Hot bending glass graded forming die

A technology for step-by-step molding and glass, which is applied in the field of forming molds and hot-bending glass step-by-step molding molds. It can solve problems such as low yield, damage, and impact on product yield, so as to reduce optical distortion, improve optical performance, and increase The effect of appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described below in conjunction with accompanying drawing.

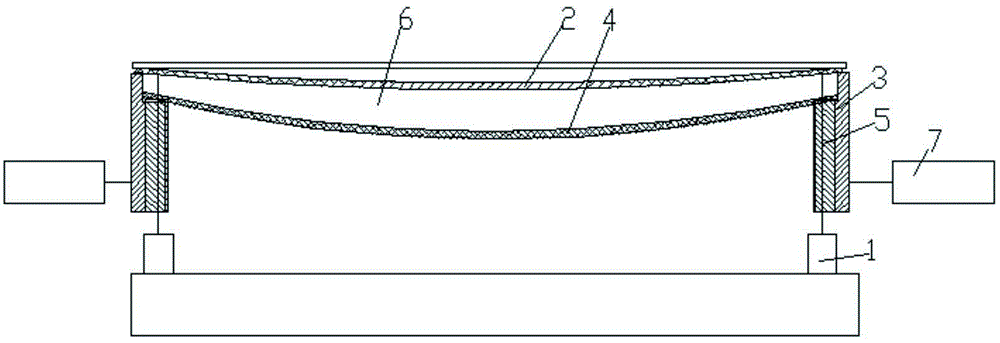

[0012] as attached figure 1 A hot bending glass step-forming mold shown includes a preforming frame, a forming frame and a control assembly 1 for controlling the up and down movement of the preforming frame; the preforming frame includes several first arc-shaped fixing frames 2 and a pair of The movable preform frame 3 pivotally connected to the two ends of the first fixed frame 2; the forming frame includes several second arc-shaped fixed frames 4 and the forming frames 5 at the two ends of the second arc-shaped fixed frame 4; There is a gap 6 between the first arc-shaped fixing frame 2 and the second arc-shaped fixing frame 4, the first arc-shaped fixing frame 2 is arranged in a staggered manner above the second arc-shaped fixing frame 4, and the heat-bent glass is graded The forming die also comprises a second control assembly 7 for controlling the movable preform frame 3 .

[0013...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com