Floating roadbed

A floating track bed and floating slab technology, applied in the directions of roads, tracks, ballast layers, etc., can solve the problems of increased vibration and noise, low lateral stiffness, and increased vibration of floating slabs, and can suppress structural vibration and noise. , Improve system stability and improve the effect of structural damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

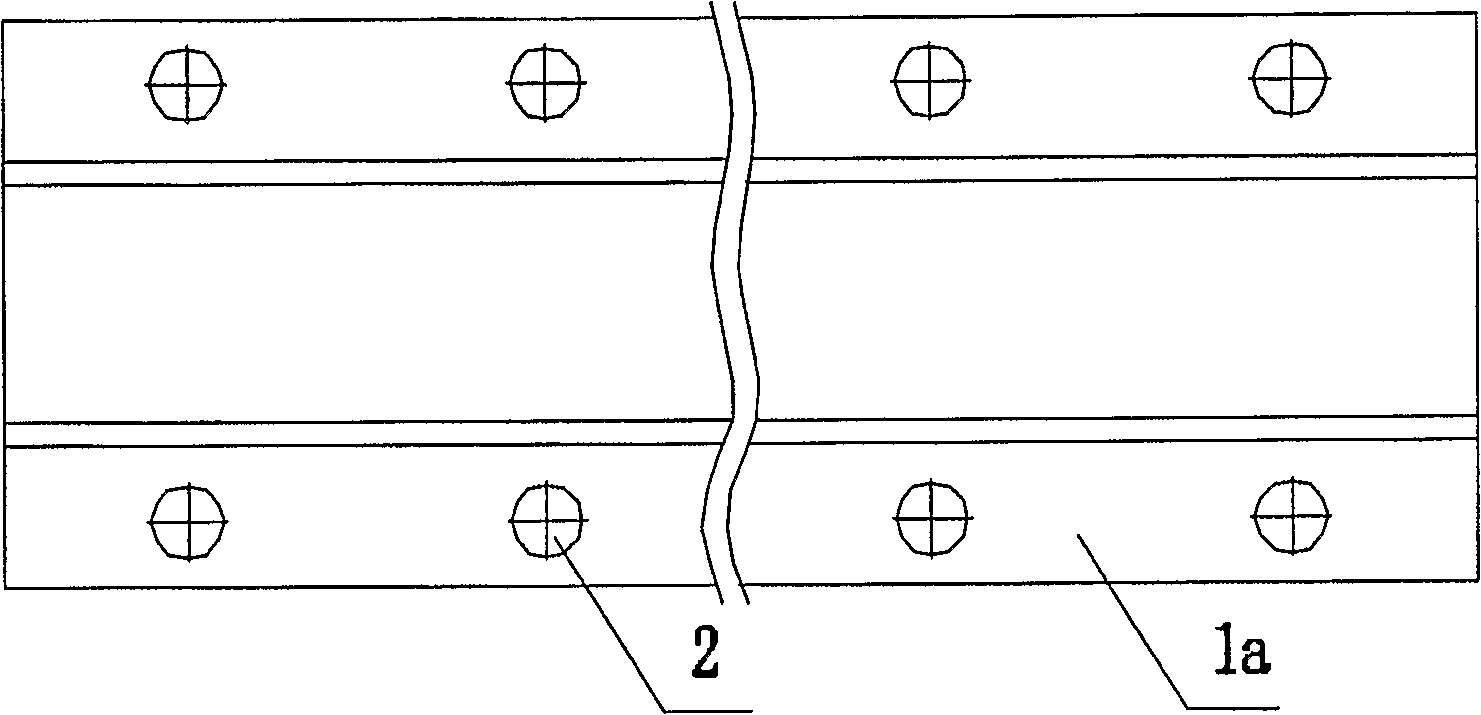

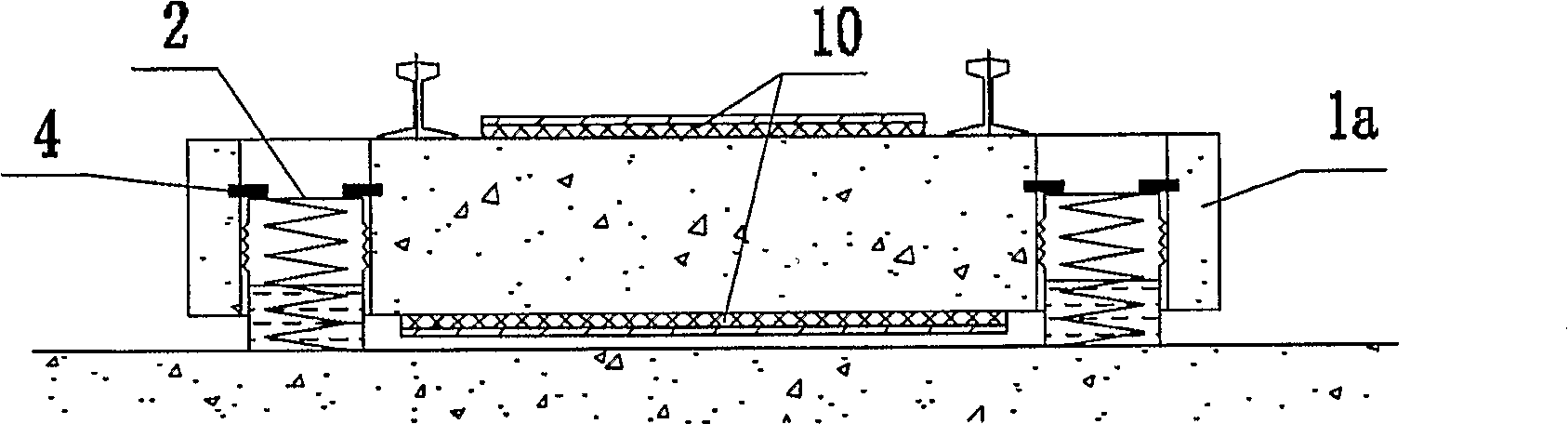

[0047] As shown in Fig. 1, Fig. 2, Fig. 3 and Fig. 4, the floating plate 1a is plate-shaped and formed by concrete pouring on site, and two rows of through holes are evenly distributed on the outer side of the floating plate corresponding to the rail; A coupling sleeve 3 is buried, and a support block 4 is welded on its inner wall. The floating plate 1a is elastically supported on the spring isolator 2 through the support block 4, forming a built-in floating ballast bed.

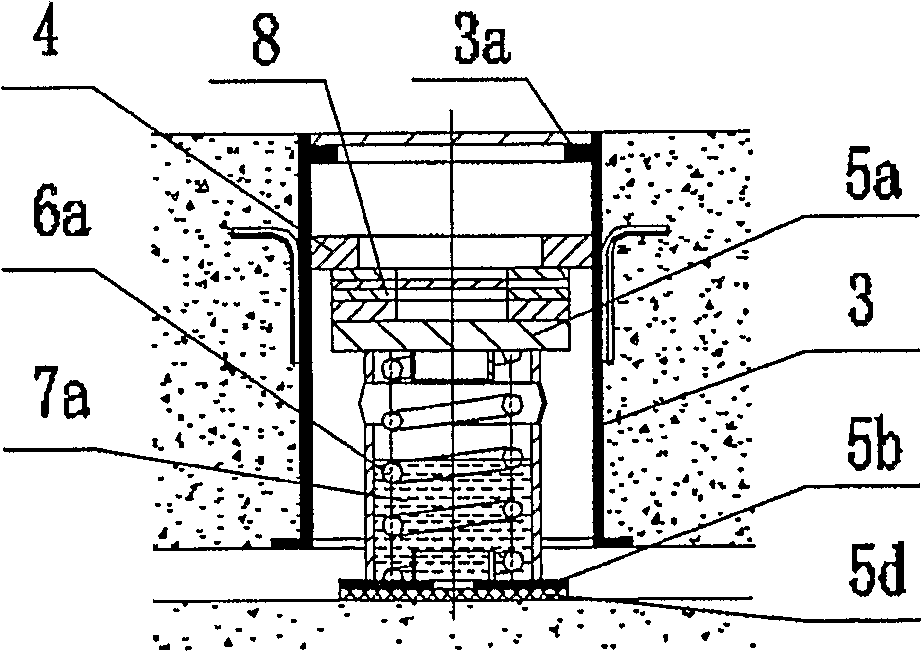

[0048] The internal structure of the coupling sleeve 3 and the spring isolator 2 is shown in Figure 3, including a coil spring 6a and a spring housing 5. The spring housing 5 is composed of upper and lower spring sleeves, wherein the upper sleeve is provided with a transferable The upper top plate 5a of the spring support force, the lower sleeve is provided with the lower bottom plate 5b, both are steel welded parts, sealed and connected as one by a flexible sealing ring 5c; the spring sleeve is provided with...

Embodiment 2

