Round sleeve steel-wood assembly node and mounting method thereof

A steel-wood combination and circular sleeve technology, applied in the direction of construction and building structure, can solve the problems of integrity, poor mechanical performance, weakened vertical column force transmission section, cracking along the texture and other problems, reaching a huge market Potential, high bearing capacity, the effect of enhancing the seismic capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

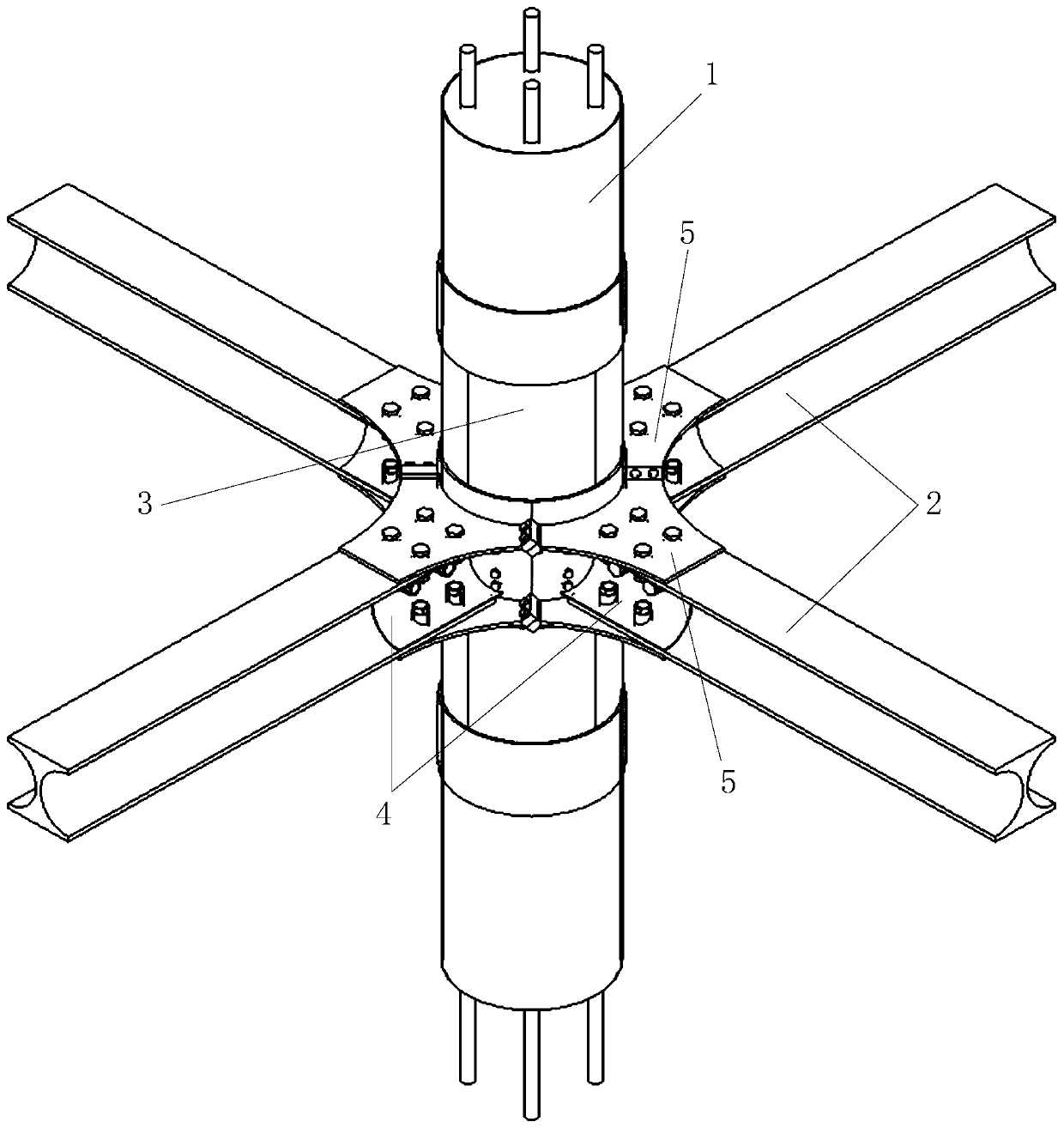

[0043] Embodiment 1, a kind of circular sleeve steel-wood composite node, such as figure 1 with figure 2 As shown, it includes FRP circular wooden columns 1, X-shaped wooden beams 2, core connecting members 3, arc-shaped connectors 4 and spliced outer ring plates 5; the upper and lower adjacent FRP circular wooden columns 1 pass through core connecting members 3 Connected, after the upper and lower adjacent FRP circular wooden columns 1 are connected, they are connected with the X-shaped wooden beam 2 through the arc connector 4, and finally the whole is fixed by splicing the outer ring plate 5;

