacy on ultra violent resistance.

Owner:TIANE CHEM FIBER GROUP CORP BAODING +1

Antibacterial high-temperature-aging-resistant polyimide film and preparation method thereof

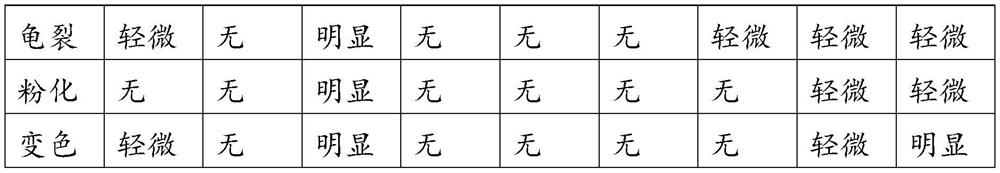

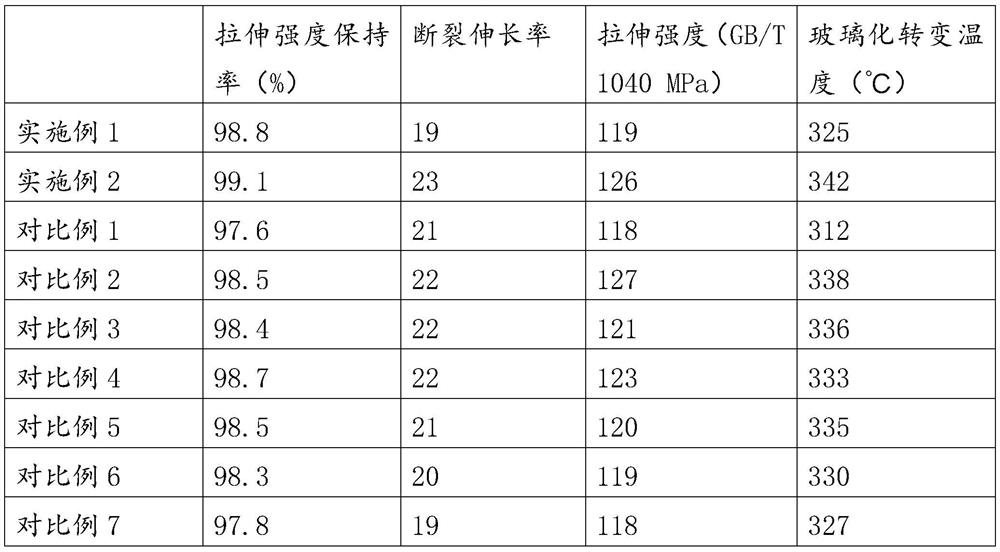

The invention relates to an antibacterial high-temperature-aging-resistant polyimide film and a preparation method thereof. The method comprises the following steps: (1) adding diamine and a solvent,then adding dianhydride and an antibacterial functional monomer, and carrying out reaction for 10-24h so as to obtain polyamide acid containing the antibacterial functional monomer; (2) activating SiO2 at 250-280 DEG C under the reflux of anhydrous toluene, and then, carrying out surface treatment by using perfluorooctyl triethoxysilane; (3) adding maleic anhydride and SiO2 subjected to the surface treatment into polyamide acid, performing stirring for 2-3 hours, and performing gradient heating and thermal imidization to obtain polyimide; (4) adding nano TiO2 into a polyvinyl alcohol colloidalsolution with a concentration of 10%, and performing uniform stirring; (5) uniformly mixing a product obtained in the step (3) and a mixture obtained in the step (4), and performing granulating; and(6) performing film blowing to form the polyimide film. According to the invention, the SiO2, the TiO2 and the antibacterial functional monomers are added into the polyimide, so that the obtained polyimide film has excellent high temperature aging resistance and long-acting antibacterial property, and is suitable for food packaging under African hot weather conditions.

Owner:凯正包装科技(广东)有限公司 +1

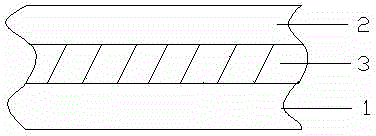

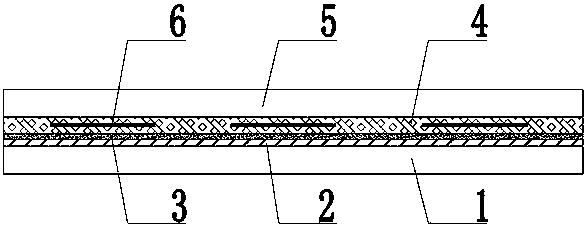

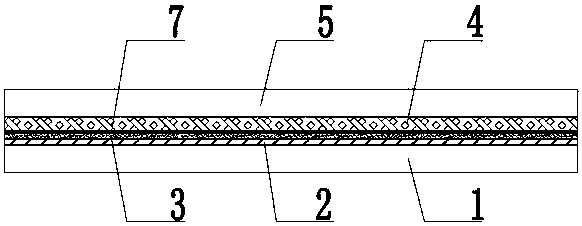

Compound bamboo carbon sweat-absorption knitted fabric

InactiveCN105365280AImprove moisture wickingAchieve cool and drySynthetic resin layered productsFiberPolyester

