Damping structure and composite material

A technology of damping composite materials and damping structures, which is applied to springs, springs, springs/shock absorbers made of plastic materials, etc., can solve the problems of inability to achieve vibration and noise reduction effects, and achieve obvious vibration and noise reduction effects. Reduce the intensity of vibration or sound, the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

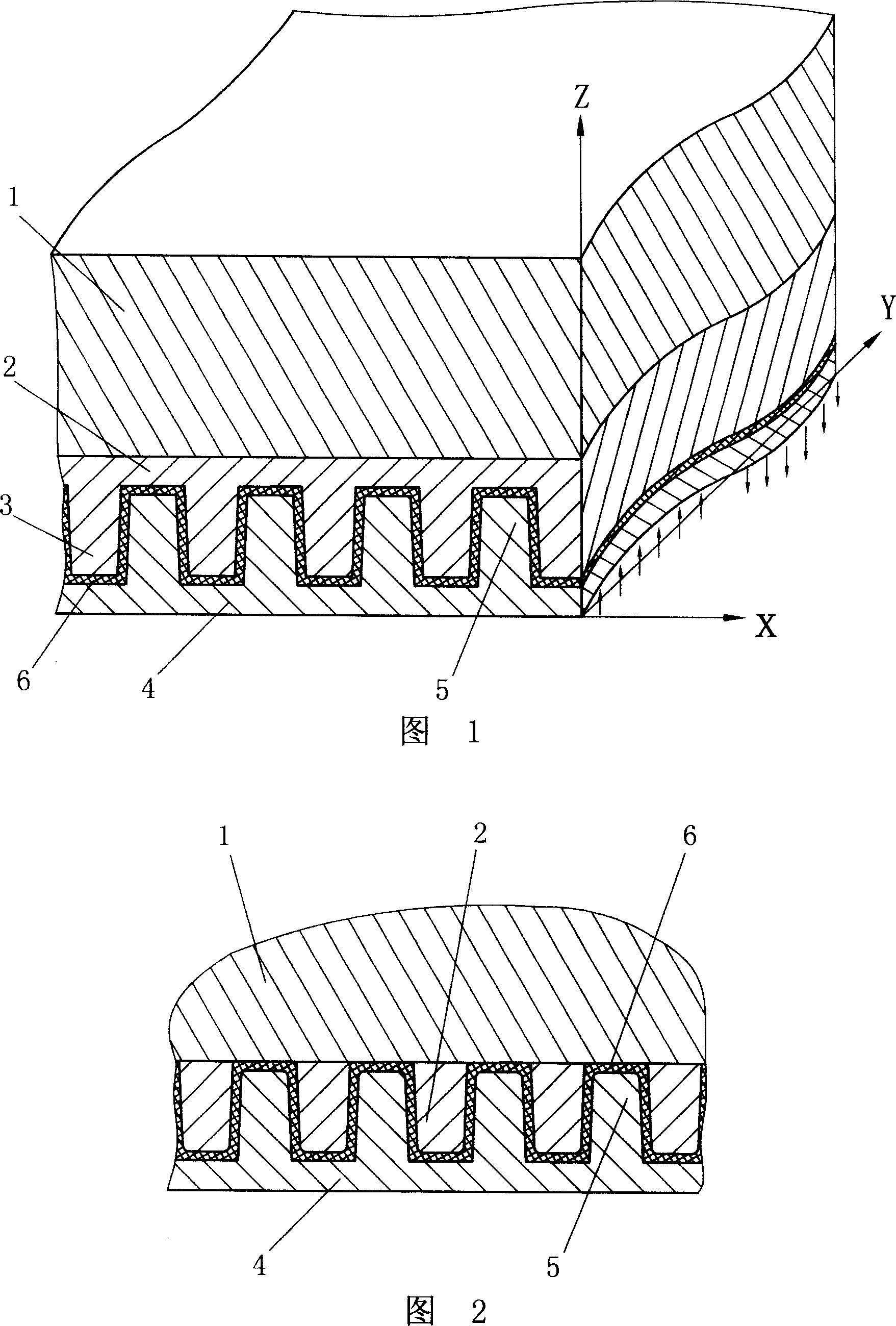

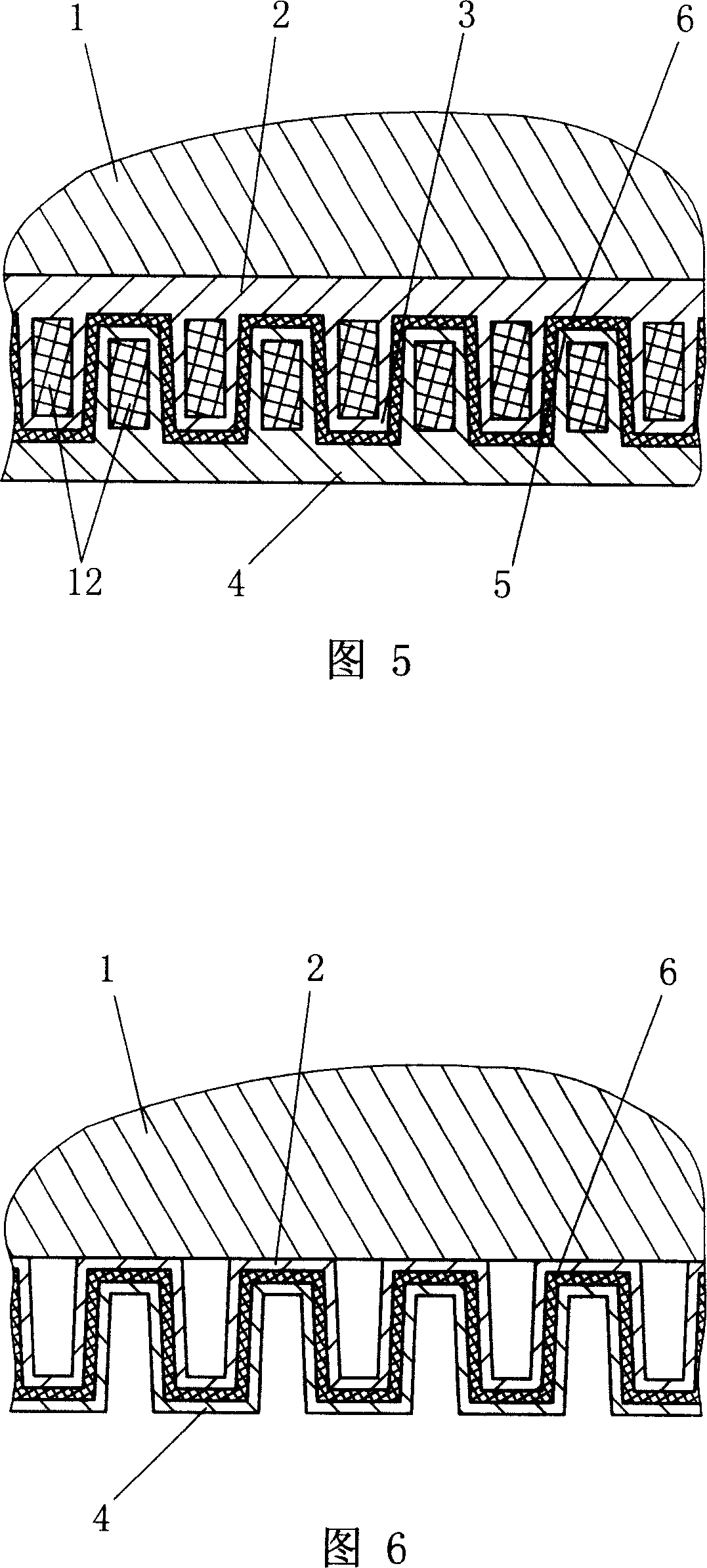

[0033] As shown in Figure 1, the component body 1 is a plate-shaped easy-to-vibrate casing of the machine, its main vibration shape is bending vibration, and the bending axis is the X axis. The connecting body 2 is fixed on the component body 1 with an adhesive, Protruding ribs 3 are provided at intervals on the connecting body 2, and the protruding ribs 3 cooperate with the protruding ribs 5 on the constraining body 4. The extending direction of the protruding ribs is the direction of the Y axis (perpendicular to the direction of the X axis). A continuous damping layer 6 is arranged between the connecting body 2 and the inner surface of the constraining body 4, and the material of the damping layer is vulcanized high-damping rubber. The above structures can be arranged continuously or at intervals on the surface of the component body.

[0034] When the component body is excited to vibrate, it bends and deforms around the X-axis. At this time, the damping material is forced to...

