Anti-falling prefabricated floor slab unit

a prefabricated floor and slab technology, applied in the direction of building components, building types, constructions, etc., can solve the problems of design a full-prefabricated floor slab with excellent seismic performance, and achieve the effects of reducing construction costs, reducing construction costs, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]The invention is described in further detail below with reference to the following figures and embodiments:

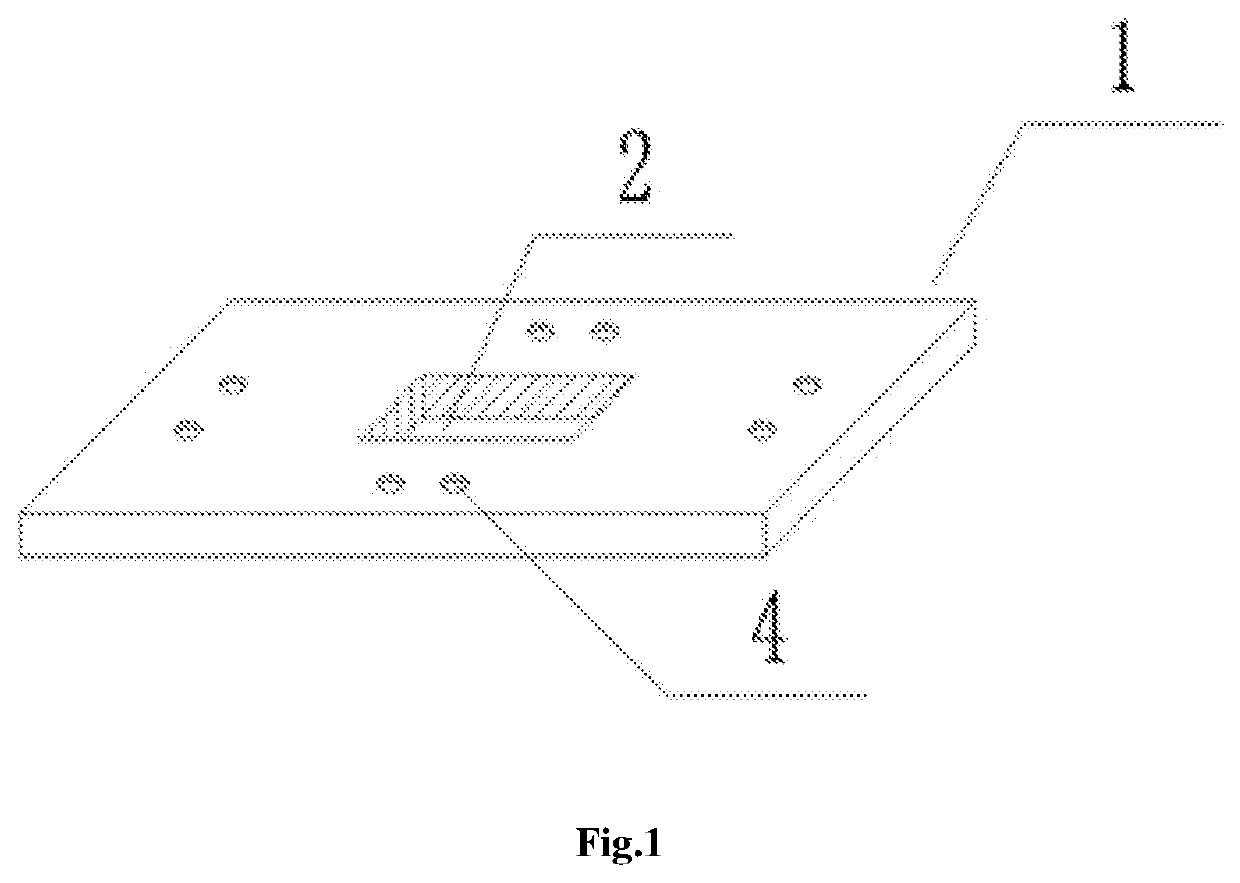

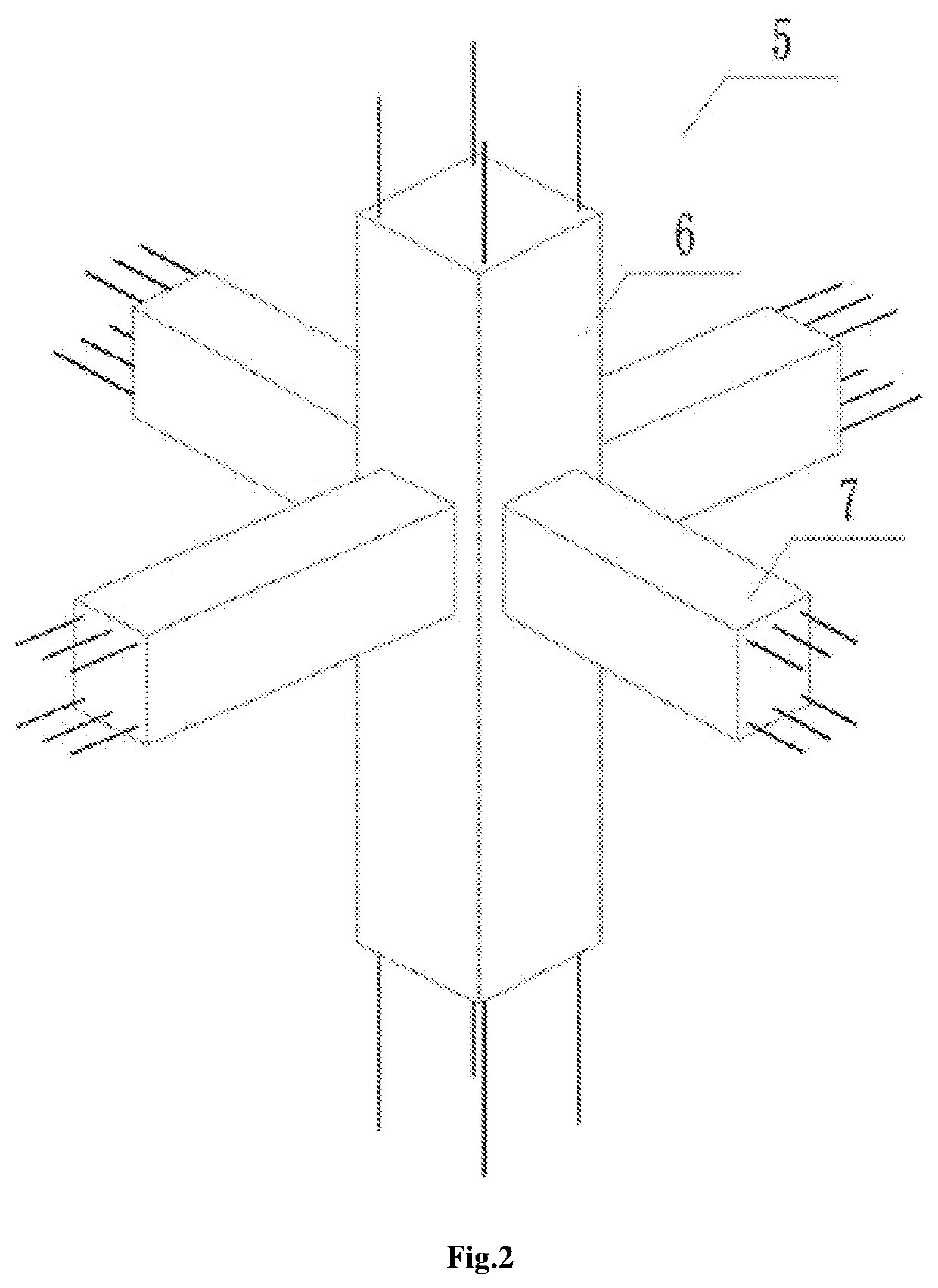

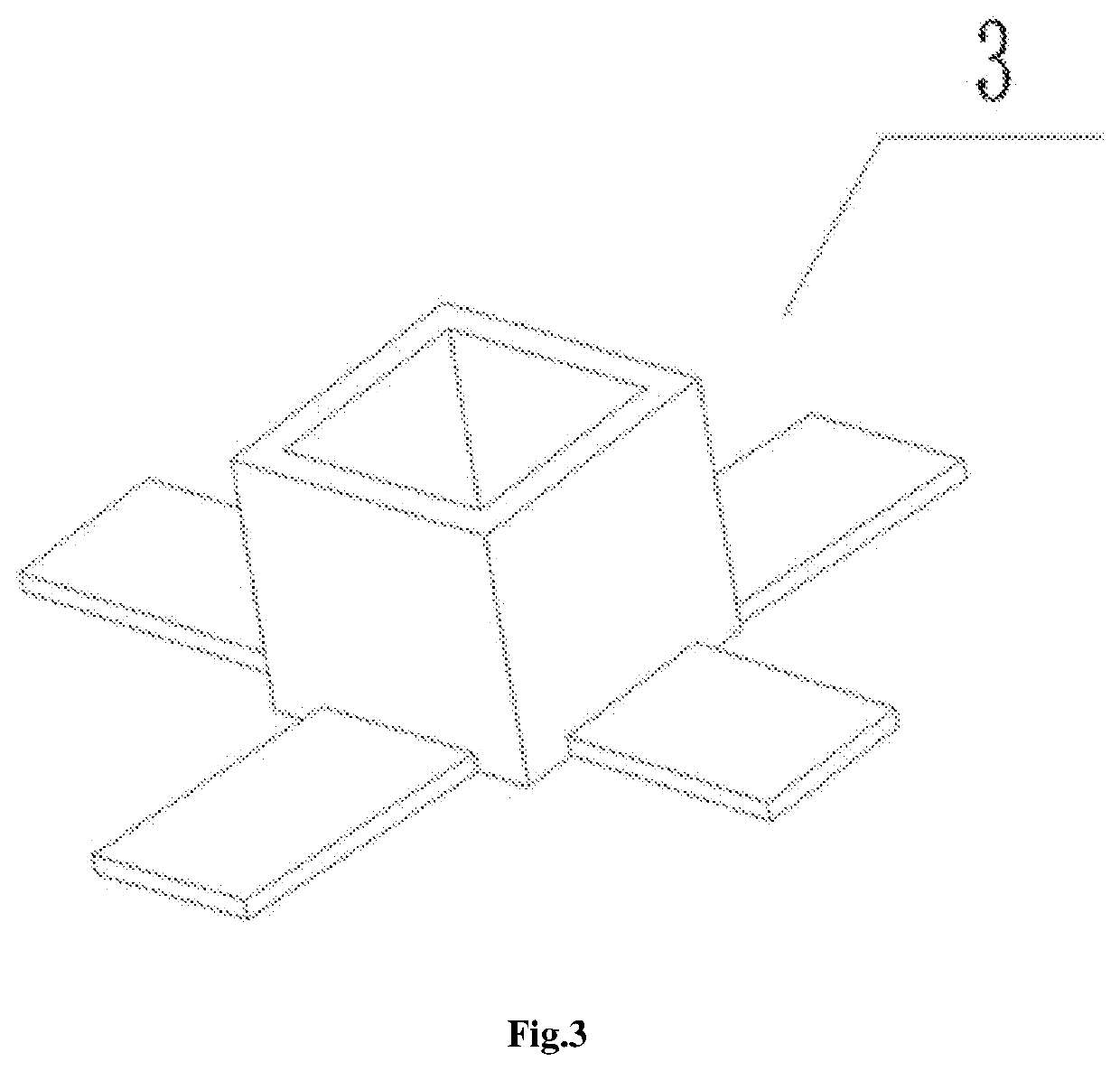

[0018]1. An anti-falling prefabricated floor slab unit 1, wherein, the prefabricated floor slab unit 1 is provided with a slab-column mounting hole 2 matched with a column unit 6 in cross section; and the anti-falling prefabricated floor slab unit 1 is provided with a slab-beam mounting hole 4 which is connected with an embedded part on the top surface of a beam unit 7 or / and a lotus root beam unit to mount the anti-falling prefabricated floor slab unit 1. The anti-falling prefabricated floor unit 1 is provided with a connecting member 3 connected with the column unit 6 and / or the beam unit 7 (as shown in FIG. 1, 2, 3).

[0019]2. An anti-falling prefabricated floor slab unit 1, wherein, the prefabricated floor slab unit 1 is provided with a slab-column mounting hole 2 matched with a column unit 6 in cross section; and the anti-falling prefabricated floor slab unit 1 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com