Semi-assembled prefabricated beam and preparation method and design method thereof

A technology of prefabricated assembly and steel beams, applied in the direction of joists, girders, truss beams, etc., can solve the problems of difficult realization of steel structure houses and high maintenance costs, so as to reduce the lateral displacement response, reduce the overall cost, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

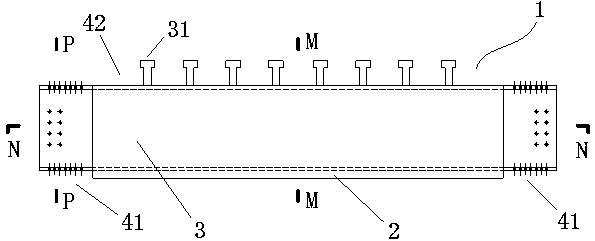

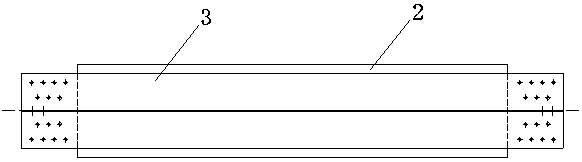

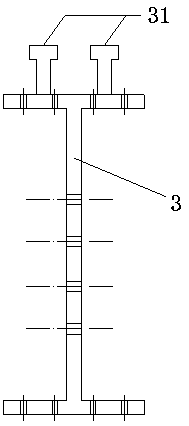

[0033] Embodiment one: if Figure 1~4 As shown, a semi-combined prefabricated assembled beam, the semi-combined prefabricated assembled beam 1 includes an H-shaped steel beam 3 and an outer cladding protective layer 2, and the outer cladding protective layer 2 is arranged on the H-shaped steel beam 3 The outer surface of the H-shaped steel beam 3 is provided with bolt holes on the flanges and webs at both ends, and the two ends of the H-shaped steel beam 3 are respectively reserved with end connection nodes for connecting steel columns. Covering area 41, the upper flange of the H-shaped steel beam 3 is welded with studs 31, and the outer surface of the upper flange of the H-shaped steel beam 3 is reserved with an uncoated area of the upper connection node for connecting the concrete floor 42.

[0034] In this first embodiment, the outer cladding protective layer 2 is preferably but not limited to a reinforced concrete outer cladding 2, and the outer cladding protective laye...

Embodiment 2

[0048] Embodiment two: if Figure 5 As shown, the difference between it and the first embodiment is that the grooves on both sides of the H-shaped steel beam 3 are provided with thermal insulation filling layers 23 .

[0049] In the second embodiment, the thermal insulation filling layer 23 is preferably but not limited to the foam thermal insulation layer 23 . During manufacture, the foam insulation layer 23 is filled in the grooves on both sides of the H-shaped steel beam 3, and then the reinforced concrete layer is covered.

Embodiment 3

[0050] Embodiment three: as Image 6 As shown, the difference between it and the second embodiment is that the steel bar used in the reinforced concrete outer cladding layer 2 extends above the studs 31, that is, the stirrups of the outer cladding protective layer 2 are directly extended into the floor area. During construction, the pegs 31 and stirrups extending into the floor slab are poured on-site in the floor slab, so that the floor slab is reliably connected with the H-shaped steel beam 3 and the outer cladding protection layer 2 into one. Certainly, if the steel wire mesh concrete outer cladding is selected as the outer cladding protective layer 2 , the steel wires of the steel wire mesh concrete outer cladding may also extend above the pegs 31 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com