TPF photovoltaic member

A technology of photovoltaic components and FRP boards, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve problems such as insufficient bonding strength, degumming safety hazards, etc., and achieve the effect of delaying aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

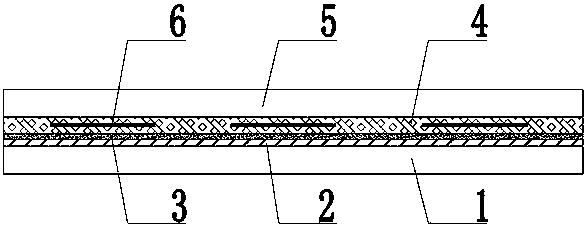

[0018] Embodiment one: figure 1 Shown is an embodiment of the present invention, glass 5 is the upper substrate, TPF composed of FRP plate 1, PET film 2 and Tedlar coating 3 is the lower substrate, between the upper and lower substrates, the battery is placed through the gel layer 4 Sheet 6, the upper substrate of glass 5, and the lower substrate of TPF are bonded into a whole.

Embodiment 2

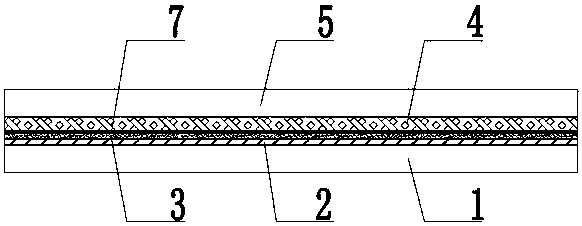

[0019] Embodiment two: figure 2 Shown is another embodiment of the present invention, glass 5 is the upper substrate, TPF composed of FRP plate 1, PET film 2 and Tedlar coating 3 is the lower substrate, and thin film solar cells 7 are coated on the upper substrate of glass 5 , the above-mentioned structure is bonded into a whole through the glue layer 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com