Rotary efficient damping anti-galloping spacer with wire clamps

A wire clip rotary type, spacer bar technology, applied in the direction of maintaining the distance between parallel conductors, mechanical vibration damping devices, etc. Dance effect and other issues, to achieve the effect of large structural damping, structural versatility, and avoidance of dancing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention provides a wire clamp rotating type high-efficiency damping anti-dancing spacer. The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

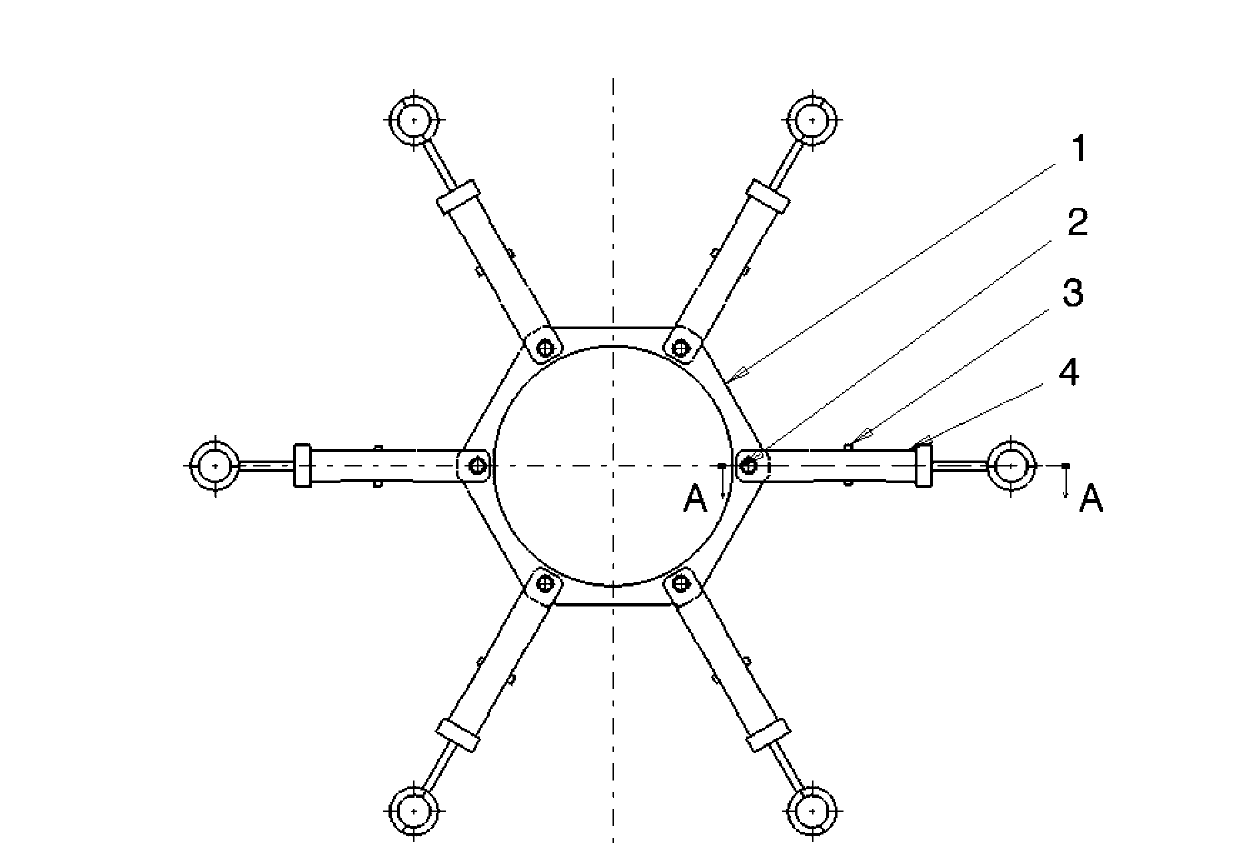

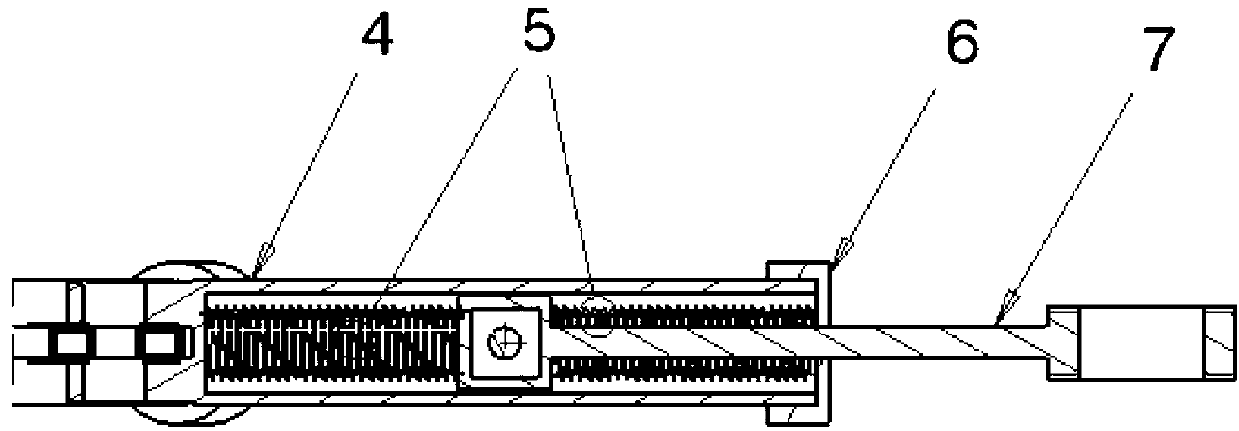

[0019] This embodiment provides a six-split wire clamp rotating type high-efficiency damping spacer, such as figure 1 shown. The spacer body frame 1 is a regular hexagonal structure, and each corner of the spacer body frame 1 is connected to a rotatable sleeve 4 through a pin 2; An end cover 6 with a hole, and a wire clip 7 with one end matched with the slide groove through a slider is installed in the sleeve 4; springs 5 are respectively installed in the sleeve 4 and both sides of the slider of the wire clip 7, and the two sides of the spring 5 The ends are fixedly connected with the sliders of the sleeve 4 and the wire clip 7 respectively; The slide block of short pin 3 and wire clip 7 is all positioned at the middle part of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com