Embodiment 2

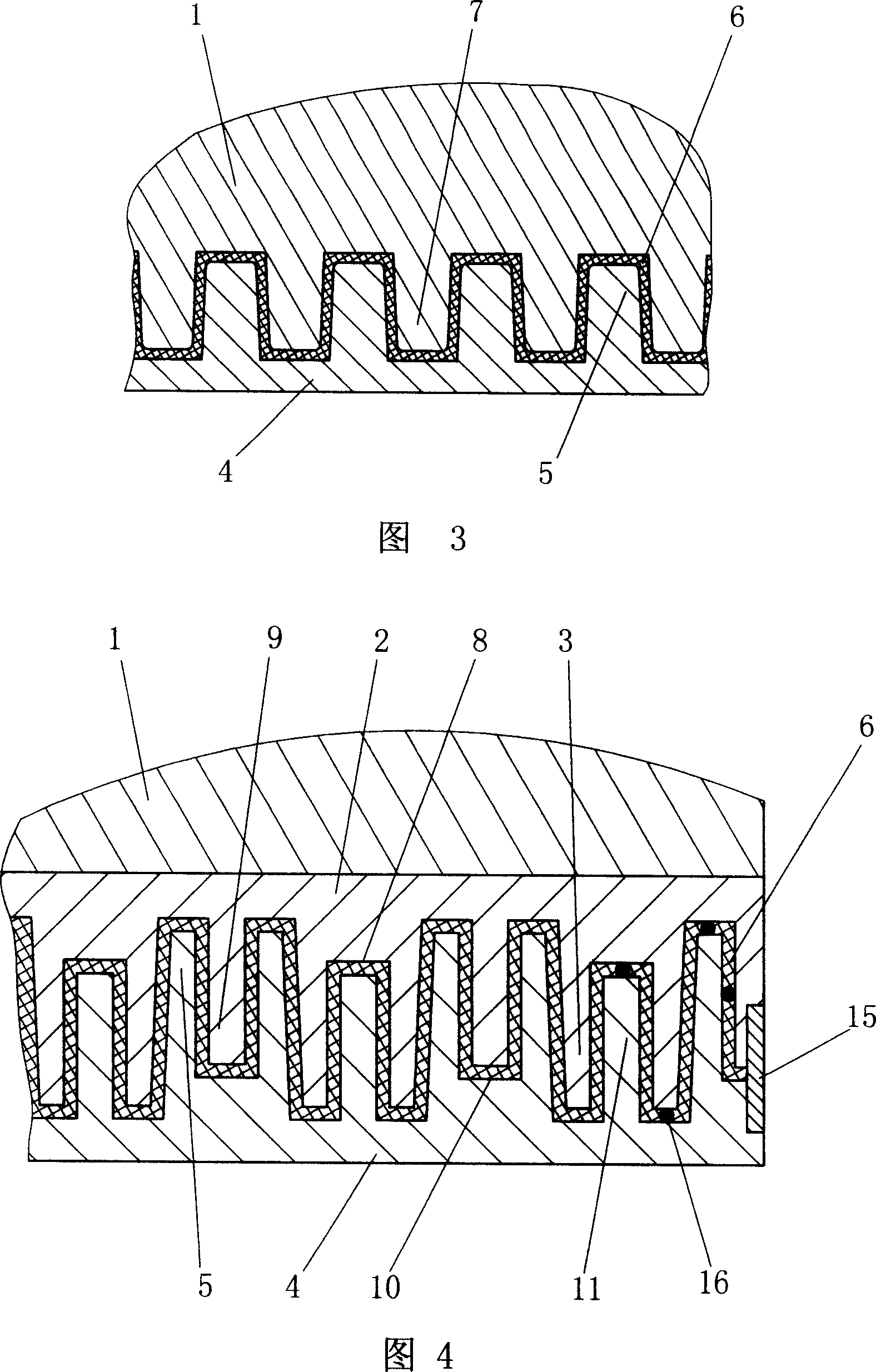

[0039] As shown in Figure 2, the difference from Embodiment 1 is that the connecting body 2 is simplified into a plurality of independent ribs, which are welded and fixed at intervals on the surface of the component body 1 and interlaced with the ribs 5 on the constraining body 4 Cooperate. At this time, a damping layer 6 is set between the outer surface of the component body 1 and the connecting body 2 and the inner surface of the constraint body 4, and a solid damping material, high-damping polyurethane is set in the damping layer, and the order of implementation is to mix the two-component damping materials well. Finally, paint it on the concave-convex surface of the constraining body, then press the constraining plate and the component, and the damping material is cured to form a damping layer.

Embodiment 3

[0041] As shown in FIG. 3 , as an extension of the structure described in Example 1, for the component body 1 integrally cast with ribs 7 on its surface, the ribs 7 on its surface can be regarded as connectors. The ribs 7 on the surface of the component body cooperate with the ribs 5 on the constraining body 4. At this time, a damping layer 6 is set between the surface of the component body and the inner surface of the constraining body, and a solid damping material modified damping asphalt is set in the damping layer.

[0042] When the component 1 or the constraint body 4 is made of metal material, the connecting ribs on its surface can be formed by casting, machining or forging; when the component 1 or the constraint body 4 is made of aluminum, aluminum-magnesium alloy, or thermoplastic material, the rib Extrusion molding or injection molding can be used; when the member 1 or the constraint body 4 is a concrete structure, the ribs can be poured. For example, when the compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com