Graphene flame-retardant elastic composite, composite film and preparing method of composite film

An elastic composite material and graphene technology, applied in the direction of coating, etc., can solve the problems of poor bending resistance, spontaneous combustion, etc., and achieve the effect of overcoming poor bending resistance, simple process, and mature and stable construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

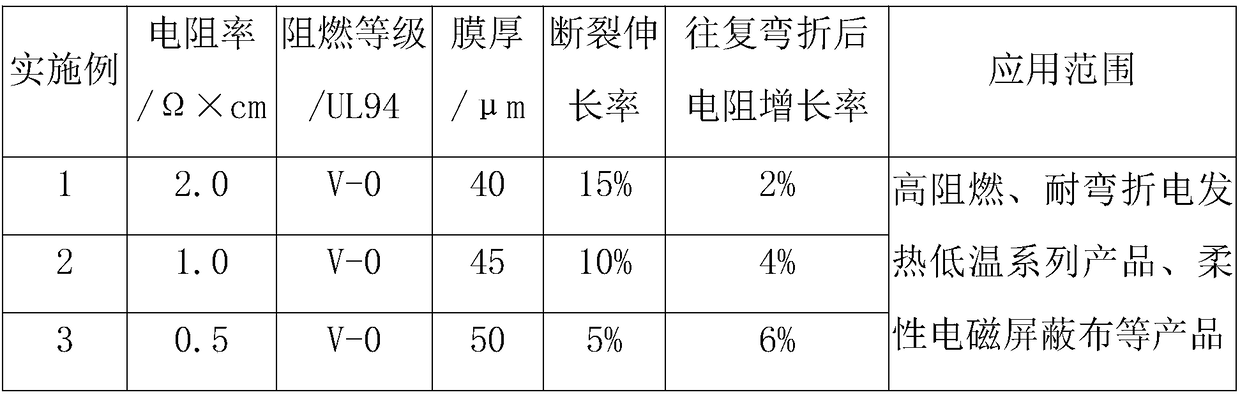

Examples

Embodiment 1

[0028] The present embodiment provides a kind of preparation method of graphene flame retardant elastic composite film, specifically comprises the following steps:

[0029] (1) 20g thermoplastic polyolefin elastomer TPO, 200g solvent N-methylpyrrolidone, 25g flame retardant Mg 2 Al-TCP (magnesium aluminum tetrachlorophthalate) was mixed and stirred, dissolved and homogeneously dispersed for 0.5 h at a rotational speed of 10,000 rpm and a temperature of 60° C., to prepare a flame-retardant elastic resin slurry.

[0030] (2) Take 5g of graphene microchips and add them to 95g of N-methylpyrrolidone as a solvent and 1g of sodium dodecylbenzenesulfonate as a dispersant, mix and stir, then put them into an ultrasonic machine with a set power of 80w and a time of 30min Ultrasonic dispersion is carried out to obtain a graphene microsheet dispersion.

[0031] Wherein, the graphene microflakes are prepared by the compression ignition method, and the specific process is as follows:

[...

Embodiment 2

[0037] The present embodiment provides a kind of preparation method of graphene flame retardant elastic composite film, specifically comprises the following steps:

[0038] (1) Mix and stir 20g thermoplastic polyurethane elastomer TPU, 200g solvent N,N-dimethylformamide, 30g composite flame retardant zinc borate and aluminum hydroxide (mass ratio 2:1), at a speed of 12000rpm, The temperature was 60° C. for 0.5 h to dissolve and disperse homogeneously to prepare a flame retardant elastic resin slurry.

[0039] (2) Take 10g of graphene microchips and add them to 90g of N,N-dimethylformamide as a solvent and 2g of dispersant polyvinylpyrrolidone, mix and stir, then put them into an ultrasonic machine with a set power of 80w and a time of 60min. Ultrasonic dispersion to obtain a graphene microplatelet dispersion.

[0040] Wherein, the graphene microchips are prepared by compression ignition method, and the specific process is consistent with that of Example 1.

[0041] (3) Mix a...

Embodiment 3

[0045] The present embodiment provides a kind of preparation method of graphene flame retardant elastic composite film, specifically comprises the following steps:

[0046] (1) Mix and stir 20g thermoplastic styrene elastomer TPS, 200g solvent propylene glycol methyl ether acetate, 20g composite flame retardant triphenyl phosphate and red phosphorus (mass ratio 1:1), at a speed of 13000rpm, temperature Dissolving and dispersing homogeneously for 0.5 h at 80° C. to prepare flame retardant elastic resin slurry.

[0047] (2) Take 15g of graphene microchips and add them to 85g of dimethyl sulfoxide as a solvent and 2g of dispersant sodium dodecylbenzenesulfonate, mix and stir, then put them into an ultrasonic machine with a set power of 80w and a time of 60min Ultrasonic dispersion is carried out to obtain a graphene microsheet dispersion.

[0048] Wherein, the graphene microchips are prepared by compression ignition method, and the specific process is consistent with that of Exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com