High-efficiency and large-torque disk type switching magnetoresistive motor

A switched reluctance motor, high torque technology, applied in the magnetic circuit static parts, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc. , winding commutation difficulties, etc., to achieve the effect of reducing inter-pole flux leakage and winding inductance, improving motor running torque, and reducing motor loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

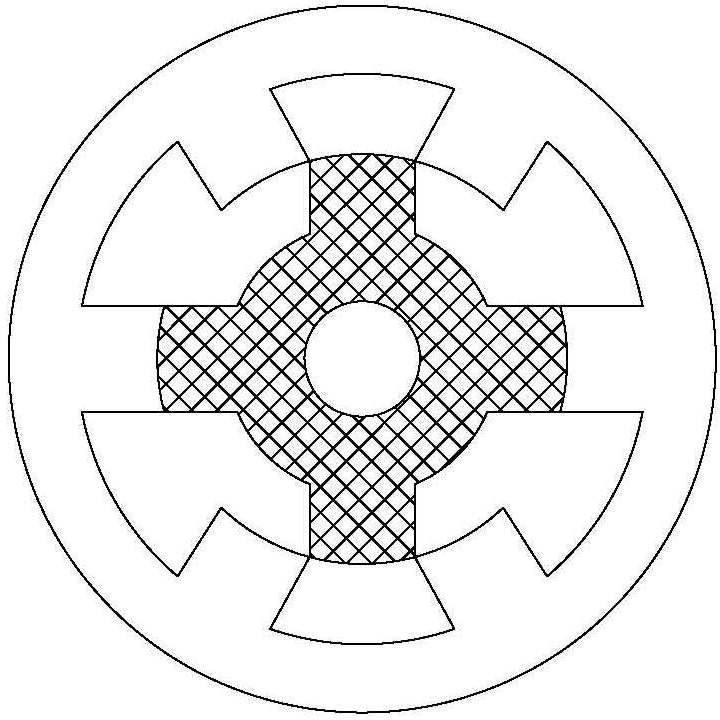

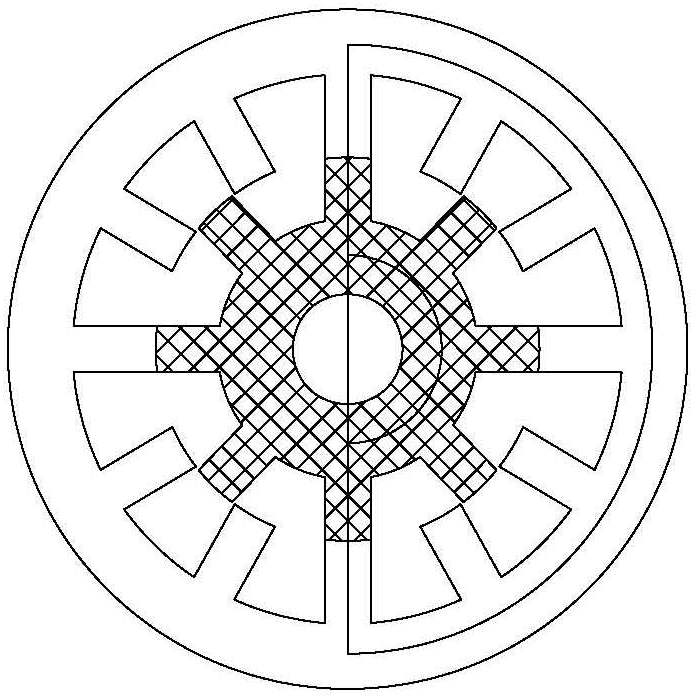

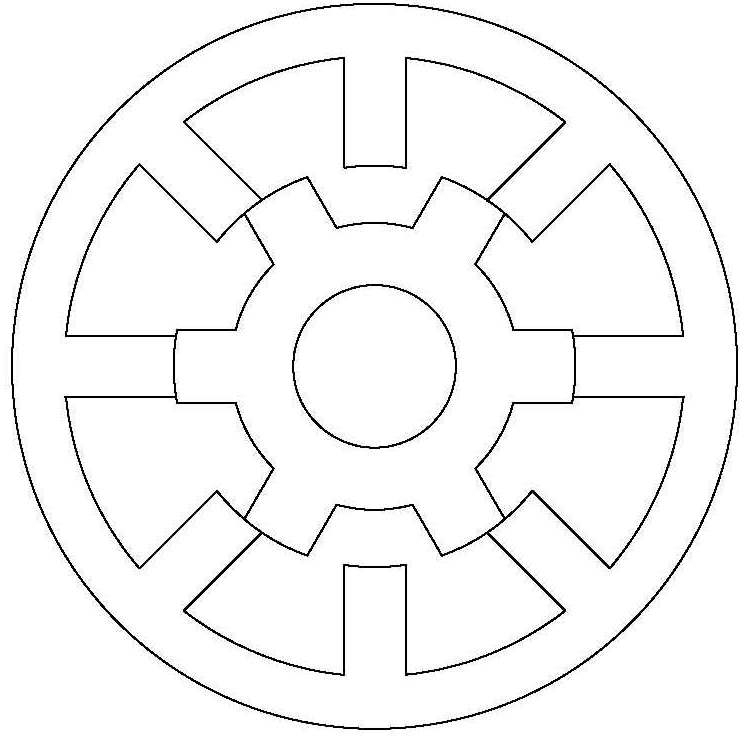

[0036] Hereinafter, the present invention takes a 12 / 8-pole axial magnetic field disc switched reluctance motor as an example to provide a specific implementation mode of the present invention.

[0037] See attached Image 6 , a high-efficiency, high-torque disc-type switched reluctance motor, including a stator 10 and a rotor 20 fixed by a rotating shaft 21, that is, the internal structure of the motor is a structure with a single stator and a single rotor on the same steel shaft, so Both the stator 10 and the rotor 20 are in the shape of a yoke disc ring, and both include a disc and an iron core formed on the disc, that is to say, the stator 10 includes a stator disc 11 and an iron core formed on the disc. The stator tooth core 13 on the disk 11 , the rotor 20 includes a rotor disk 23 and the rotor tooth core 13 formed on the rotor disk 22 . The iron core 13 of the stator 20 is wound with a stator winding 12 . Also see attached Figure 7 And attached Figure 8 , The iron c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com