Turbomachine stator damper device

A machine stator and turbine technology, applied in the direction of stator, shock absorber, shock absorber, etc., can solve problems such as unbalanced blades, unbalanced use of turbines, and difficult implementation of processing technology, so as to increase structural damping, reduce costs, shorten Effect of development and commissioning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

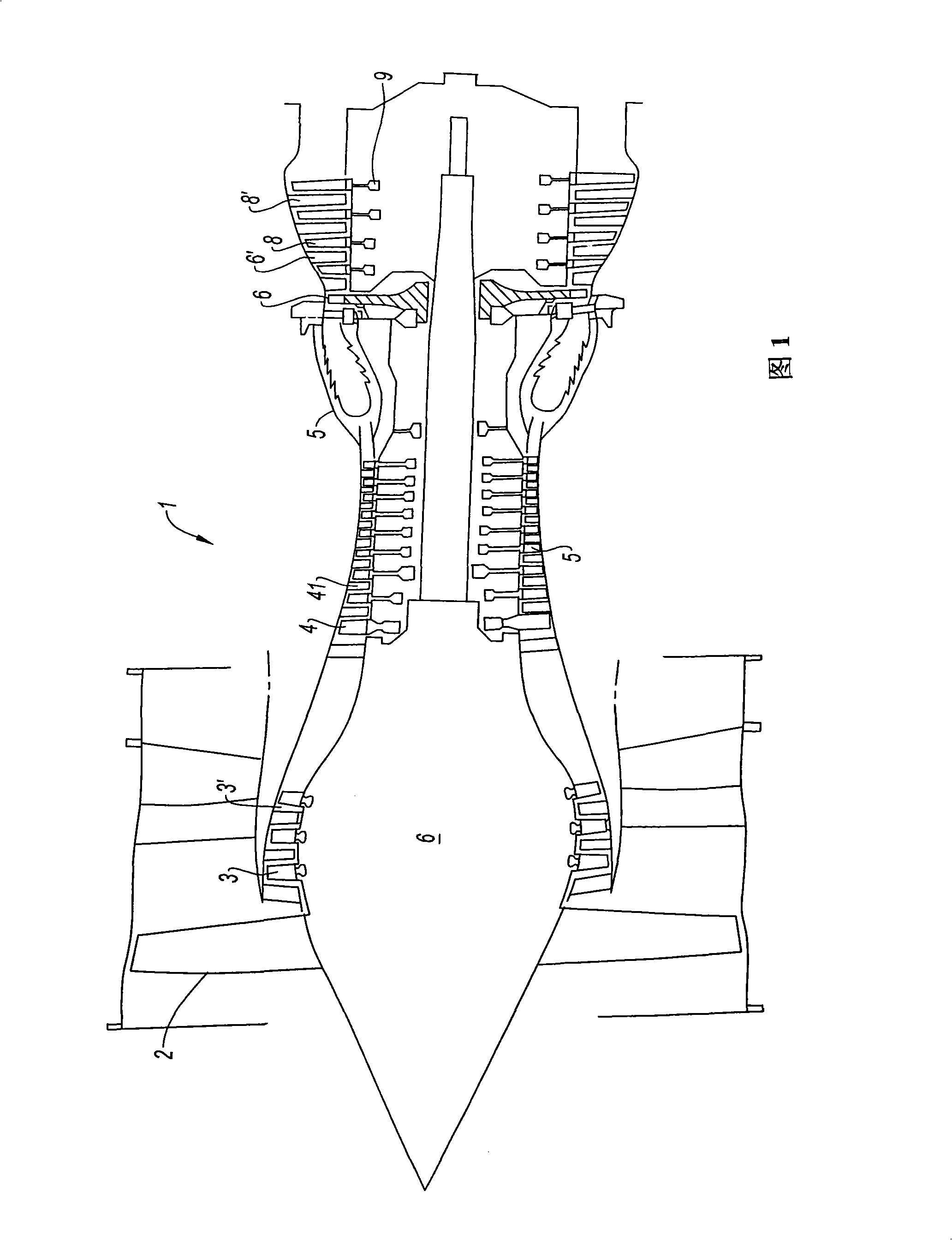

[0032] FIG. 1 is a schematic diagram of a turbine in the form of a twin-rotor turbofan engine 1 . The fan 2 at the front end provides wind power to the engine. The air compressed by the fan is distributed into two concentric streams. The two air streams are exhausted directly into the atmosphere and provide the majority of the engine's thrust. Instead, the raw air flow is directed through several compression stages to the combustion chamber, where it is mixed with fuel and combusted. Hot gas is supplied to each turbine stage, which drives the fan and compression stages. The gas is then vented into the atmosphere.

[0033] This engine consists of several stator vane ring impellers: one downstream of the fan to synchronize the second airflow before it is injected, and one between the moving impeller of the compressor and the upstream guide vane assembly between the high-pressure and low-pressure turbine wheels. impeller.

