A vertical vibration isolation spherical steel bearing with a disc structure vibration isolator

A technology of vibration isolators and spherical steel, applied in the direction of friction dampers, etc., can solve the problems of difficult fatigue life of bridge vibration isolation bearings, aging of bearing rubber, etc., to ensure normal vertical bearing capacity and vertical bearing capacity The effect of increasing the force and satisfying the large vertical load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

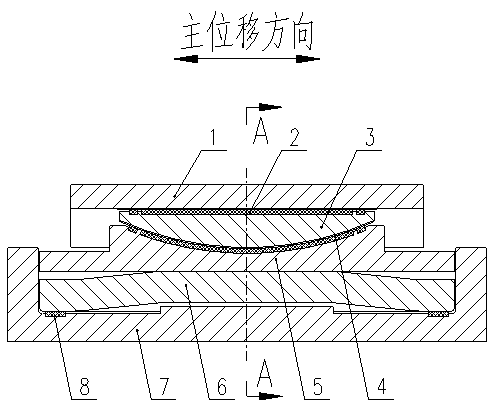

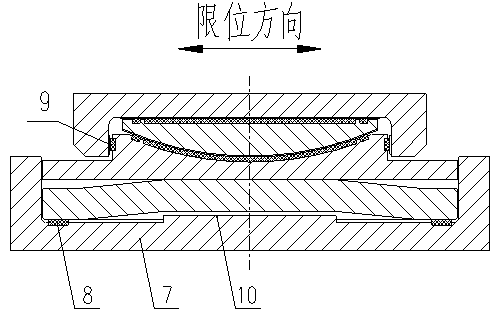

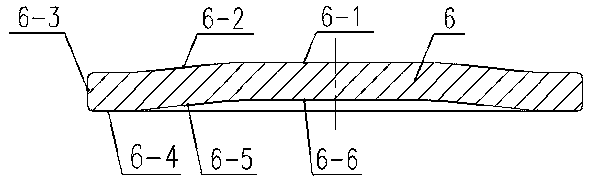

[0031] One-way movable vertical vibration isolation spherical steel bearing with disc structure vibration isolator, such as figure 1 , 2 shown. It is mainly composed of an upper seat plate 1, a middle seat plate 3, a lower seat plate 5, a disc structure vibration isolator 6, a base plate 7 and a plurality of friction pairs. The disk structure vibration isolator 6 is arranged in the space surrounded by the base plate 7, the disk structure vibration isolator 6 is an axisymmetric structure, and the outer surface of the disk structure vibration isolator 6 mainly has an outer center top surface 6-1, It consists of an outer inclined surface 6-2, a side surface 6-3, a bottom support surface 6-4, an inner inclined surface 6-5, an inner center bottom surface 6-6, and the like. There is a deformation gap between the side 6-3 of the disc structure vibration isolator 6 and the inner side wall of the base plate 7, and the deformation gap is used for the vertical force deformation of the ...

Embodiment 2

[0037] A vertical vibration-isolation hyperboloid spherical shock-absorbing steel bearing with a disc structure vibration isolator with one-way activity is given, such as Figure 4 , 5 shown. It is mainly composed of an upper seat plate 1, a middle seat plate 3, a lower seat plate 5, a disc structure vibration isolator 6, a base plate 7, a limit plate 11 and a plurality of friction pairs. The disk structure vibration isolator 6 is arranged in the space surrounded by the base plate 7, the disk structure vibration isolator 6 is an axisymmetric structure, and the outer surface of the disk structure vibration isolator 6 mainly has an outer center top surface 6-1, It consists of an outer inclined surface 6-2, a side surface 6-3, a bottom support surface 6-4, an inner inclined surface 6-5, an inner center bottom surface 6-6, and the like. There is a deformation gap between the side 6-3 of the disc structure vibration isolator 6 and the inner side wall of the base plate 7, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com