Preparation method of amorphous boron-doped graphite phase carbon nitride quantum dot, quantum dot prepared by same and application of quantum dot

A graphite-phase carbon nitride and amorphous technology, applied in the field of fluorescent materials, can solve the problems of dependent behavior, self-quenching excitation wavelength, low fluorescence quantum yield, etc., and achieve the promotion of exciton formation, high selectivity and sensitivity , Optimize the effect of optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

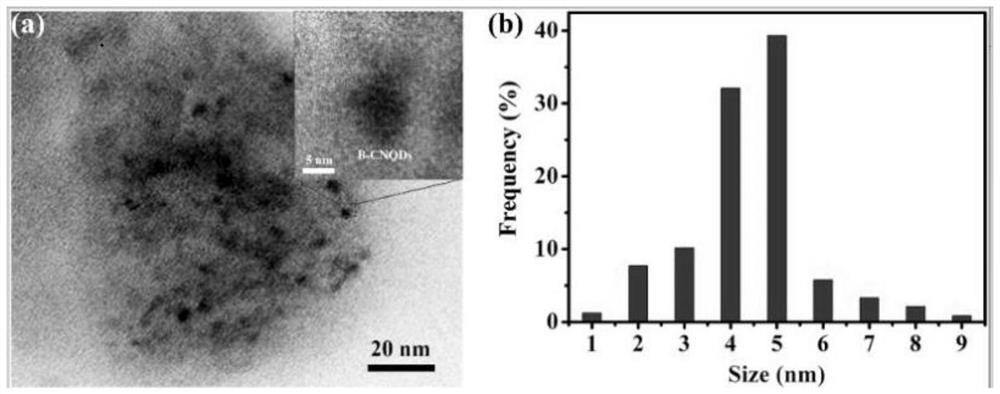

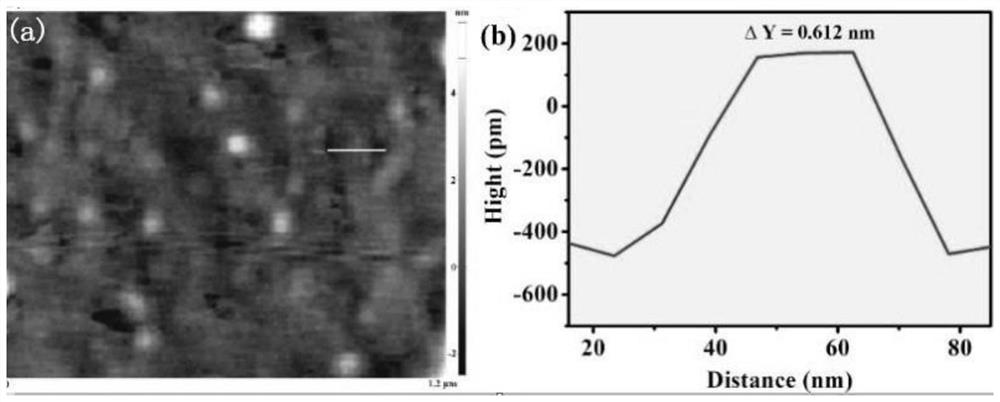

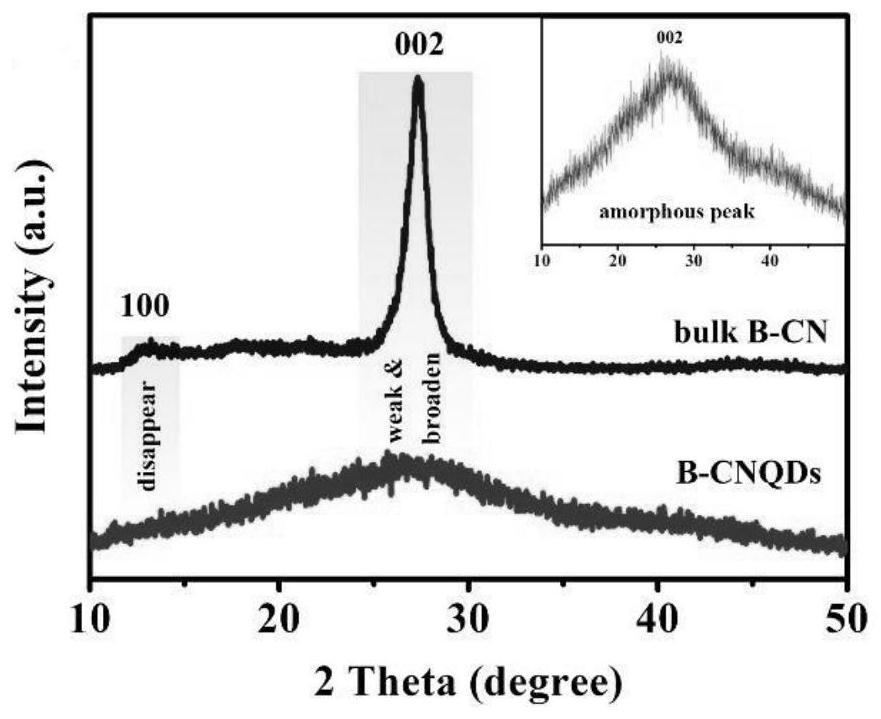

[0038] A preparation method of amorphous boron-doped graphite phase carbon nitride quantum dots (B-CNQDs), comprising the following steps:

[0039] (1) Using citric acid as a carbon source, boric acid as a boron source, and urea as a nitrogen source, add an appropriate amount of deionized water and grind evenly to obtain a mixture;

[0040] (2) Put the mixture into an autoclave and heat up to 180°C for 2 hours;

[0041] (3) naturally cool to normal temperature to obtain a reaction solution, and mix the reaction solution with 4 times the volume of deionized water for ultrasonic treatment;

[0042] (4) The solution obtained in step (3) is collected by membrane filtration to collect the supernatant;

[0043] (5) Dilute the supernatant to obtain the amorphous B-CNQDs suspension.

[0044] Wherein, the mol ratio of citric acid, boric acid, and urea described in step (1) is 1:6:6.

[0045] Wherein, the heating rate described in step (2) is 5° C. / min.

[0046] Wherein, the time of...

Embodiment 2

[0050] A preparation method of amorphous boron-doped graphite phase carbon nitride quantum dots (B-CNQDs), comprising the following steps:

