Encapsulating structure and encapsulating method of high-Q-value optical micro-cavity coupling system based on LTCC (Low Temperature Co-Fired Ceramic)

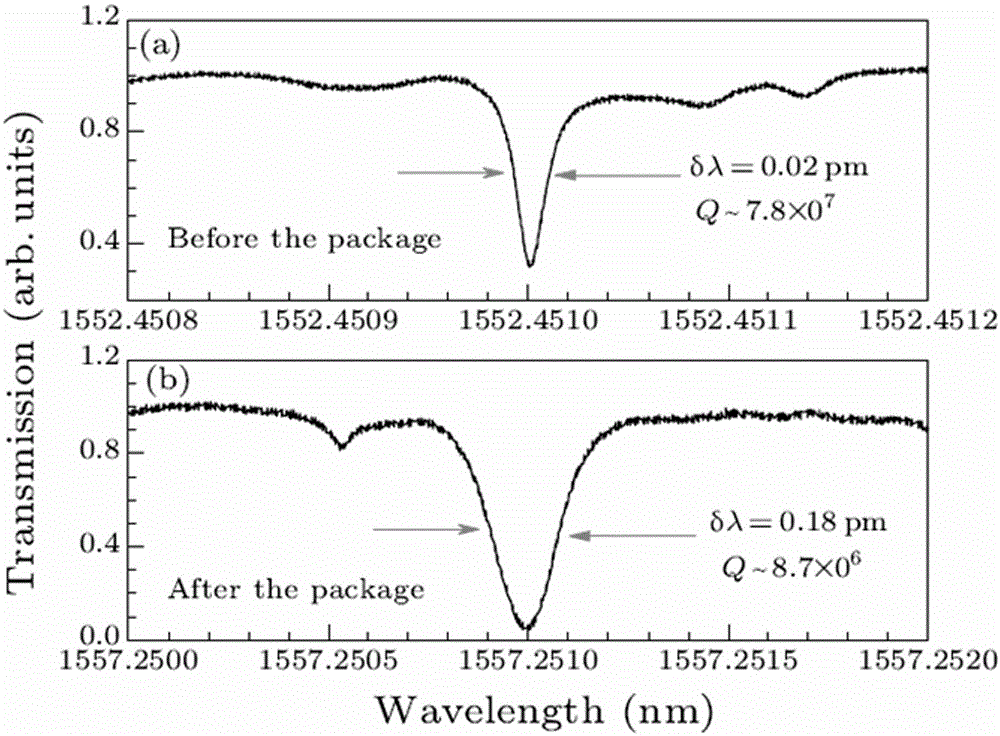

An optical microcavity and packaging structure technology, applied in the coupling of optical waveguides, optics, optical components, etc., can solve the problems of instability of the coupling system and easy to be affected by changes in the external environment, so as to improve the shock resistance of the structure and improve the temperature stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

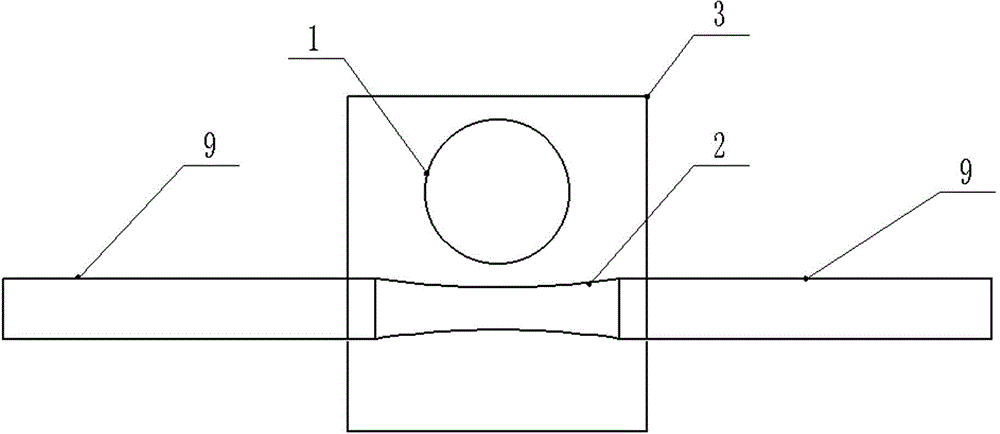

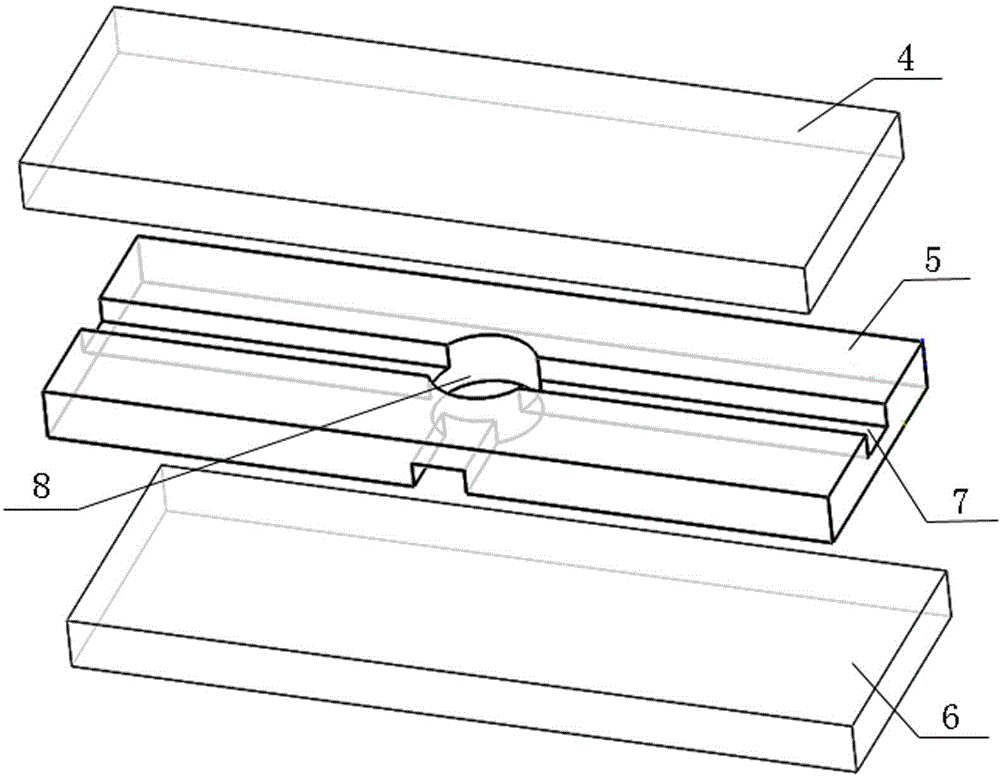

[0023] The packaging structure of the LTCC-based high-Q optical microcavity coupling system includes an optical microcavity 1 and a coupler 2, and also includes an outer ceramic packaging structure, which includes an upper top plate 4 and a middle plate bonded together 5 and the lower base plate 6, the middle plate 5 is provided with a fiber groove 7 connecting two opposite ends, the middle part of the fiber groove 7 is provided with a through hole 8, and the optical microcavity 1 and the coupler 2 are contained in an optically transparent packaging material A package body 3 is formed inside, and the package body 3 is embedded in the outer ceramic package structure.

[0024] The encapsulation method of the above encapsulation structure comprises the following steps:

[0025] S1: The upper top plate 4, the middle plate 5 and the lower bottom plate 6 are prepared by using ceramic materials, and the middle plate is provided with an optical fiber groove 7 and a through hole 8;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com