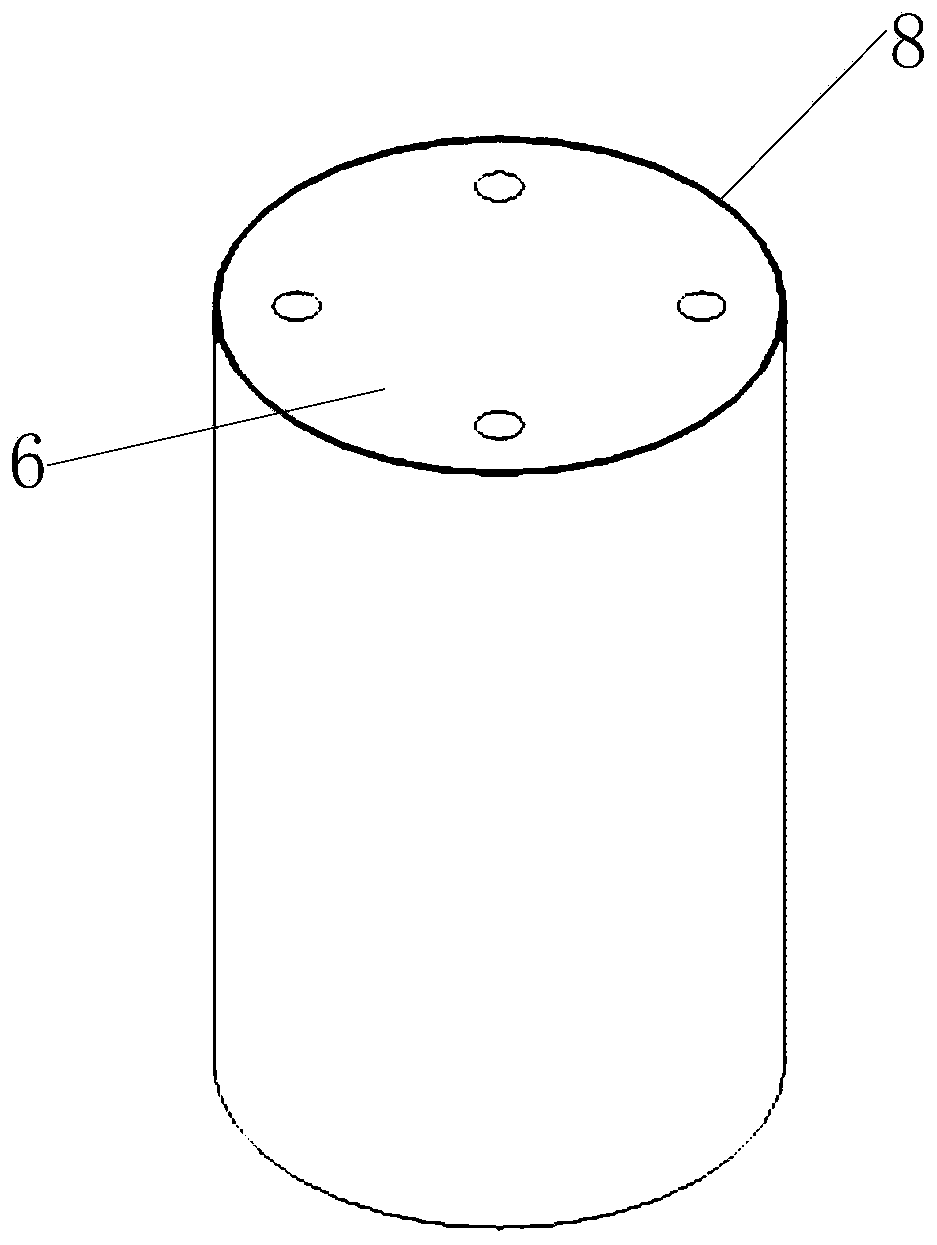

[0044] Such as image 3 with 4As shown, they are the structural schematic diagrams of the FRP circular wooden column 1 and the X-shaped wooden beam 2 respectively, and the FRP circular wooden column 1 includes a circular wooden column 6 and an FRP fiber cloth 8 arranged on the outer surface of the circular wooden column 6 , by winding the FRP fiber cloth 8 on the outer layer to...

