Spliced shear wall with steel-plate concrete and reinforced concrete arranged inside and construction technology

A technology of reinforced concrete and steel plate concrete, applied to walls, building components, building types, etc., can solve problems such as long construction period, environmental pollution, and complex construction, and achieve the effect of saving materials, ensuring product quality, and increasing structural seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] In this embodiment, the connecting steel plate I4 and the connecting steel plate II8 are external connecting steel plates, and the built-in steel plate I is a non-porous built-in steel plate 7 .

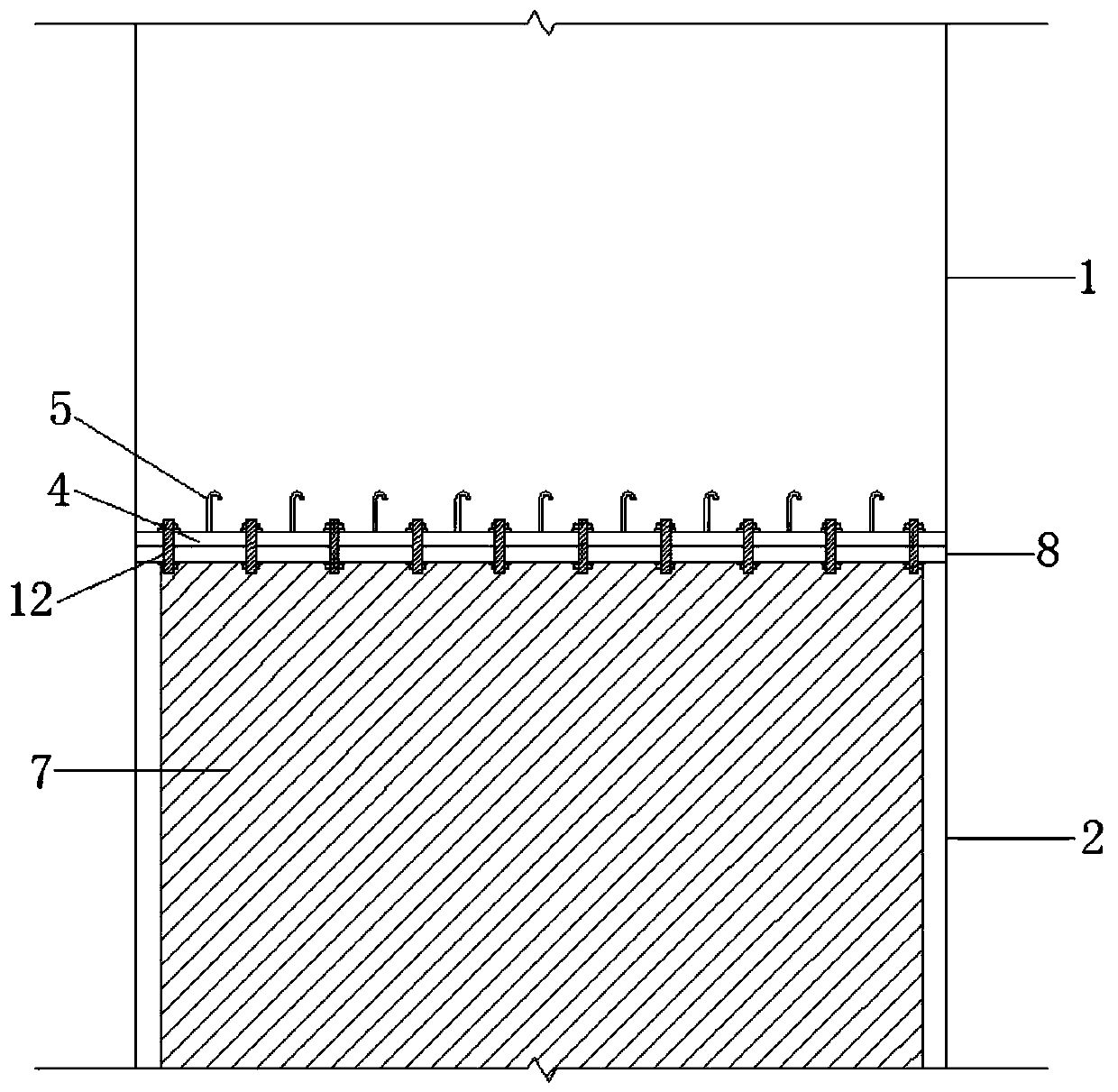

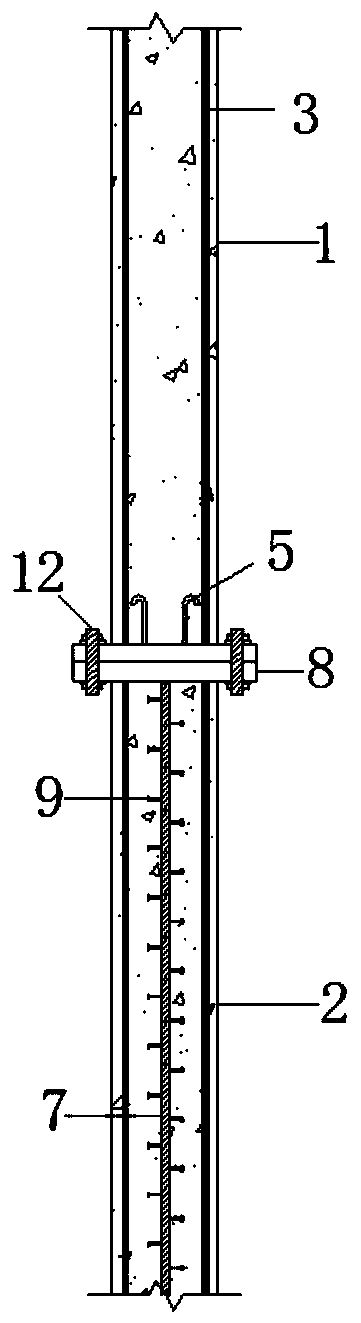

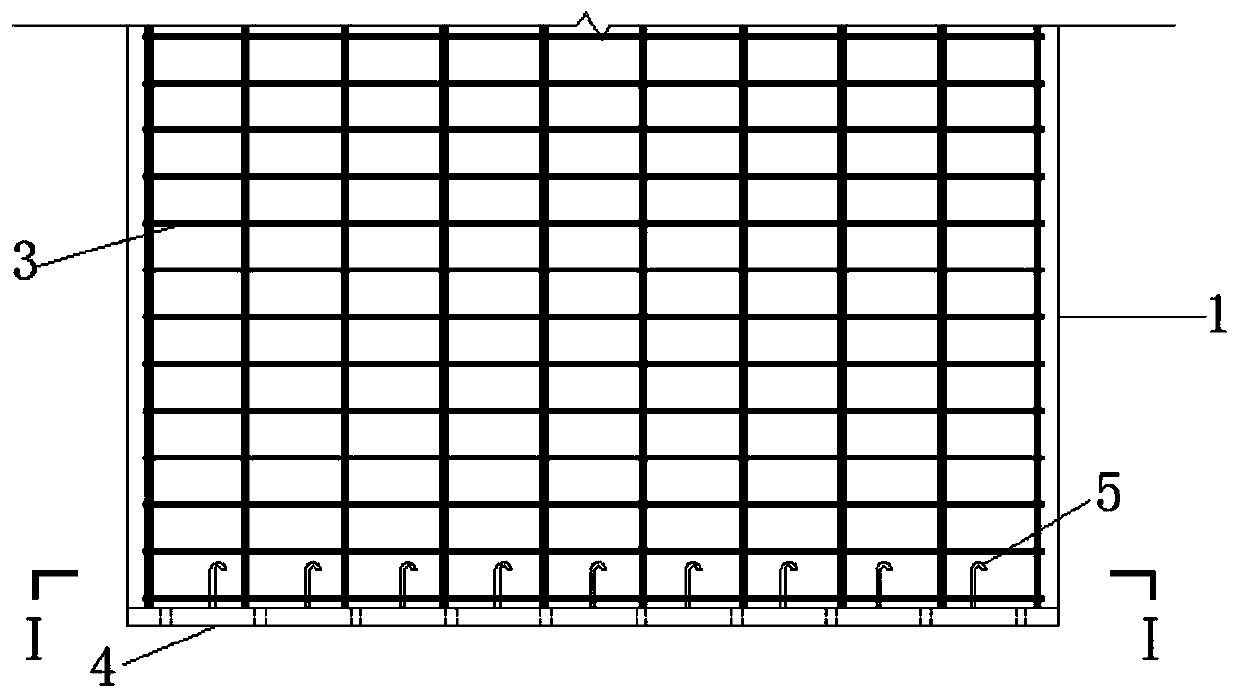

[0074] Such as Figure 1 to Figure 14 , Figure 30 As shown, a built-in steel plate concrete and reinforced concrete splicing shear wall includes a reinforced concrete shear wall 1 and a steel plate concrete shear wall 2; the reinforced concrete shear wall 1 includes a skeleton I and concrete, and the skeleton I includes Reinforcement cage I3, connecting steel plate I4, and several embedded parts 5, said reinforcing cage I3 is formed by binding longitudinal steel bars and stirrups, one end of reinforcing cage I3 is welded with connecting steel plate I4, and the surface of connecting steel plate I4 is welded with several embedded parts 5 , and the embedded part 5 is located inside the reinforcement cage, and bolt holes I are evenly opened in the circumferential direction of th...

Embodiment 2

[0081] In this embodiment, the connecting steel plate I4 and the connecting steel plate II8 are external connecting steel plates, and the built-in steel plate I is the built-in steel plate 11 with holes.