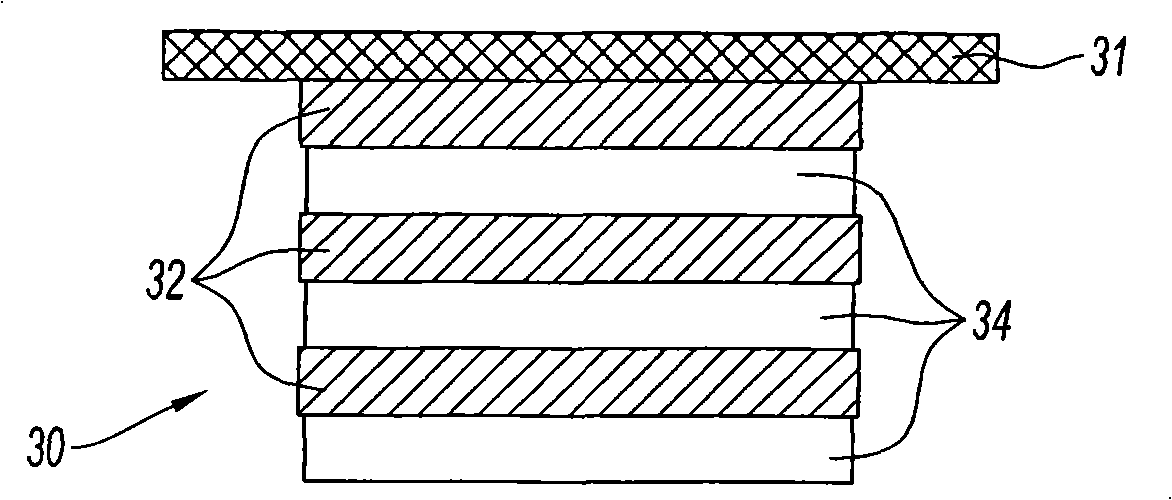

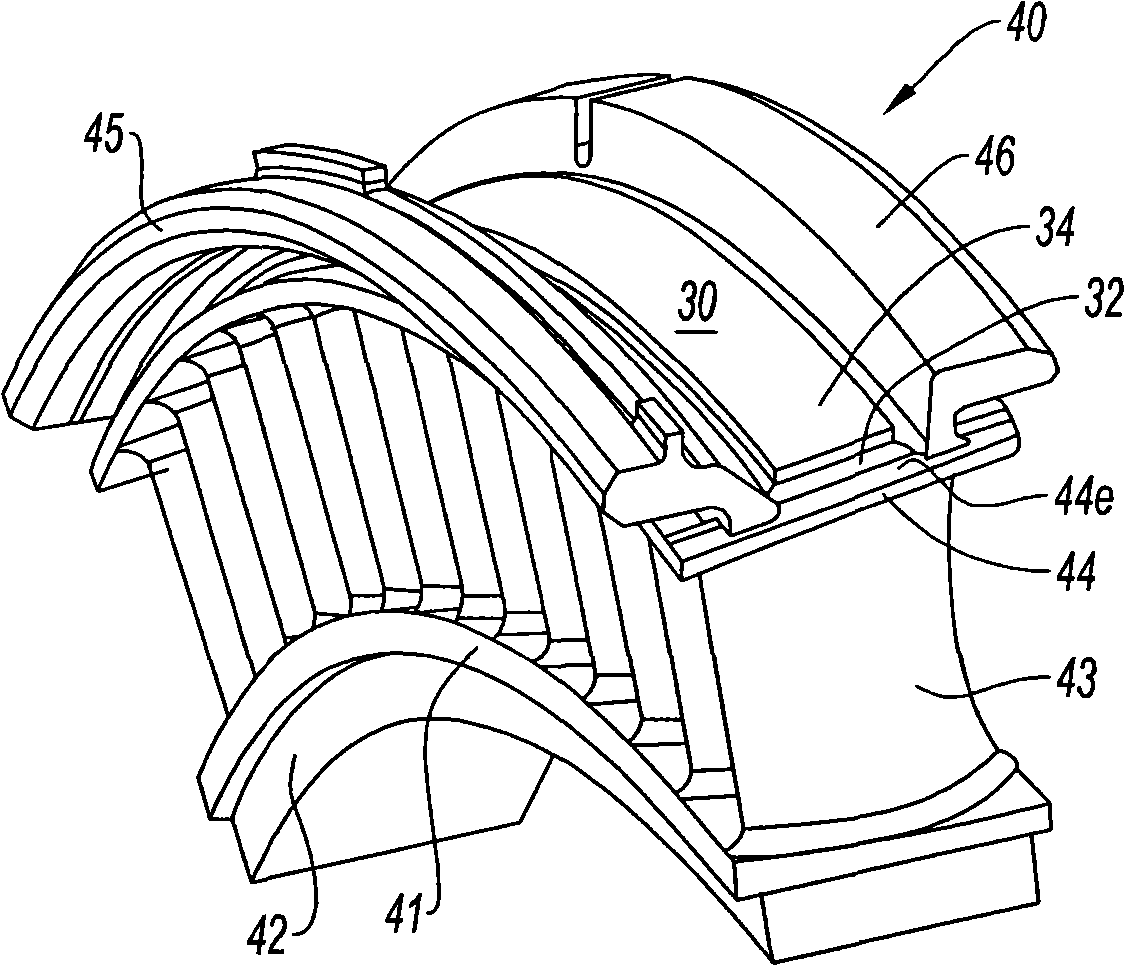

[0034] According to the invention, a vibration-damp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com