Electrorheological elastomer vibration isolator in compression-shear mixed mode

An electro-rheological elastomer, mixed-mode technology, used in shock absorbers, springs/shock absorbers, springs, etc., can solve the problem of difficulty in fully exerting the variable stiffness and damping characteristics of electro-rheological elastomers and the material properties of electro-rheological elastomers The problems of low utilization rate and small vertical displacement of electrorheological elastomers can improve the utilization rate of materials, ensure the bearing capacity, and increase the vertical displacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

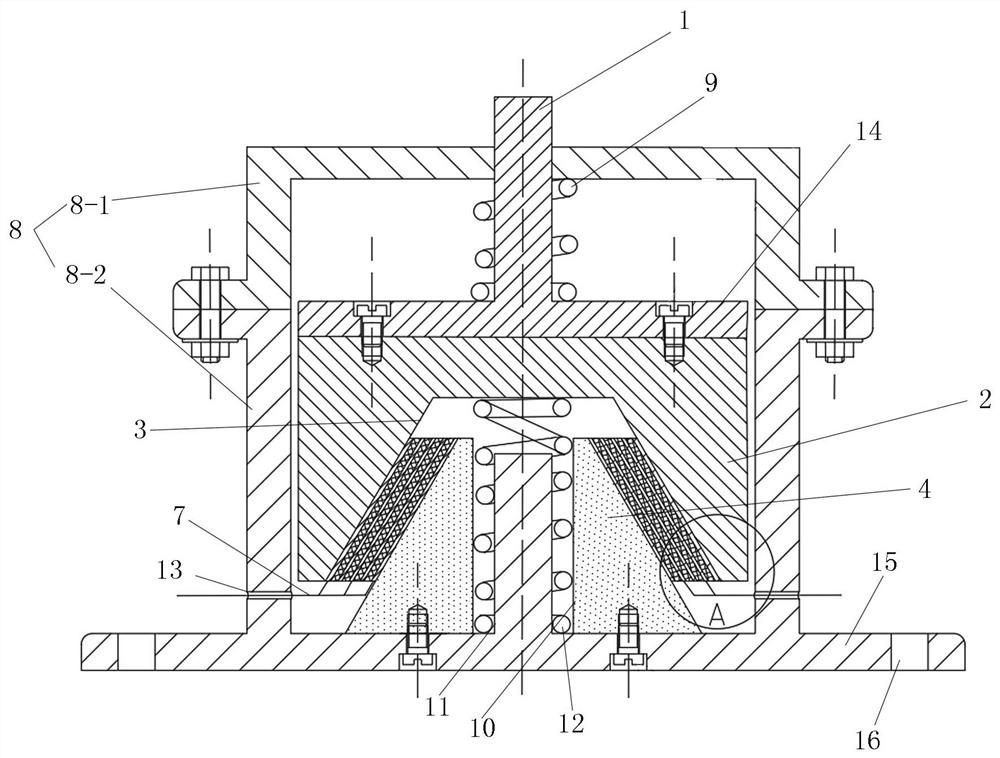

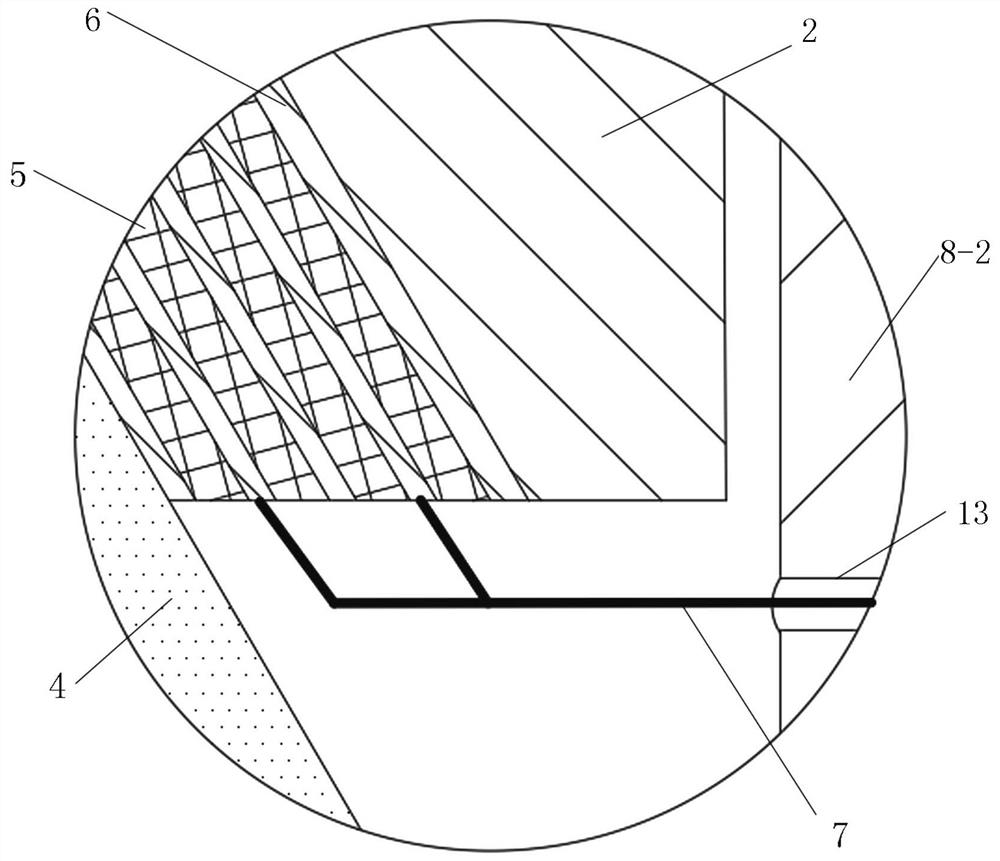

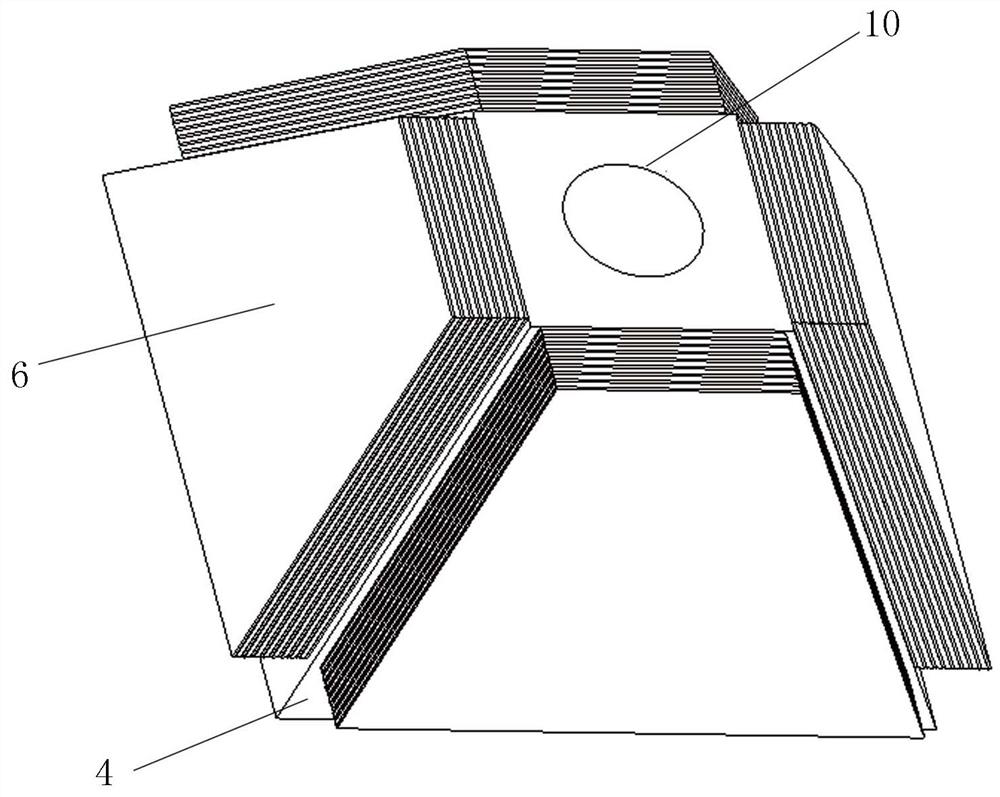

[0013] A pressure-shear mixed mode electrorheological elastomer vibration isolator, including a housing 8, a gland 2 located in the housing 8, and a support platform 4 with a tapered surface, the bottom surface of the support platform 4 is located at the bottom of the housing 8 In the center, the gland 2 is located above the support platform 4, the bottom surface of the gland 2 is provided with a groove 3 that is compatible with the support platform 4, and a multi-layer is fixed between the side wall of the groove 3 and the side wall of the support platform 4. Electrode pieces, electrorheological elastomers 5 are fixed between adjacent two layers of electrode pieces, the electrode pieces close to the groove 3 are fixed on the side wall of the groove 3, and the electrode pieces close to the support platform 4 are fixed on the side of the support platform 4 wall, so that the electrorheological elastomer 5 located between the groove 3 of the gland 2 and the support table 4 realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com