Minitype foil aerodynamic pressure bearing

A gas dynamic pressure bearing and foil technology, applied in the direction of sliding contact bearings, rotating bearings, bearings, etc., can solve problems such as difficult to assemble bearing performance, difficult to process wave foils, and difficulties, so as to improve the carrying capacity and make it easy to take off , the effect of large carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

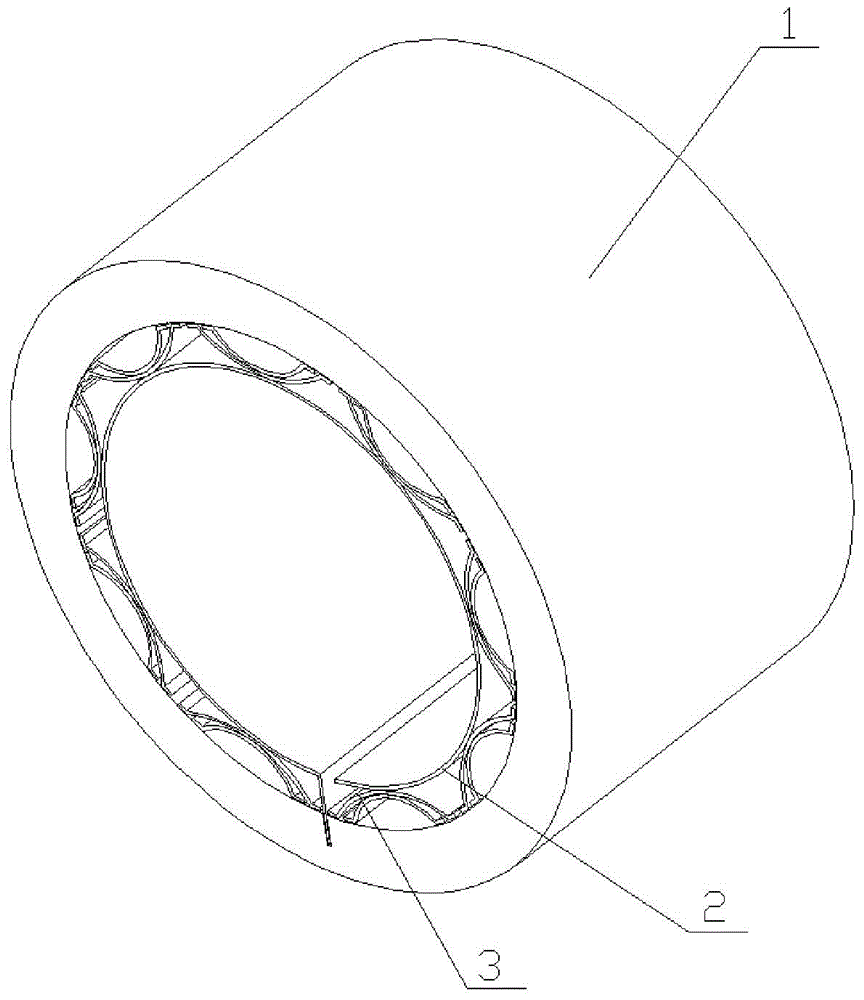

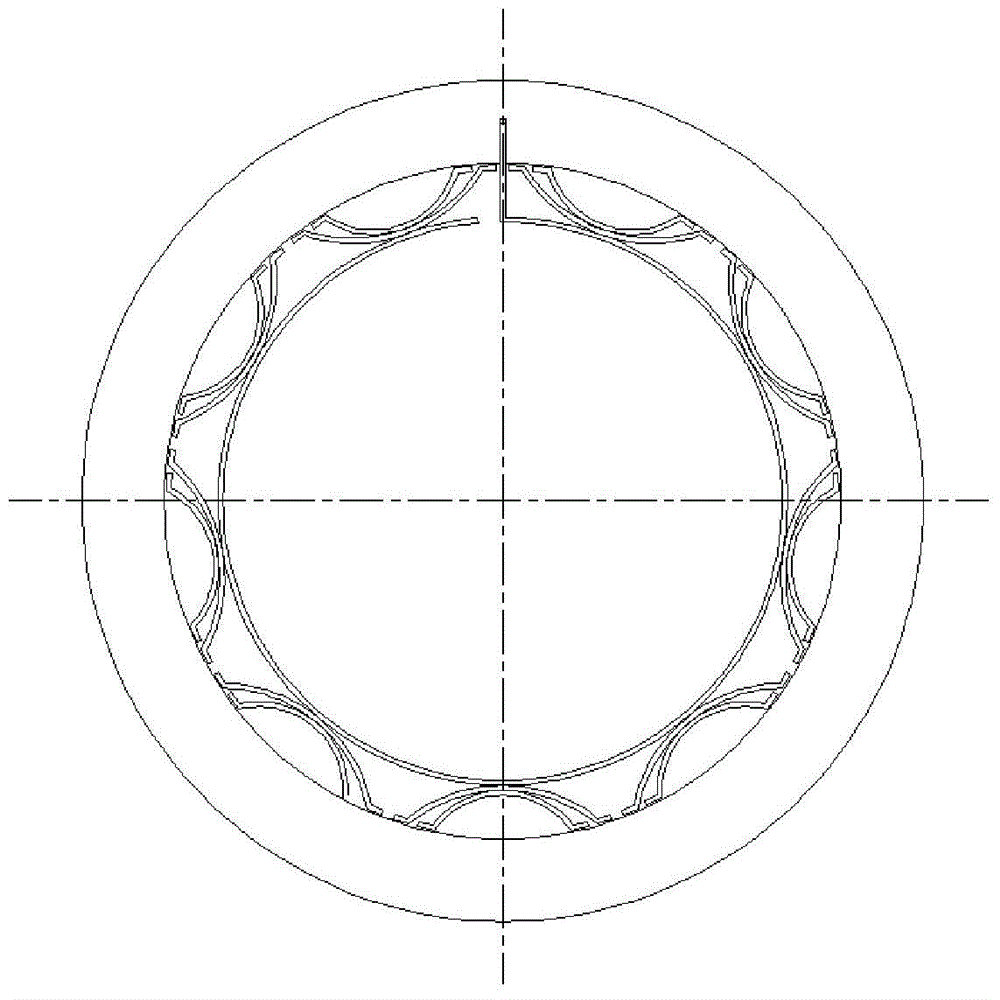

[0026] Such as figure 1 As shown, a miniature foil gas dynamic pressure bearing, the gas bearing includes a bearing body 1 , a top foil 2 and a composite elastic wave foil structure 3 . The bearing body 1 is the main structure of the bearing, which plays the role of installation, protection and support; the top layer foil 2 is the inner surface of the bearing, so that the bearing has a continuous air pressure distribution; the composite elastic wave foil structure 3 provides a certain damping and stiffness. Such as figure 2 As shown, the composite elastic wave foil structures 3 are evenly distributed between the bearing body 1 and the top foil 2, and there are N pieces in total.

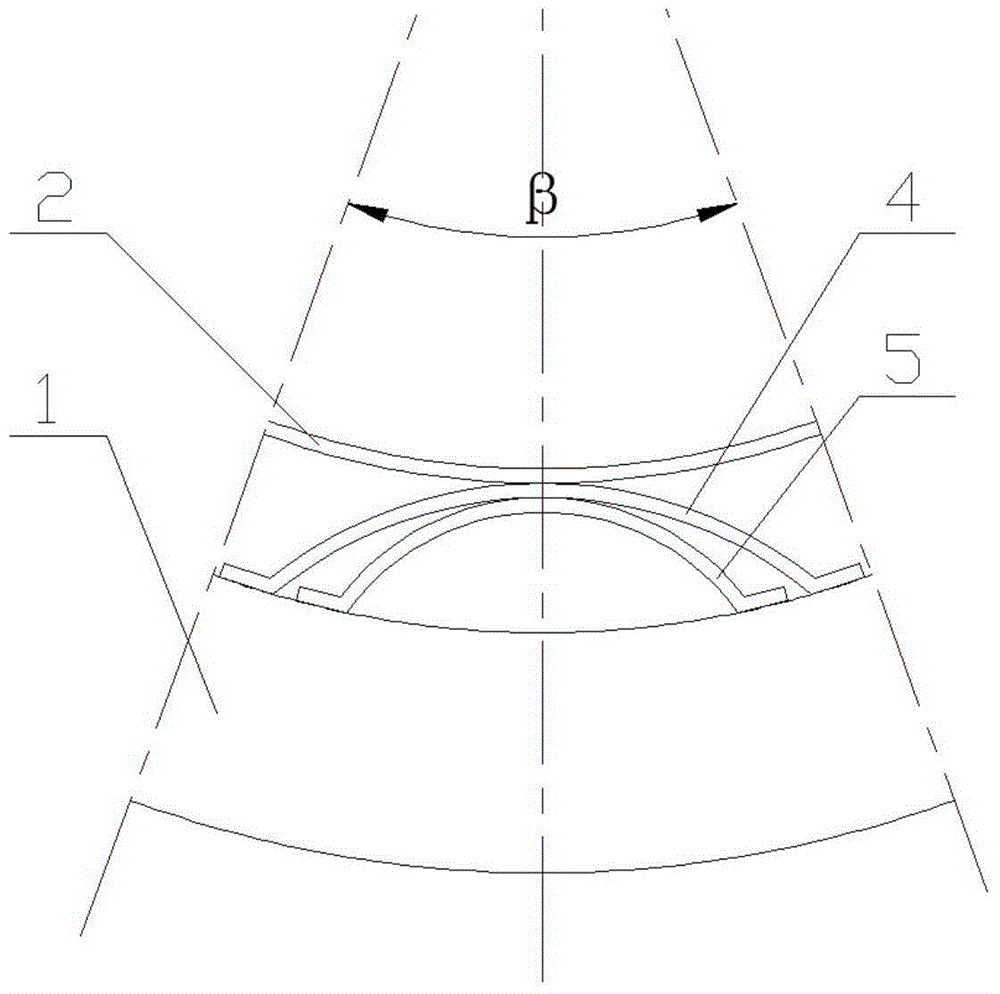

[0027] Such as image 3 As shown, the composite elastic wave foil structure 3 is composed of an outer elastic wave foil 4 and an inner elastic wave foil 5, which are manufactured as a whole using LIGA processing technology, and there are 2N pieces in total; each composite elastic wave foil struct...

Embodiment 2

[0030] Image 6 Shown is a schematic structural view of another micro-foil aerodynamic pressure bearing provided in the second embodiment of the present invention.

[0031] The working principle of the bearing in this embodiment is generally the same as that in Case 1, except that the corrugated foil structure in this embodiment is a multi-legged structure. The composite elastic wave foil structure 3 in the first embodiment requires high dimensional accuracy, and the installation is not very convenient, and the structure is relatively complicated. The difference from Example 1 is that the multi-legged structure in Example 2 retains the advantages of the composite elastic wave foil structure 3, but does not require too high dimensional accuracy, and the processing difficulty is relatively low, so it is more convenient to manufacture, and at the same time The installation is not troublesome, and the damping characteristics are better, which further improves the impact vibration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com