[0051] (1) Using citric acid as a carbon source, boric acid as a boron source, and urea as a nitrogen source, add an appropriate amount of deionized water and grind evenly to obtain a mixture;

[0052] (2) Put the mixture into an autoclave, heat up to 180°C and react for 1.5h;

[0053] (3) naturally cool to normal temperature to obtain a reaction solution, and mix the reaction solution with 4 times the volume of deionized water for ultrasonic treatment;

[0054] (4) The solution obtained in step (3) is collected by membrane filtration to collect the supernatant;

[0055] (5) Dilute the supernatant to obtain the amorphous B-CNQDs suspension.

[0056] Wherein, the mol ratio of citric acid, boric acid, and urea described in step (1) is 1:5:5.

[0057] Wherein, the heating rate in step (2) is 4°C / min.

[0058] Wherein, the time of ultraso...

Embodiment 3

[0062] A preparation method of amorphous boron-doped graphite phase carbon nitride quantum dots (B-CNQDs), comprising the following steps:

[0063] (1) Using citric acid as a carbon source, boric acid as a boron source, and urea as a nitrogen source, add an appropriate amount of deionized water and grind evenly to obtain a mixture;

[0064] (2) Put the mixture into an autoclave, heat up to 180°C and react for 2.5h;

[0065] (3) naturally cool to normal temperature to obtain a reaction solution, and mix the reaction solution with 4 times the volume of deionized water for ultrasonic treatment;

[0066] (4) The solution obtained in step (3) is collected by membrane filtration to collect the supernatant;

[0067] (5) Dilute the supernatant to obtain the amorphous B-CNQDs suspension.

[0068] Wherein, the mol ratio of citric acid, boric acid, and urea described in step (1) is 1:7:7.

[0069] Wherein, the heating rate in step (2) is 6° C. / min.

[0070] Wherein, the time of ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com