[0056] As shown in Figure 5, Figure 6, and Figure 7, the difference from Embodiment 1 is that the lower surface of the floating plate 1b is provided with a boss, and the spring isolator 2 is supported on the outer recess of the boss to form an external floating Set the board. The spring isolator is basically similar to that of Embodiment 1. The shape of the spring shell is a cuboid, which is composed of upper and lower sleeves and connected with rubber seals. Two coil springs 6a are placed inside, and the upper and lower ends of the coil springs are respectively embedded in solid damping material 7b. , such as high-damping viscoelastic polyurethane that can be cured after pouring, not only provides damping for the spring isolator, but also plays the role of connecting the upper and lower sleeves. Compared with liquid damping, the solid damping is not afraid of water ingress, and only from waterproof Angularly, no seal or even a spring sleeve can be provided. This multi-spring...

Embodiment 3

[0060] As shown in Fig. 8, Fig. 9, Fig. 10 and Fig. 11, compared with Example 1, the floating plate 1c is in the shape of a ladder, and the spring isolator is an external type, consisting of two parallel cast-in-place concrete beams and multiple Composed of two parallel cross-link rods 11, here is a steel pipe, the surface of the cross-link rod in the concrete beam slab is provided with anchor ribs to form a firm connection with the concrete beam slab, and constraints are provided on the upper and lower surfaces and the outer surface of the concrete beam slab The damping layer 10 is composed of a 2-3 mm thick high damping modified asphalt layer and a 2-5 mm thick steel plate bonded to each other. When the concrete beam slab is excited by the vibration of the track to generate vibration deformation, due to the inconsistent deformation of the constrained steel plate and the concrete beam slab, the damping material layer is forced to undergo shear-based deformation. Because the da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com