Antibacterial high-temperature-aging-resistant polyimide film and preparation method thereof

A technology of polyimide film and high temperature resistance, which is applied in the field of polyimide film to achieve the effect of improving toughness, long-lasting antibacterial performance, and excellent long-term antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

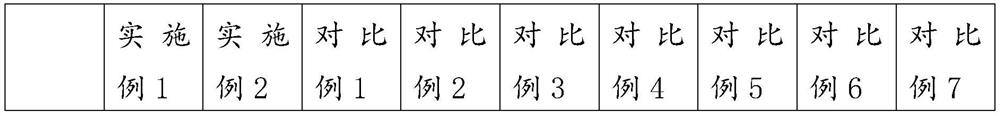

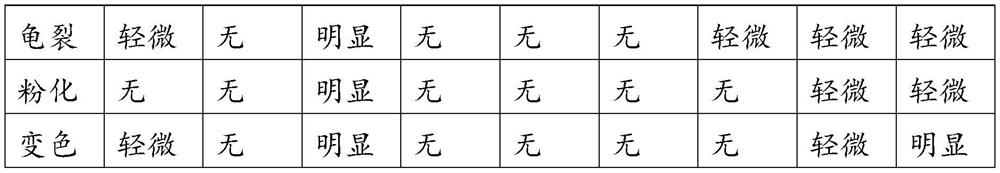

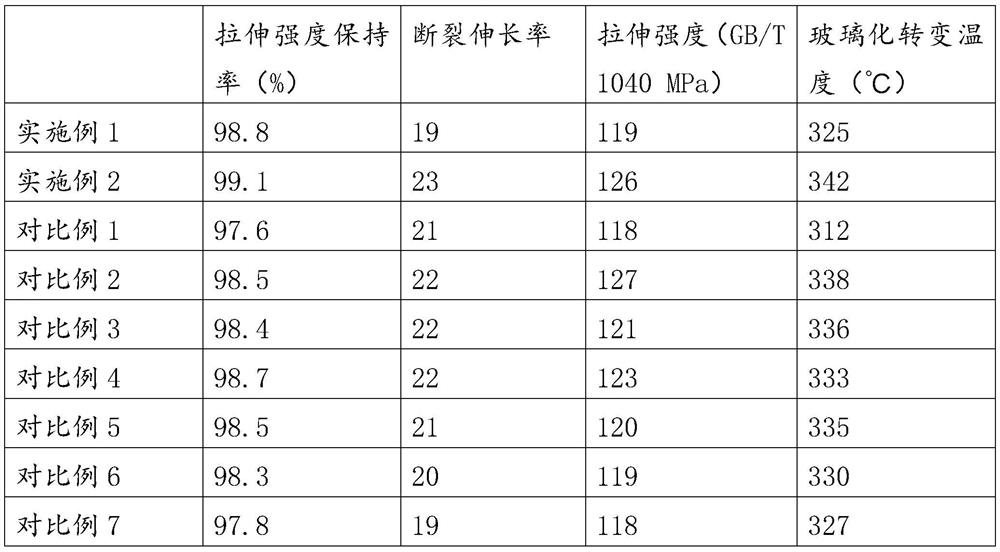

Examples

Embodiment 1

[0032] A preparation method of an antibacterial high temperature aging resistant polyimide film, comprising the following steps:

[0033] (1) Under the protection of argon, first add 4,4'-oxydiphenylamine and 4,4'-diaminodiphenyl ether solvent, after ultrasonic dissolution is complete, then add pyromellitic dianhydride and dimethylol Based on hydantoin, after reacting for 15 hours, the bubbles were vacuumed out to obtain polyamic acid containing antibacterial functional monomers; wherein the content of dimethylol hydantoin was 1% of the total mass of the antibacterial, high temperature and aging-resistant polyimide film.

[0034] (2) Under argon protection, add silicon dioxide and activate it at 280°C for 12 hours under the reflux of anhydrous toluene; surface treat the activated silicon dioxide with tridecafluorooctyltriethoxysilane;

[0035] (3) Add maleic anhydride and the surface-treated silica obtained in step (2) to the polyamic acid containing antibacterial functional m...

Embodiment 2

[0038] A preparation method of an antibacterial high temperature aging resistant polyimide film, comprising the following steps:

[0039] (1) Under the protection of argon, first add 4,4'-oxydiphenylamine and 4,4'-diaminodiphenyl ether solvent, after ultrasonic dissolution is complete, then add pyromellitic dianhydride and dimethylol Based on hydantoin, after reacting for 15 hours, the bubbles were vacuumed out to obtain polyamic acid containing antibacterial functional monomers; wherein the content of dimethylol hydantoin was 1% of the total mass of the antibacterial, high temperature and aging-resistant polyimide film.

[0040] (2) Under argon protection, add silicon dioxide and activate it at 280°C for 12 hours under anhydrous toluene reflux; use tridecafluorooctyltriethoxysilane to surface-treat the activated silicon dioxide; The silicon dioxide is nano silicon dioxide with a particle size of 100-300nm.

[0041] (3) Add maleic anhydride and the surface-treated silica obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com