Fluorescent inflaming-retarding multifunctional double-layer fabric and preparing method thereof

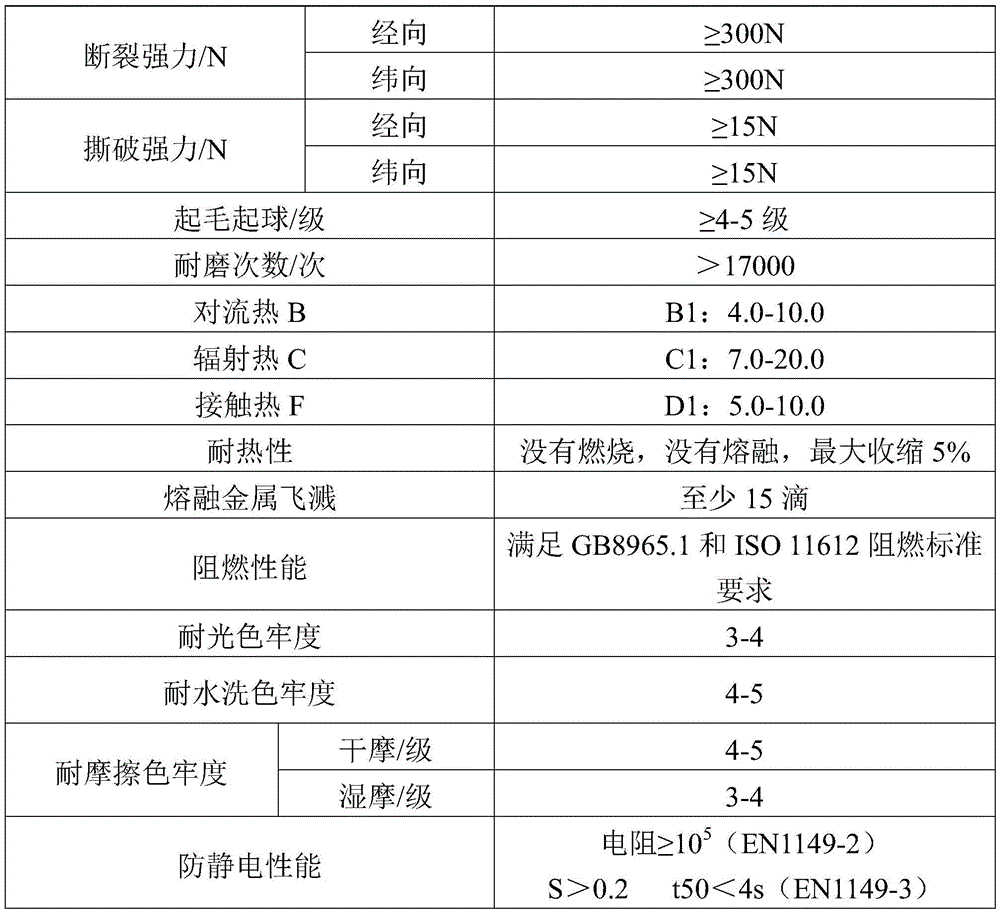

A double-layer fabric, multi-functional technology, applied in dyeing method, multi-strand fabric, textile and other directions, can solve the problems of difficult to meet safety protective clothing, single function, etc., achieve anti-splash of molten metal, simple preparation method, and promote development Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

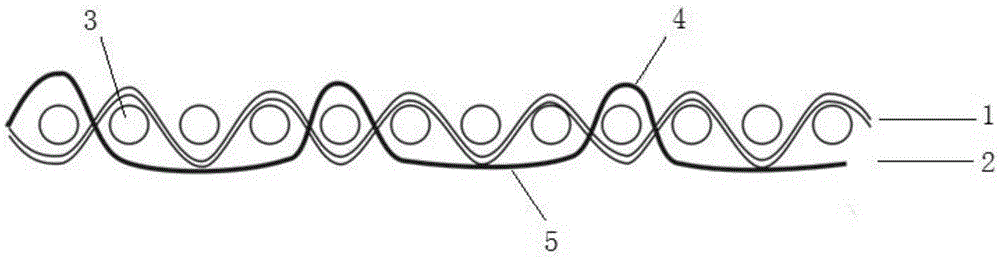

Image

Examples

Embodiment 1

[0052] Preparation of fluorescent flame-retardant multifunctional double-layer fabric:

[0053] Step 1, select the raw material fiber: select dyeable flame-retardant polyester filament with a yarn count of 150D for the surface layer, accounting for 40%, and use infusible aramid blended yarn for the inner layer, accounting for 60%. The specific proportion of the inner layer is 93% of aramid fiber 1313, 5% of aramid fiber 1414, and 2% of conductive fiber.

[0054] After fully mixing the fibers required for the inner layer above, pretreatment, cotton cleaning, carding, drawing, roving, spun yarn, and winding are sequentially performed to obtain a yarn count of 55 S / 2 Aramid 1313 / 1414 / Conductive Fiber 93 / 5 / 2 blended yarn. Among them, the cylinder speed is 330r / min, the licker-in speed is 750r / min, and the doffer speed is 38r / min. The total draft of the pre-merging is 6.8 times, and the draft of the back zone is 1.97 times; the total draft of the blending is 8.6 times, and the d...

Embodiment 2

[0060] Preparation of fluorescent flame-retardant multifunctional double-layer fabric:

[0061] Step 1, select the raw material fiber: the surface layer is made of 175D dyeable flame-retardant polyester filament, accounting for 46%, and the inner layer is made of infusible aramid blended yarn, accounting for 54%. The specific proportion of the inner layer is 90% of aramid fiber 1313, 8% of aramid fiber 1414, and 2% of conductive fiber.

[0062] After fully mixing the raw materials required for the above inner layer, pretreatment, cotton cleaning, carding, drawing, roving, spun yarn, and winding are sequentially performed to obtain a yarn count of 40 S / 2 Aramid 1313 / 1414 / Conductive Fiber 90 / 8 / 2 blended yarn. Among them, the cylinder speed is 330r / min, the licker-in speed is 750r / min, and the doffer speed is 38r / min. The total draft of the pre-merging is 6.8 times, and the draft of the back zone is 1.97 times; the total draft of the blending is 8.6 times, and the draft of the...

Embodiment 3

[0068] Preparation of fluorescent flame-retardant multifunctional double-layer fabric:

[0069] Step 1, select raw material fibers: use 200D dyeable flame-retardant polyester filaments for the surface layer, accounting for 42%, and use infusible aramid blended yarns for the inner layer, accounting for 58%. The specific proportion of the inner layer is 88% of aramid fiber 1313, 9% of aramid fiber 1414, and 3% of conductive fiber.

[0070] After fully mixing the fibers required for the inner layer above, pretreatment, cotton cleaning, carding, drawing, roving, spun yarn, and winding are sequentially performed to obtain a yarn count of 25 S / 2 Aramid 1313 / 1414 / Conductive Fiber 88 / 9 / 3 blended yarn. Among them, the cylinder speed is 330r / min, the licker-in speed is 750r / min, and the doffer speed is 38r / min. The total draft of the pre-merging is 6.8 times, and the draft of the back zone is 1.97 times; the total draft of the blending is 8.6 times, and the draft of the back zone is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com