Variable stiffness shock absorption device with embedded connecting beam and working method thereof

A shock-absorbing device and variable-stiffness technology, which is used in earthquake-proof, building components, building structures, etc., can solve the problem that the bearing capacity, reliability, and stiffness of coupling beam energy-dissipating devices are relatively strict and cannot fully meet high-rise structures. The problems of energy dissipation and shock absorption, complex stress state, etc., can improve the seismic performance of the structure, reduce the characteristic frequency of the structure, and improve the fatigue performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to facilitate the understanding of the structure of the present invention, the following description will be made in conjunction with the accompanying drawings and embodiments.

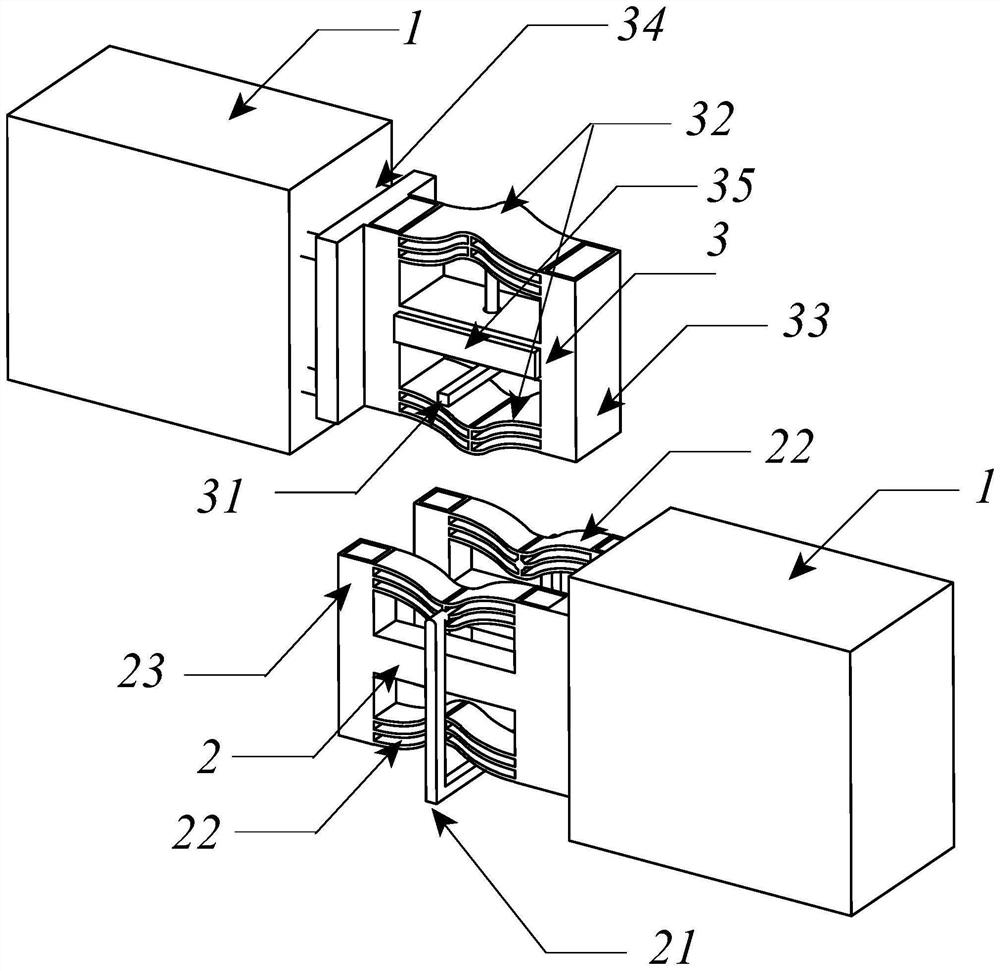