[0082] Such as Figure 15 to Figure 20 , a built-in steel plate concrete and reinforced concrete splicing shear wall, including a reinforced concrete shear wall 1 and a steel plate concrete shear wall 2; the reinforced concrete shear wall 1 includes a skeleton I and concrete, and the skeleton I includes a steel cage I3, connecting steel plate I4, several embedded parts 5, the steel cage I3 is formed by binding longitudinal steel bars and stirrups, one end of the steel cage I3 is welded with a connecting steel plate I4, and the surface of the connecting steel plate I4 is welded with several embedded parts 5, and The embedded part 5 is located inside the reinforcement cage, and bolt holes I are evenly opened in the circumferential direction of the connecting steel plate I4, an...

Embodiment 3

[0089] In this embodiment, the connecting steel plate I4 and the connecting steel plate II8 are inner connecting steel plates, and the built-in steel plate I is a non-porous built-in steel plate 7 .

[0090] Such as Figure 21 to Figure 29 As shown, a built-in steel plate concrete and reinforced concrete splicing shear wall includes a reinforced concrete shear wall 1 and a steel plate concrete shear wall 2, the reinforced concrete shear wall 1 includes a skeleton I and concrete, and the skeleton I includes Reinforcement cage I3, connecting steel plate I4, and several embedded parts 5, said reinforcing cage I3 is formed by binding longitudinal steel bars and stirrups, one end of reinforcing cage I3 is welded with connecting steel plate I4, and the surface of connecting steel plate I4 is welded with several embedded parts 5 , and the embedded part 5 is located inside the steel cage, bolt holes I are evenly opened in the circumferential direction of the connecting steel plate I4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com