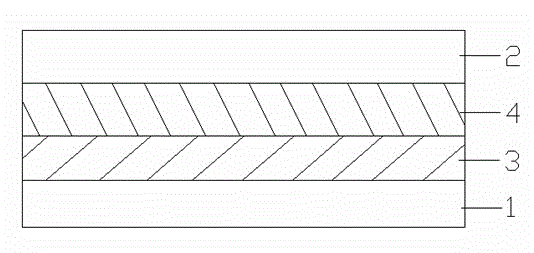

The invention relates to a compound bamboo carbon sweat-absorption knitted fabric. The fabric comprises a base cloth layer (1) and a fabric layer (2). A single-direction sweat-guide layer (3) and a sweat-absorption layer (4) are sequentially arranged between the base cloth layer (1) and the fabric layer (2). The single-direction sweat-guide layer (3) is a single-direction high polymer thin film. The sweat-absorption layer (4) is made of super-water-absorption fiber. The base cloth layer is of a dual-layer knitted structure formed by microporous polyester fiber on the inner layer and polyester base bamboo carbon fiber on the outer layer. Clothes made of the fabric can not adhere to human bodies, and people are kept refreshing. The fabric has health care functions with far infrared emission, negative ion emission and the like.

Owner:钟俊杰

Composite bamboo charcoal knitted warm-keeping fragrant fabric

InactiveCN105459480AHas the function of keeping warmIncrease the fragranceSynthetic resin layered productsProtective garmentPolyesterCarbon fibers

The invention relates to a composite bamboo charcoal knitted warm-keeping fragrant fabric. The composite bamboo charcoal knitted warm-keeping fragrant fabric comprises a base cloth layer (1) and a surface fabric layer (2), wherein the base cloth layer (1) is suede-like, a fragrant interlayer (3) is arranged between the base cloth layer (1) and the surface fabric layer (2) and composed of a fragrant agent which is coated with a film and neatly arranged between the base cloth layer (1) and the surface fabric layer (2), the base cloth layer is a double-layer knitted structure formed by internal microporous polyester fiber and external polyester-based bamboo charcoal fiber. The suede-like base cloth layer of the fabric is capable of keeping warm; the fragrant interlayer can slowly give off fragrance, so fragrance can be maintained for a long time, and the fabric is popular among people; and the fabric has health-care function like far-infrared and negative ion emission.

Owner:周和兴

Composite bamboo charcoal knitted fabric electric arc protection garment

InactiveCN104138089AHeat resistantWith insulationProtective garmentSpecial outerwear garmentsPolyesterCarbon fibers

The invention relates to a composite bamboo charcoal knitted fabric electric arc protection garment, which comprises a garment body, wherein flame-retardant materials are added in cloth of the garment body, and the steps of flame-retardant sorting liquid padding (room temperature), pre-drying, ammonia curing, oxidizing and water washing, drying, preshrinking and finished product obtaining are carried out; a base cloth layer is compounded on the back side of the garment body, and the base cloth layer is of a double-layer knitted structure formed by inner layer microporous polyester fiber and outer layer polyester-base bamboo charcoal fiber. When the composite bamboo charcoal knitted fabric electric arc protection garment is adopted, the contact injury of the human body skin and the electric arc heat energy can be reduced to the minimum. The composite bamboo charcoal knitted fabric electric arc protection garment also has the health care functions such as far infrared ray and negative ion emission.

Owner:JIANGYIN TIANCHENG TEXTILE

Multifunctional textile sterilizing and degreasing agent

InactiveCN105733826ABactericidalDeodorizingAnionic surface-active compoundsFibre treatmentFatty alcoholFatty acid

The invention relates to the technical field of fine chemicals, and specifically relates to a multifunctional textile sterilizing and degreasing agent. The sterilizing and degreasing agent is composed of the following raw materials, by weight: 40-60 parts of deionized water, 20-30 parts of polyoxyethylene fatty alcohol ether sulfate sodium, 4-8 part of sodium dodecylbenzenesulfonate, 5-10 parts of silica, 4-8 parts of zinc oxide, 4-8 parts of magnesium oxide, 3-6 parts of silver oxide, and 20-30 parts of a fatty acid ethylene oxide adduct penetrant. The invention aims at providing the multifunctional textile sterilizing and degreasing agent with the advantages of reasonable formula and convenient application.

