A semi-rigid integral seamless bridge structure supported by steel sheet piles and its construction method

A technology of seamless bridges and steel sheet piles, which is applied in infrastructure engineering, bridges, sheet pile walls, etc., can solve the problems of affecting the vertical bearing capacity of the pile body, the lateral displacement cannot be too large, and the pile body damage, etc. The effect of soil disturbance, convenient construction and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

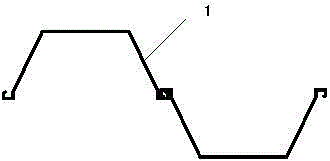

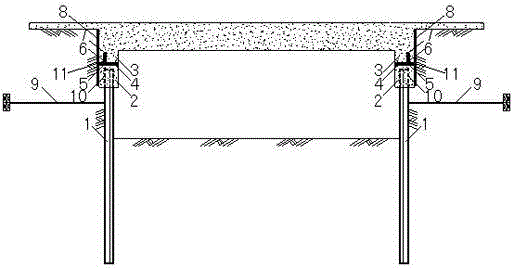

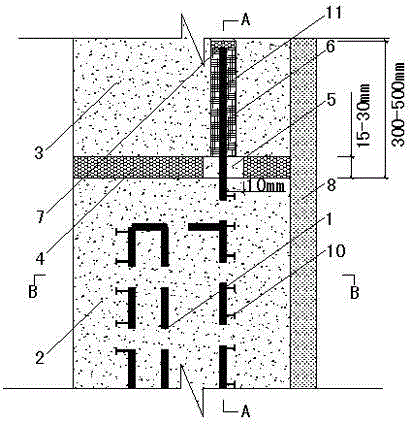

[0031] Such as figure 2 As shown, a novel integral abutment bridge structure supported by steel sheet piles includes a bridge end girder 3, a pile cap 2, an anchor rod 9 and a supporting steel sheet pile 1 pile body. The weak axis of the pile body of the steel sheet pile 1 is bent, adopts a special connection structure with the end beam 3 , and is connected with the anchor rod 9 . The special connection structure refers to a semi-rigid connection structure in which the pile cap 2 and the end beam 3 are connected by a part of the web 11 of the steel sheet pile 1, and foam rubber 4 is filled at the joint between the two. Steel sheet pile 1 can be directly inserted into the soil as a seamless bridge support pile, which facilitates construction, reduces disturban...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com