Double-layer PC plate type conversion layer of post-poured upper-portion structure and construction method

A construction method and transfer layer technology, which can be used in building components, building structures, and building materials processing, etc., can solve the problems of self-heavy and high cost, and achieve the effect of reducing the total thickness, reducing costs, and being conducive to earthquake resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

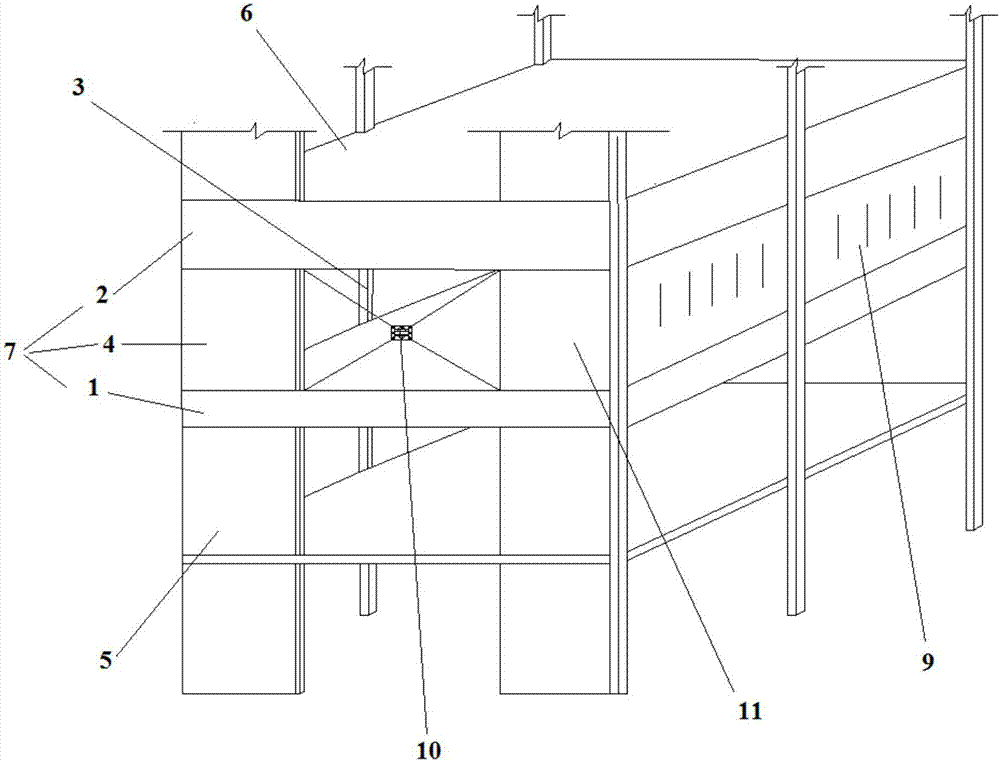

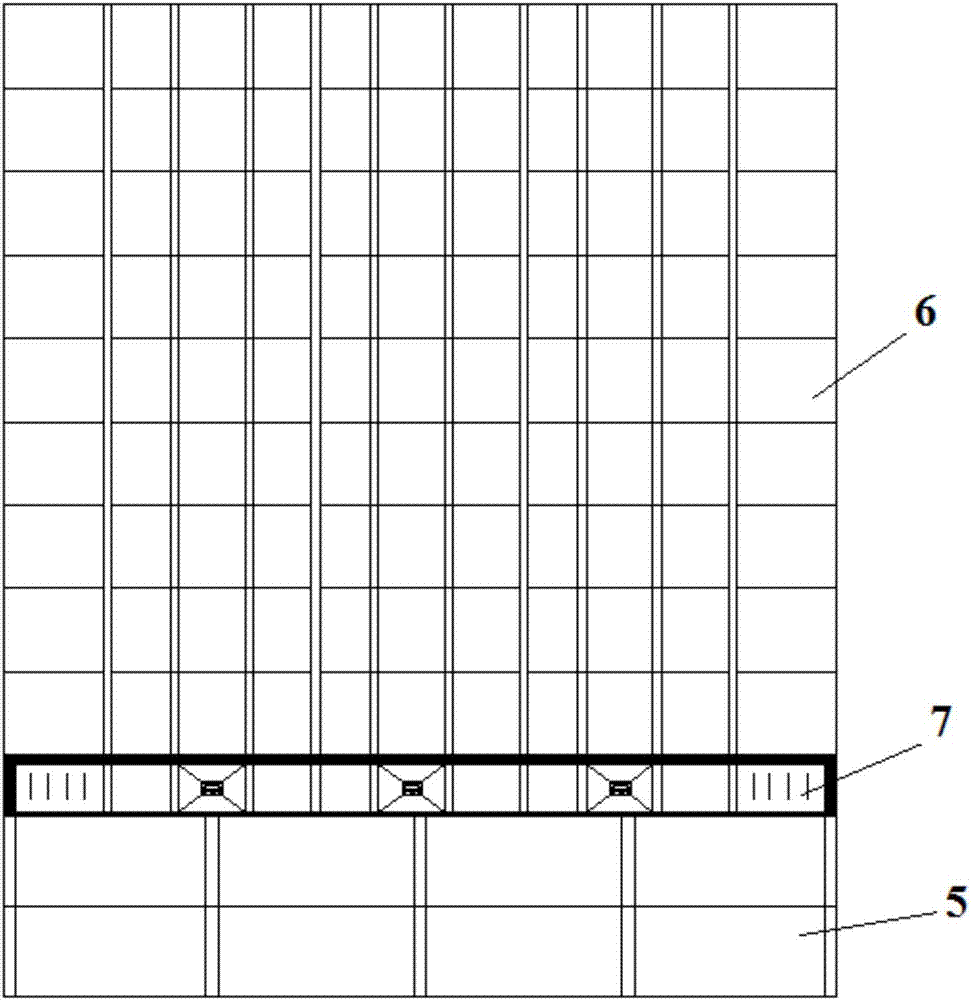

[0056] Comply with the above technical solutions, such as Figure 2 to Figure 7 As shown, this embodiment provides a double-layer RC plate conversion layer of the post-cast superstructure, including the first layer of RC conversion board 1 and the second layer of RC conversion board 2, the first layer of RC conversion board 1 and the second layer RC conversion plates 2 are supported by frame columns 3 to form a hollow layer 4;

[0057] The first layer of RC conversion board 1 is located at the bottom of the frame column 3 and connected to the substructure 5, and the second layer of RC conversion board 2 is located at the top of the frame column 3 and connected to the superstructure 6;

[0058] The thickness of the first layer of RC conversion board 1 is smaller than the thickness of the second layer of RC conversion board 2, and the second layer of RC conversion board 2 is provided with hidden beams 8;

[0059] The hollow layer 4 is provided with a post-casting shear wall 11 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com