Owner:田建频

Whitening and anti-aging cosmetic and its preparation method

InactiveCN109260122AAnti-allergicImprove regenerative abilityCosmetic preparationsToilet preparationsGlycerolPolyphenol

The invention discloses a whitening and anti-aging cosmetic, made from the following parts by weight of raw materials: 5-8 part of pineapple alcohol extract, 5-10 parts of dendrobium officinale freeze-dried powder, 3-5 parts of angelica extract, 3-5 parts of wild chrysanthemum vitamin, 1-3 parts of glycerol glucoside, 1-3 part of hamamelis extract, 2-3 parts of ceramide, 5-8 parts of mountain ginseng alcohol extract, palmitoyl tripeptide-1 1-3 part, 1-3 parts of beta-glucan, 3-6 part of coix seed extract, 5-10 parts of polygonatum odoratum supercritical fluid extract, 3-5 parts of persimmon leaf polyphenol and 45-65 part of deionized water. The present invention has remarkable whitening, anti-oxidation, anti-wrinkle and promoting epidermal regeneration effects.

Owner:HENGSHUI UNIVERSITY

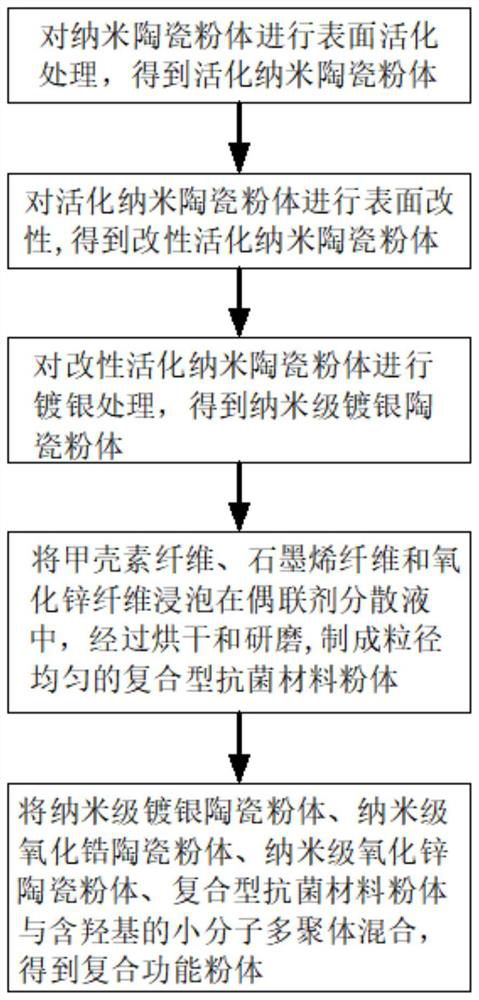

Preparation process of antistatic and antibacterial nano composite functional powder

InactiveCN112538755AGood dispersionHas antibacterial propertiesBiochemical fibre treatmentLight resistant fibresOxide ceramicFiber

The invention discloses a preparation process of antistatic and antibacterial nano composite functional powder. The preparation method comprises the following steps that surface activation treatment is carried out on nano-ceramic powder, surface modification is carried out on the activated nano-ceramic powder, silver plating treatment is carried out on the modified activated nano-ceramic powder, chitin fibers, graphene fibers and zinc oxide fibers are soaked in a coupling agent dispersion liquid, composite antibacterial material powder with uniform particle size is prepared, and all the powderis mixed with a hydroxyl-containing micromolecular polymer to obtain composite functional powder. The composite functional powder is prepared from nanoscale silver-plated ceramic powder, nanoscale zirconium oxide ceramic powder, nanoscale zinc oxide ceramic powder, chitin fibers, graphene fibers and zinc oxide fibers, and the prepared composite functional powder has antistatic, antibacterial, anti-infrared and anti-ultraviolet effects; and when the composite functional powder is applied to the textile fabric, the textile fabric can further have the functions of static electricity, bacteria resistance, infrared resistance and ultraviolet resistance.