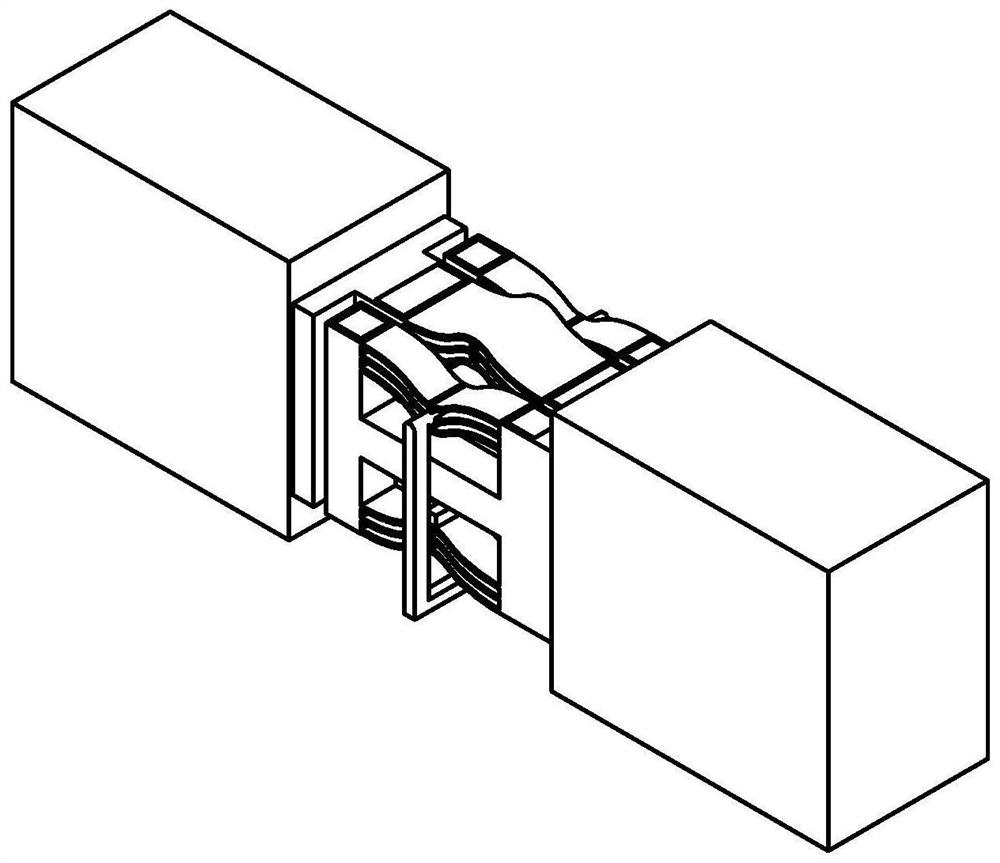

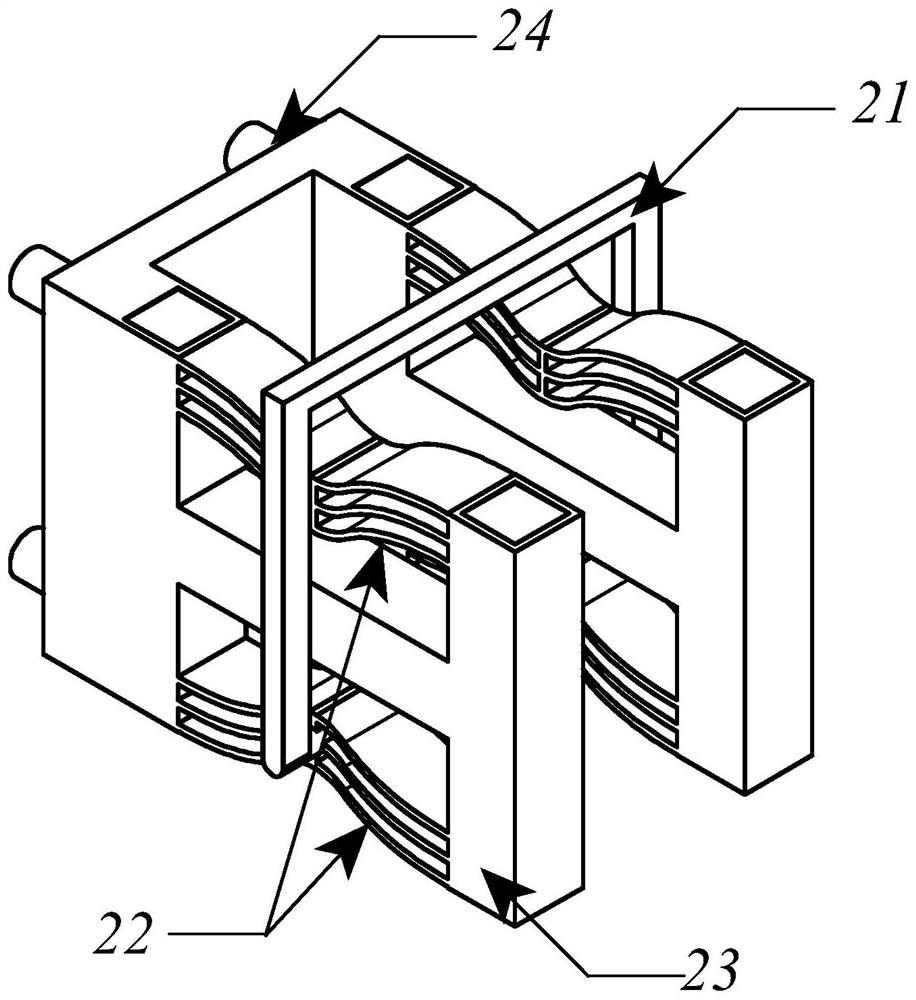

[0044] like figure 1 As shown, the device consists of a U-shaped joint 2 and a T-shaped joint 3 that match each other;

[0045] The closed side of the U-shaped joint 2 is connected to the connecting beam, and the open side is connected to the T-shaped joint 3. The U-shaped joint 2 includes a first steel member 23 with an H-shaped longitudinal section, and is connected to the upper and lower parts of the first steel member 23. The two concave hyperbolic spring steel sheet groups 22 on both sides are respectively the first concave hyperbolic spring steel sheet group and the second concave hyperbolic spring steel sheet group, and each group of concave hyperbolic spring steel sheet groups is composed of It is composed of a plurality of concave hyperbolic spring steel sheets, and a first v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com