Embodiment 2

[0050] Embodiment 2. Based on the circular sleeve steel-wood composite node proposed in Embodiment 1, this embodiment proposes a method for its installation, such as Figure 17 As shown, the following steps are included. Of course, during the specific implementation, the following steps can be slightly changed according to the actual situation:

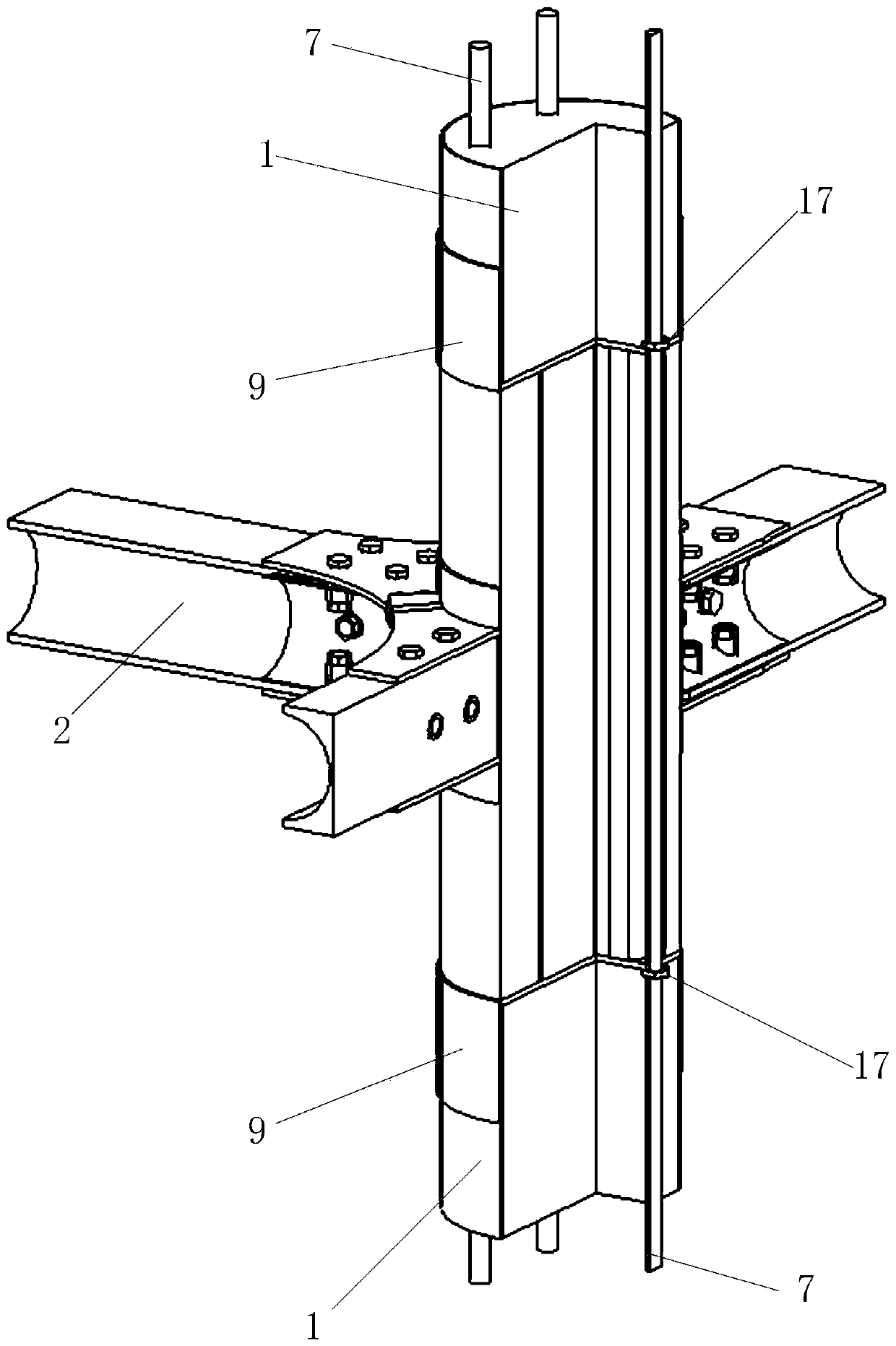

[0051] The first step is to set the round steel sleeve plate 9 on the FRP round wood column 1 that has been injected with glue, and there are pull bolts on the penetrating steel bars, and rotate the fan-shaped splicing joint of the connecting sleeve 10 with the round solid wood 11 inside for 45° Screw it into the docking slot on the corresponding side of the circular steel sleeve plate 9;

[0052] The second step is to fix the connecting sleeve 10 between the circular steel sleeve plates 9, fill in 4 filling blocks 12, and glue them together to form a whole;

[0053] The third step is to install the filling member 4 on the middle tai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com