Owner:南京伯纳德防护用品有限公司

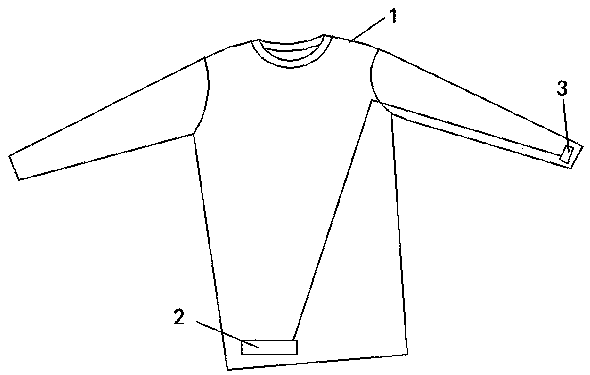

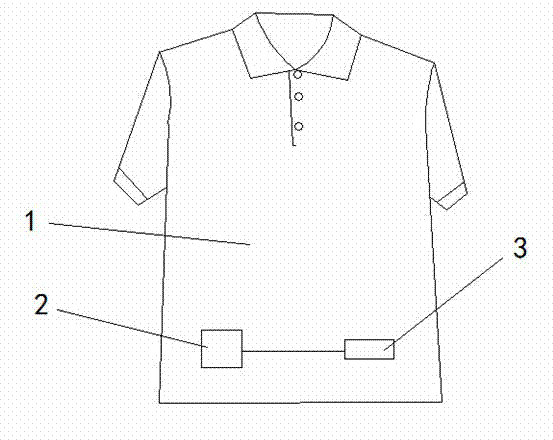

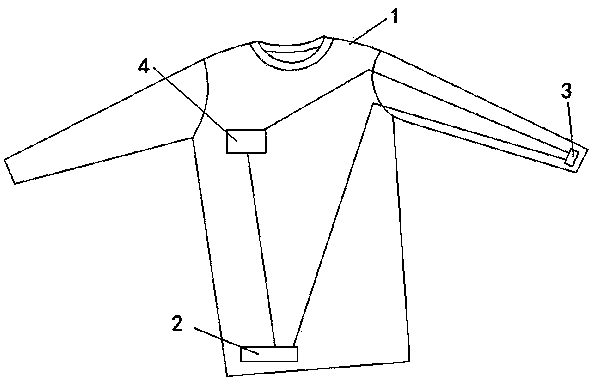

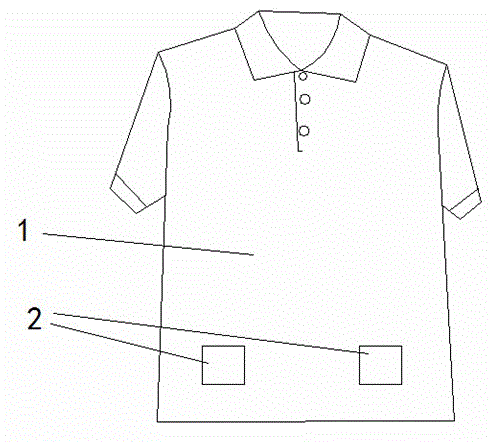

Garment which has exercise assisting function and is made of combined bamboo carbon knitted fabric

InactiveCN104172555AReal-time understanding of walking stepsAchieve the effect of auxiliary fitnessProtective garmentSpecial outerwear garmentsPolyesterFiber

The invention relates to a garment which has an exercise assisting function and is made of a combined bamboo carbon knitted fabric. The garment comprises a garment body (1). A walking sensor (2) is arranged at a hip of the garment body (1), a step number counter (3) is arranged at a cuff, and the walking sensor (2) is connected with the step number counter (3) by a wire; the garment body is made of the fabric, the fabric is of a double-layer knitted structure, and the double-layer knitted structure comprises inner-layer microporous polyester fibers and outer-layer polyester-based bamboo carbon fibers. The garment has the advantages that people can know walking step numbers in real time and can judge whether to carry out extra exercise activities or not, and accordingly exercise assisting effects can be realized; anti-ultraviolet effects can be realized by the garment.

Owner:HEILAN HOME

Composite bamboo charcoal knitted fabric children garment with high safety

InactiveCN104116201AHigh tensile strengthImprove moisture wickingWeft knittingWarp knittingYarnGlass fiber

The invention relates to a composite bamboo charcoal knitted fabric children garment with high safety. Fabric used in the garment is formed by yarn in a tatting mode, the yarn is composed of glass fibers, polyvinyl chloride fibers and polyimide fibers, and the polyvinyl chloride fibers and the polyimide fibers are spirally twisted by using the glass fibers as a center shaft. A layer of base cloth is compounded on the back face of the fabric, and the base cloth is of a double-layer knitted structure which is formed by inner layer microporous polyester fibers and outer layer polyester base bamboo charcoal fibers. By means of the composite bamboo charcoal knitted fabric children garment with high safety, the defect that the glass fibers are brittle is overcome, and the electrostatic protection function is further achieved. The composite bamboo charcoal knitted fabric children garment with high safety has a bactericidal effect and achieves the antibacterial and anti-odor purposes.

