Preparation process of antistatic and antibacterial nano composite functional powder

A nano-composite, antistatic technology, applied in the fields of biochemical fiber treatment, textile and papermaking, fiber treatment, etc., can solve the problems of antistatic and antibacterial ability weakening, and achieve the effect of improving dispersion, uniformity of silver plating and excellent coverage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

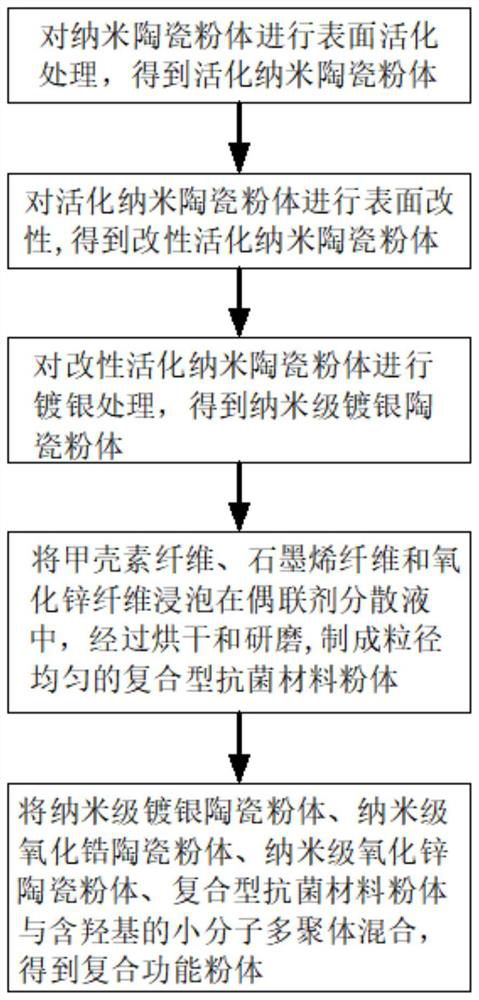

[0023] according to figure 1 As shown, this embodiment proposes a preparation process for antistatic and antibacterial nanocomposite functional powders, including the following steps:

[0024] Step 1: Select nano-ceramic powder with a particle size of 30nm, and perform surface activation treatment on the nano-ceramic powder, specifically: roughen the surface of the nano-ceramic powder to form countless micropores on the surface of the nano-ceramic powder , grooves, so that the surface of the nano-ceramic powder changes from a hydrophobic surface to a hydrophilic body, and then absorb a layer of divalent tin compound on the surface of the nano-ceramic powder in the roughened nano-ceramic powder sensitization solution (such as SnCl2) , and then undergo a hydrolysis reaction to complete the sensitization treatment, and finally immerse the sensitized nano-ceramic powder in an activation solution (such as palladium chloride) to be activated to obtain an activated nano-ceramic powde...

Embodiment 2

[0030] according to figure 1 As shown, this embodiment proposes a preparation process for antistatic and antibacterial nanocomposite functional powders, including the following steps:

[0031] Step 1: Select nano-ceramic powder with a particle size of 45nm, and perform surface activation treatment on the nano-ceramic powder, specifically: roughen the surface of the nano-ceramic powder to form countless micropores on the surface of the nano-ceramic powder , grooves, so that the surface of the nano-ceramic powder changes from a hydrophobic surface to a hydrophilic body, and then absorb a layer of divalent tin compound on the surface of the nano-ceramic powder in the roughened nano-ceramic powder sensitization solution (such as SnCl2) , and then undergo a hydrolysis reaction to complete the sensitization treatment, and finally immerse the sensitized nano-ceramic powder in an activation solution (such as palladium chloride) to be activated to obtain an activated nano-ceramic powde...

Embodiment 3

[0037] according to figure 1 As shown, this embodiment proposes a preparation process for antistatic and antibacterial nanocomposite functional powders, including the following steps:

[0038] Step 1: Select nano-ceramic powder with a particle size of 60nm, and perform surface activation treatment on the nano-ceramic powder, specifically: roughen the surface of the nano-ceramic powder to form countless micropores on the surface of the nano-ceramic powder , grooves, so that the surface of the nano-ceramic powder changes from a hydrophobic surface to a hydrophilic body, and then absorb a layer of divalent tin compound on the surface of the nano-ceramic powder in the roughened nano-ceramic powder sensitization solution (such as SnCl2) , and then undergo a hydrolysis reaction to complete the sensitization treatment, and finally immerse the sensitized nano-ceramic powder in an activation solution (such as palladium chloride) to be activated to obtain an activated nano-ceramic powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com