Gas treatment device for electric control room under coal mine

An electrical control room and gas treatment technology, applied in the directions of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve problems such as poor working conditions, safety accidents, and narrow underground tunnel space, and achieve the effect of convenient and flexible installation and debugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

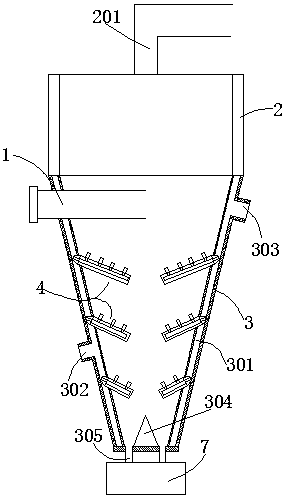

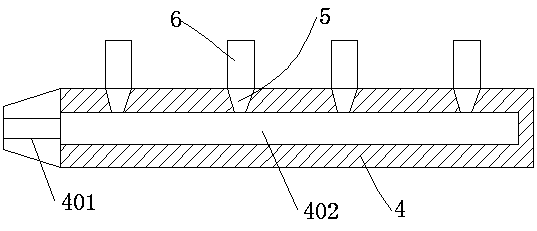

[0038] In this embodiment, the structure of the conical cylinder and the ventilation partition is as follows: it includes a hollow shell and a draft tube 1 for guiding the air flow, and the shell includes a cylindrical part 2 with a cylindrical upper end and a cylindrical part with a lower end. The conical conical part 3 is provided with a gas discharge port 201 on the cylindrical part 2, and a hollow interlayer is provided in the housing wall of the conical part 3. The outer wall is provided with a cold air inlet 302 and a cold air outlet 303 connected to the cold air passage 301. The cold air inlet 302 is connected to the existing cold source in the electrical control room through the connecting pipeline, and the cold air outlet 303 is connected to the circulation pipeline. Connected to realize air circulation, on the inner wall of the conical part 3, there are several downward-sloping ventilation partitions 4, and several of the ventilation partitions 4 are spaced up and dow...

Embodiment 2

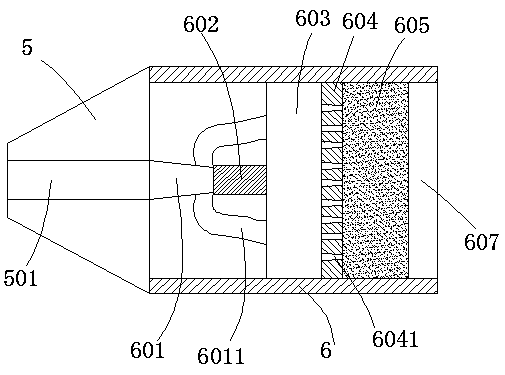

[0040] The structure of the conical cylinder and the ventilation partition in this embodiment is the same as that in Embodiment 1, the main difference is that the structure of the gas nozzle is different, so only the structure of the gas nozzle is described here, such as Figure 4 As shown, the gas nozzle structure includes a screw joint 5 and a pipe body 6 connected to the screw joint. Evening plate 604, buffer chamber 605, dispersing plate 606 and exhaust port 607, the airflow channel II501 in the screw joint and the air inlet chamber 601 realize sealing butt joint, and several cone-shaped The vent hole 6041, the larger end of the vent hole 6041 faces the air storage chamber 603, a cotton layer is arranged in the buffer chamber 605, and a plurality of through holes are arranged on the dispersion plate 606, and the through holes are located in the dispersion It is composed of a central hole in the middle of the plate and a plurality of inclined divergent holes arranged around...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com