Owner:JIANGYIN YASHUN GARMENT

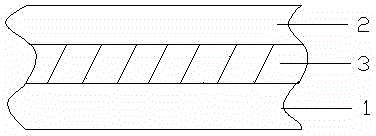

Mosquito-repellent composite bamboo charcoal knitted fabric

InactiveCN105365294AProtect the skinPrevent sunburnSynthetic resin layered productsProtective garmentPolyesterEngineering

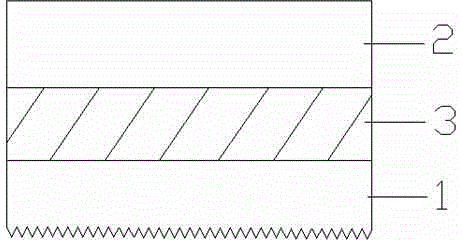

The invention relates to mosquito-repellent composite bamboo charcoal knitted fabric. The mosquito-repellent composite bamboo charcoal knitted fabric comprises a base fabric layer (1) and a face fabric layer (2). A mosquito-repellent interlayer (3) is arranged between the base fabric layer (1) and the face fabric layer (2) and is composed of a mosquito-repellent agent which is wrapped in a thin film and tidily arranged between the base fabric layer (1) and the face fabric layer (2). The base fabric layer is of a double-layer knitted structure formed by inner layer micropore polyester fibers and outer layer polyester-based bamboo charcoal fibers. The mosquito-repellent composite bamboo charcoal knitted fabric has the function of slowly releasing a mosquito-repellent smell and can constantly repel mosquitoes, and thus people are protected against bites of mosquitoes. The mosquito-repellent composite bamboo charcoal knitted fabric has the ultraviolet resisting function.

Owner:吴佳音

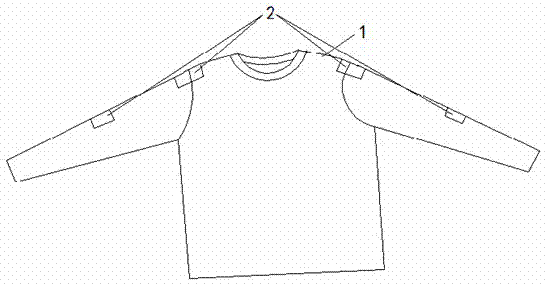

Composite bamboo charcoal knitted garment capable of charging battery

InactiveCN104126892AAchieve bactericidal effectHas a bactericidal effectBatteries circuit arrangementsElectric powerPolyesterCarbon fibers

The invention relates to a composite bamboo charcoal knitted garment capable of charging a battery. The composite bamboo charcoal knitted garment comprises a garment body (1). Photovoltaic conversion modules (2) are arranged on the shoulder portions of the garment body (1). A voltage stabilization module (3) is arranged on the front portion of the garment body (1). A charging module (4) is arranged on a pocket. The photovoltaic conversion modules (2), the voltage stabilization module (3) and the charging module (4) are connected through wires. The garment body is made of shell fabric. The shell fabric is a double-layer knitted layer formed by inner-layer micropore polyester fibers and outer-layer polyester-based bamboo charcoal fibers. When a person walks outdoors in the composite bamboo charcoal knitted garment, the photovoltaic conversion modules absorb light and heat to generate voltage so as to charge the battery. The composite bamboo charcoal knitted garment capable of charging the battery also achieves the health-care functions of far-infrared ray emission, negative ion emission and the like.

Owner:JIANGYIN YINGXIN WEAVING

Composite bamboo carbon knitted fabric garment capable of counting for running

InactiveCN104207349AAchieve bactericidal effectHas a bactericidal effectProtective garmentSpecial outerwear garmentsPolyesterPolymer science

The invention relates to a composite bamboo carbon knitted fabric garment capable of counting for running, which comprises a garment body (1), wherein a gravity sensor (2) is arranged at the waist of the garment body (1), and a step number display (3) is arranged at the lower part of the front body; the gravity sensor (2) and the step number display (3) are connected by a lead. The garment body is made of a fabric, and the fabric is of a double-layer knitted structure formed by an inner microporous polyester fiber layer and an outer polyester-based bamboo carbon fiber layer. When a person runs, the composite bamboo carbon knitted fabric garment provided by the invention can allow the person to know the running mileage and the consumed calorie. The composite bamboo carbon knitted fabric garment capable of counting for running provided by the invention has the healthcare functions of far infrared and negative ion emission and the like.

