Flex banner and processing technology thereof

A processing technology, light box cloth technology, applied in other home appliances, electronic equipment, lamination and other directions, can solve the problems of no anti-oxidation, waterproof and flame retardant, simple composition of light box cloth, no processing technology, etc., and achieve good stirring effect. , The effect of strong versatility and good flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

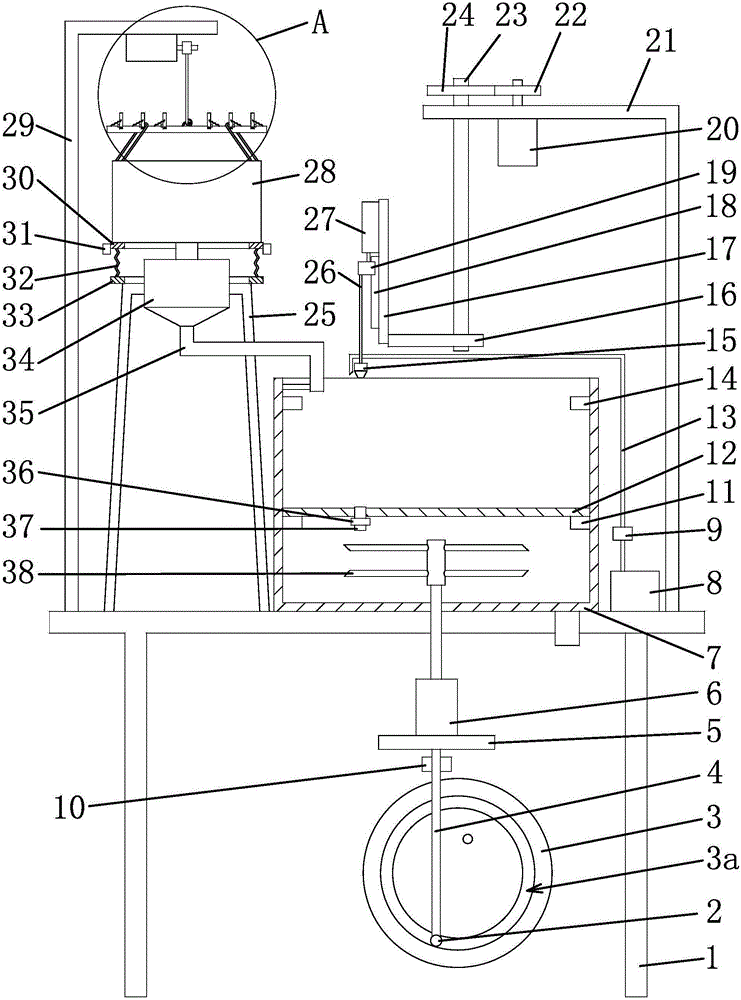

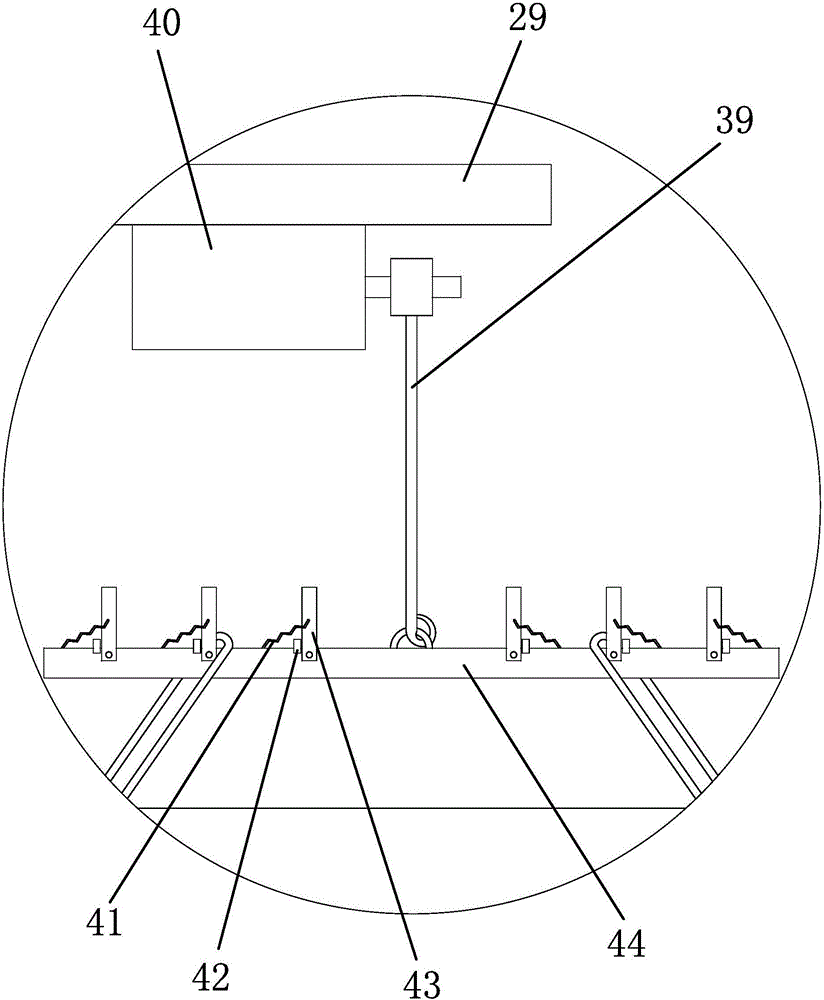

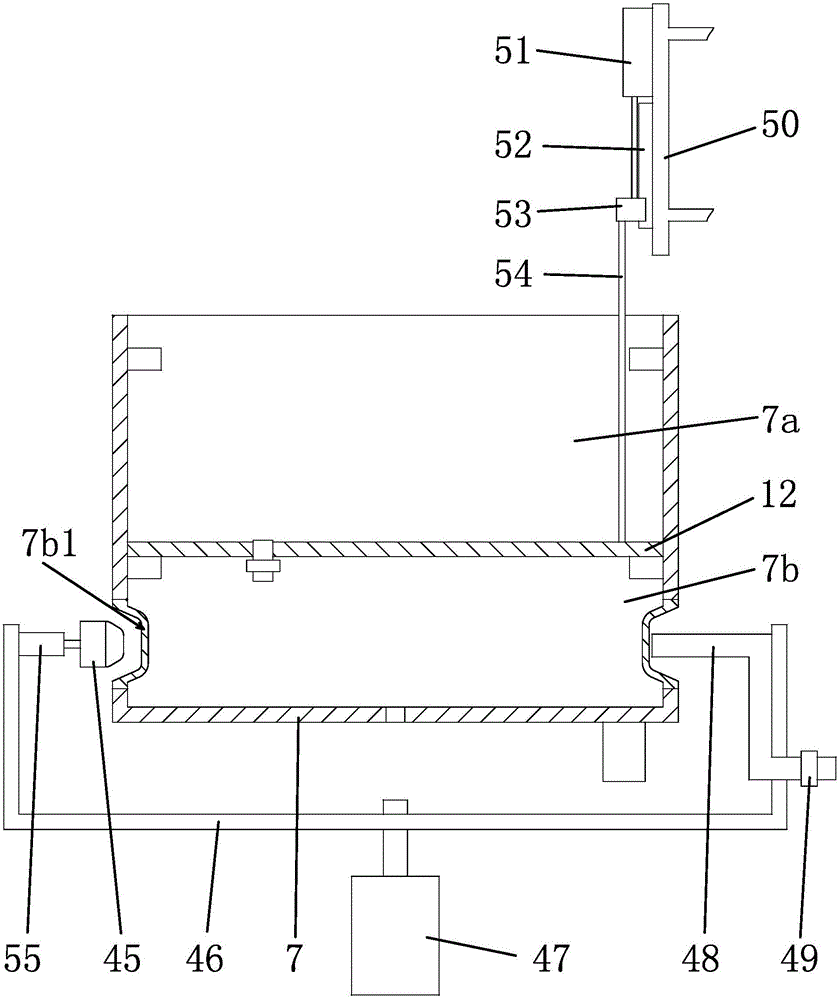

[0047] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0048] This light box cloth comprises three layers, the upper and lower layers are PVC films, and the middle layer is mesh cloth. In this embodiment, the mesh cloth adopts existing products available on the market; the PVC film includes the following components by weight Divide: 80-90 parts of polyvinyl chloride resin, 10-18 parts of epoxy resin, 10-16 parts of calcium carbonate, 15-35 parts of plasticizer, 3-9 parts of antioxidant, 5-10 parts of butyltin dilaurate , 1-3 parts of flame retardant and 3-6 parts of liquid stabilizer; In the present embodiment, plasticizer, antioxidant, flame retardant and liquid stabilizer adopt the existing product that can buy on the market; Adopt This component, by taking polyvinyl chlorid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com