Preparation method for composite inflaming retarding core-board

A blockboard, composite flame retardant technology, which is applied in the joining of wooden veneers, wood processing appliances, and wood treatment, etc., can solve the problems of affecting the quality of decoration, uneven moisture content of blockboard core board, residual stress, etc. , to achieve the effect of improving the overall stability and appearance quality, improving the comprehensive utilization rate and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

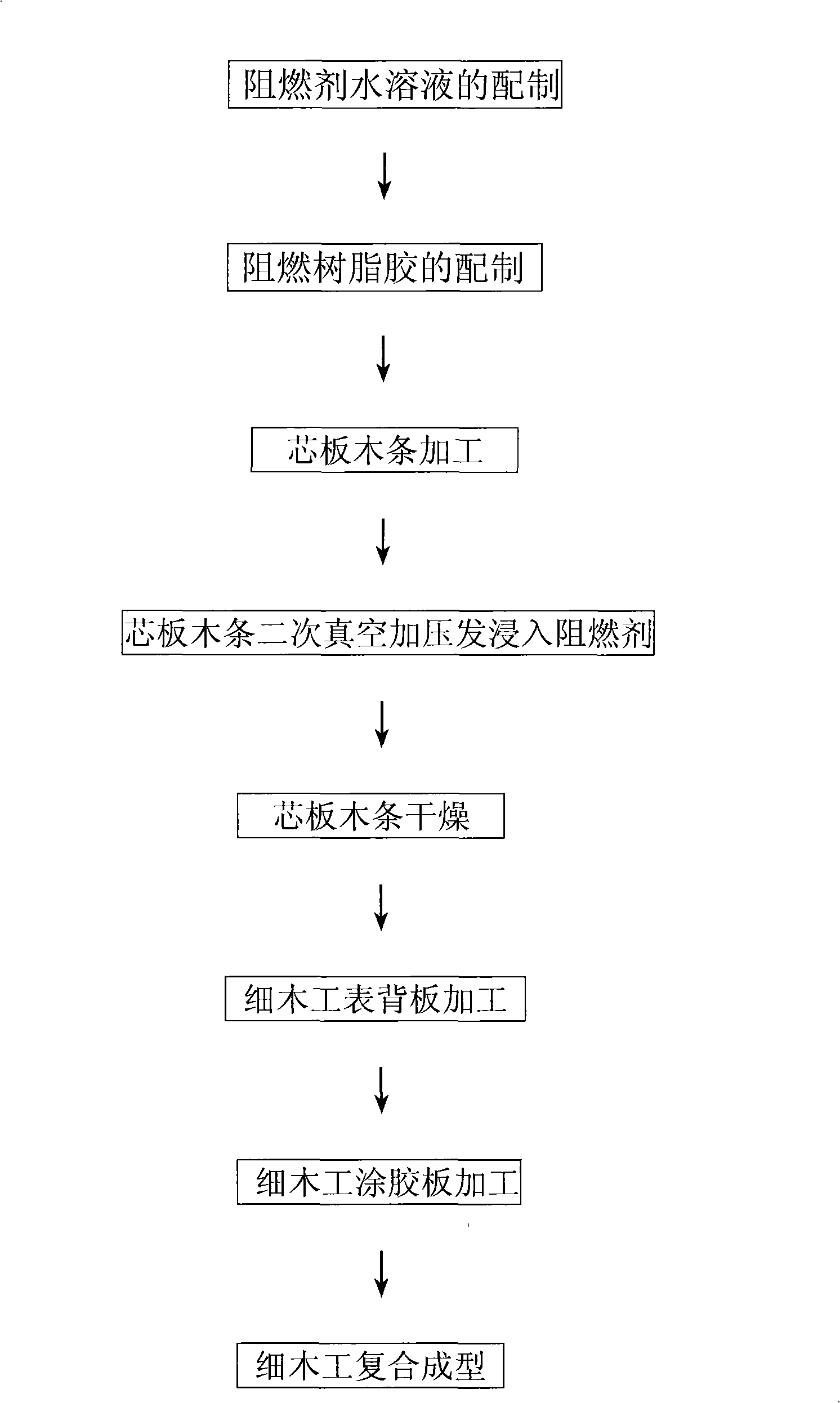

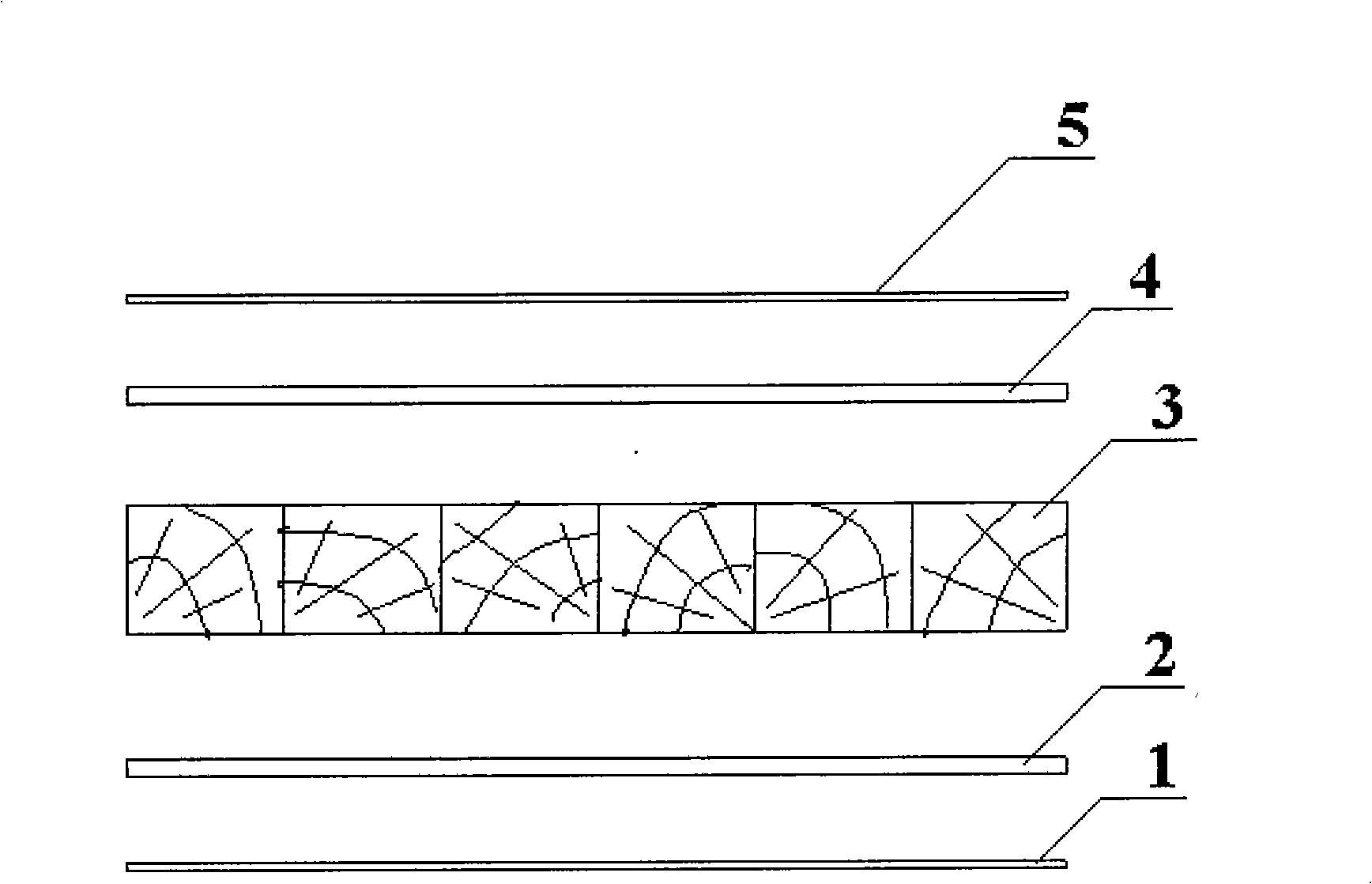

[0033] Below in conjunction with accompanying drawing, the present invention will be further described:

[0034] combine Figure 1-Figure 2 , the present embodiment provides a method for making a composite flame-retardant blockboard, which is realized by the following specific steps:

[0035] 1. The preparation method of flame retardant water solvent: the ALFR type flame retardant selected as the flame retardant is a non-halogen water-based environmentally friendly flame retardant that does not contain formaldehyde and has strong flame retardant performance, easy penetration, and Loss, smoke suppression and anti-mildew effects, its main ingredients are hydroxymethyl phosphate amidinourea and boric acid, the appearance is white powdery substance, molecular formula: OHCH2HNC(NH2)NHCONH2·H2PO4+H3BO3. When preparing, add the flame retardant into warm water at about 50 degrees at a ratio of 15:85, and stir well to dissolve the flame retardant into a transparent solution.

[0036]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com