Owner:JIANGYIN YASHUN GARMENT

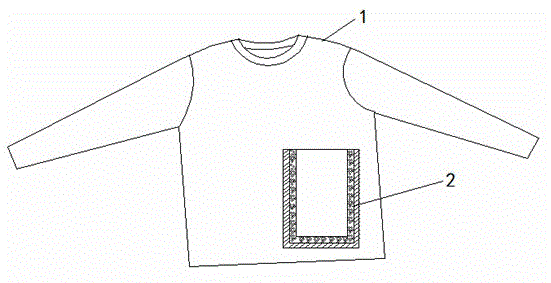

Composite bamboo carbon knitted garment suitable for treating arthritis

InactiveCN104116232AAchieve bactericidal effectHas a bactericidal effectMedical devicesProtective garmentPolyesterFiber

The invention relates to a composite bamboo carbon knitted garment suitable for treating arthritis. The garment comprises a garment body (1). A medicine placement interlayer (2) is arranged at the joint position of the garment body (1). The face, close to the garment, of the medicine placement interlayer (2) is made of rubber, and the face, close to the skin, of the medicine placement interlayer (2) is made of gauze. The garment body is made of a fabric which is of a double-layer knitted structure composed of inner-layer micro-hole polyester fibers and outer-layer polyester-base bamboo carbon fibers. When the arthritis needs to be treated, medicine is placed to the medicine placement interlayer, the medicine penetrates through the gauge to make contact with the joint tissue, and therefore the arthritis treating effect is achieved. The composite bamboo carbon knitted garment suitable for treating the arthritis has the healthcare functions such as emitting far infrared rays and anions.

Owner:JIANGSU HONGLIU BEDSHEET LIMITED

Composite bamboo-charcoal knitted fabric garment capable of keeping food warm

InactiveCN104146370AAvoid direct contactStop the spreadProtective garmentSpecial outerwear garmentsPolyesterPolymer science

The invention relates to a composite bamboo-charcoal knitted fabric garment capable of keeping food warm. The composite bamboo-charcoal knitted fabric garment comprises a garment body (1), a pocket of the garment body (1) is provided with a large insulation interlayer (2) which is foam, and the garment body (1) is made of fabric. The fabric is of a double-layer knitted structure formed by inner microporous polyester fibers and outer polyester-base bamboo charcoal fibers. When food is put into the pocket after being packed, the foam in the insulation interlayer can prevent the food from being in direct contact with outside air, heat diffusion of the food can be effectively prevented, and accordingly effect of keeping the food warm is achieved. The composite bamboo-charcoal knitted fabric garment has healthcare functions of far infrared and negative ion emission and the like.

Owner:JIANGYIN MINGPIN KNITTING

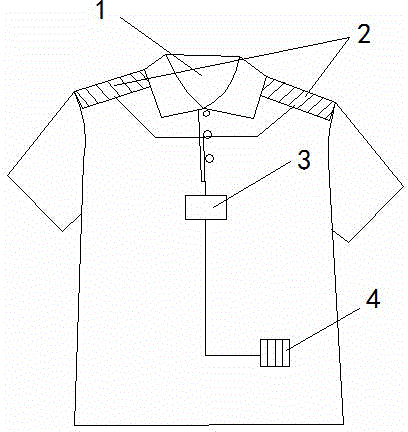

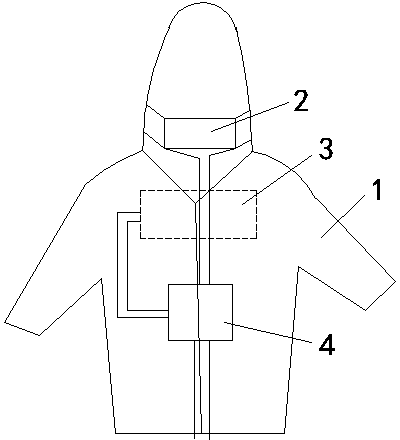

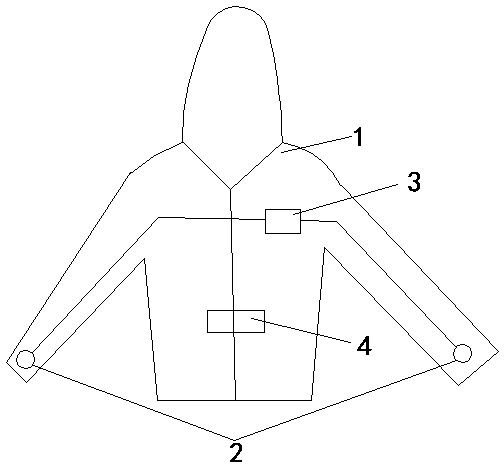

Composite bamboo charcoal knitted fabric garment capable of achieving humidification function for breathing

