Metal corrugated-metal rubber composite material and preparation method thereof

A technology of metal rubber and composite materials, applied in the direction of metal layered products, chemical instruments and methods, lamination devices, etc., can solve the problems of significant energy absorption and vibration reduction, poor energy consumption performance, etc., and achieve light weight and low cost , to create a simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

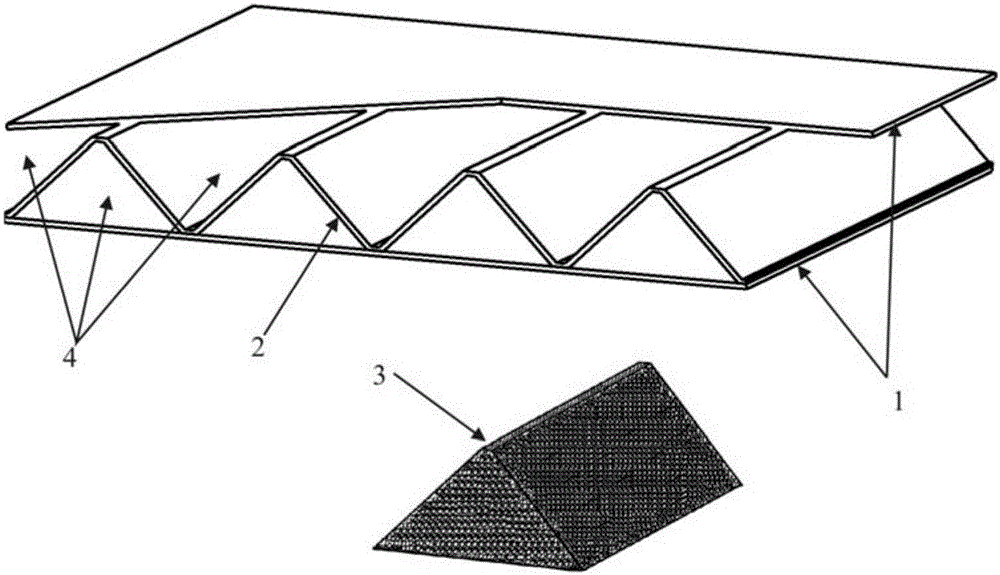

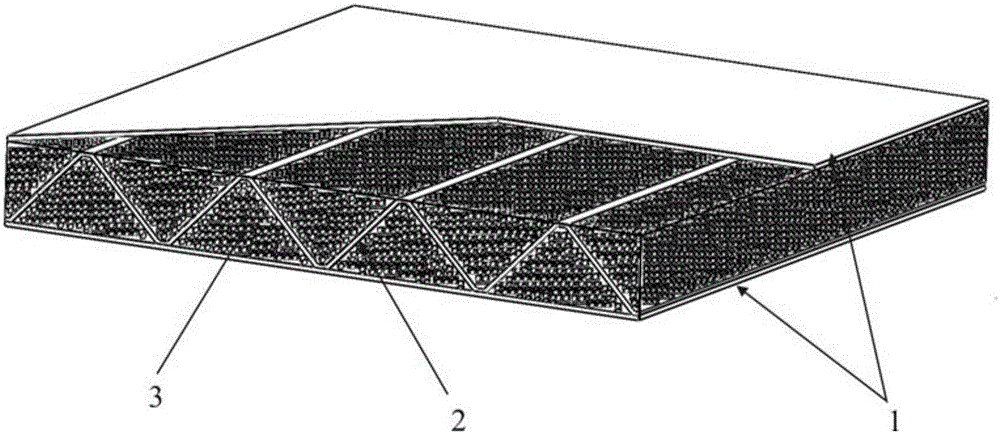

[0023] 1) First, the flattened aluminum alloy plate is molded and folded to form a corrugated structure core 2, and then the formed corrugated structure core 2 and the panel 1 of the aluminum alloy plate are cleaned to remove oil and rust. The corrugated structure core 2 and the panel 1 are glued together by casting glue to form a corrugated structure lattice metal sandwich panel, see figure 1 ;

[0024] 2) Then, according to the space size of the hole 4 in the core body 2 of the corrugated structure, the metal rubber blank whose metal wire material is OCr18Ni9Ti is put into a corresponding mold and pressed repeatedly by a press to make it match the hole 4 in the core body 2 of the corrugated structure. Triangular prisms or trapezoidal prisms that are suitable for the space size of the prisms. During the pressing process, vibration loads are applied in the direction perpendicular to the pressing forming to obtain members with three-dimensional damping and uniform strength. Mi...

Embodiment 2

[0027] 1) First, the flattened aluminum alloy plate is molded and folded to form a corrugated structure core 2, and then the formed corrugated structure core 2 and the panel 1 of the aluminum alloy plate are cleaned to remove oil and rust. The corrugated structure core 2 and the panel 1 are glued together by casting glue to form a corrugated structure lattice metal sandwich panel, see figure 1 ;

[0028] 2) Then, according to the space size of the hole 4 in the corrugated structure core 2, the metal rubber blank whose metal wire material is Ti-50.3% Ni shape memory alloy is put into the corresponding mold and pressed repeatedly by a press to form a corrugated shape. The triangular prism or trapezoidal prism whose space size is suitable for the hole 4 in the structural core 2 applies a vibration load in the direction perpendicular to the press forming during the pressing process to obtain a member with three-dimensional damping and uniform strength. The formed blank needs to be...

Embodiment 3

[0031] 1) First, the flattened aluminum alloy plate is molded and folded to form a corrugated structure core, and then the formed corrugated structure core 2 and the panel 1 of the aluminum alloy plate are cleaned to remove oil and rust. Glue the corrugated structure core 2 and the panel 1 to form a corrugated structure lattice metal sandwich panel, see figure 1 ;

[0032] 2) Then, according to the space size of the hole 4 in the corrugated structure core 2, the metal rubber blank made of the metal wire material is Mn-20Cu-5Ni-2Fe manganese-based damping alloy is put into the corresponding mold and pressed repeatedly by the press Form a triangular prism or a trapezoidal prism suitable for the space size of the hole 4 in the corrugated structure core 2, and apply a vibration load in the direction perpendicular to the press forming during the pressing process to obtain a member with uniform damping and strength in three directions, and the formed billet The parts need to be the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com