InactiveCN104188170AProtect the skinPrevent sunburnProtective garmentSpecial outerwear garmentsPolyesterPolymer chemistry

The invention relates to a composite bamboo charcoal knitted fabric garment capable of achieving the humidification function for breathing. The composite bamboo charcoal knitted fabric garment capable of achieving the humidification function for breathing comprises a garment body (1), wherein a mask (2) is arranged on a collar of the garment body (1), an ultrasonic humidifier (3) is arranged on the back portion of the garment body (1), an air storage box (4) is arranged on the front side of the garment body (1), and the mask, the ultrasonic humidifier and the air storage box are connected through guide pipes; the garment body is made of fabric, and the fabric is of a double-layer knitted structure formed by an inner microporous polyester fiber layer and an outer polyester-base bamboo charcoal fiber layer. When a worker wearing the garment enters a working place with the high environment standard, the ultrasonic humidifier starts to work to deliver moisture into the air storage box, in this way, when the worker breathes, air passes through the air storage box and then contains moisture, and the worker can be supplied with water. The composite bamboo charcoal knitted fabric garment capable of achieving the humidification function for breathing is antibacterial and capable of preventing odor.

Owner:JIANGYIN HANXIN TEXTILE

Fragrant composite bamboo carbon knitted fabric

InactiveCN105365293AIncrease the fragranceImprove moisture wickingSynthetic resin layered productsProtective garmentFiberPolyester

The invention relates to a fragrant composite bamboo carbon knitted fabric which comprises a base fabric layer (1) and a shell fabric layer (2). Fragrant interlayers (3) are arranged between the base fabric layer (1) and the shell fabric layer (2) and composed of a fragrant agent, and the fragrant agent is wrapped in films to be trimly arranged between the base fabric layer (1) and the shell fabric layer (2); the base fabric layer is of a double-layer knitted structure formed by inner-layer microporous polyester fibers and outer-layer polyester-based bamboo carbon fiber. According to the fragrant composite bamboo carbon knitted fabric, the function of slowly releasing fragrance is achieved, and therefore the fragrance can last for a long time and be popular with people; the uvioresistant function is achieved.

Owner:陆秋亚

Non-toxic and harmless compound antiseptic agent

The invention relates to the technical field of antiseptic agents, in particular to a non-toxic and harmless compound antiseptic agent. The non-toxic and harmless compound antiseptic agent is preparedfrom the following components in parts by weight: 10-20 parts of ammonium citrate, 5-15 parts of wax stearate, 5-15 parts of sodium borate, 1-10 parts of geraniol, 1-10 parts of propylene glycol, 3-8parts of eugenol, 1-5 parts of silicone polyether, and the balance of water. The non-toxic and harmless compound antiseptic agent is rich in raw material source, low in manufacturing cost and convenient to prepare, has the effects of sterilization, deodorization and ultraviolet resisting, and is nontoxic and harmless.

Owner:柳州市皇之品贸易有限公司

Anti-ultraviolet and anti-bacterial sports garment material

InactiveCN108260866AHas anti-ultraviolet effectAntibacterialGarment special featuresVegetal fibresUltravioletAnti bacterial

The invention provides an anti-ultraviolet and anti-bacterial sports garment material. The material is prepared from the following materials: hemp fibers, trimethylene terephthalate and wood fibers. Apreparation method of the anti-ultraviolet and anti-bacterial sports garment material comprises the following steps: (1) soaking the hemp fibers in trimethylene terephthalate for 1-2 days; (2) soaking the wood fibers in trimethylene terephthalate for 1-2 days; and (3) carrying out uniform weaving on the hemp fibers and the wood fibers at the ratio of 1 to 1. The anti-ultraviolet and anti-bacterial sports garment material has the advantages of resisting ultraviolet rays, preventing radiation, and inhibiting bacteria.

Owner:天津寰宇赫奕工程科技有限公司

Short fiber of polyethylene terephthalate and method for producing same

ActiveCN101525782BImprove performanceImprove breathabilityMelt spinning methodsMonocomponent polyesters artificial filamentFiberPolyester

Owner:TORAY IND INC

TPF photovoltaic member

InactiveCN107819049AHas anti-ultraviolet effectSolve the problem of insufficient bonding strengthSynthetic resin layered productsPhotovoltaic energy generationEngineeringSolar cell

The invention discloses a TPF photovoltaic member which mainly comprises glass, TPF substrate, a solar cell and a colloidal layer. The TPF photovoltaic member is mainly characterized in that an uppersubstrate is made of the glass, a lower substrate is made of the TPF substrate, and the solar cell is packaged between the upper substrate and the lower substrate via the colloidal layer; the upper substrate, the lower substrate and the solar cell are bonded into an integral body via the colloidal layer to complete member packaging operation. In the TPF photovoltaic member, a TPF material sheet isadopted, and a problem of insufficient strength of bonding between a conventional FRP plate and the colloidal layer of the member is effectively solved; a Tedlar coating has anti-ultraviolet effects,ageing of a TPF backboard can be effectively delayed, the TPF photovoltaic member is light in dead weight, structural safety of a photovoltaic curtain wall system and other photovoltaic structural bearing system can be markedly improved, the TPF photovoltaic member is diverse in shapes and colors, and abundant design elements can be provided for an aesthetic property of buildings and other photovoltaic systems.

Owner:ZHUHAI XINGYE ENERGY SAVING SCI & TECH CO LTD +2

Garment which has exercise supervising and urging functions and is made of combined bamboo carbon knitted fabric

InactiveCN104172518ASupervise fitnessAchieve bactericidal effectElectrotherapyLight therapyPolyesterFiber

The invention relates to a garment which has exercise supervising and urging functions and is made of a combined bamboo carbon knitted fabric. The garment comprises a garment body (1). A walking sensor (2) is arranged at a hip of the garment body, a step number setting device (3) and a reminder (4) are arranged at a cuff, and the walking sensor, the step number setting device and the reminder are connected with one another by wires; the garment body is made of the fabric, the fabric is of a double-layer knitted structure, and the double-layer knitted structure comprises inner-layer microporous polyester fibers and outer-layer polyester-base bamboo carbon fibers. The garment has the advantages that daily required walking step numbers can be set according to energy required to be consumed, the sensor can count when a wearer walks, the wearer can be reminded by the reminder when requirements of the set step numbers are not met in set time, and accordingly exercise supervising and urging effects can be realized; moisture can be quickly absorbed by the garment, sweat can be quickly drained by the garment, and accordingly the purpose of keeping the wearer cool, dry and comfortable can be achieved.

Owner:HEILAN HOME CLOTHING

Composite bamboo charcoal knitted fabric garment with mosquito repelling function

InactiveCN104146374ARefreshing and undisturbed summer nightAchieve bactericidal effectSynthetic resin layered productsProtective garmentPolyesterPolymer science

The invention relates to a composite bamboo charcoal knitted fabric garment with a mosquito repelling function. The composite bamboo charcoal knitted fabric garment comprises a garment body (1), the lower part of the front body of the garment body (1) is provided with sandwich layers (2), and mozzie buster is filled in the sandwich layers (2). The garment body is made of fabric, and the fabric is of a double-layer knitting structure formed by inner micropores polyester fibers and outer polyester base bamboo charcoal fibers. When people go out, the mozzie buster is arranged in the sandwich layers and can send out special fragrance to repel mosquitoes, and a cool and no-harassment summer night is brought to people. The composite bamboo charcoal knitted fabric garment has healthcare functions such as far infrared and anion emission.

Owner:JIANGYIN CHUNLAN TEXTILE

Compound bamboo carbon knit fabric clothes capable of quickly reporting traffic police

InactiveCN104172506AAchieve bactericidal effectHas a bactericidal effectOvergarmentsAlarmsPolyesterFiber

The invention relates to a piece of compound bamboo carbon knit fabric clothes capable of quickly reporting a traffic police. The piece of compound bamboo carbon knit fabric clothes capable of quickly reporting the traffic police comprises a clothes body (1), wherein a button (2) is arranged at each of sleeve openings of the clothes body (1); a GPS (3) is arranged at the pocket position; a communication module (4) is arranged at the front body position; the buttons, the GPS and the communication module are connected by wires; when an accident happens, the two buttons are pushed, and the communication module can report the GPS information to the traffic police, so that the traffic police can be informed of the accident site as soon as possible, and can reach the accident site as soon as possible; the clothes body is made of the fabric; the fabric is a double-layered knit structure formed by an inner layer of micropore polyester fiber and an outer layer of polyester based bamboo carbon fiber. The piece of compound bamboo carbon knit fabric clothes has the functions of far-infrared and negative ion emission, and the like.

Owner:JIANGYIN SHENYING KNITWEAR & TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com